Cross-material Structural Monitoring by Acoustic Reflection and Transmission

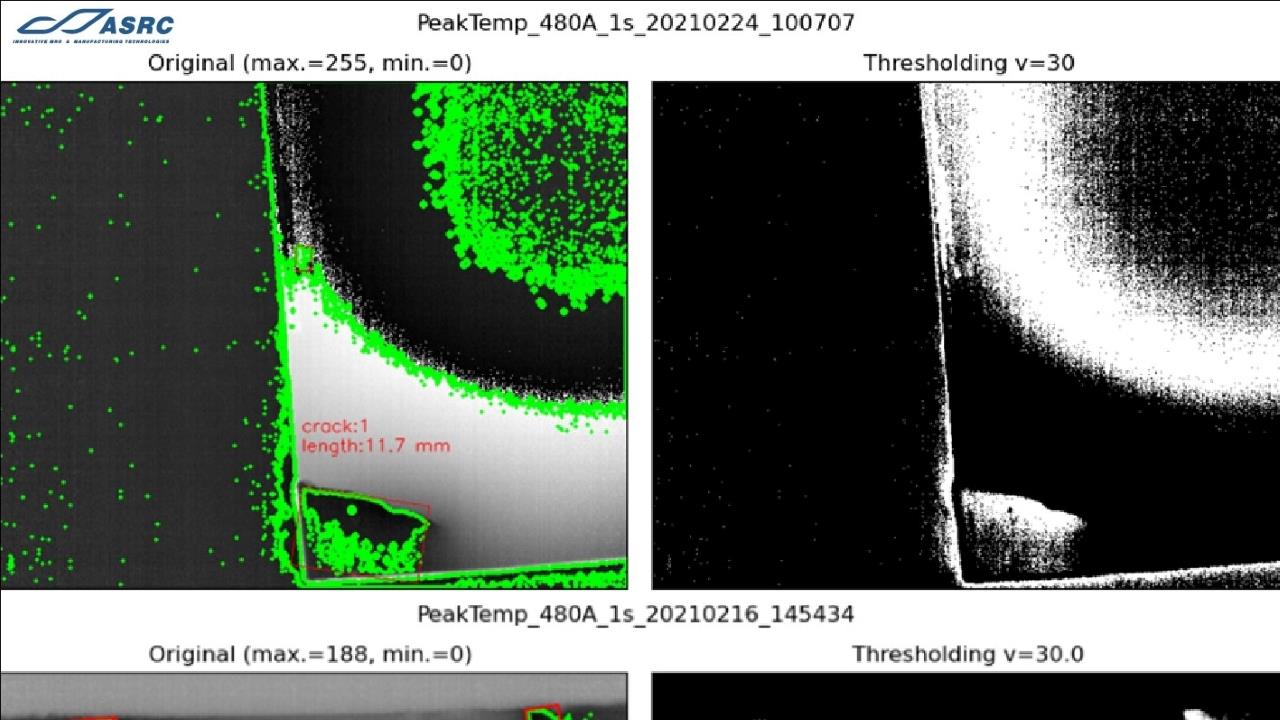

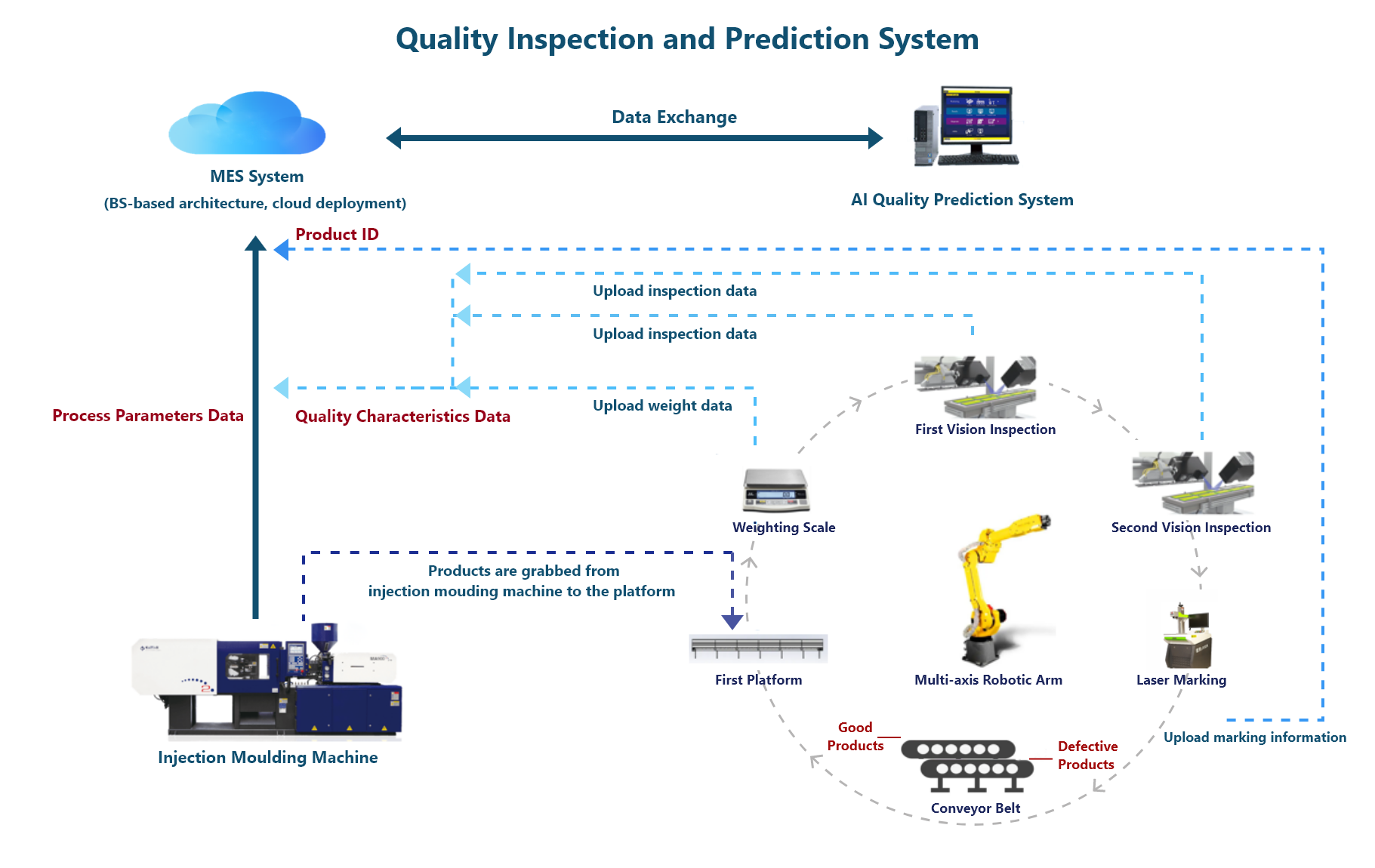

