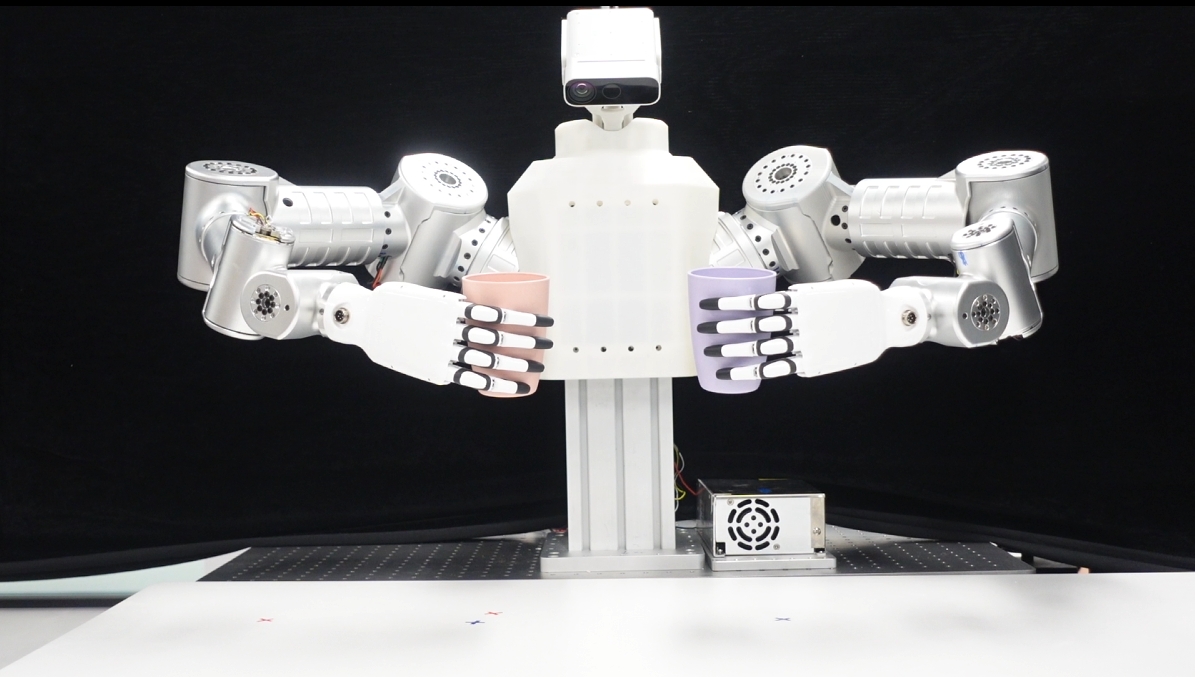

“OWL” Intelligent Production Line

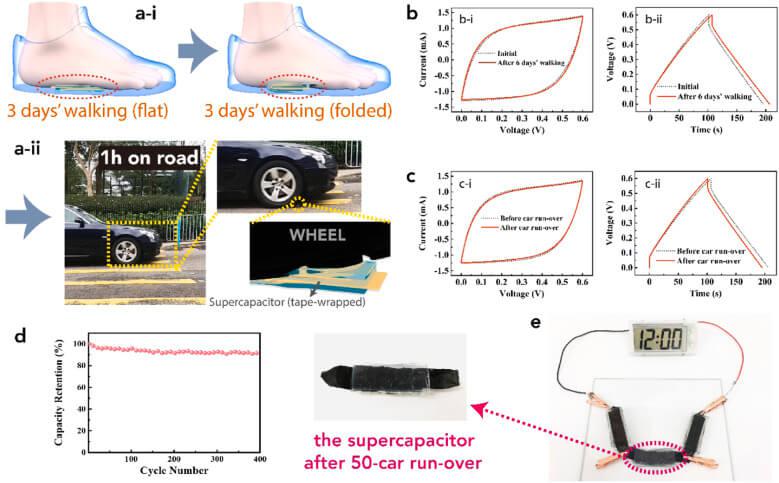

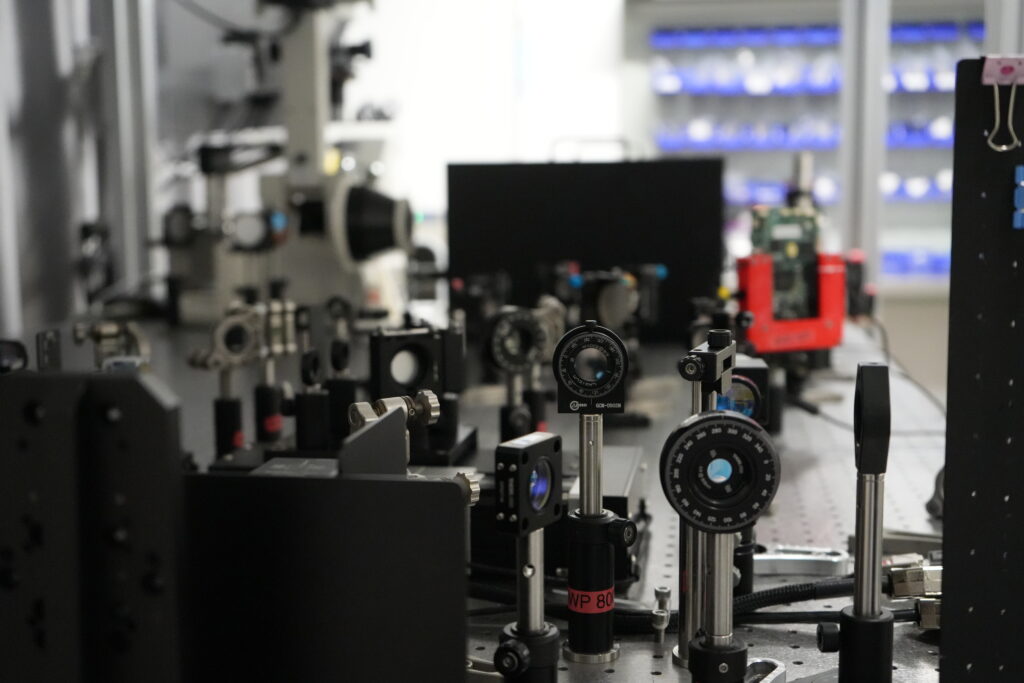

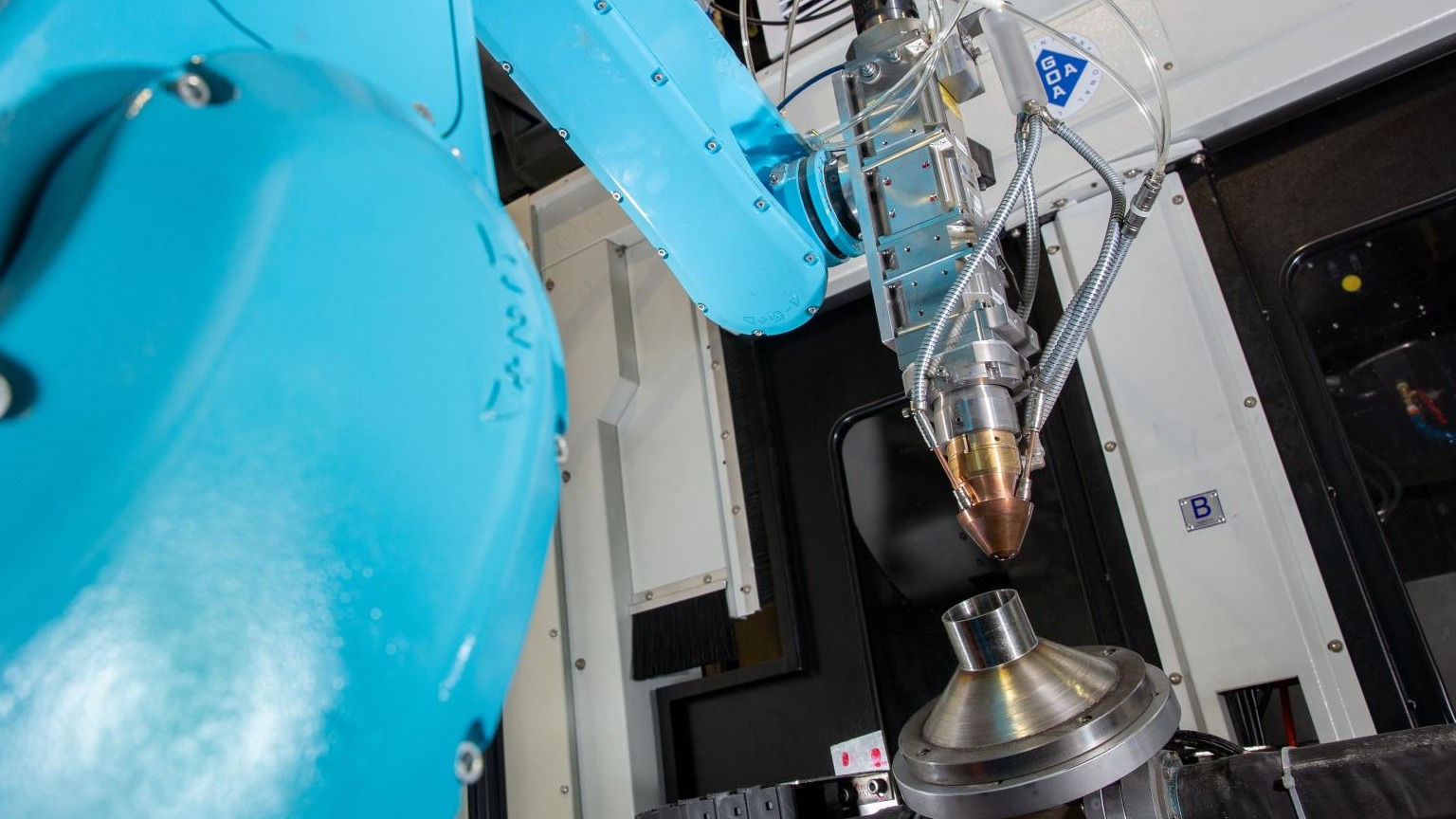

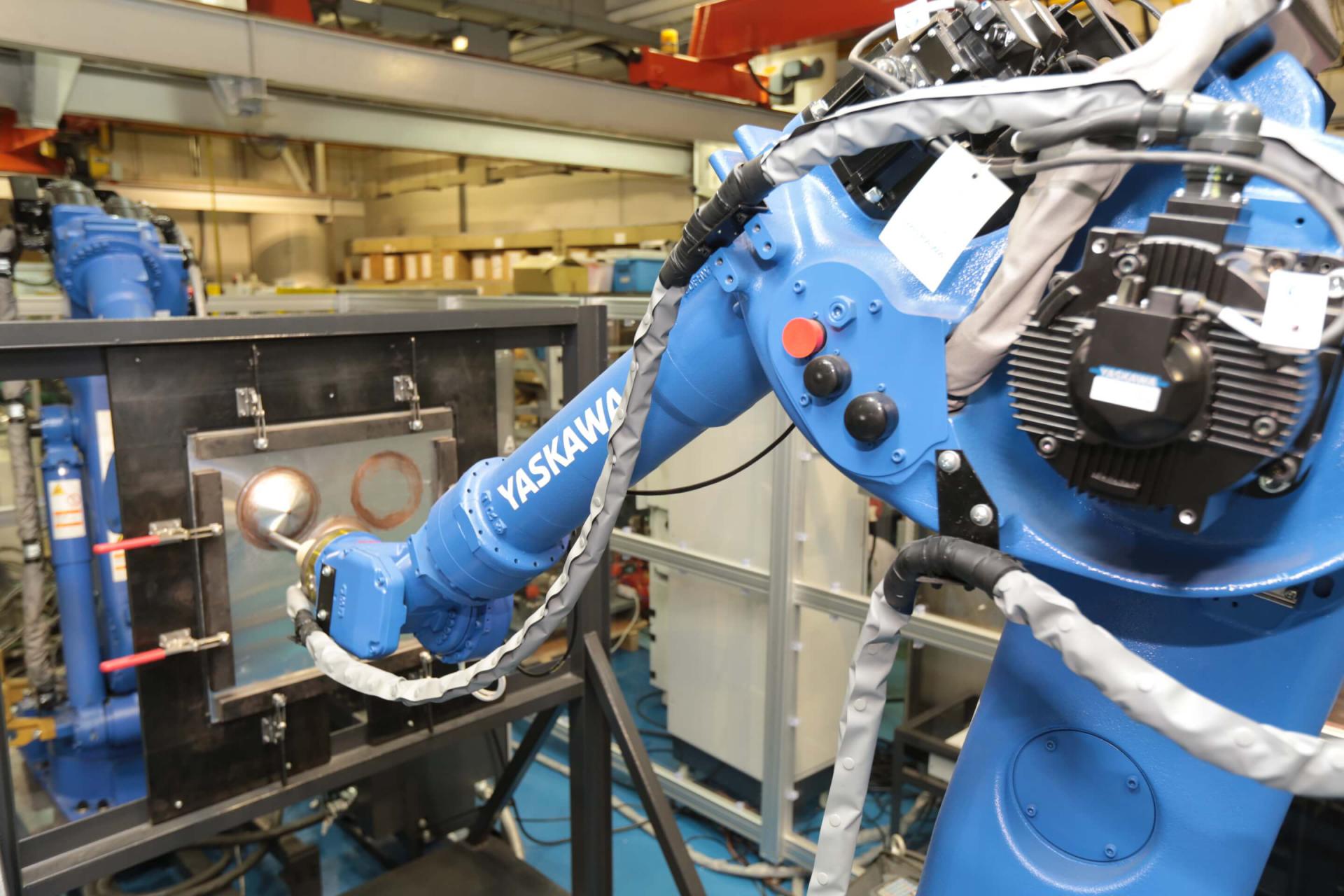

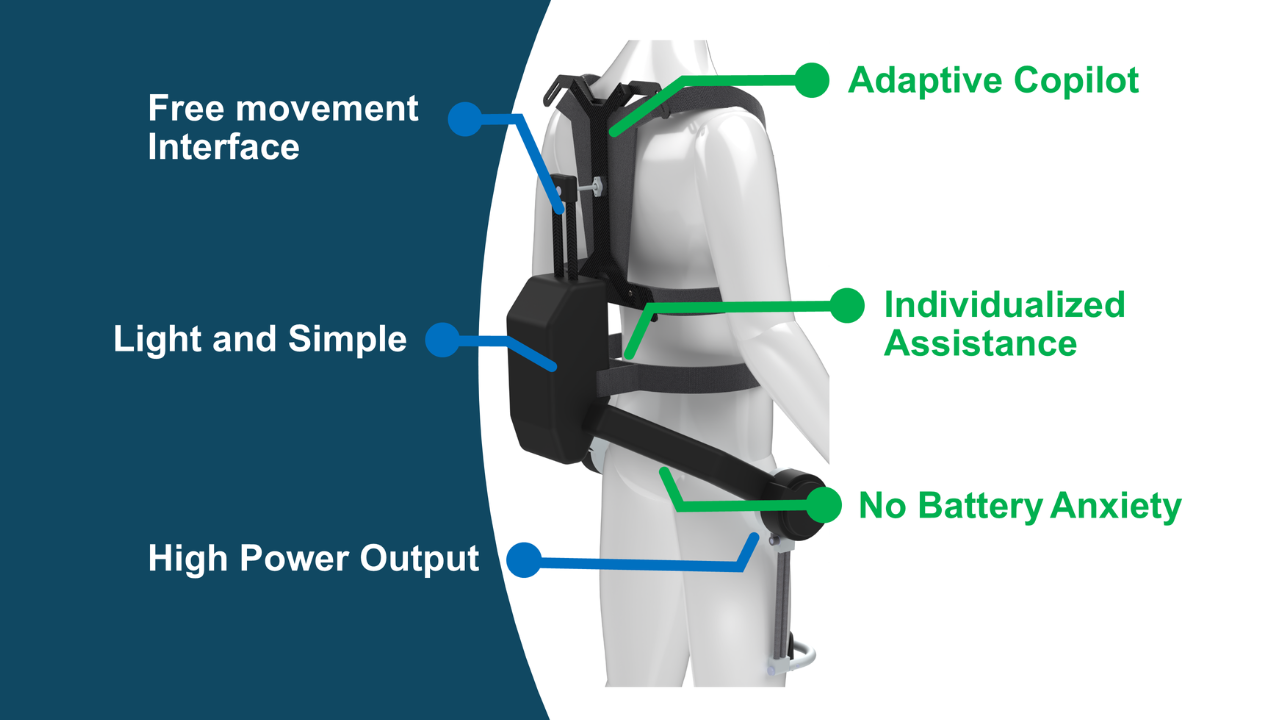

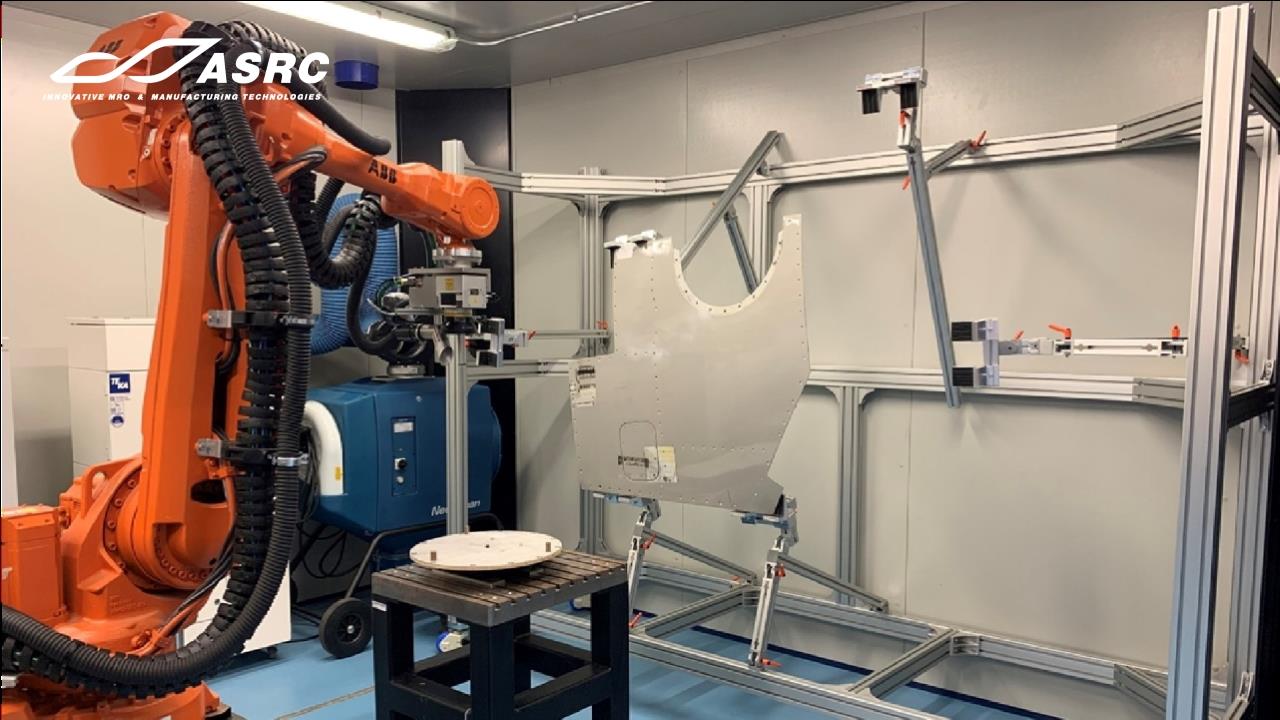

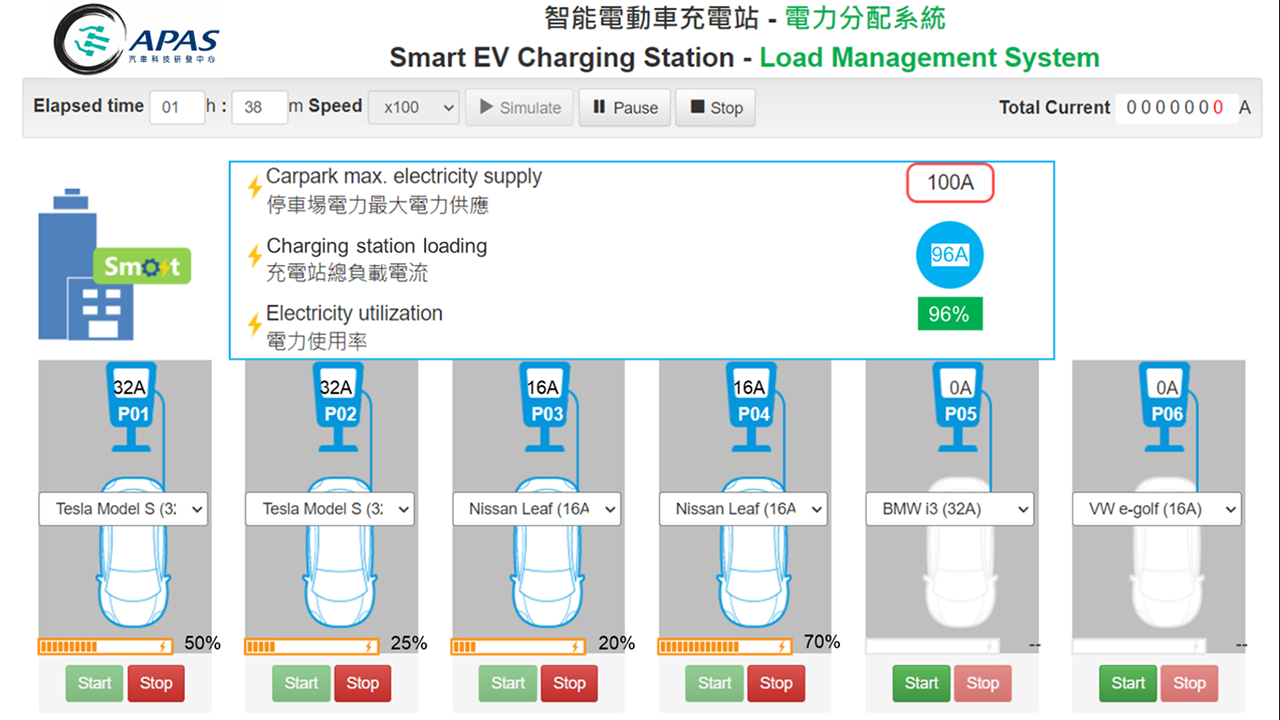

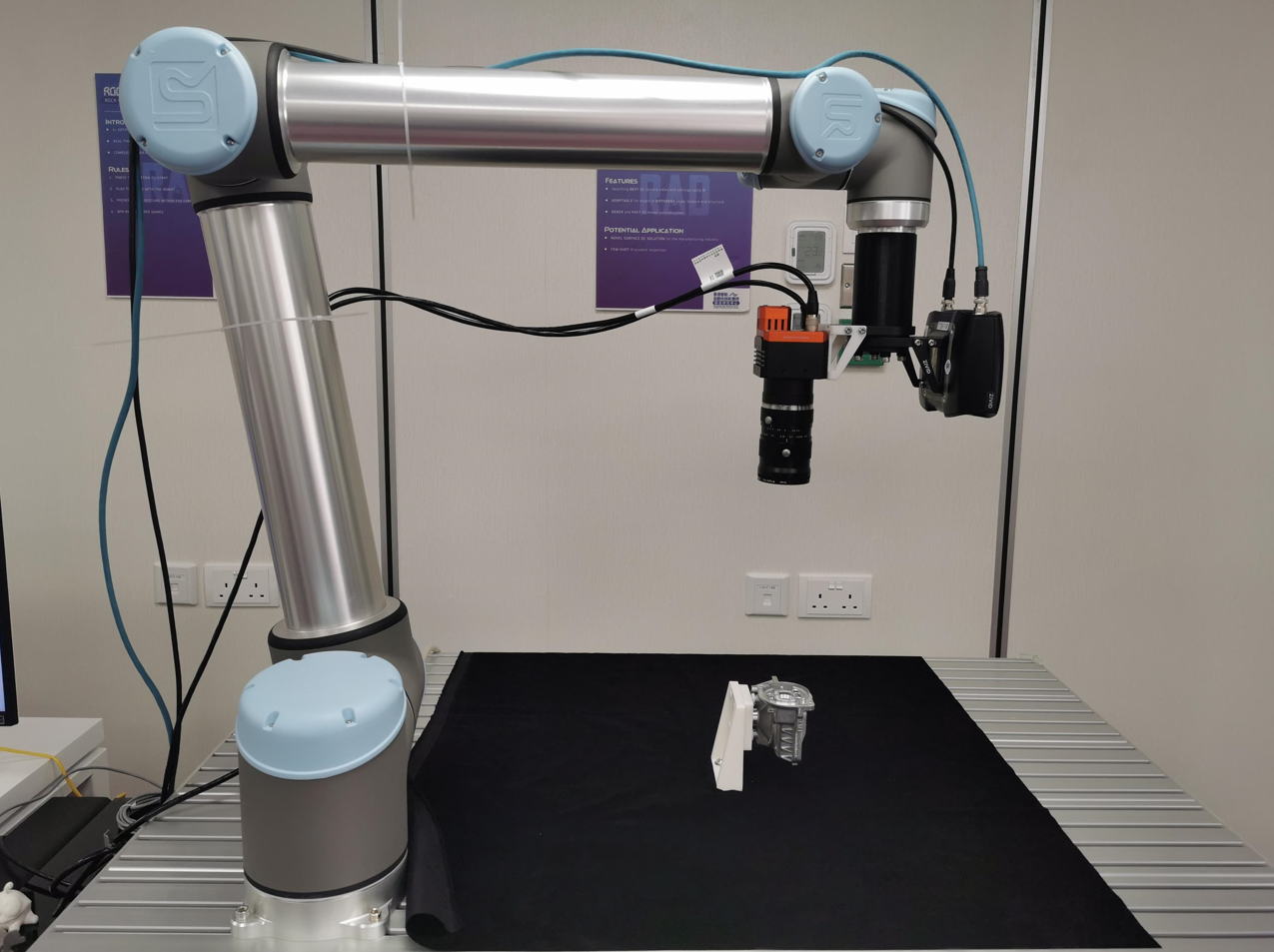

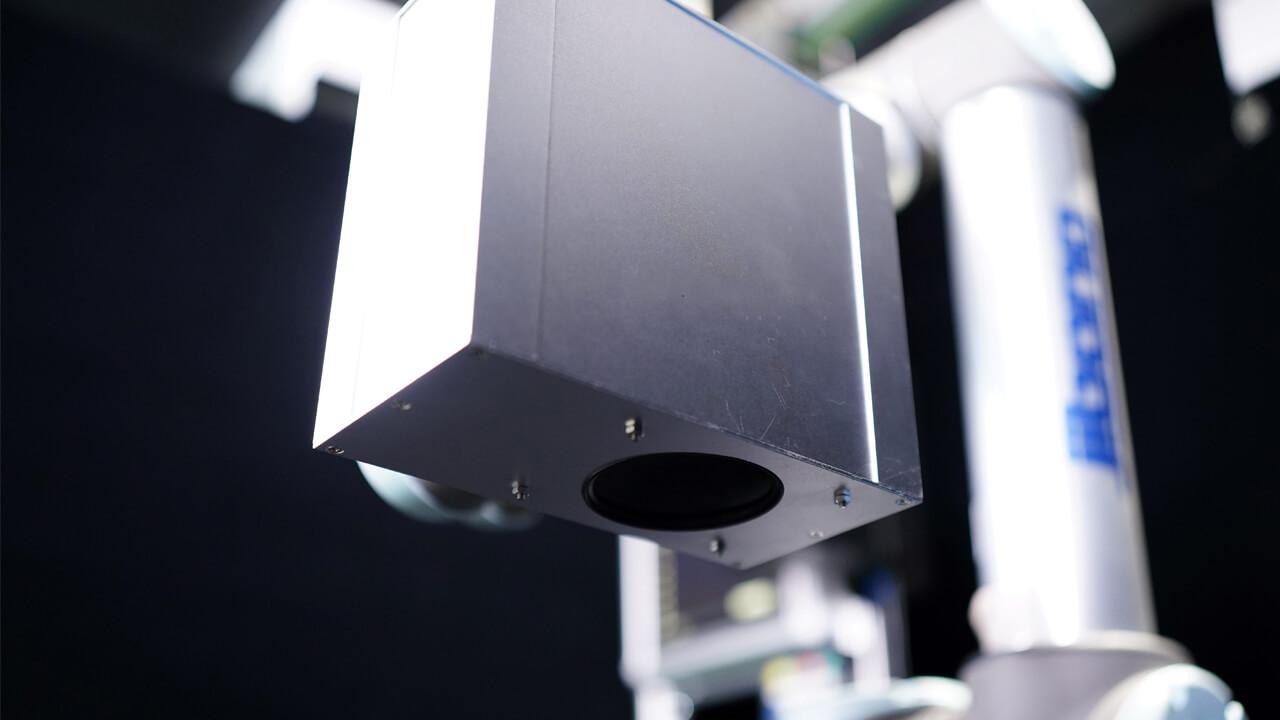

