AI-Based Quality Prediction and Root Cause Analysis System in Injection Molding Processes

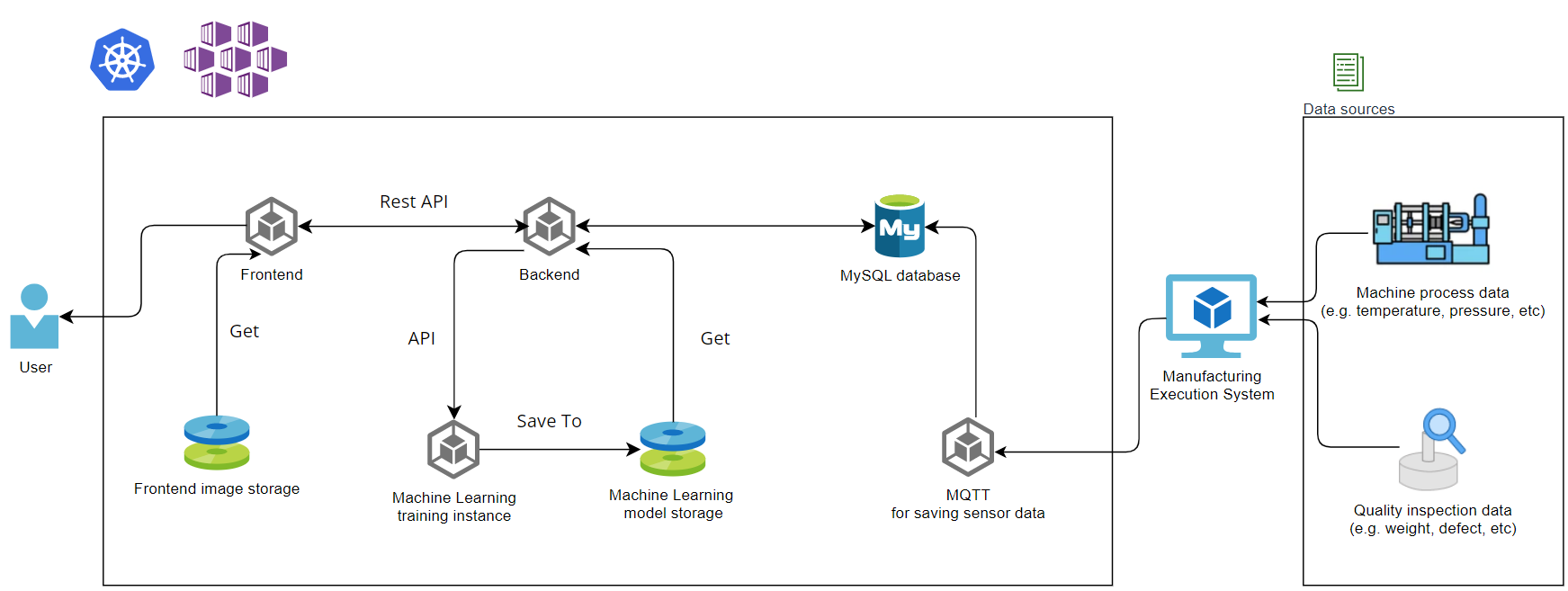

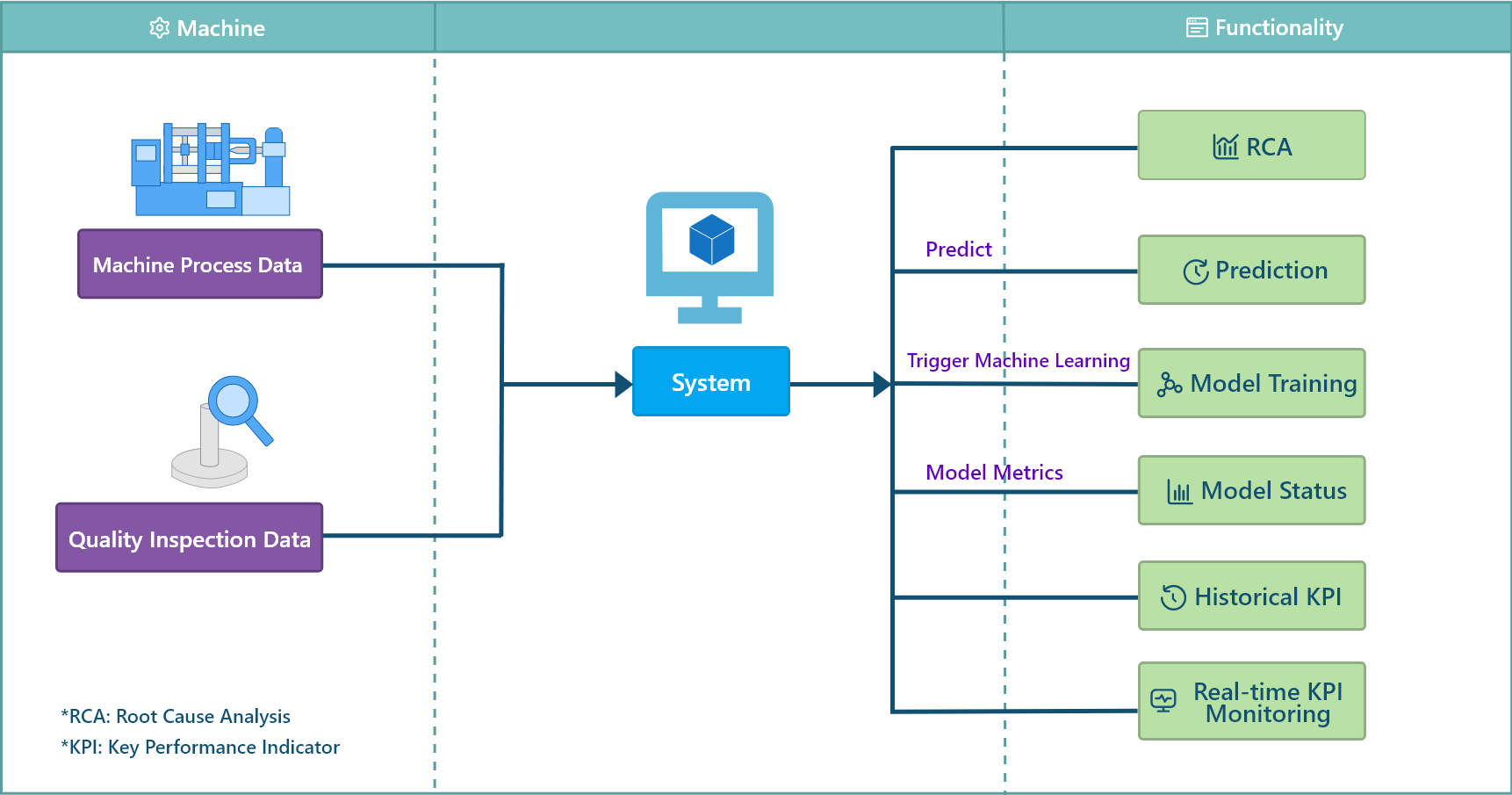

