3S Tunnel Defect Inspector

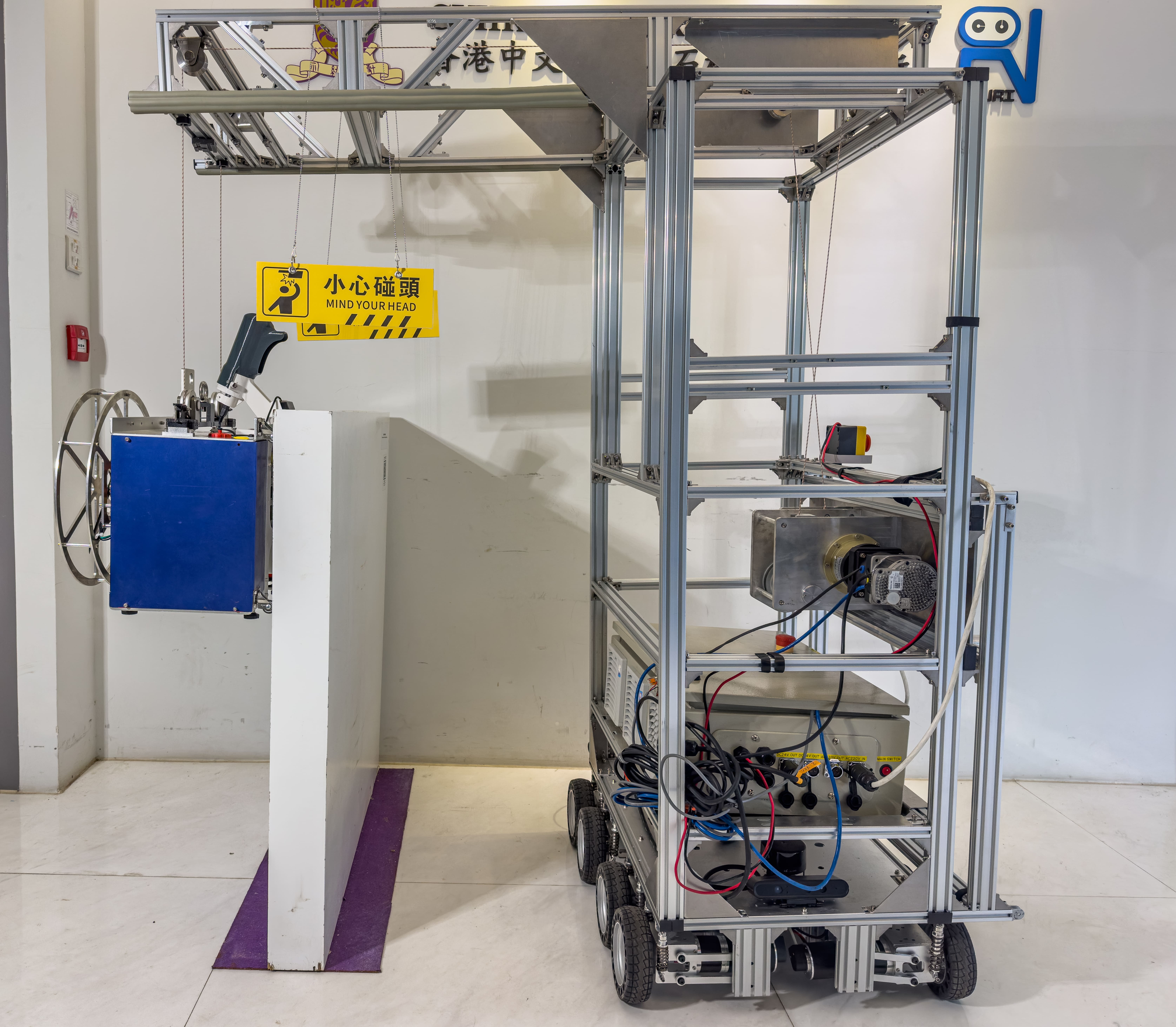

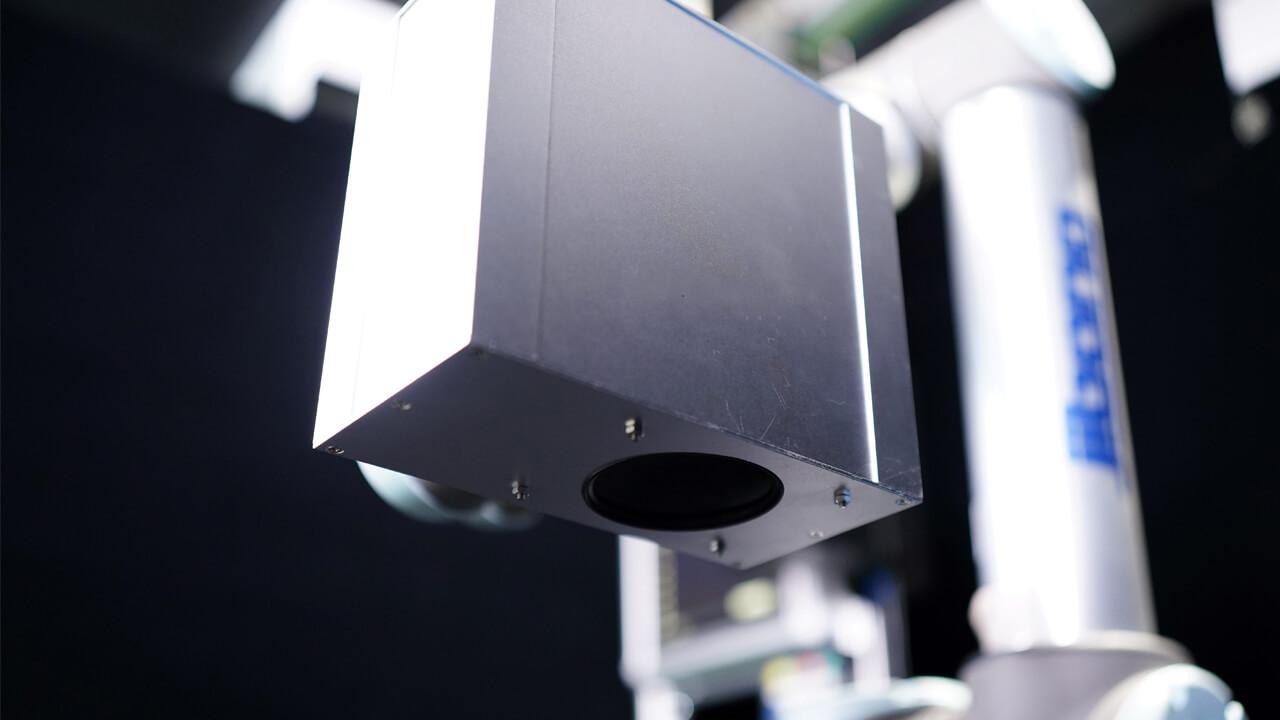

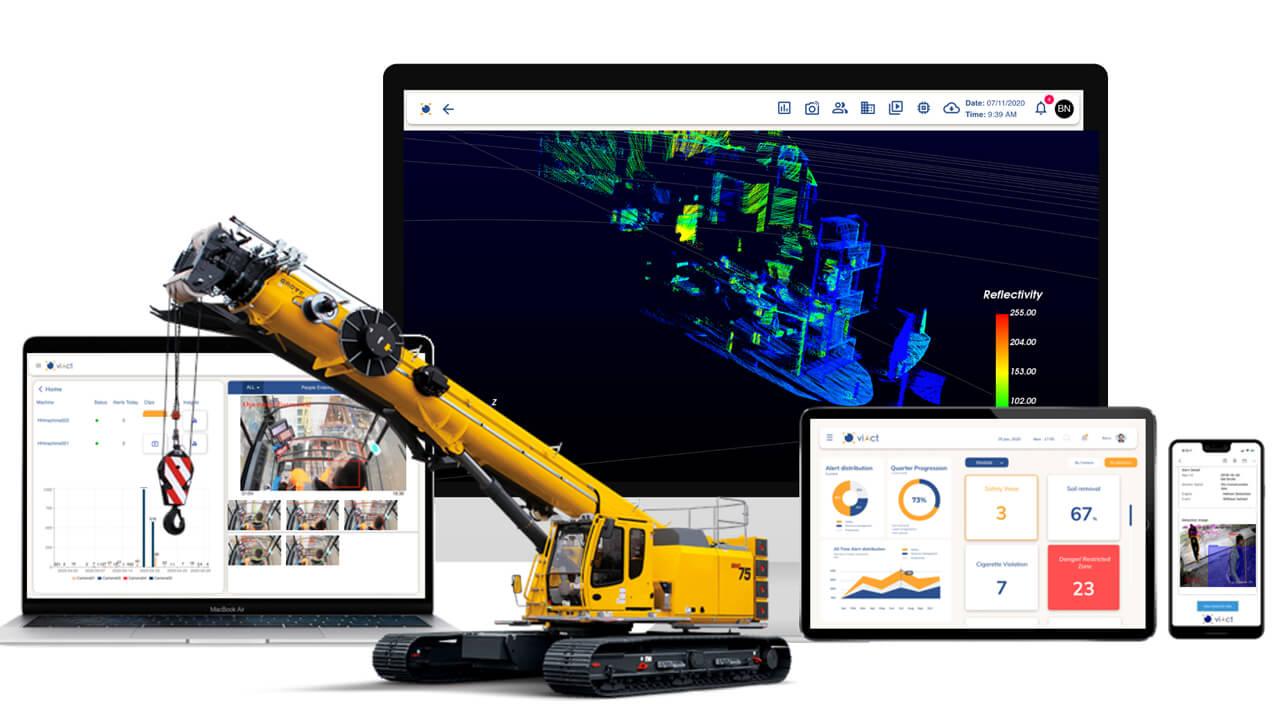

It is the first tunnel inspection system using drone with on-board Artificial Intelligence (AI) processing technology in Hong Kong. It brings digital upgrade to tunnel inspection, enabling engineers to conduct intelligent and safe inspection directly on-site. “3S” refers to “Safe”, “Smart” and “on-Site”. This system has been successfully developed and applied in the Trunk Road T2 and Cha Kwo Ling Tunnel project.

Tunnel lining defects identification is crucial for tunnel construction. However, it is difficult to detect all defects through conventional tunnel inspection; and that inspectors are required to use elevated working platform to visually inpsect and manually record inspection results in the busy tunnel area, which is not only tedious, time-consuming and inefficient, but may cause safety concerns due to working at heights for long periods.