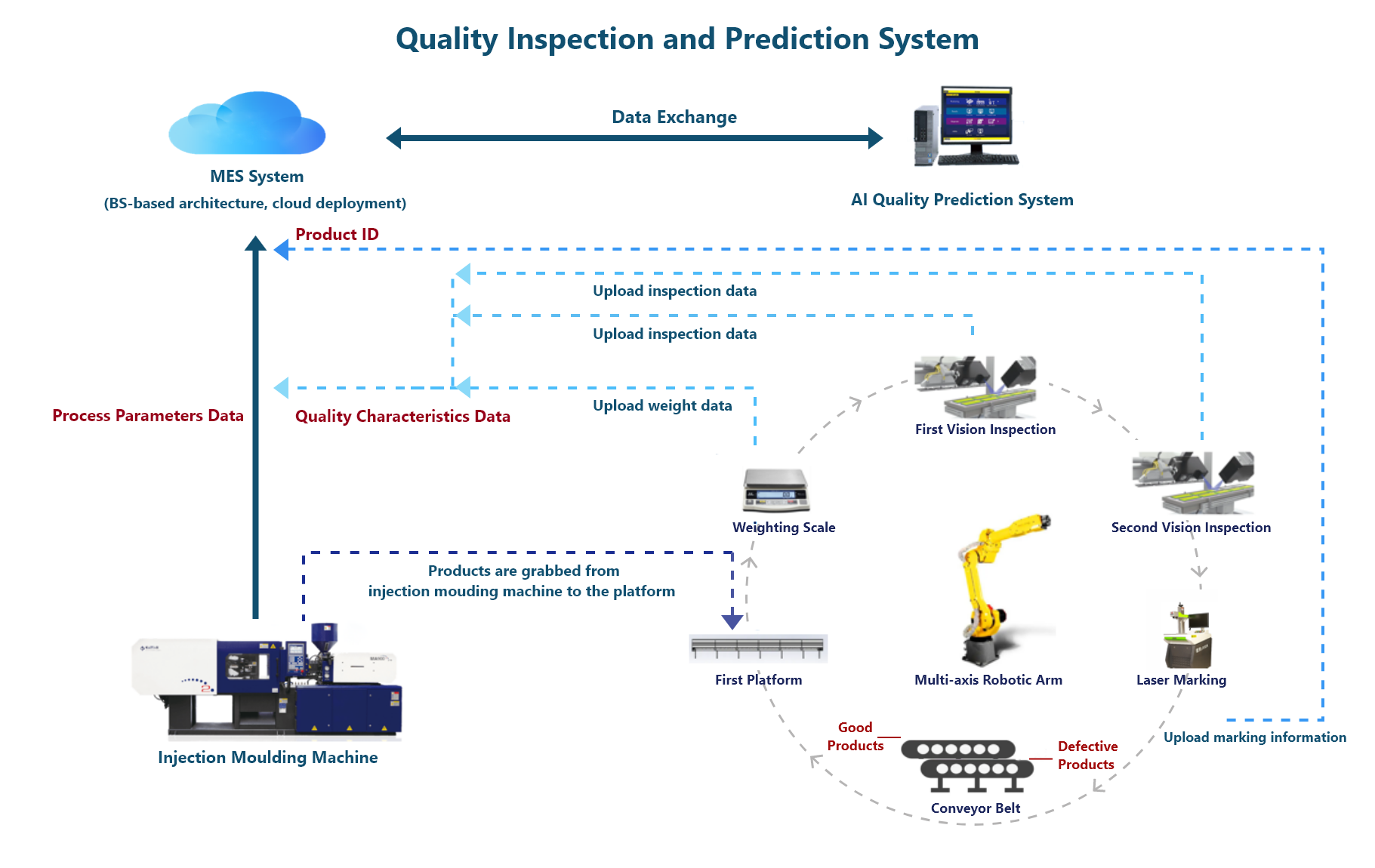

The intelligent manufacturing technologies adopted by local intelligent security product manufacturer NiRoTech, including machine vision, human machine interface, real-time data collection and data analytic technologies to tailor-make a robotics production team by HKPC to achieve intelligent manufacturing.