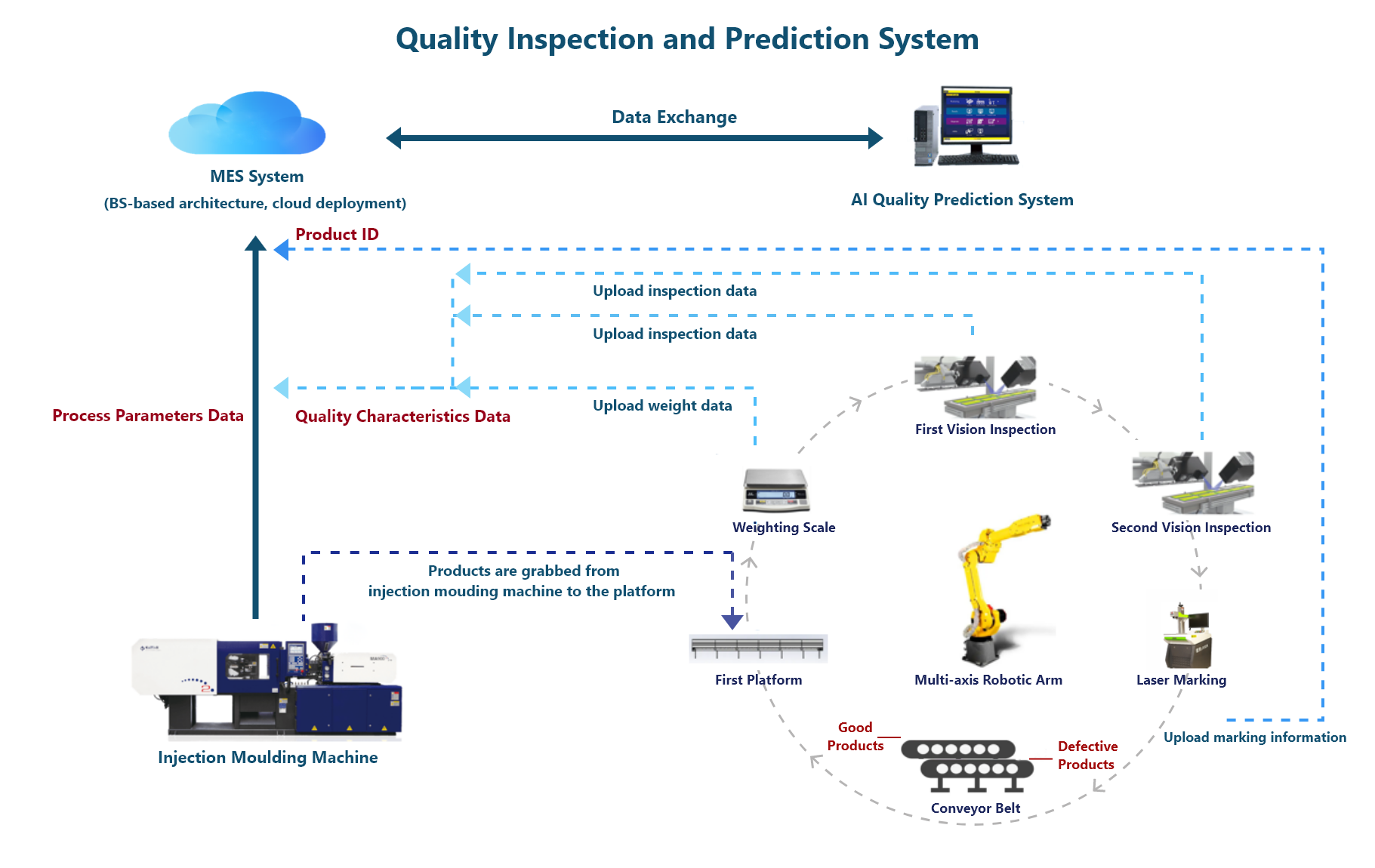

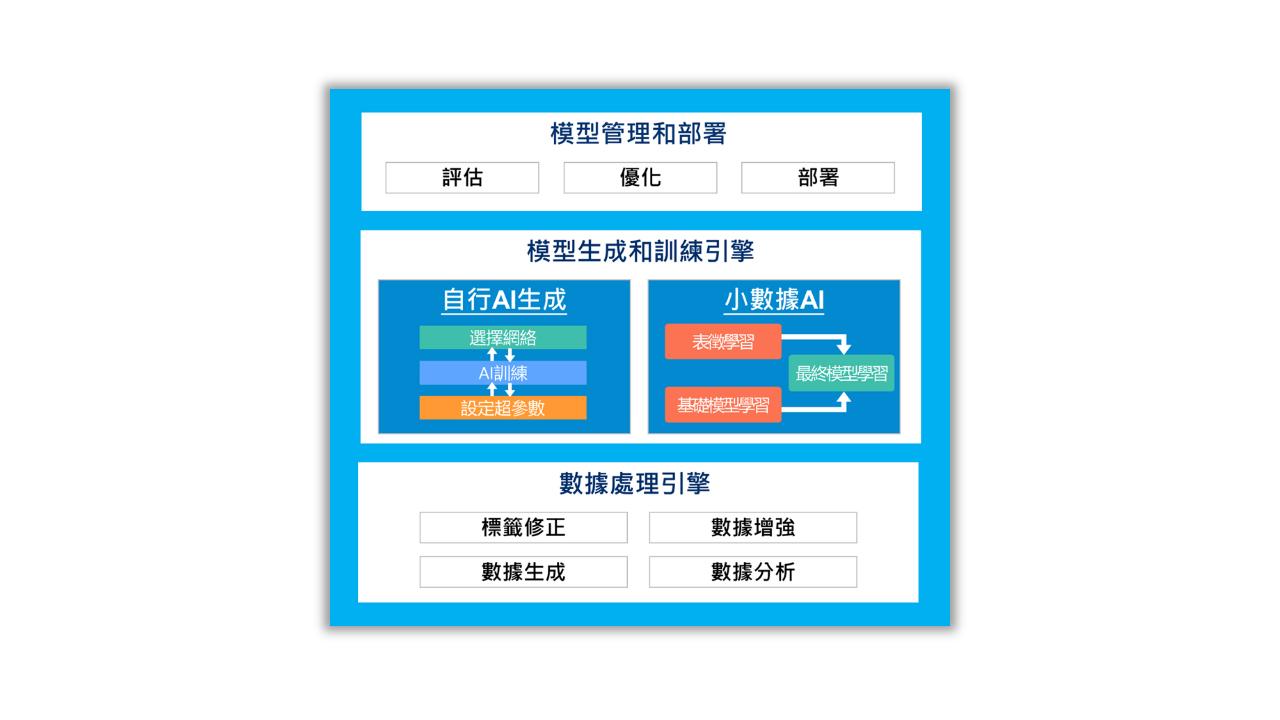

The invention pertains to an AI-based system for analysing various data obtained in previously executed manufacturing operations for performing quality prediction and root cause analysis to determine one or more possible root causes for production deviation resulted in a manufacturing process.

Solve the main problems in the production process including optimising production processes, improving product quality, and reducing inspection efforts.