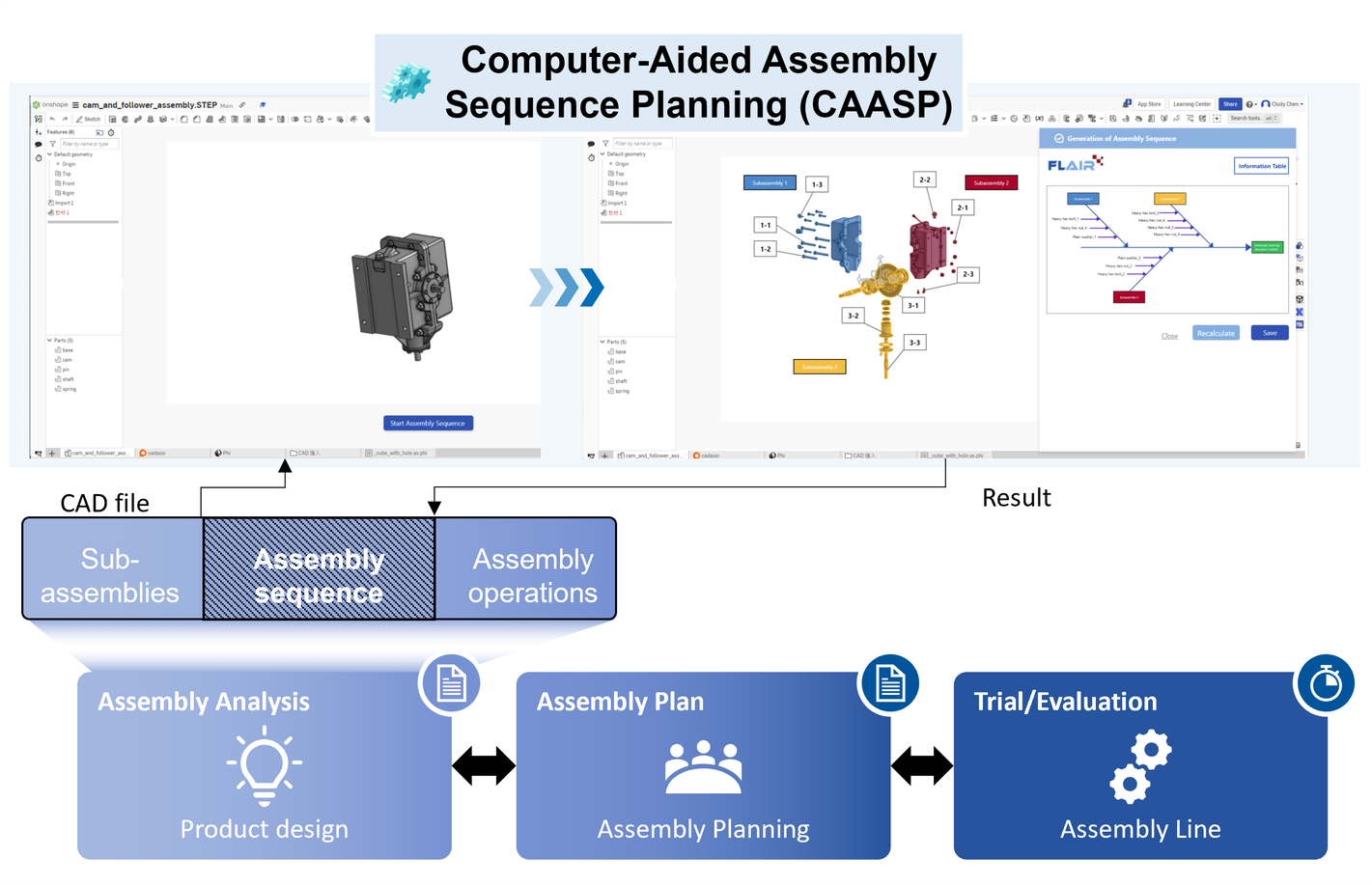

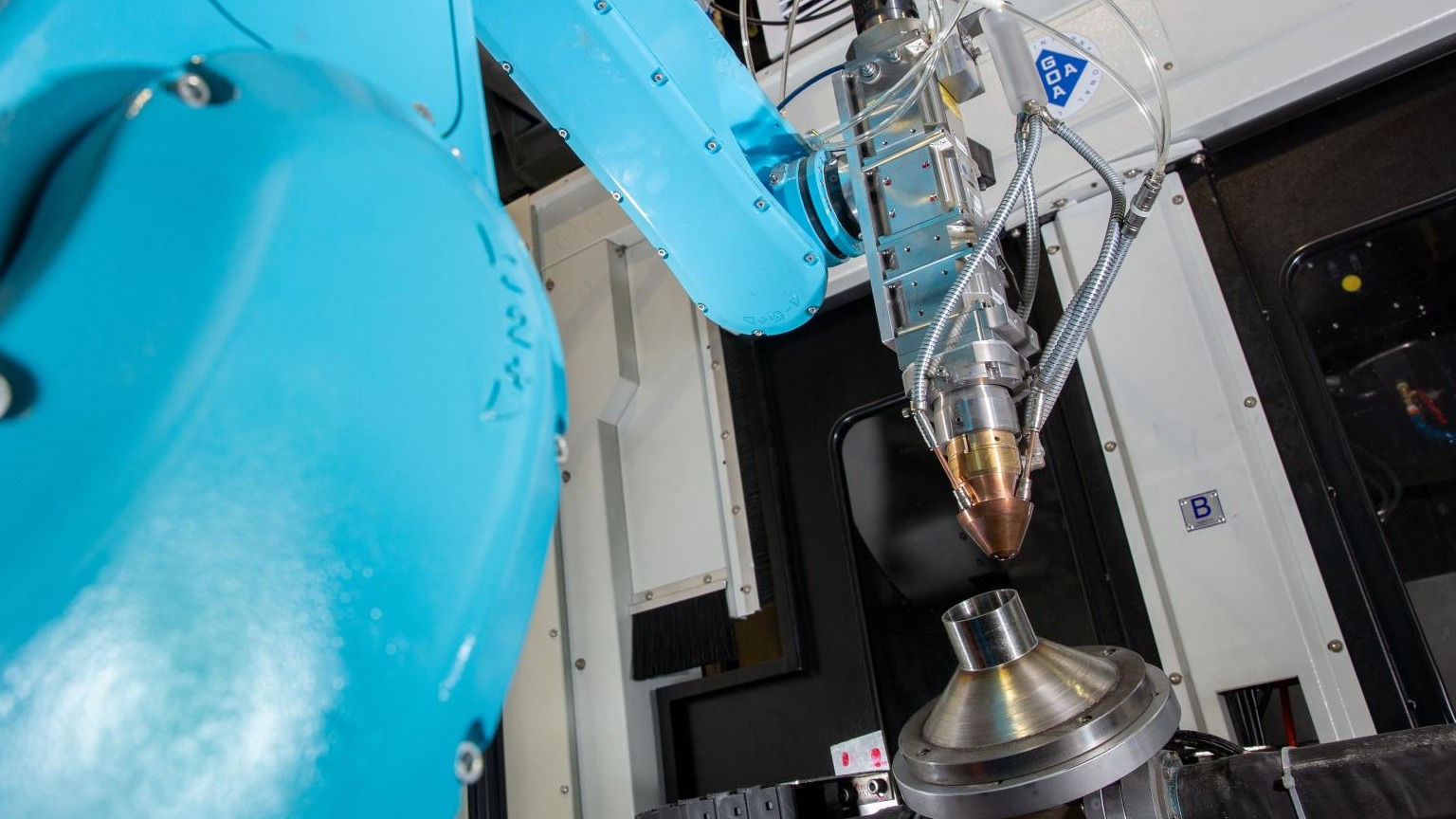

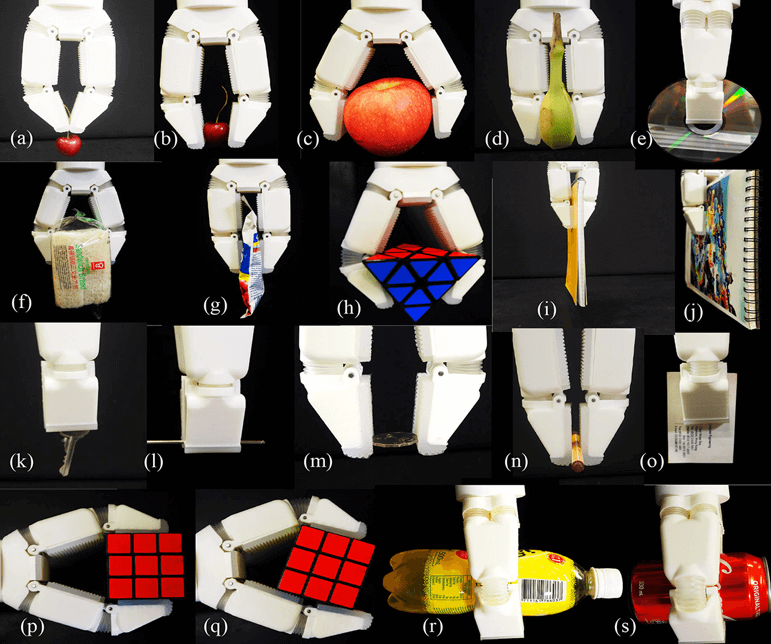

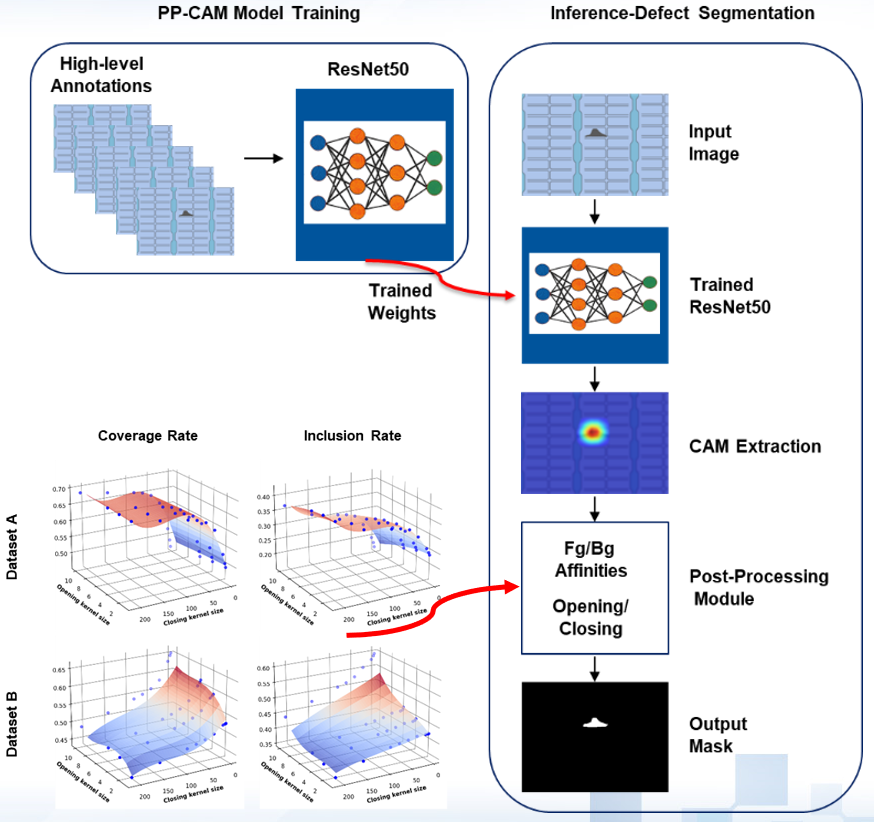

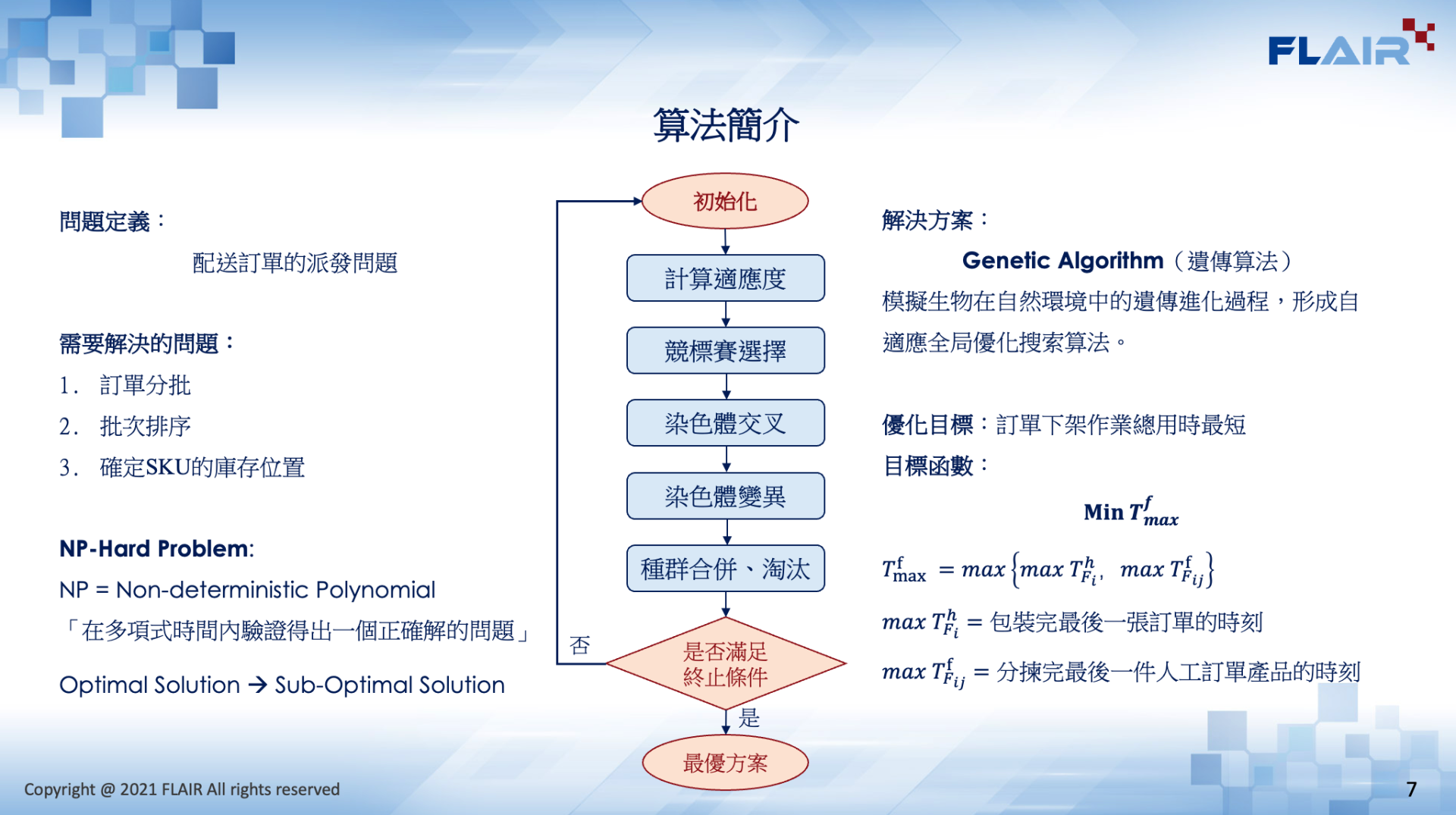