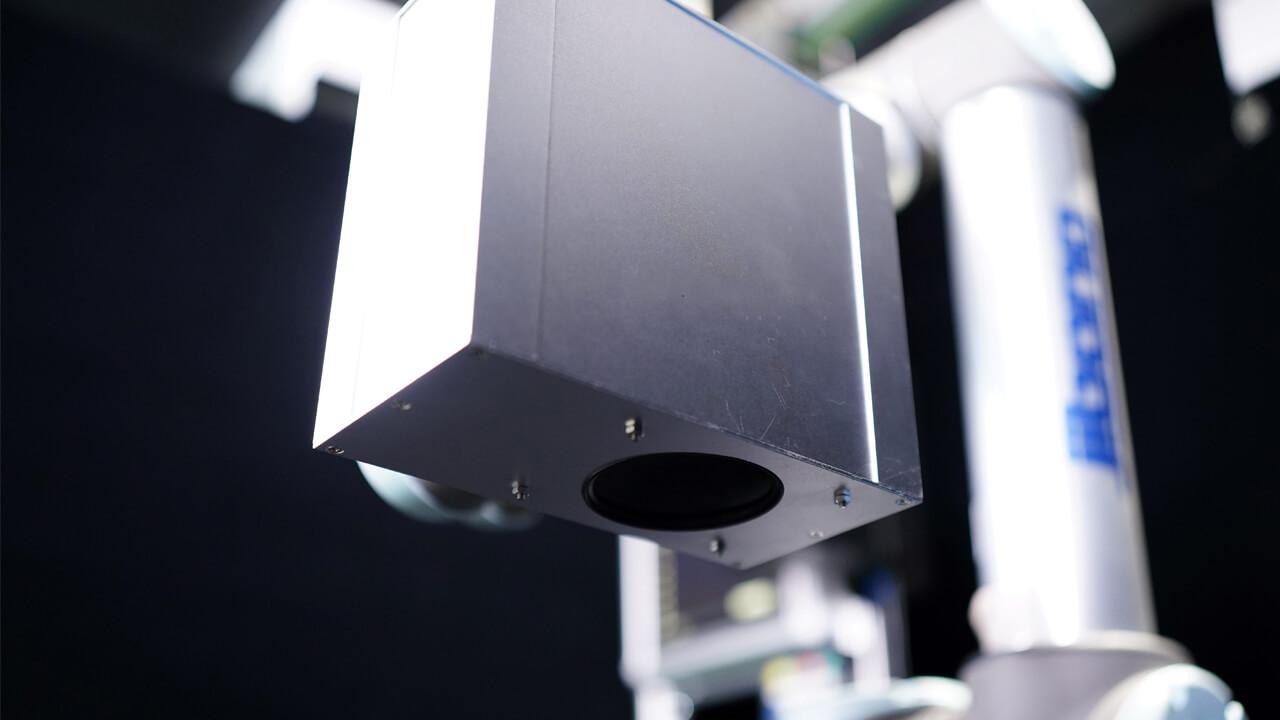

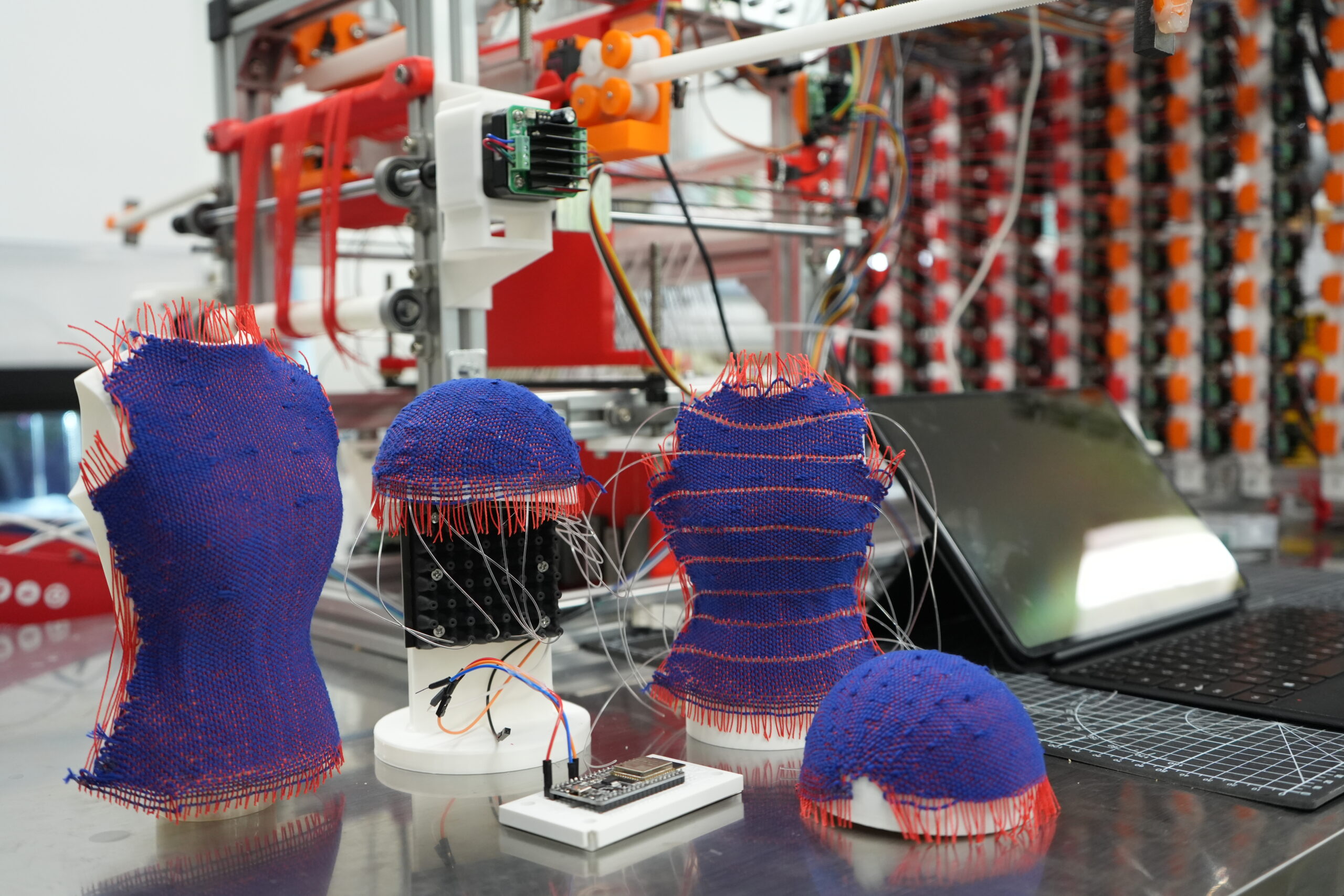

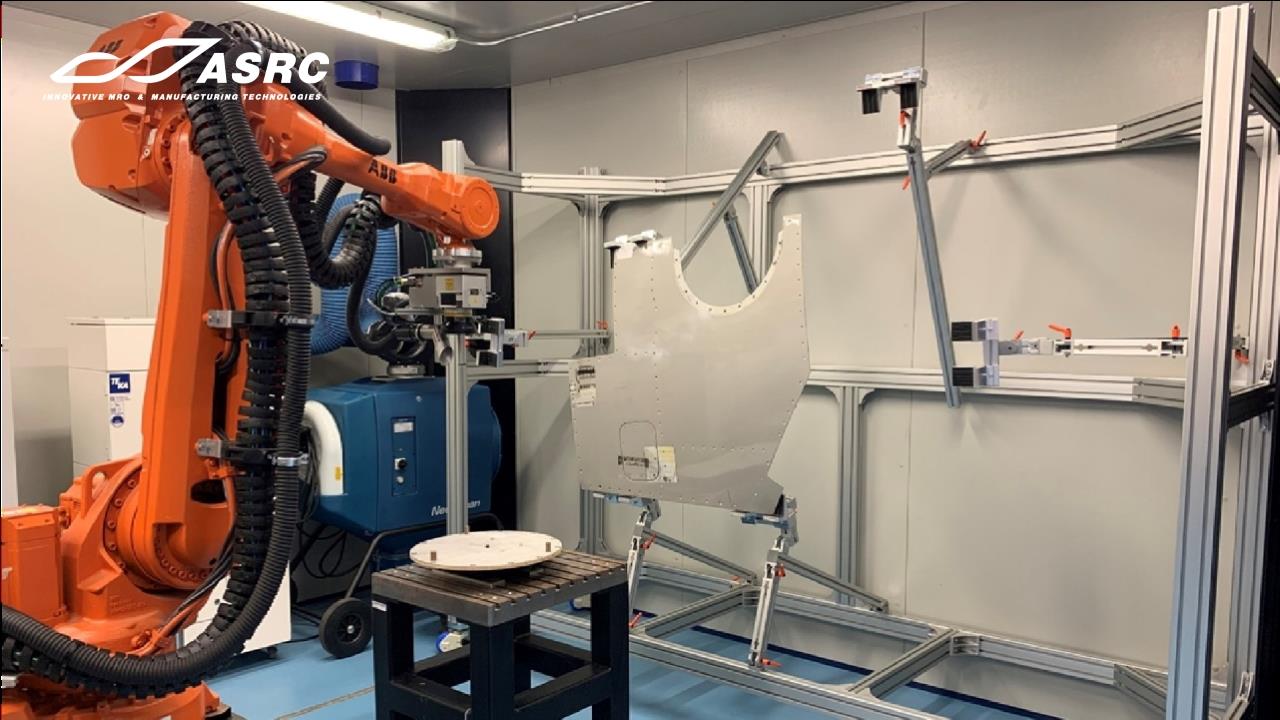

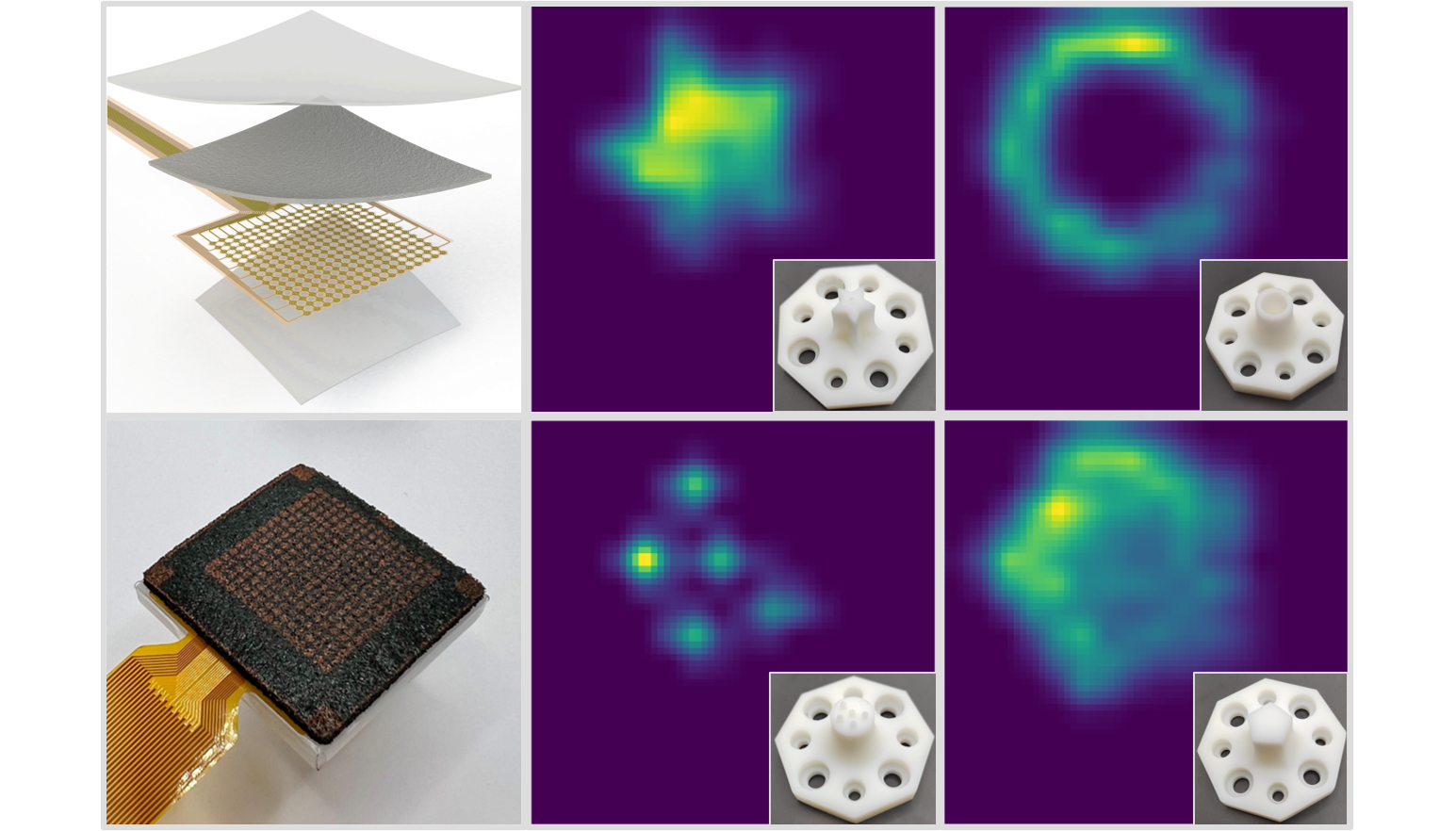