Traditional production line requires plenty of land and labour, facing the pain points of difficulty in finding land, labour shortage and high production cost.

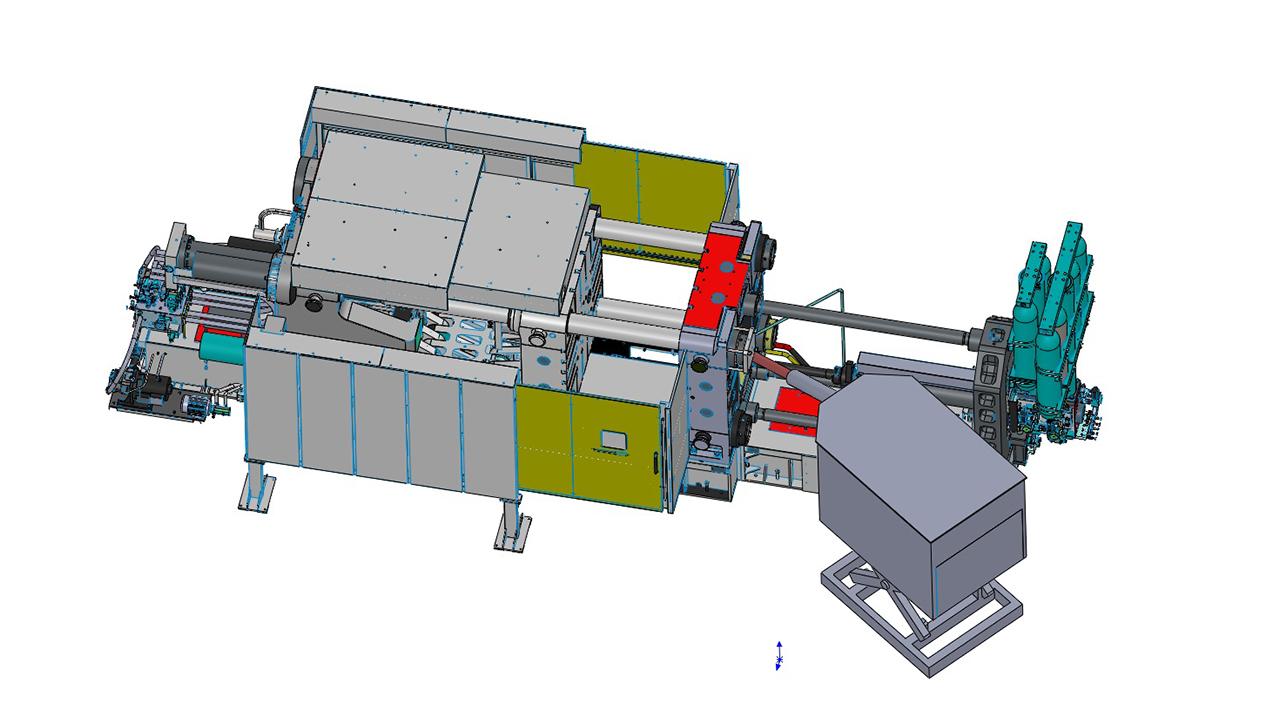

- While two production lines of 50m each are required in the past (making a total length of 100m), now it only takes 54m (equivalent to the length of four buses) and is designed in U-shape. The length of production line has been shortened by half, flexibly maximising the use of factory space.