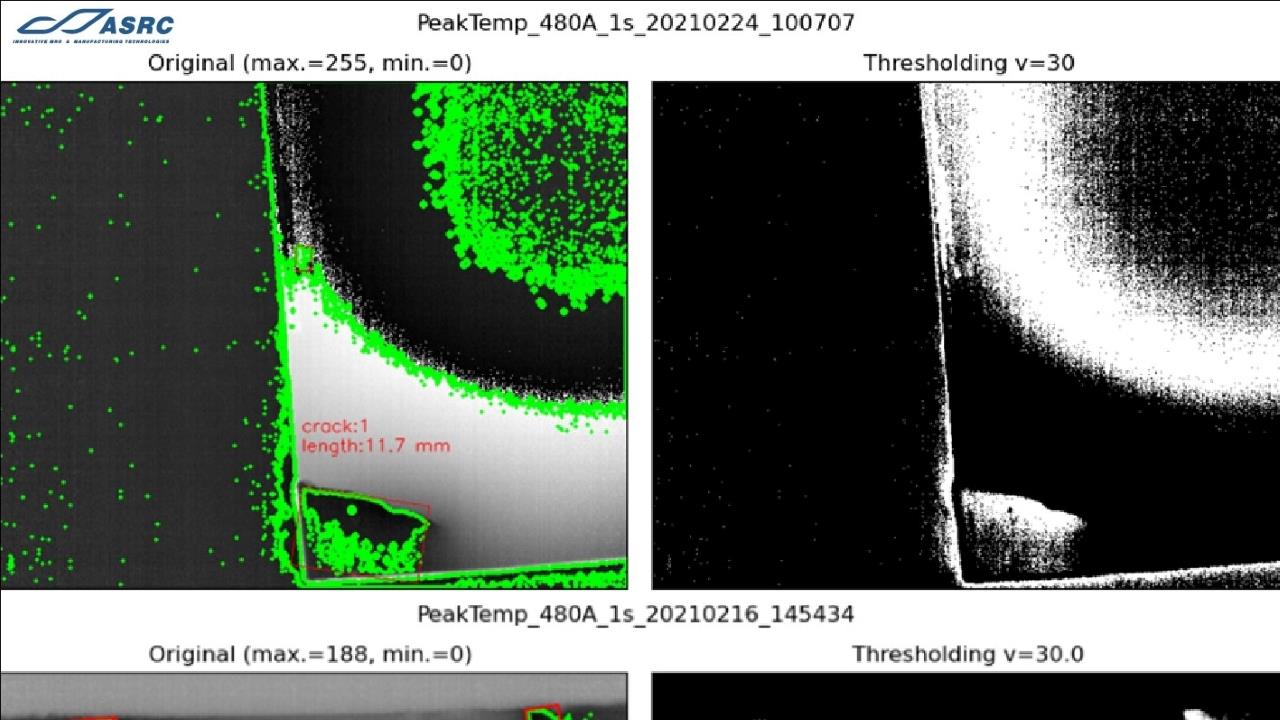

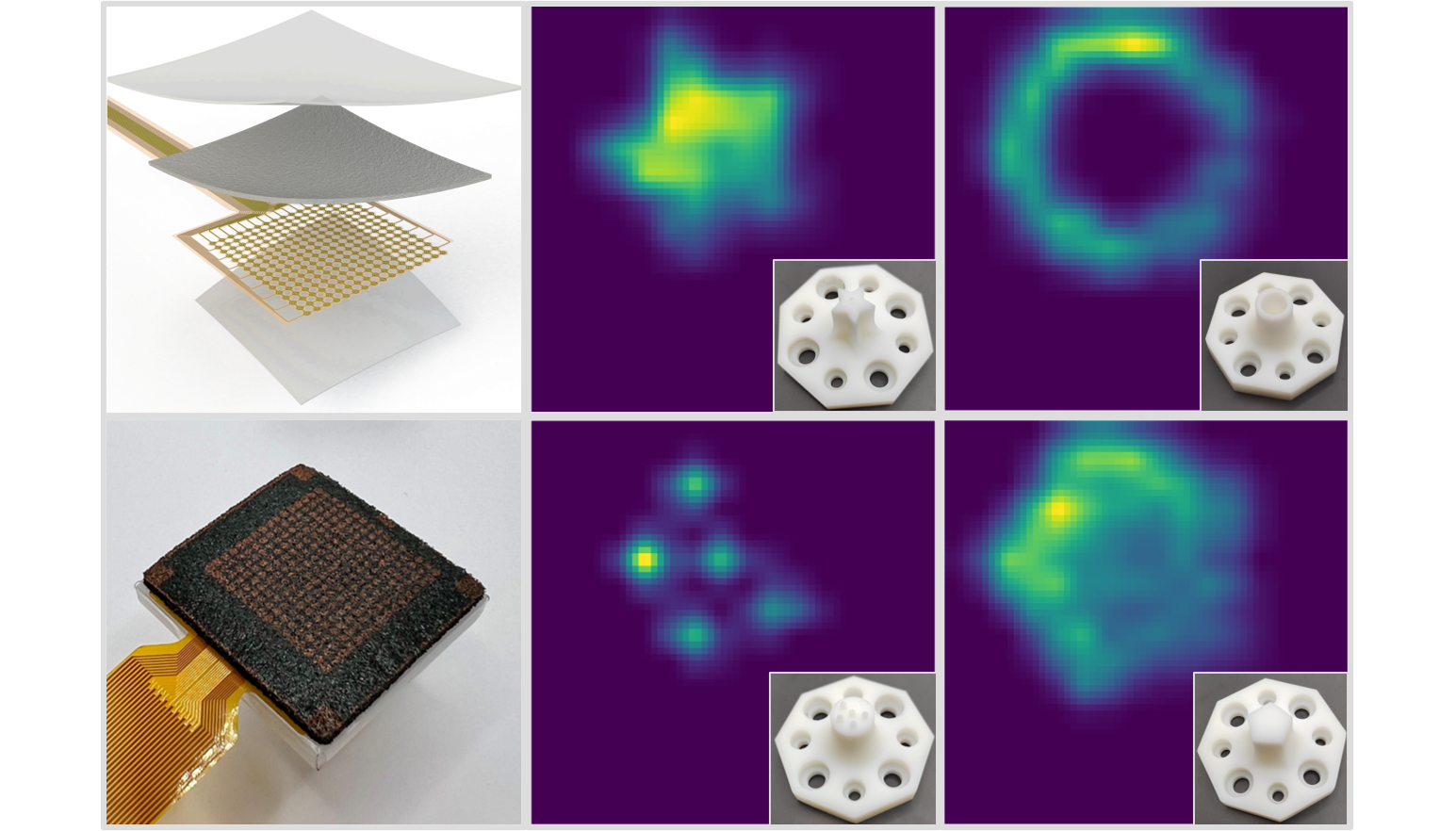

- State-of-the-art AI algorithm and robotics techniques are used to achieve intelligent inspection. By using deep neural network and transfer learning to substitue conventional visual inspection of tunnels, the accuracy can reach millimeter level, thereby enhancing the efficiency and accuracy of the inspection.

- The advanced AI chip coupled with the edge computing-based neural network makes AI detection calculation faster and more efficient, enabling engineers to conduct real-time inspection on-site and to follow up with the inspection results on-site immediately.

