Rapid Manufacture of Metallic and Composite Aircraft Components

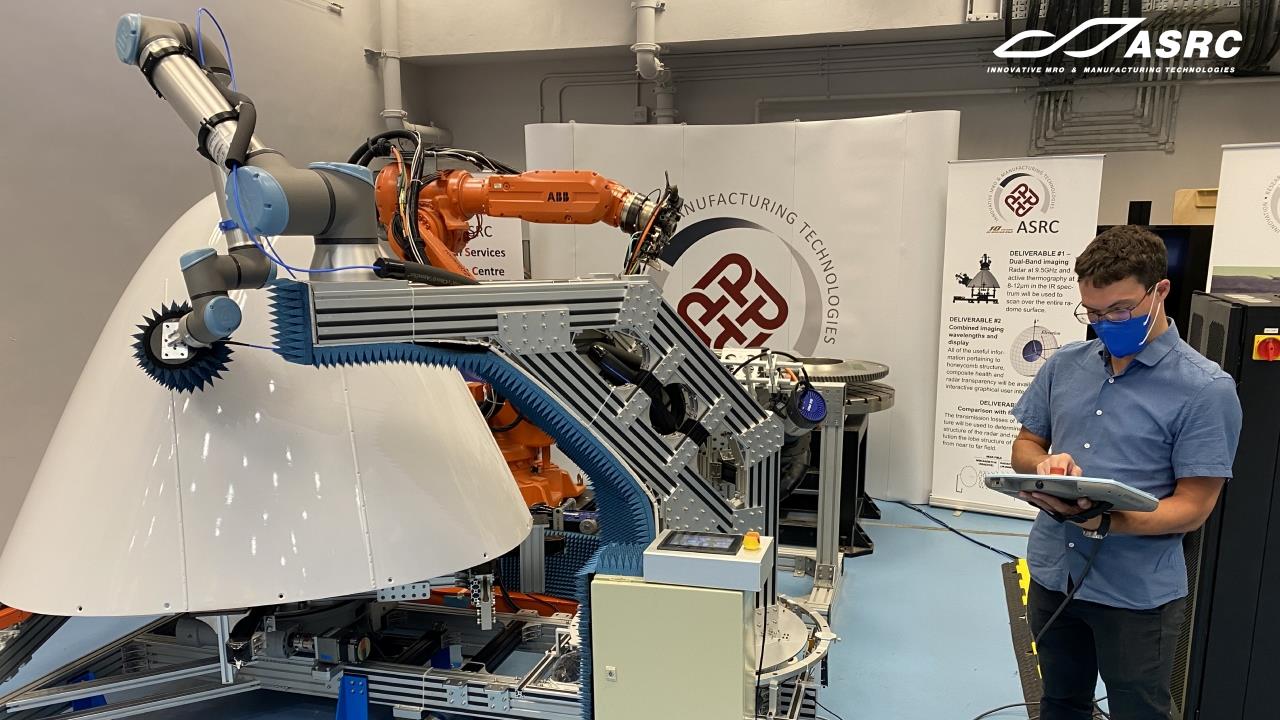

The PolyU Aviation Services Research Centre (ASRC) has developed a faster way to manufacture fixtures and components by using 3D printing instead of conventional machining. First, a 3D model of the component is obtained by scanning. This model is then used to print a fixture, to reprint the component, or to create repair doublers.

It can take a long time to manufacture and deliver fixtures and tooling for aircraft maintenance, causing delays and excessive turnaround times. 3D printing technology can resolve this problem by enabling the in-house design and manufacture of fixtures and tooling, resulting in a more effective maintenance service. This research project addresses the feasibility, capability, and cost of achieving this.

- Components manufactured using 3D printing techniques have previously been limited to non-critical, non-load bearing parts. This research has shown that 3D printing technology can now produce solid titanium, aluminium, and steel components.

- Actual production can be verified using 3D analysis during the manufacturing process. This is not possible with conventionally produced parts, where verification is only carried out after the production process is completed. Integrating this technology into the MRO industry opens up a wide range of possible productivity improvements.

- This research integrates the latest innovations associated with composite manufacture into a single process for the first time. This integration has resulted in state-of-the-art rapid production and tool-set definition.

- Descales the level of design expertise necessary to produce even the simplest type of fixture.

- Reduces turn-around-time by up to 50% without increasing cost.

- Recurring fatigue testing has shown that endurance of 3D printed metals can be almost equivalent to conventionally machined components.

- Production of fixtures and tooling

- Production of doublers

- Rapid prototyping

With over 80 years of proud tradition and ranking among the world’s top 100 institutions, The Hong Kong Polytechnic University (PolyU) aspires to be a leading university with world-class research and education.

PolyU is a home for educating thinkers, discoverers, innovators and communicators in delivering positive impact. We are committed to nurturing tomorrow’s leaders today, through a holistic education that provides graduates unrivaled placements to thrive in communities, industries and businesses.