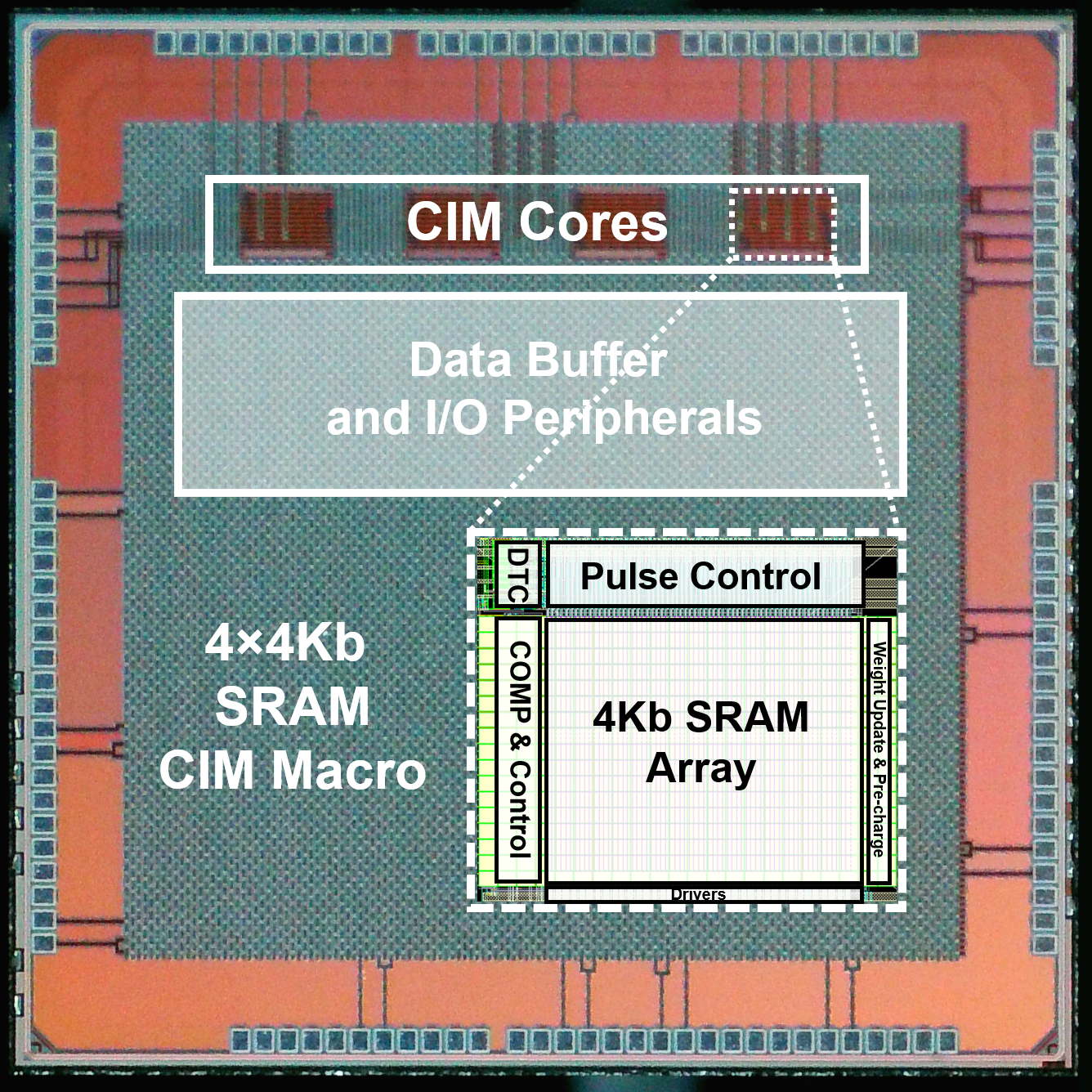

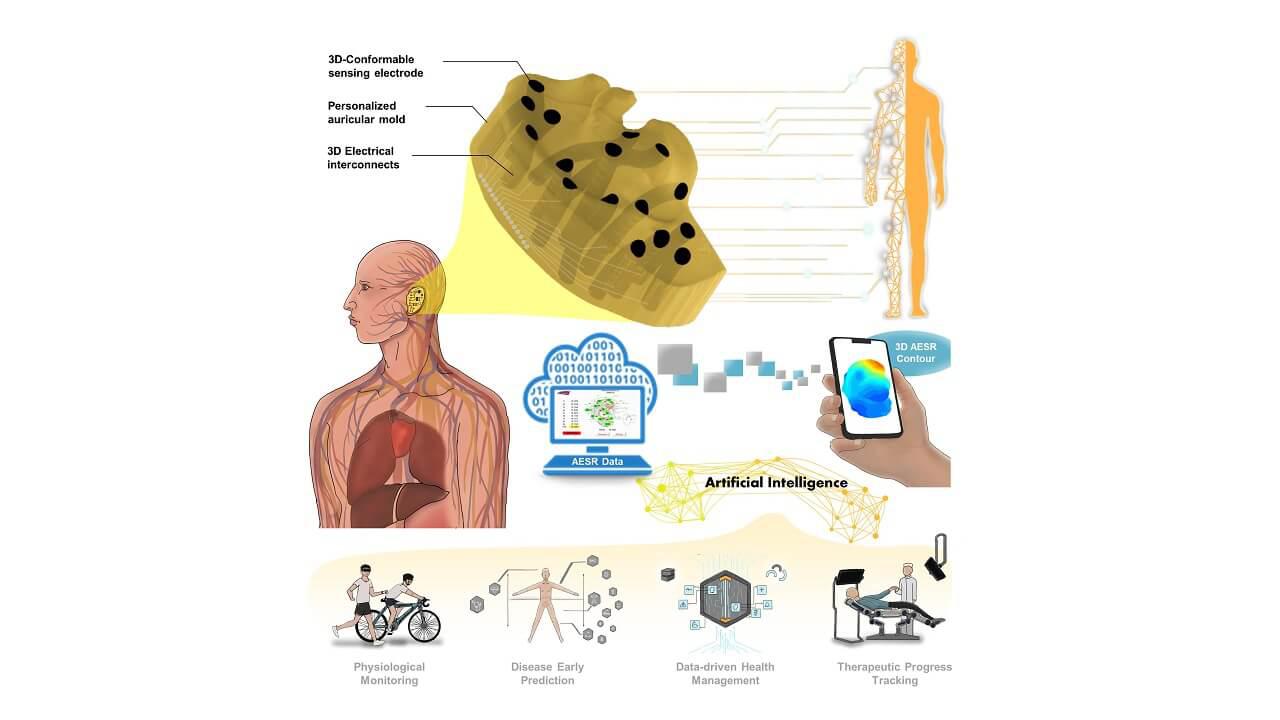

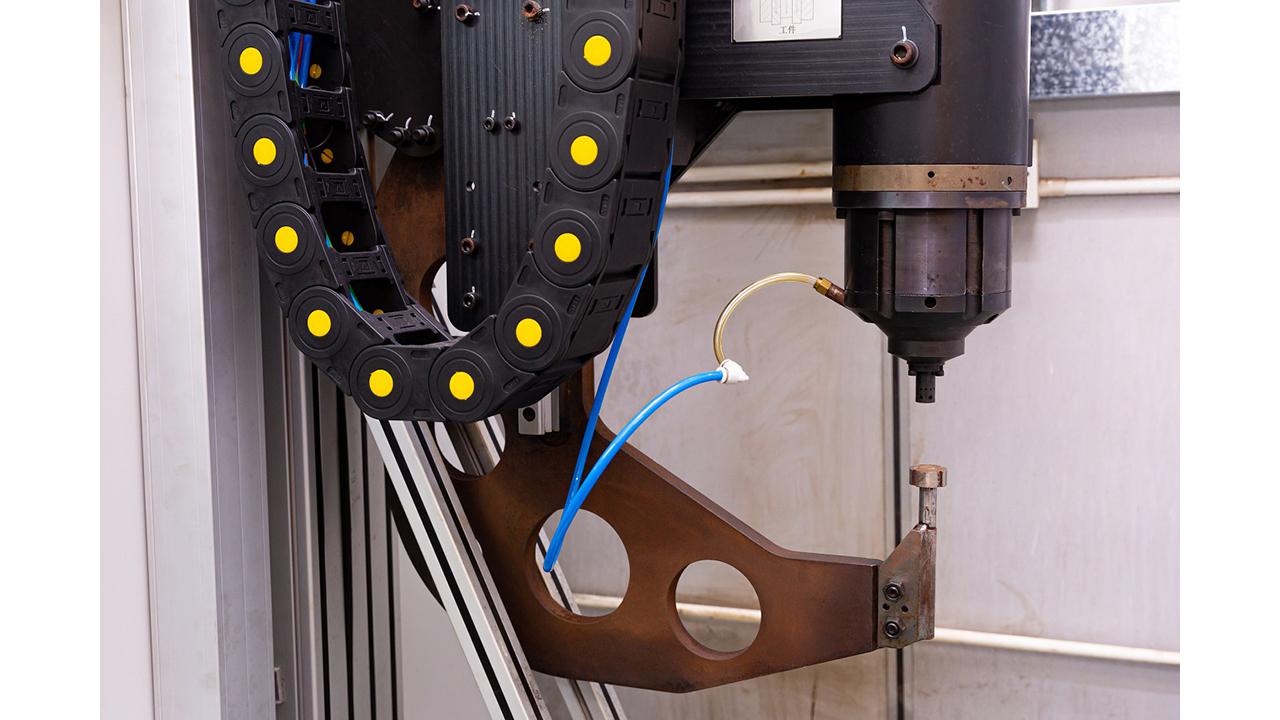

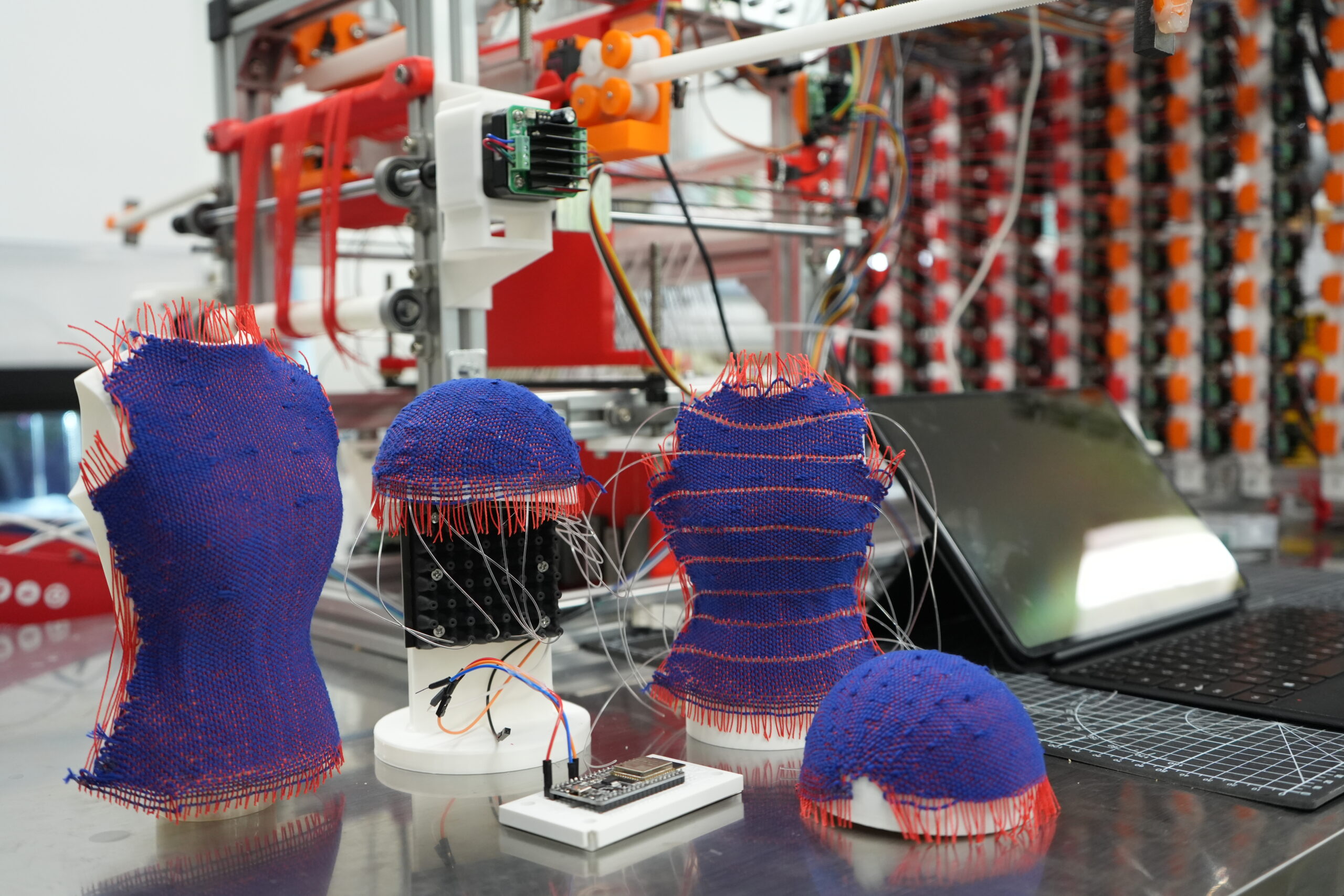

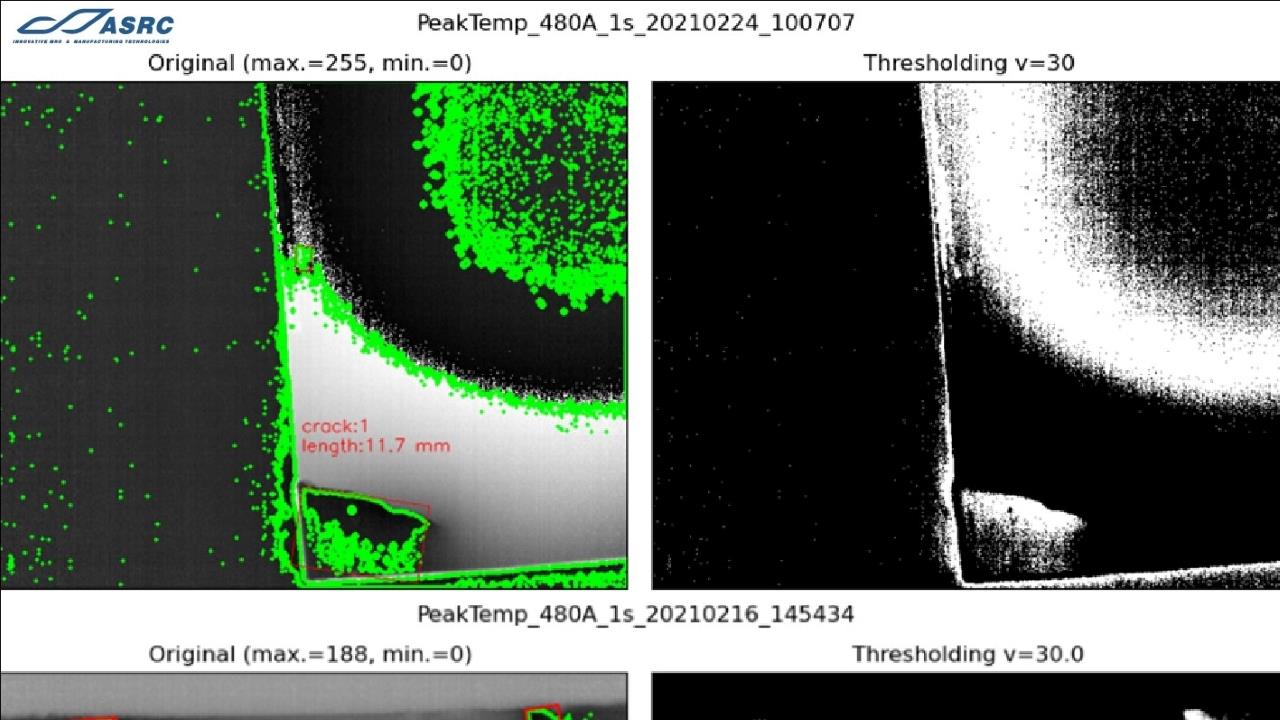

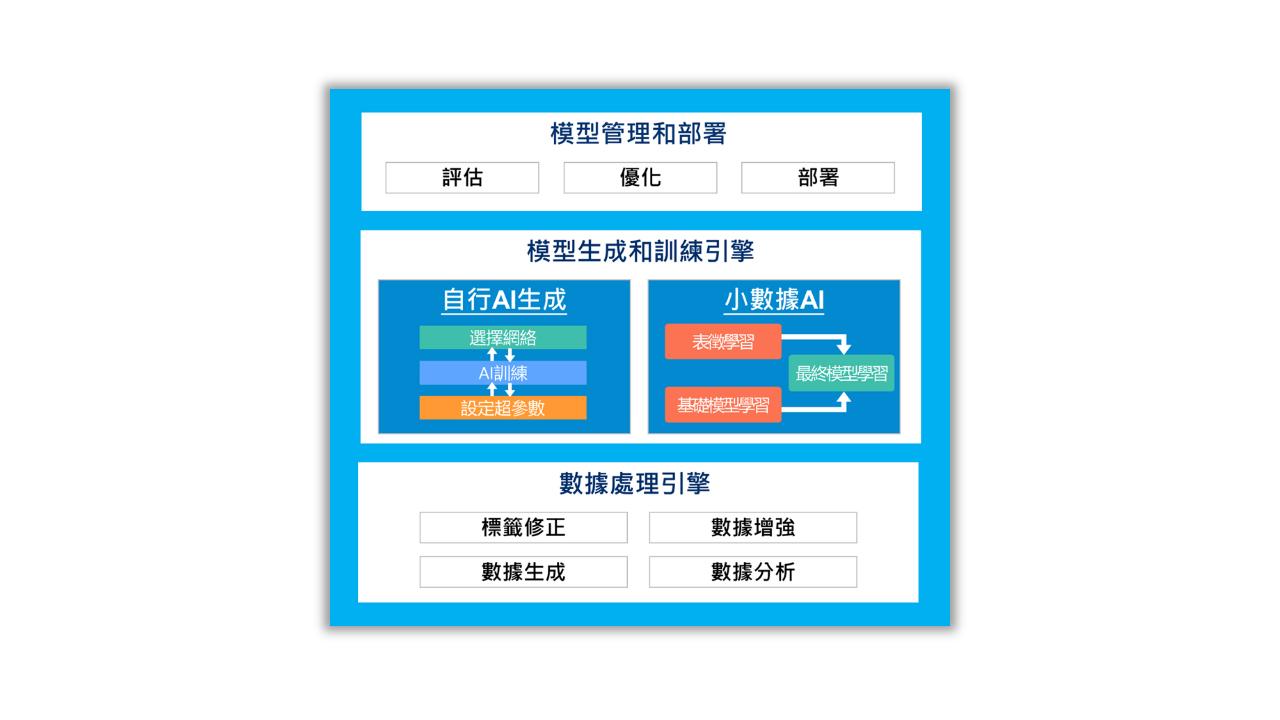

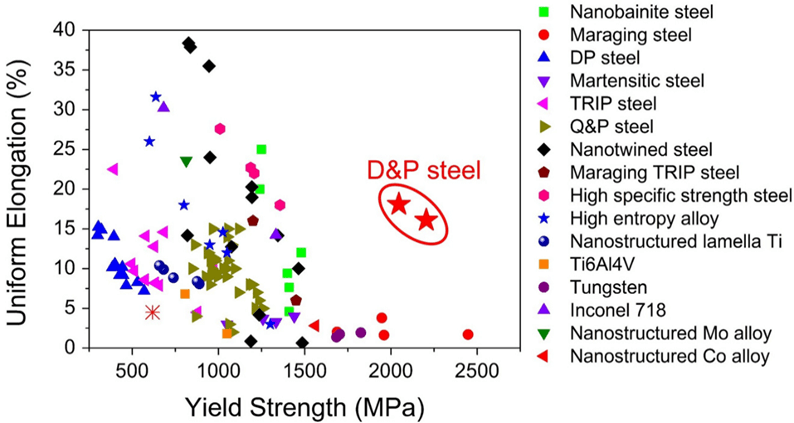