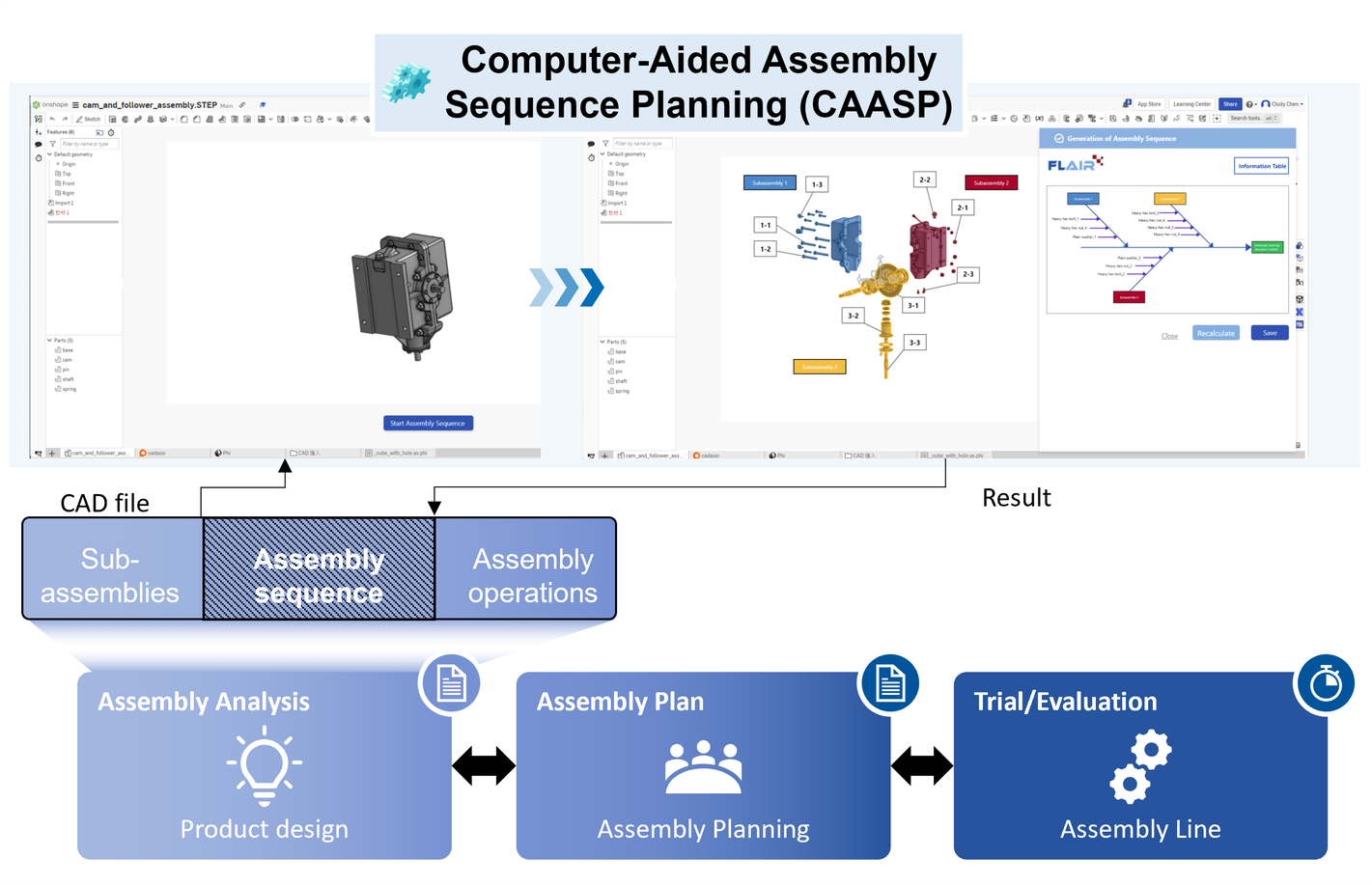

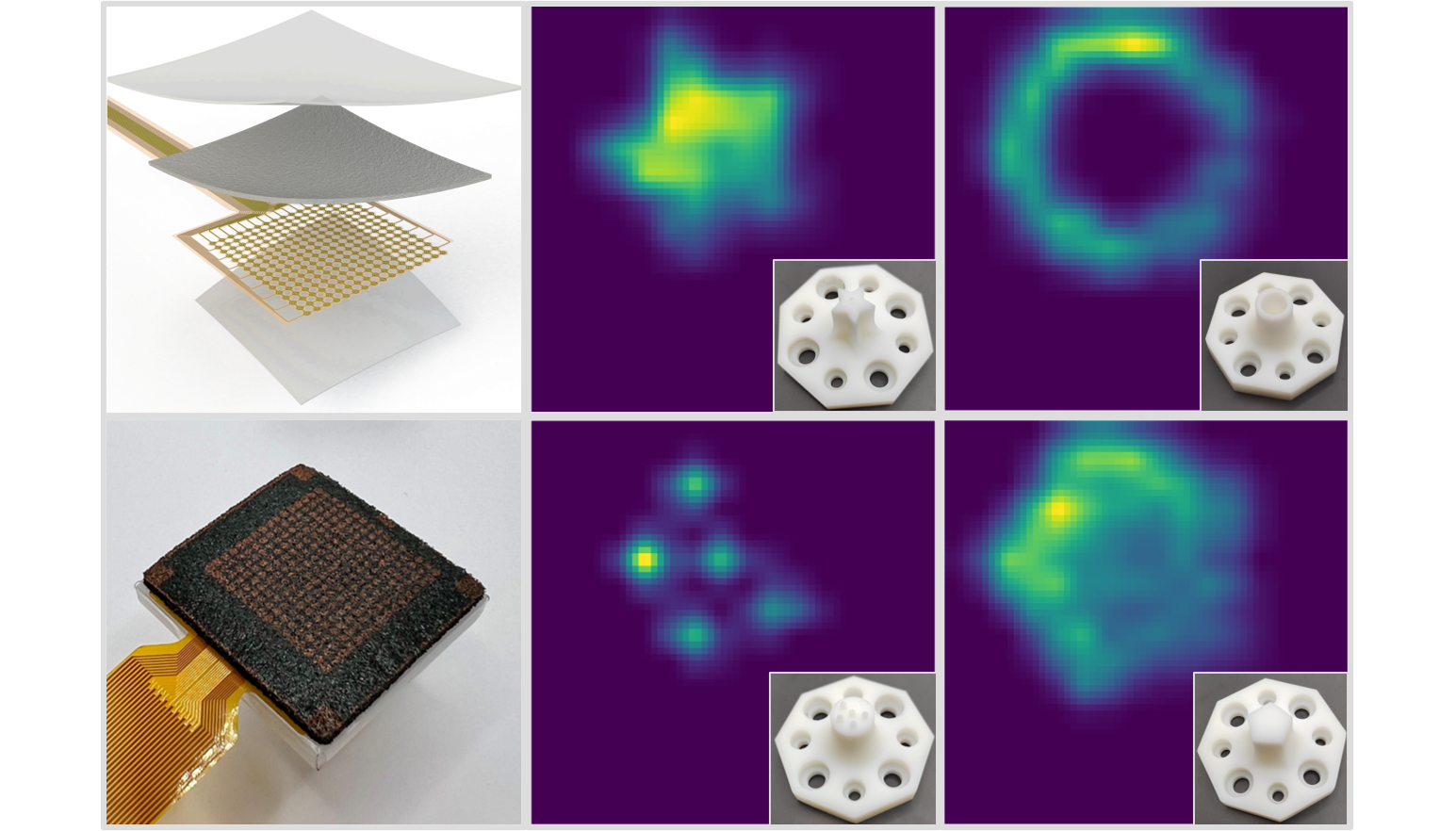

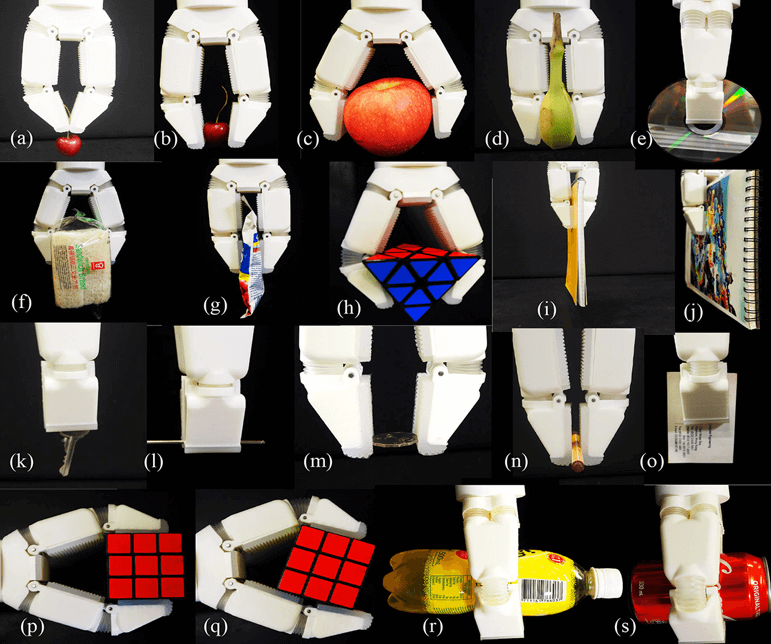

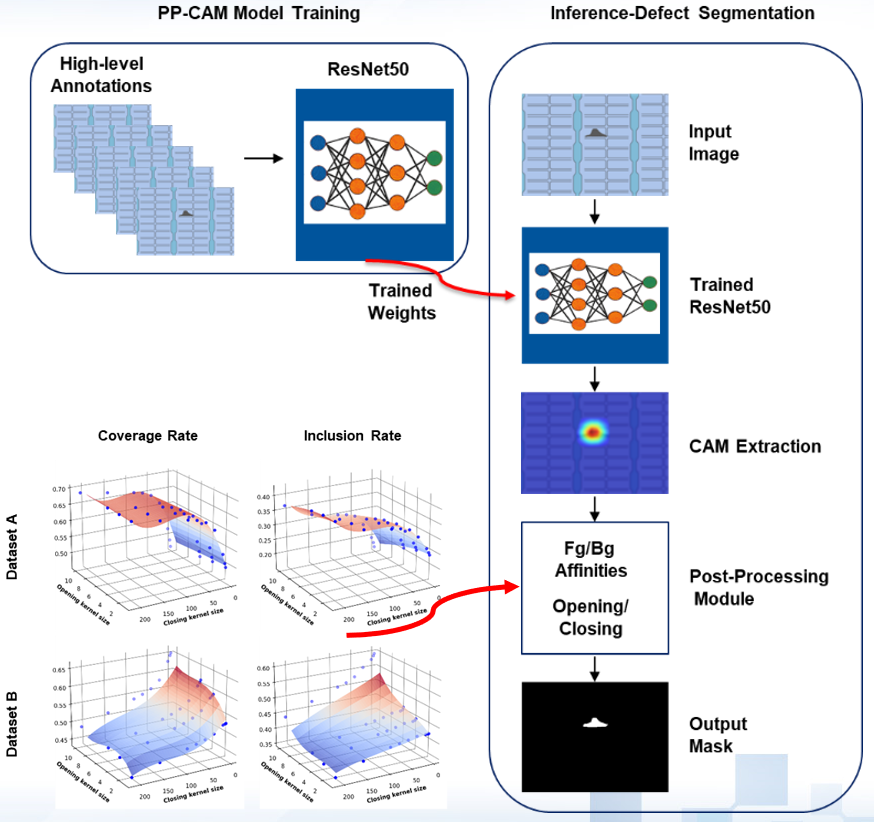

- AI-based quality analysis system for injection molding machine with prediction model adapted for predicting, based on the process parameter data and quality characteristic data and a prediction algorithm, quality characteristics of a molded product to be resulted from an injection molding process