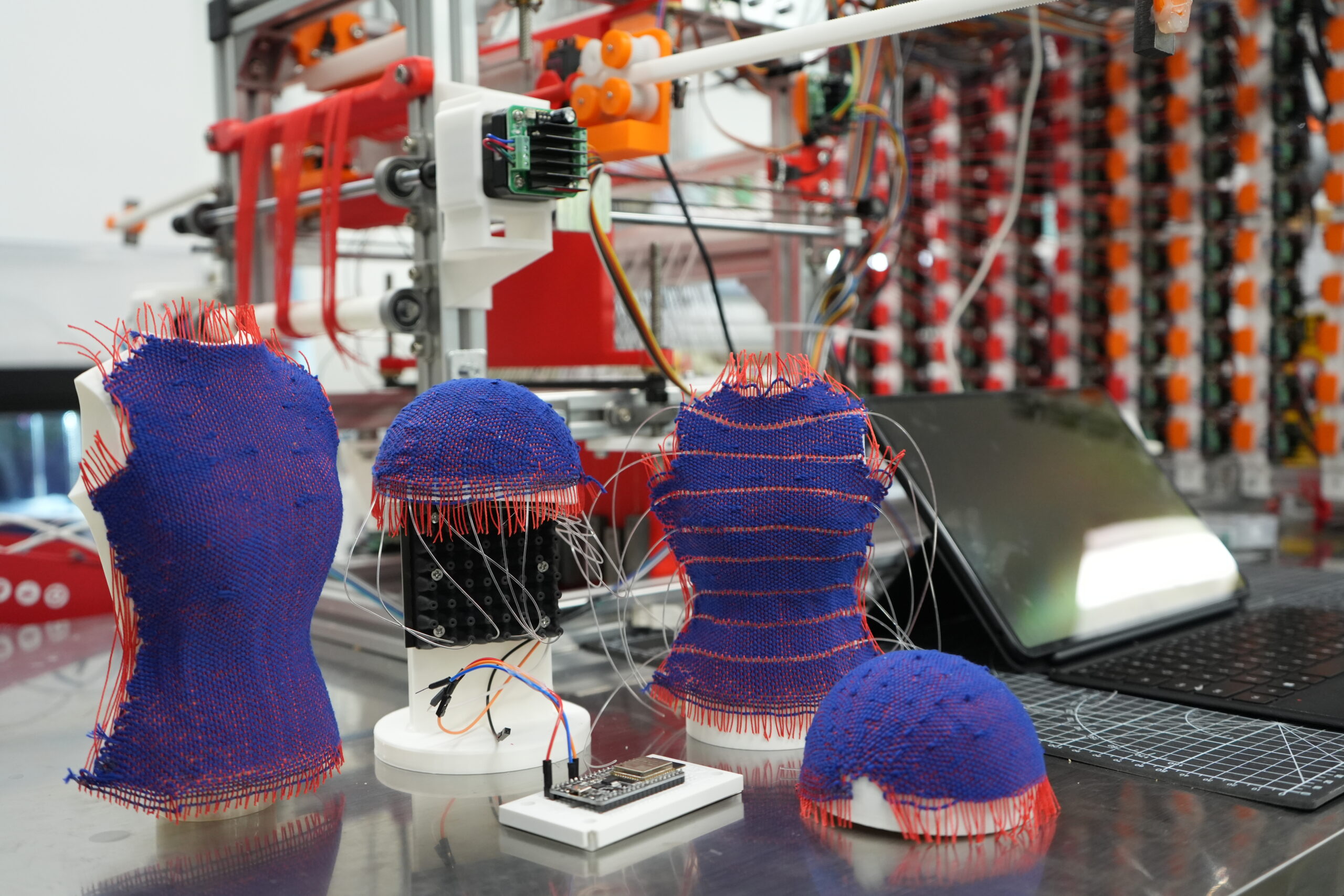

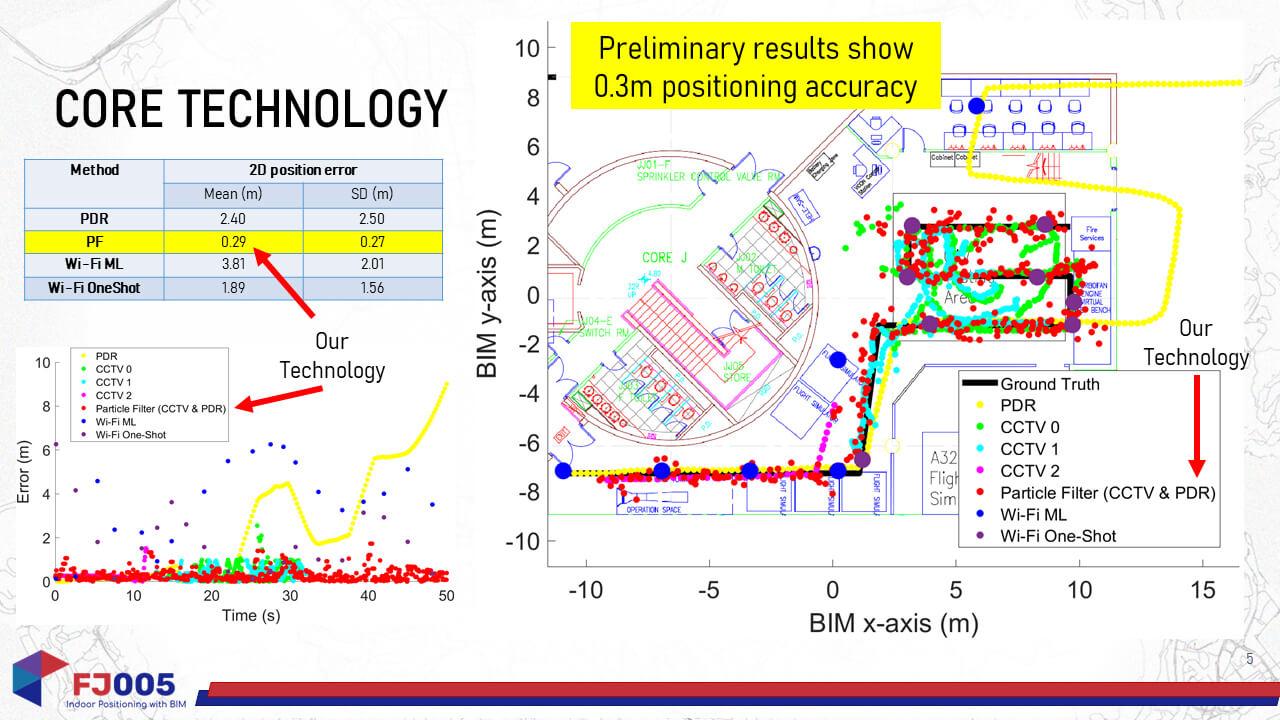

- This method innovatively combines AprilTag with QR code to allow inspections for tunnel surface defects be carried out at different locations under various conditions continuously and stably without the need of GPS signal for position determination.

- Inspectors are no longer required to use mobile working platform to carry out inspections in heavy-traffic tunnels - greatly reduces the need for working at height in crowded areas, thereby reducing the associated safety risks.

- The detection accuracy is greatly improved to millimeter level and covers all parts of the tunnel, enabling operators to identify defects efficiently and accurately.

- Following the detection, it automatically generates the digital defect reports to realize the digitalisation of the entire inspection process.

- The successful upgrade and digitalisation of tunnel inspection work will help develop intelligent tunnels. This inspection system can also be applied to other large infrastructure inspections.

- Received a Silver Medal on 28 March 2022 in the Geneva International Inventions Exhibition 2022.

- Recognized as one of the Winners in the 2022 R&D 100 Awards in the Software/Services category on 22 August 2022.

- Won the Emerging Technology – Industrial Construction Award in the Hong Kong Business Technology Excellence Awards 2022 on 15 September 2022.

- Awarded the Certificate of Merit under the innovation sub-category of An Innovative Application (All Member Group) in “The Hong Kong Institution of Engineers Grand Award 2023" on 9 March 2023