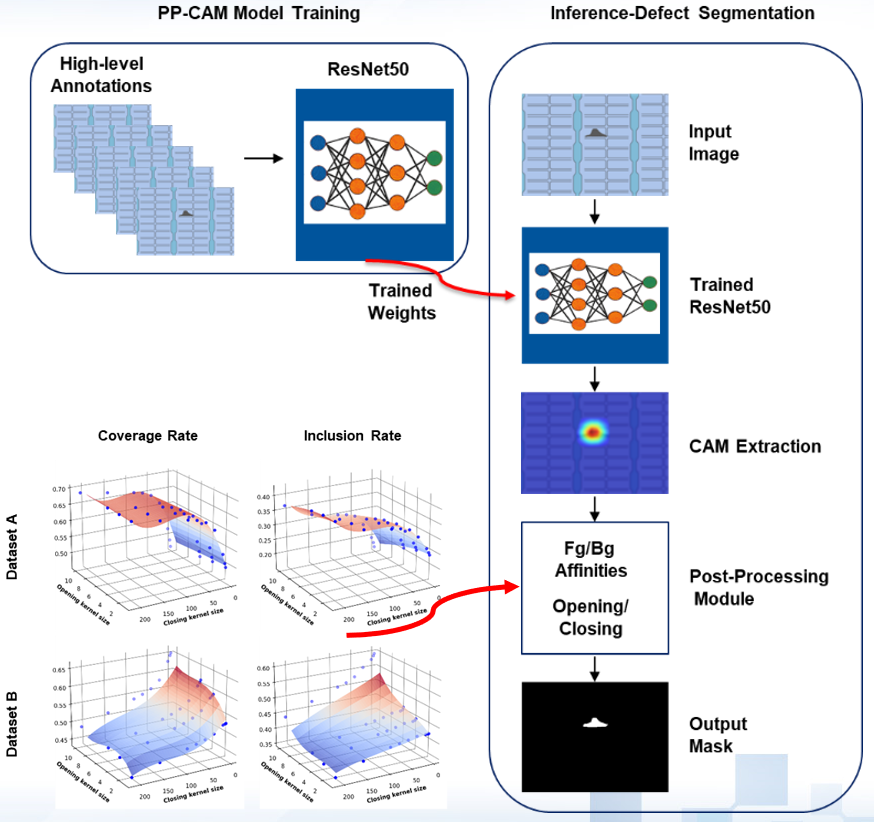

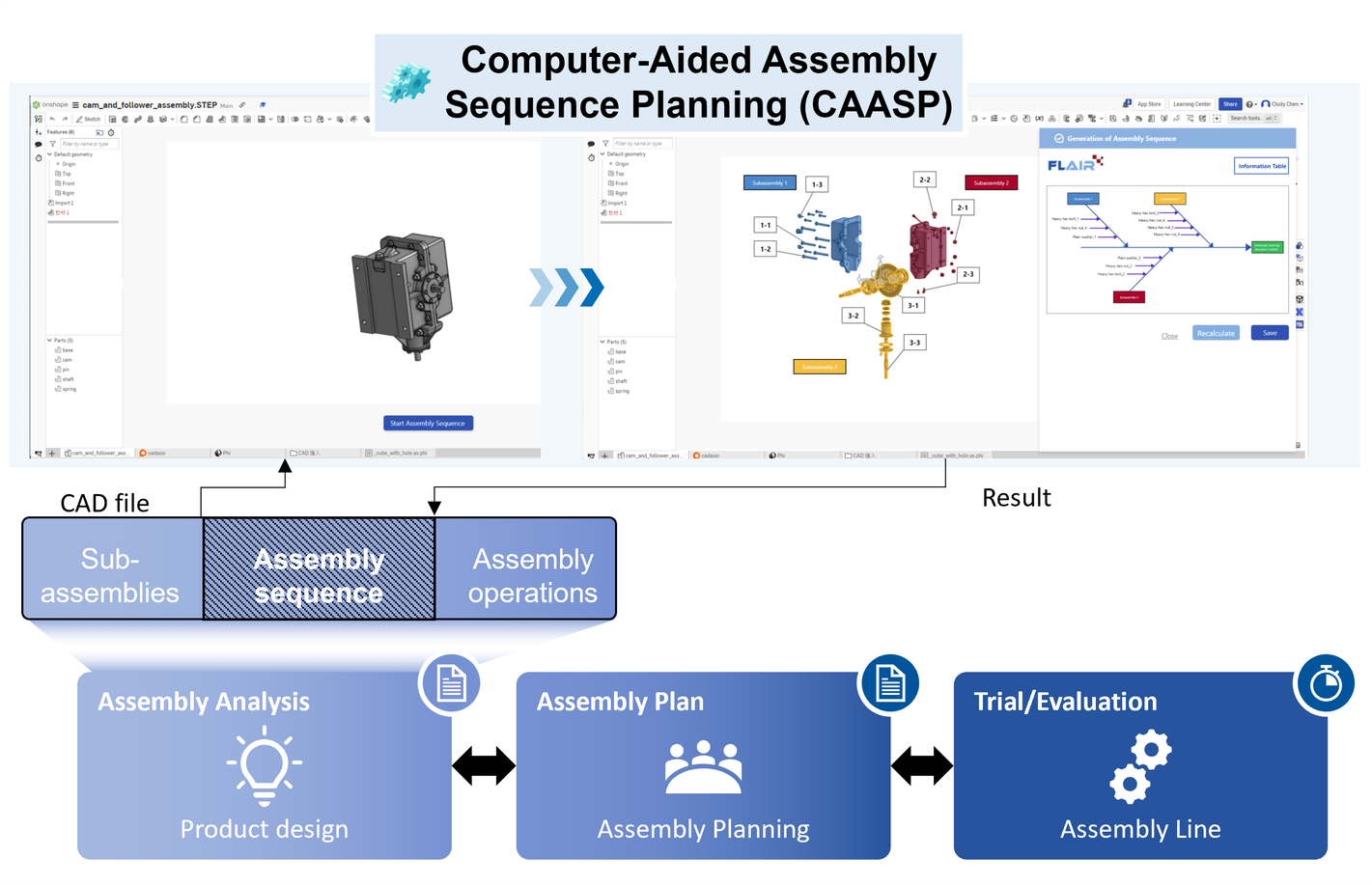

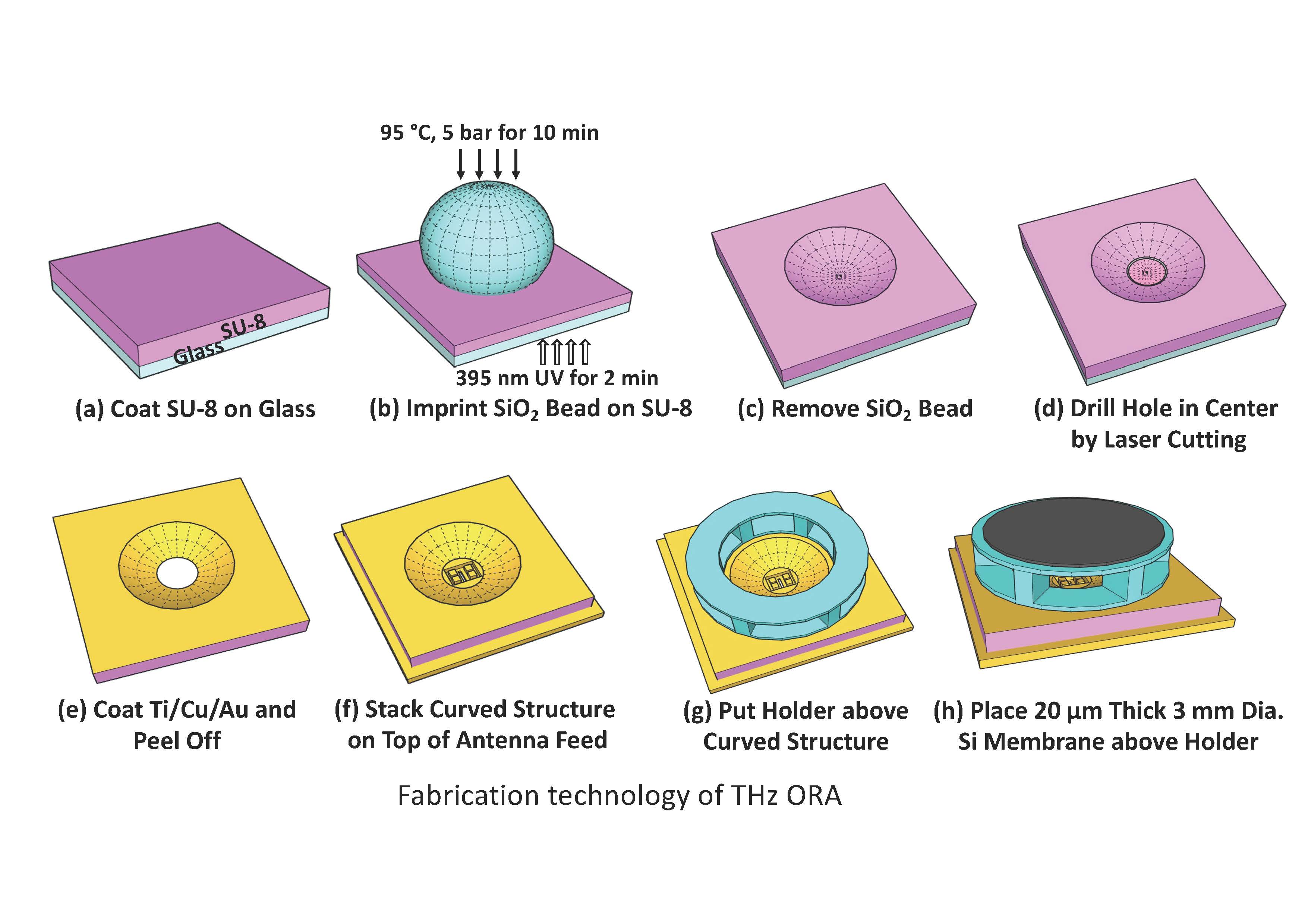

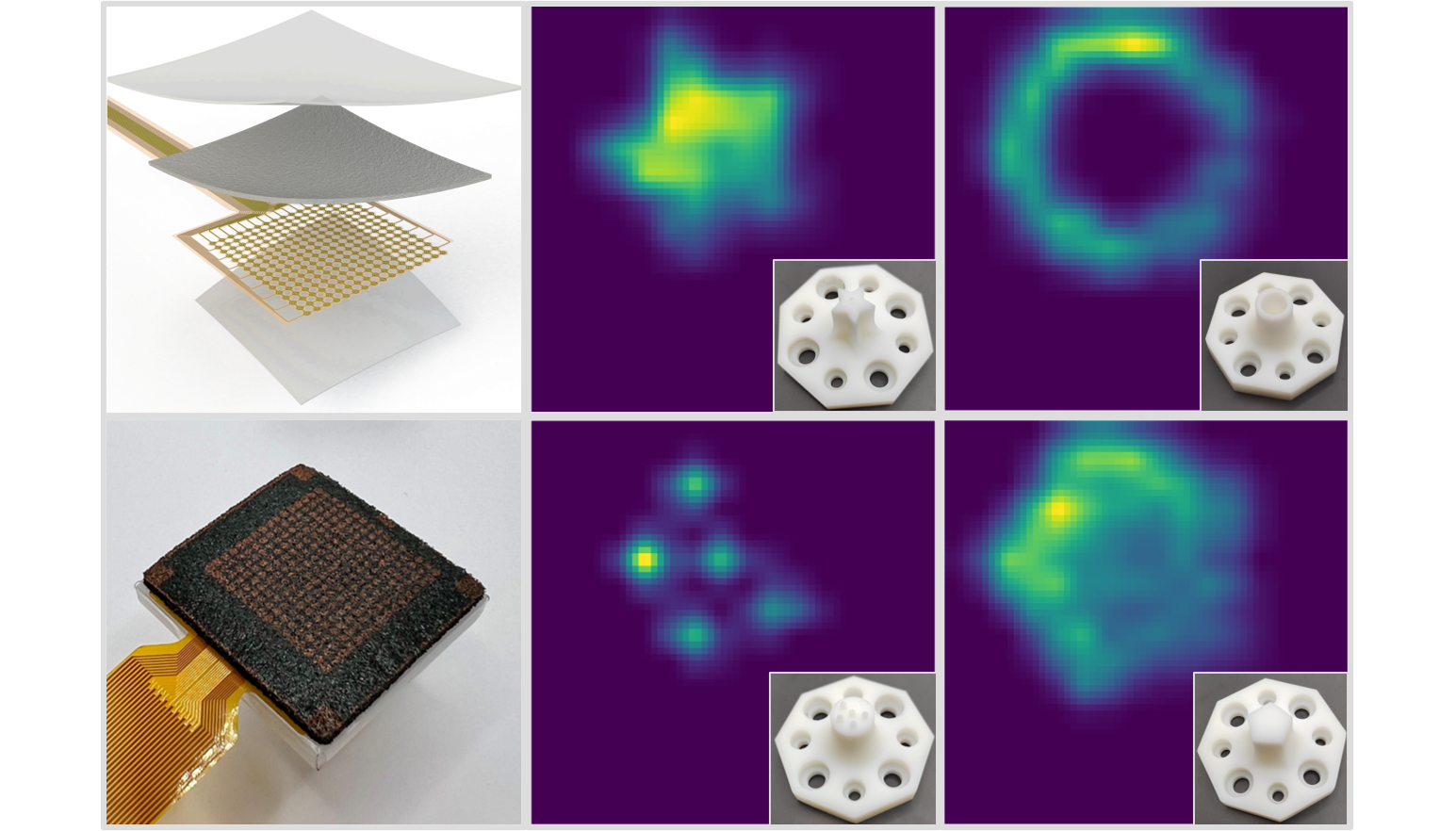

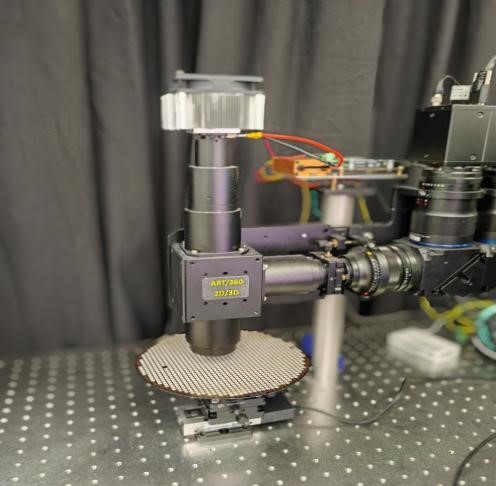

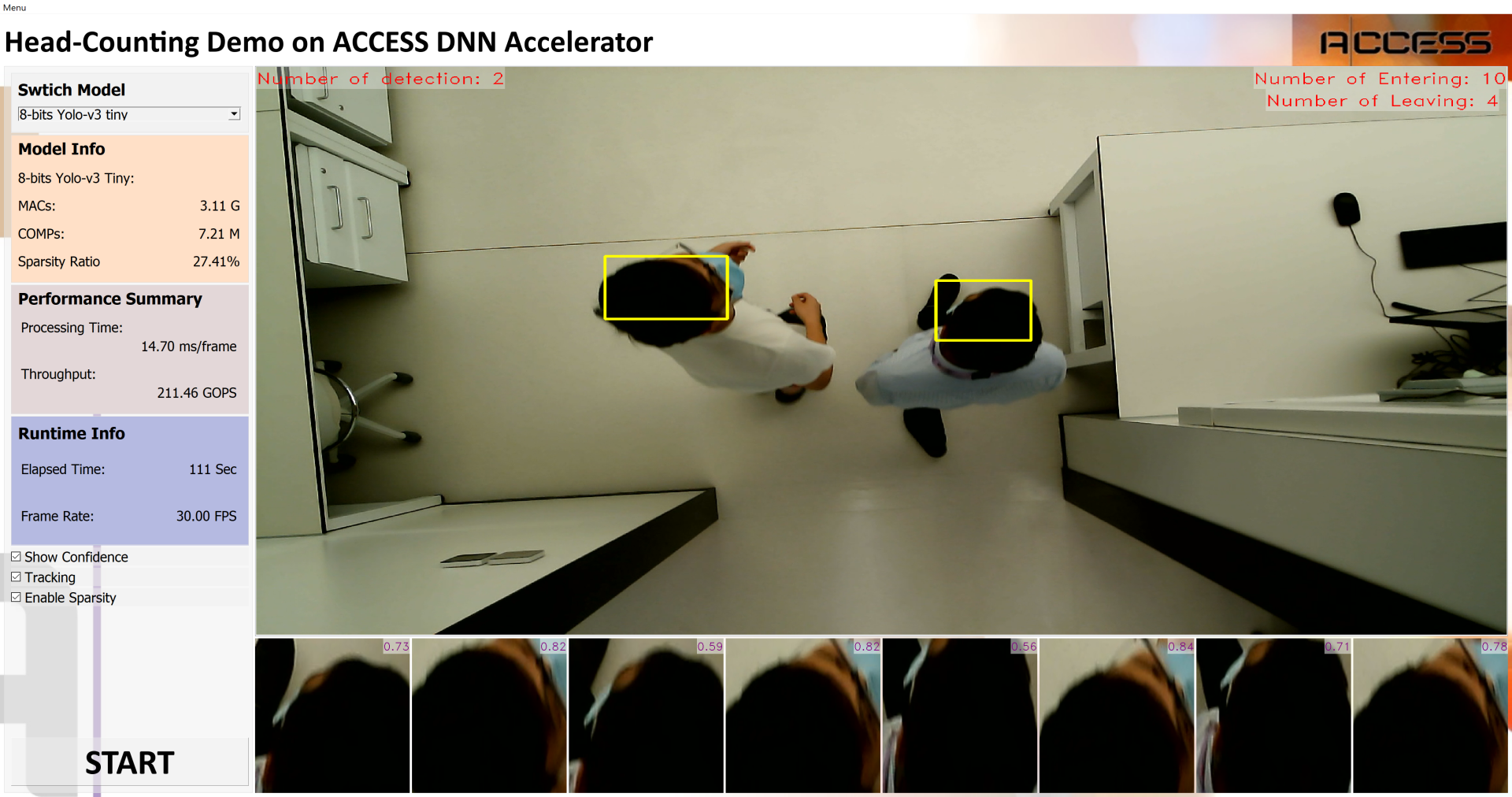

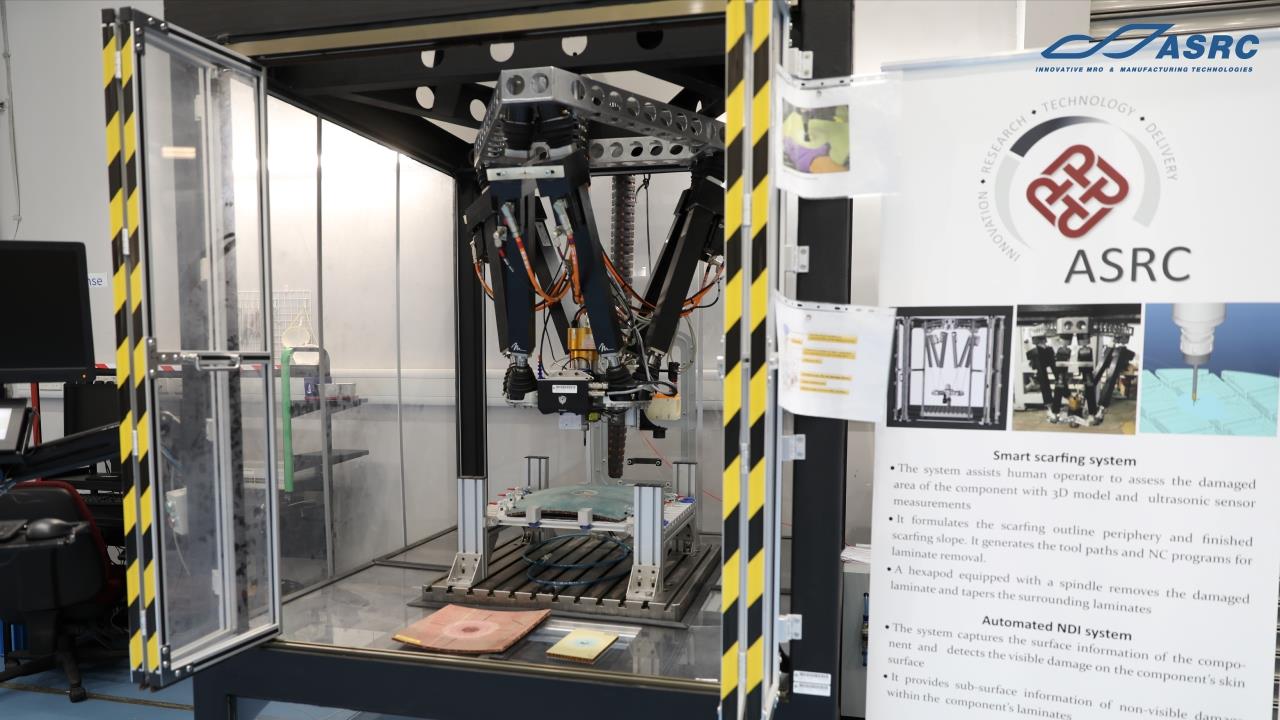