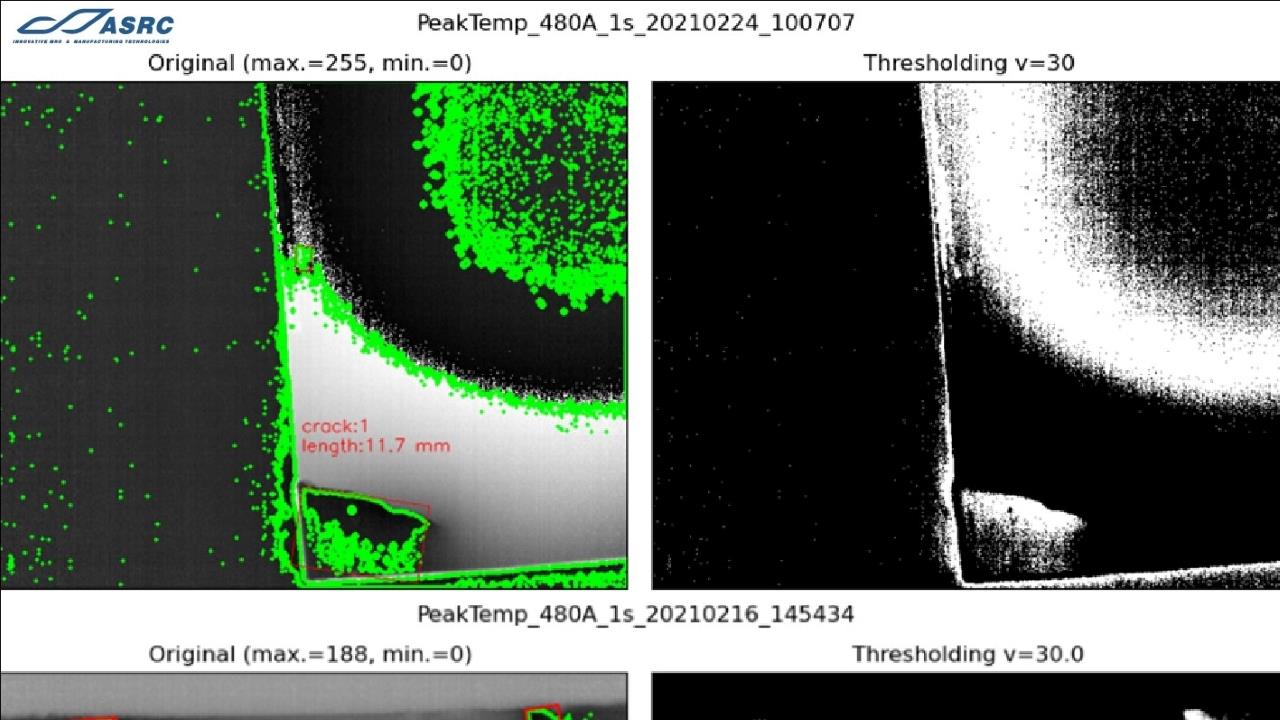

- Root cause analysis model based on quality characteristic data obtained from the molded product and a root cause analysis algorithm, one or more deviations of the molded product, and determining one or more possible causes of deviation if the deviation exceeds a predetermined tolerance threshold

- User interface for generating one or more graphical representations for indicating a comparison between quality characteristics obtained from the molded product and targeted values determined by the prediction model

- Increasing product quality and process quality

- Reducing inspection cost and rework cost

- Improving process understanding through transparency

- Applying a generic quality control platform to manufacturing industries

- Manufacturing process that requires product quality control

- Root cause analysis for defective products

Patent

- Hong Kong Short Term Patent Application No. : 32022062264.3

- PRC Utility Model Patent Application No. : 202223395486.2

The Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR) is established by the Hong Kong Productivity Council (HKPC) at the Hong Kong Science Park and is part of AIR@InnoHK, which is one of the two world-class research clusters being established by InnoHK Clusters of the HKSAR Government, to support Hong Kong in developing into an international innovation and technology hub.

FLAIR aims to engender synergy and achieve a clustering effect by attracting top-notch local, Mainland and overseas research institutions to engage in research collaboration. It will also actively approach private enterprises and industry associations for consultation and solicit their involvement in FLAIR’s work to ensure its industry orientation in addressing major R&D problems encountered by the industries in AI adoption.

As the sole founder, HKPC works together with RWTH Aachen Campus of Germany, the major collaborator of FLAIR, by bundling their strengths and repertoire of resources in technical expertise, networks, innovation and patents etc. to set up the FLAIR and support its operation.

For more information, please visit FLAIR’s website: https://www.hkflair.org