- Awarded the prestigious 2023 Edison Awards amidst fierce competition among hundreds of entries worldwide and achieved Bronze Accolade on 21 April 2023

- Received the "Regional Engineering Initiative of the Year - Hong Kong award” on 24 July 2023 at the “GovMedia Award 2023”

- Inspection of concrete structure tunnel

Patent

- Intelligent inspection drone applied to detect concrete defects in tunnel sites

- Non-GPS In-tunnel Positioning

The Hong Kong Productivity Council (HKPC) is a multi-disciplinary organisation established by statute in 1967, to promote productivity excellence through integrated advanced technologies and innovative service offerings to support Hong Kong enterprises. HKPC is the champion and expert in facilitating Hong Kong's new industrialisation empowered by i4.0 and e4.0 - focusing on R&D, IoT, big data analytics, AI and Robotic technology development, digital manufacturing, etc., to help enterprises and industries upgrade their business performance, lower operating costs, increase productivity and enhance competitiveness.

The Council is a trusted partner with comprehensive innovative solutions for Hong Kong industries and enterprises, enabling them to achieve resources and productivity utilisation, effectiveness and cost reduction, and enhanced competitiveness in both local and international marketplace. It offers SMEs and startups immediate and timely assistance in coping with the ever-changing business environment, accompanying them on their innovation and transformation journey.