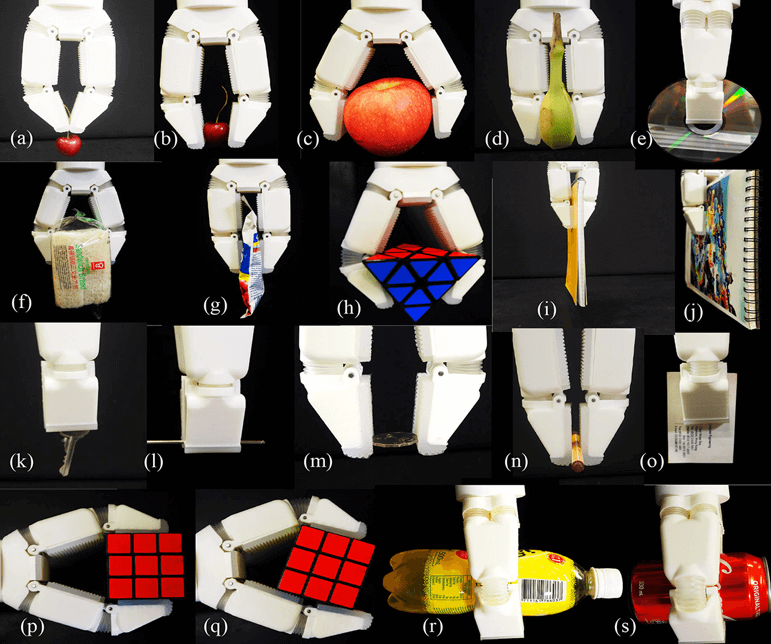

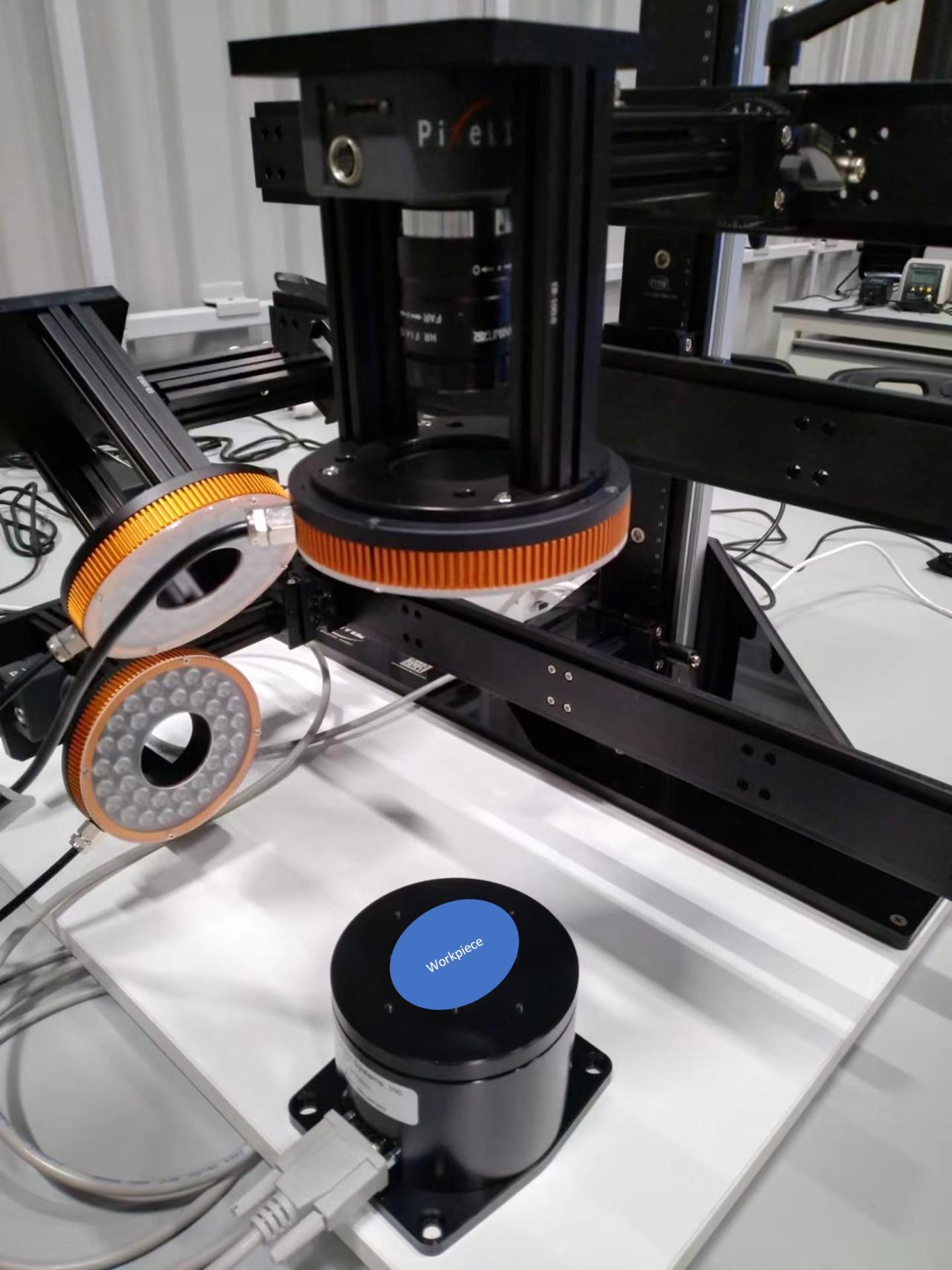

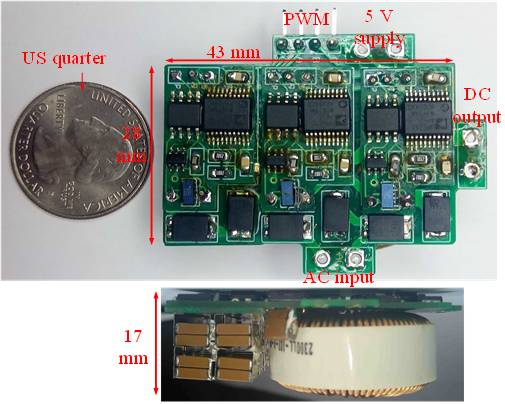

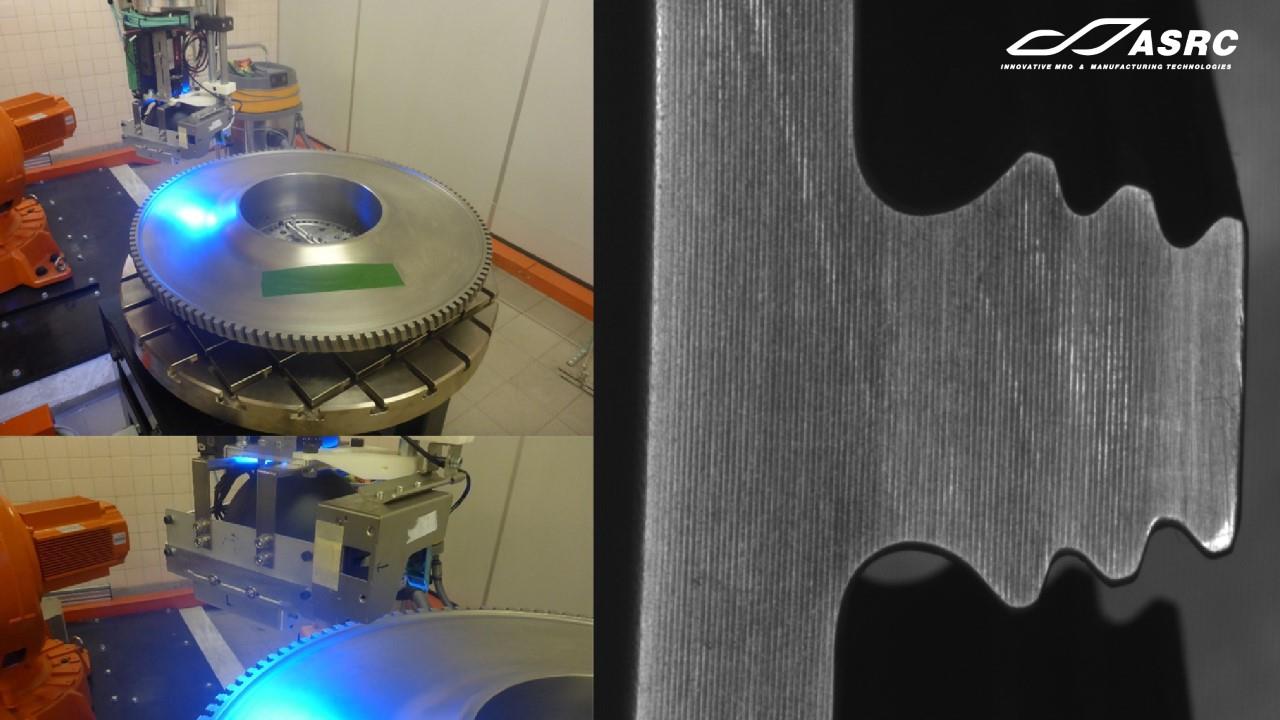

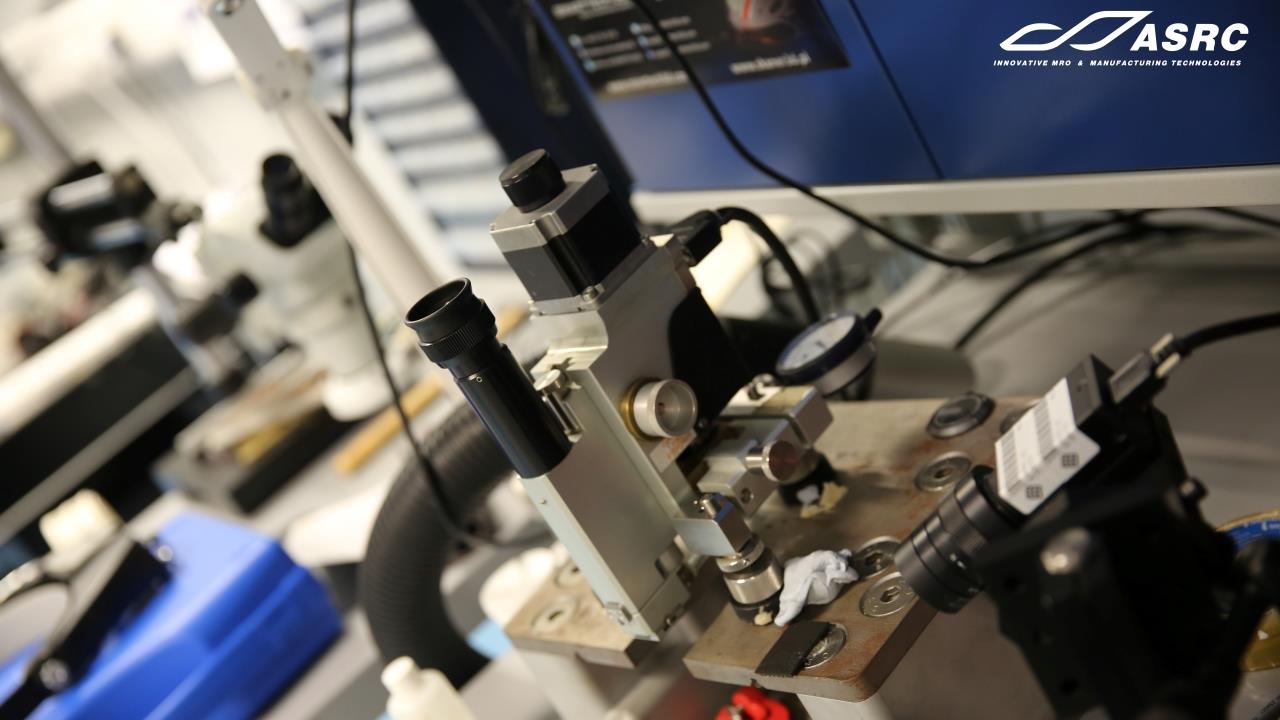

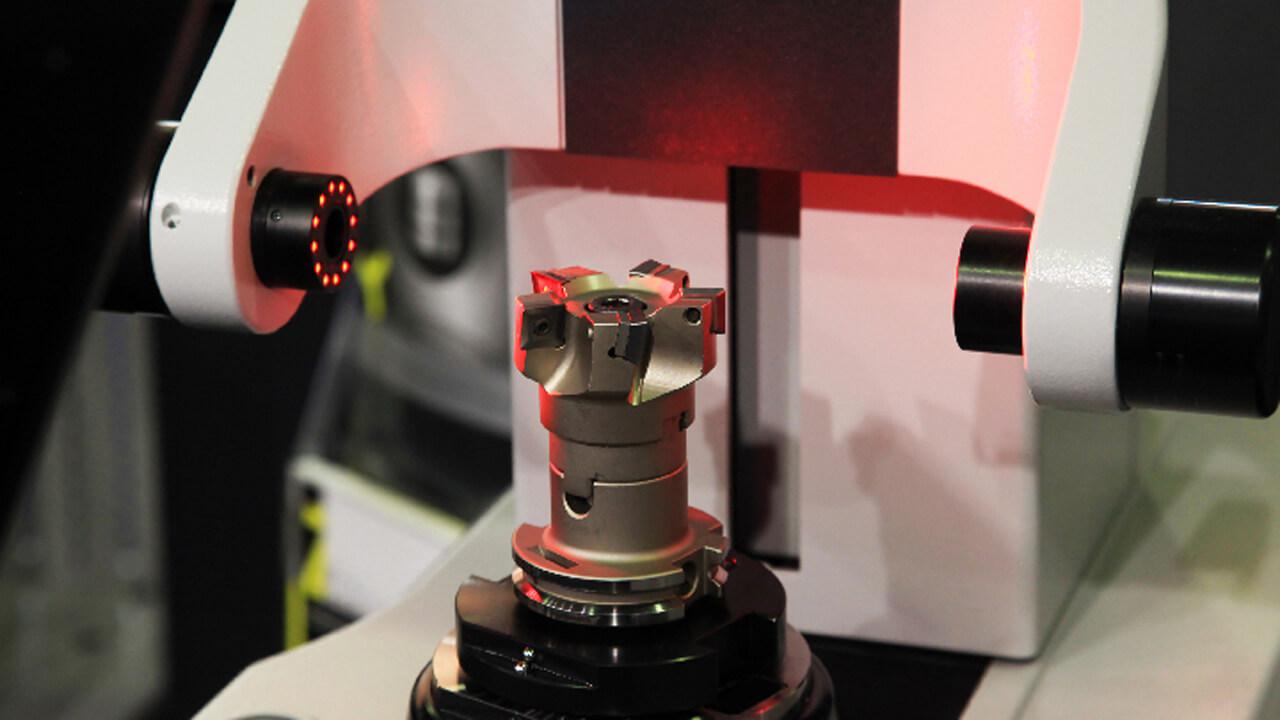

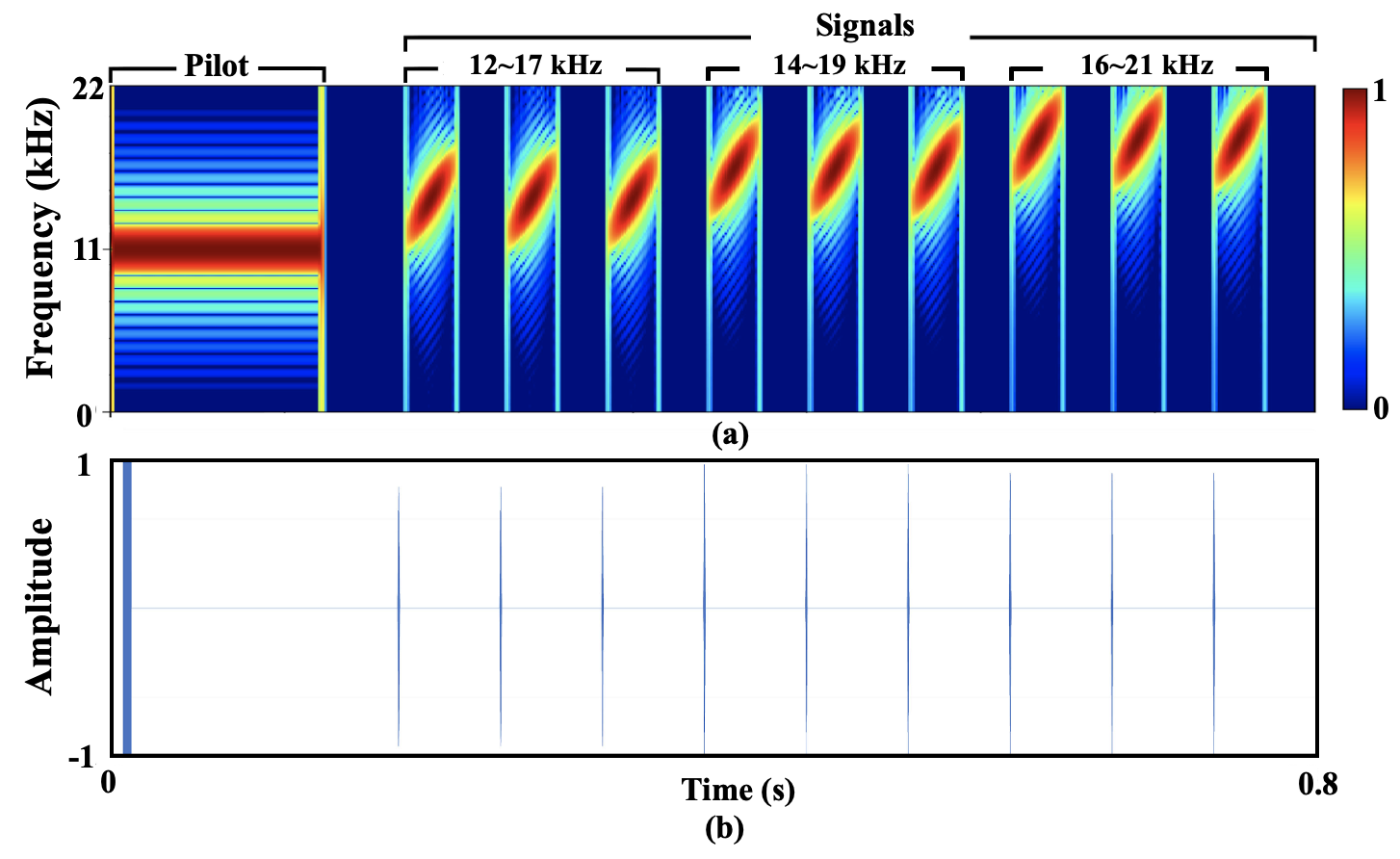

- 12 robots installed, with a series of self-developed, customised, mechanical and automatic device, fully utilising technologies, such as Internet of Things (IoT), real-time monitoring, machine vision, computer-aided design, artificial intelligence, data analytics, etc. The overall production capacity increases by 1.5 times.