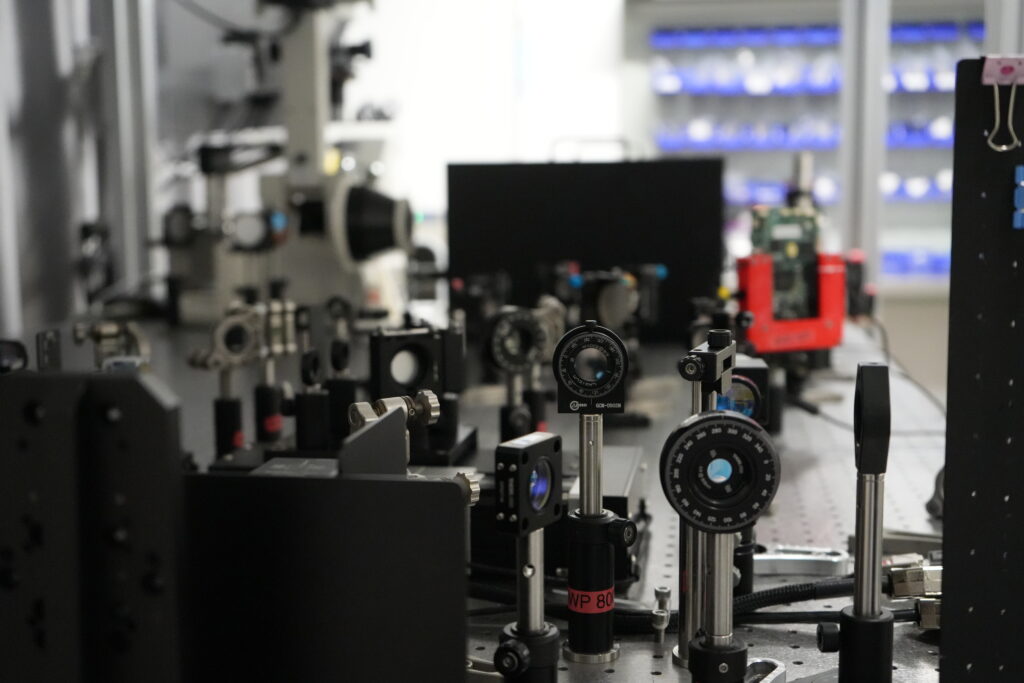

This technology utilises sensors to excite ultrasound into structures and capture the transmitted wave signals. The measured signals are decomposed to obtain the wave energy feature, which are used to train an AI model for damage identification. This technology can be used for damage inspection in various materials, e.g., metals and composites.

Cumbersome modelling work is indispensable when applying conventional model-driven ultrasonic methods for damage identification. Furthermore, ultrasound propagation modeling for one material cannot be directly applied in other materials, resulting in the damage detection model developed for one material inapplicable to another.