- It adopts advanced technologies, such as machine vision, human-machine interface, real-time data collection and data analysis to achieve digital transformation.

- Coinciding with Industry 4.0 era - enterprises can make good use of intelligent production technologies, integrating product life cycle with the entire supply chain to enhance production capacity and competiveness

- Driving Hong Kong “New Industrialisation” - less land use and labour, which can resolve pain points of the manufacturing industry ranging from difficulty in finding land, labour shortage to high production cost

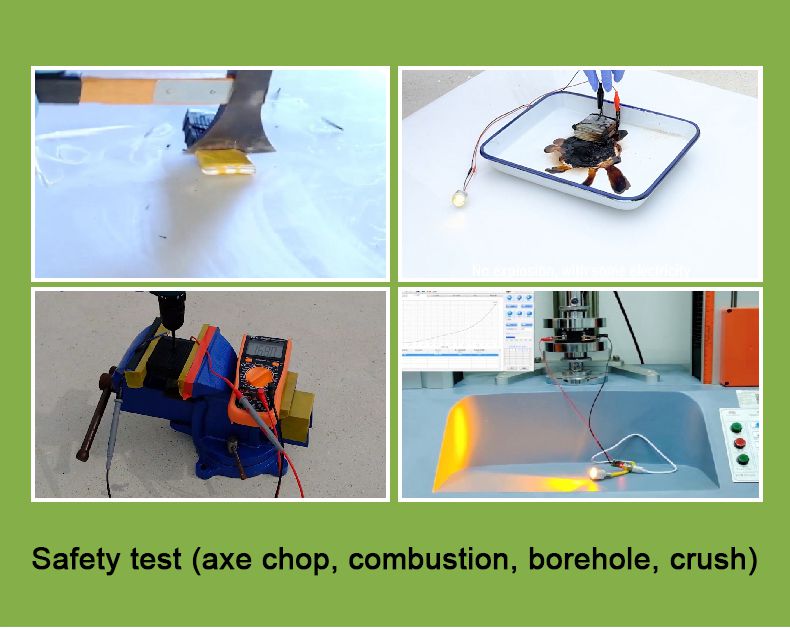

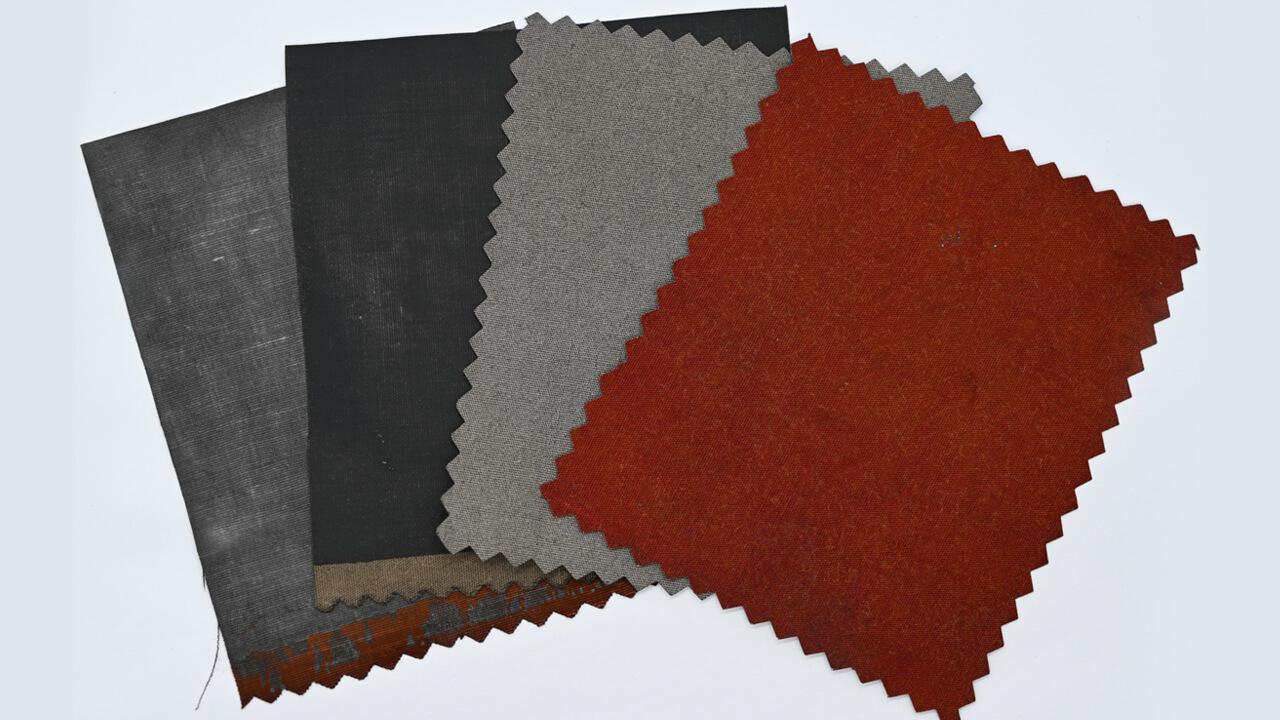

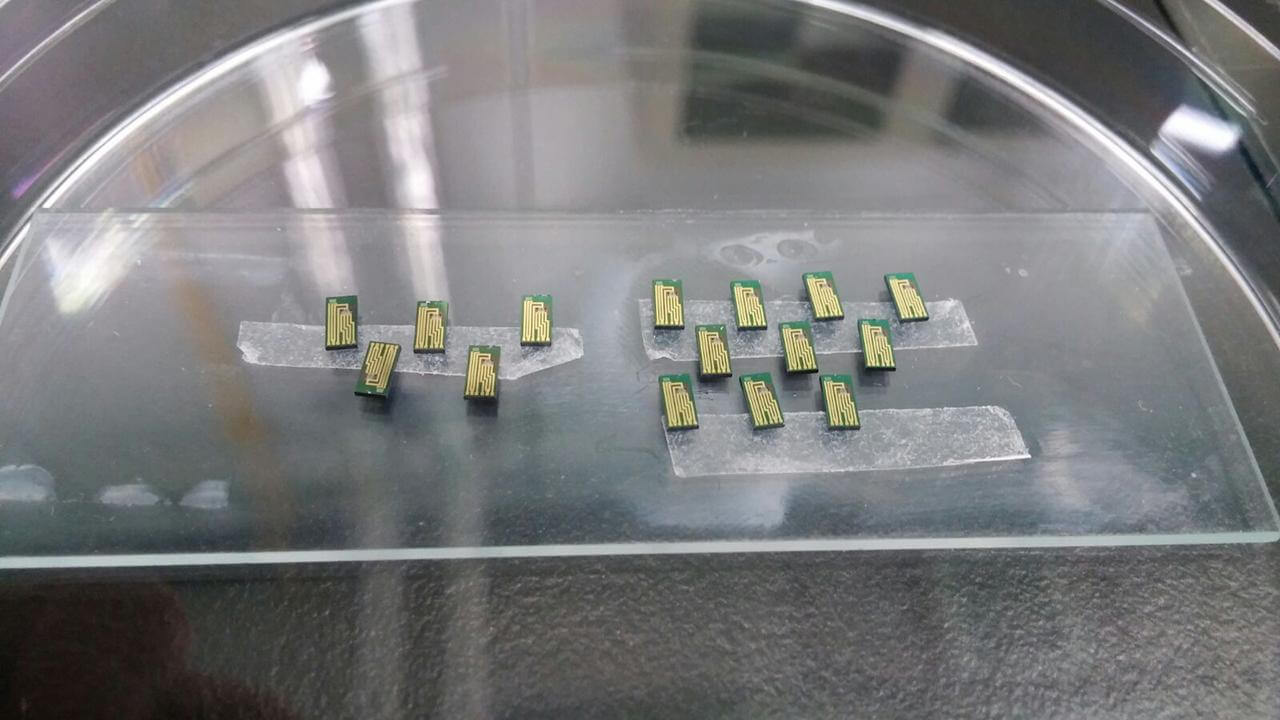

- Increasing accuracy of production processes - highly automatic and intelligent to minimise human error, reduce waste and defective products; more environmentally friendly than the labour intensive production method; enhance product quality control, reduce cost and labour, and shorten production time

- Catering for market needs - real-time data collection and monitoring system to facilitate product analysis and maintenance in future, faster time-to-market, use big data analytics to adjust production line

- HKIE MIS Industry Award 2021 Gold Award

- Harvard Business Review: Annual Award for Successful Production Transformation

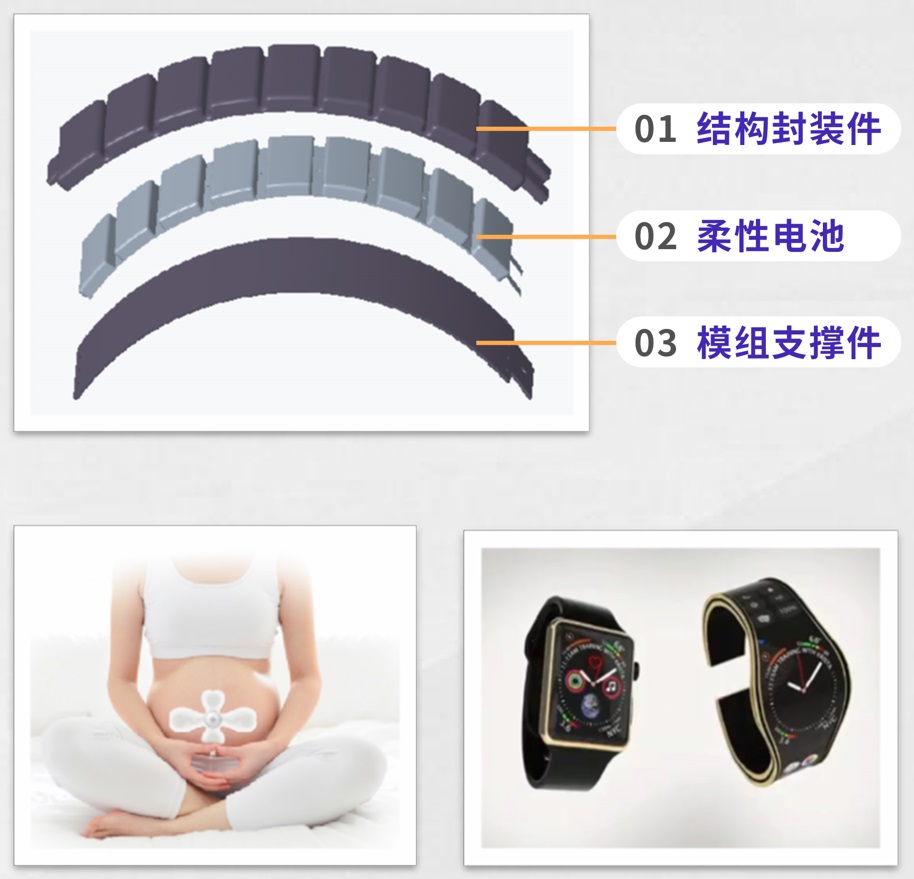

- Intelligent production line for security products

The Hong Kong Productivity Council (HKPC) is a multi-disciplinary organisation established by statute in 1967, to promote productivity excellence through integrated advanced technologies and innovative service offerings to support Hong Kong enterprises. HKPC is the champion and expert in facilitating Hong Kong's new industrialisation empowered by i4.0 and e4.0 - focusing on R&D, IoT, big data analytics, AI and Robotic technology development, digital manufacturing, etc., to help enterprises and industries upgrade their business performance, lower operating costs, increase productivity and enhance competitiveness.

The Council is a trusted partner with comprehensive innovative solutions for Hong Kong industries and enterprises, enabling them to achieve resources and productivity utilisation, effectiveness and cost reduction, and enhanced competitiveness in both local and international marketplace. It offers SMEs and startups immediate and timely assistance in coping with the ever-changing business environment, accompanying them on their innovation and transformation journey.