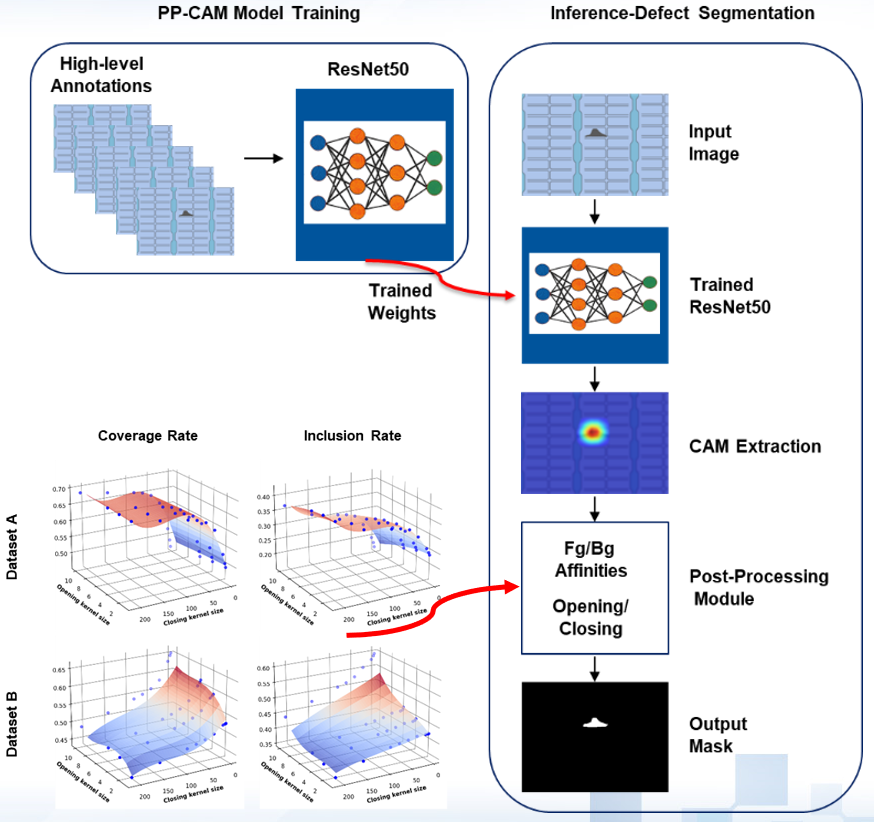

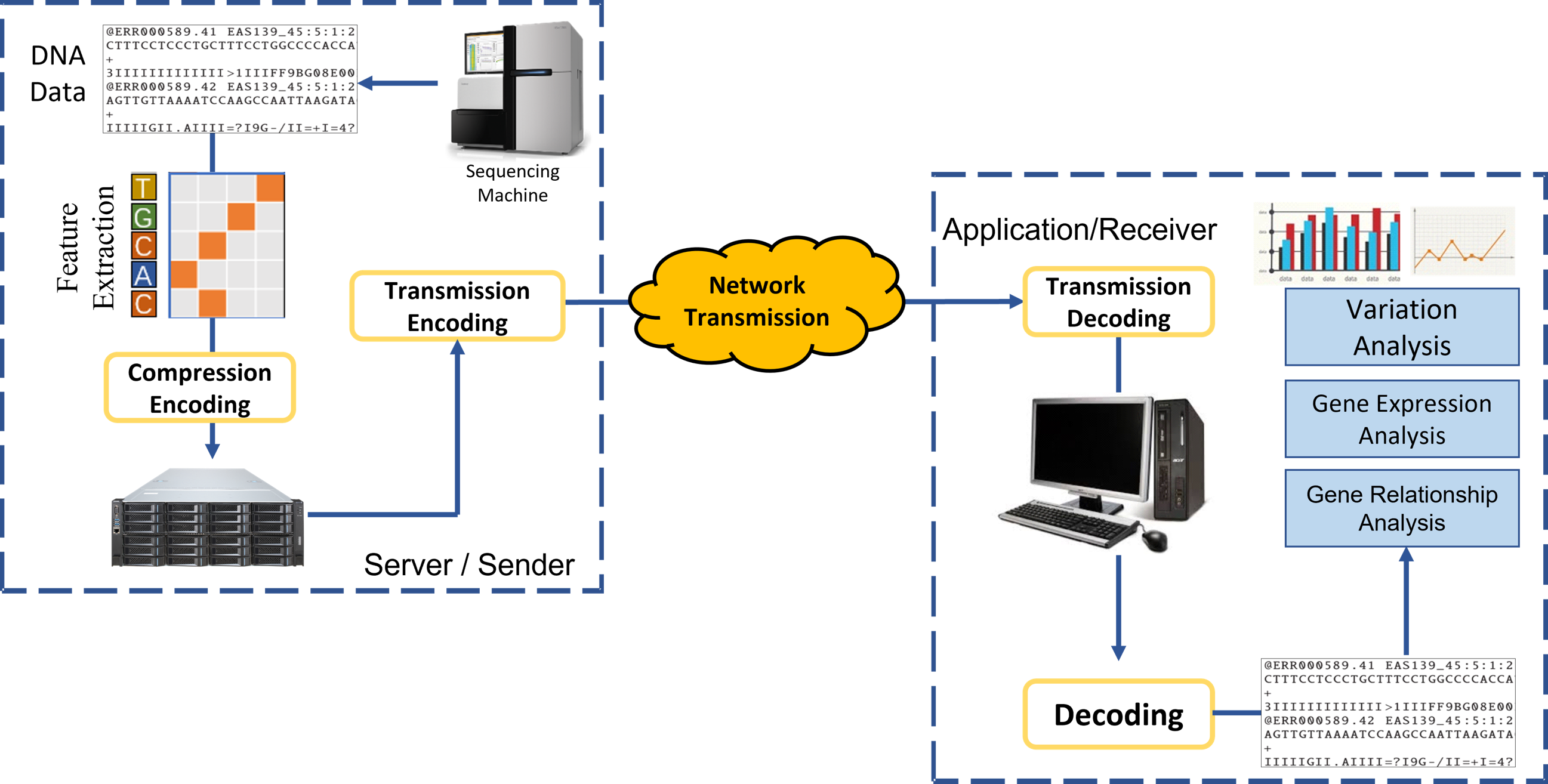

- Raw ultrasonic signals captured by ultrasonic sensors/sensor network are decomposed into discrete frequency bands to obtain the wave energy distribution features, from which wave energy distribution vectors can be constructed.

- Principal component analysis is performed to reduce dimensionality of vector, achieving high computational efficiency for subsequent classification tasks.

- An AI-based classifier is trained for automatic damage identification by using the principal components of vector as input. This technology can be applied to damage inspection and structural health monitoring in various different materials, such as metallic and composite materials.

- High efficiency by circumventing complicated wave propagation modelling in various materials.

- The applicability to different materials does not require an analysis of ultrasonic propagation, which is dependent on the specific material properties.

- The AI-based classifier for damage detection can be easily updated with a small set of ultrasound data for new material.

- A high damage identification accuracy of over 90 % is achieved.

- Bronze Medal at the “2023 Geneva International Exhibition of Inventions”

- Gold Medal at the “2023 Asia International Innovative Invention Exhibition”

- Damage inspection for pipeline, rail track and wind turbine blade

- Condition monitoring and quality control of battery production

Patent

- Short-term Patent: HK30082364

The Hong Kong Productivity Council (HKPC) is a multi-disciplinary organisation established by statute in 1967, to promote productivity excellence through integrated advanced technologies and innovative service offerings to support Hong Kong enterprises. HKPC is the champion and expert in facilitating Hong Kong's new industrialisation empowered by i4.0 and e4.0 - focusing on R&D, IoT, big data analytics, AI and Robotic technology development, digital manufacturing, etc., to help enterprises and industries upgrade their business performance, lower operating costs, increase productivity and enhance competitiveness.

The Council is a trusted partner with comprehensive innovative solutions for Hong Kong industries and enterprises, enabling them to achieve resources and productivity utilisation, effectiveness and cost reduction, and enhanced competitiveness in both local and international marketplace. It offers SMEs and startups immediate and timely assistance in coping with the ever-changing business environment, accompanying them on their innovation and transformation journey.