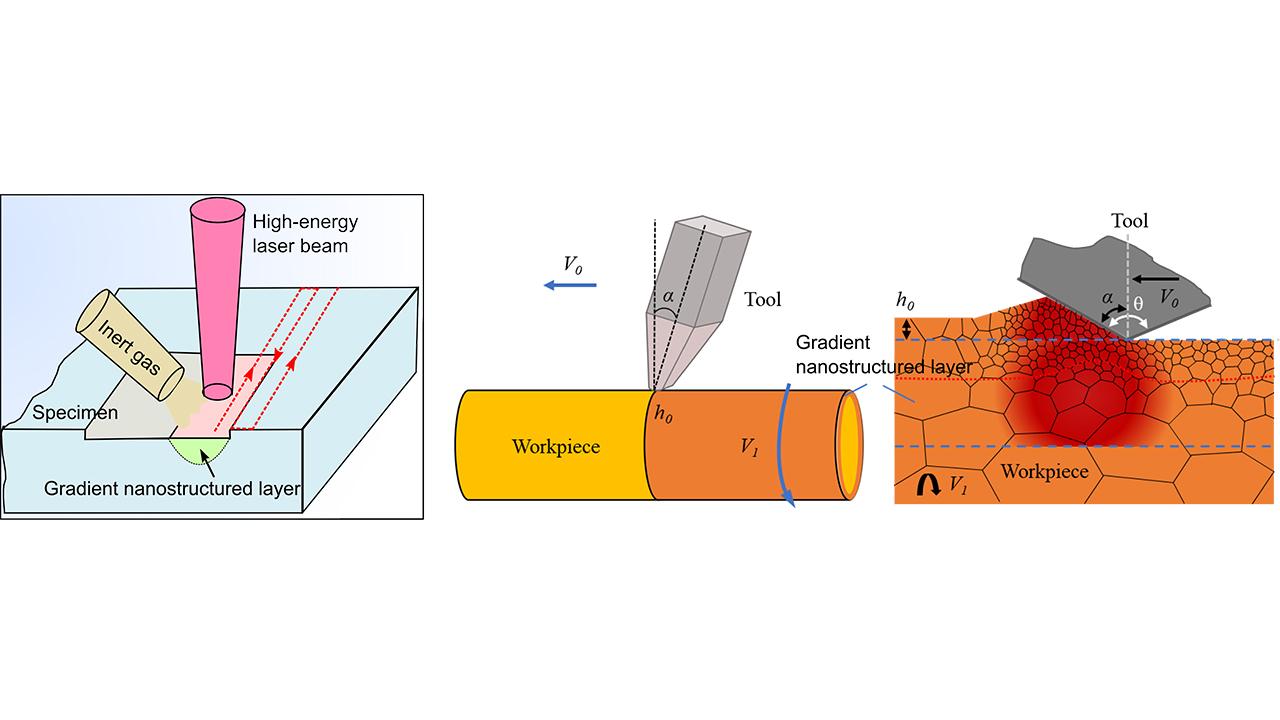

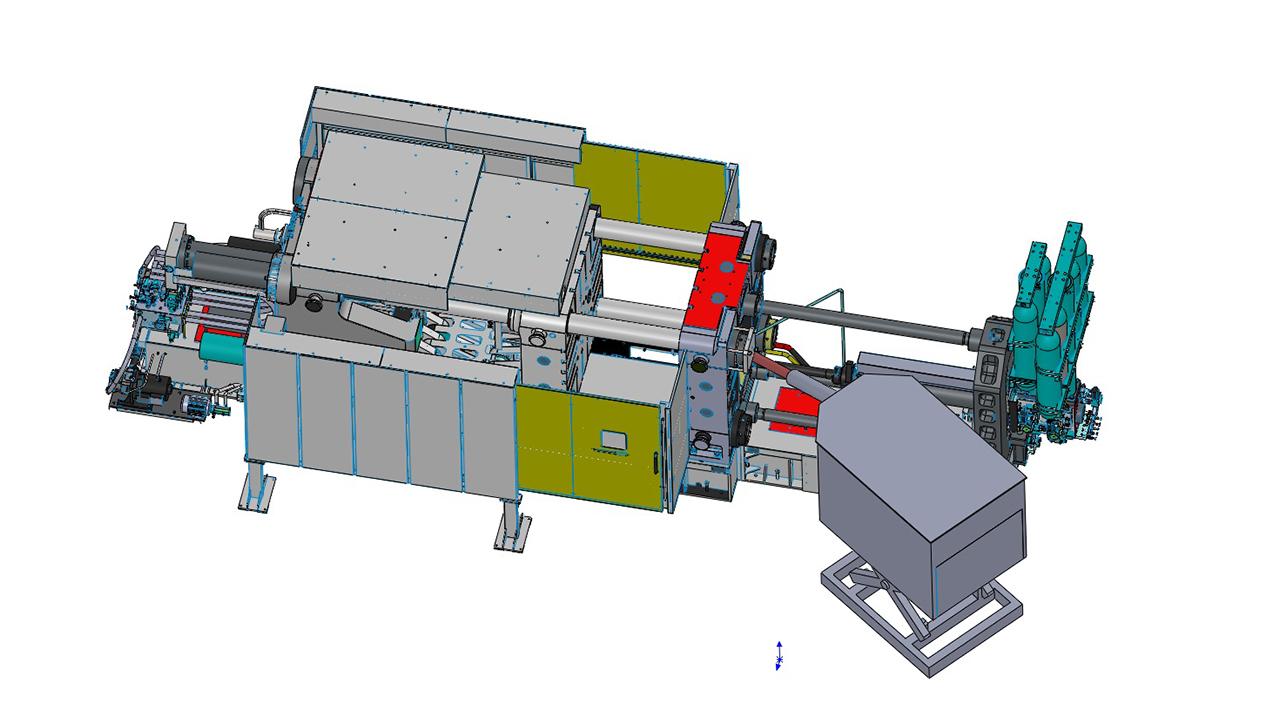

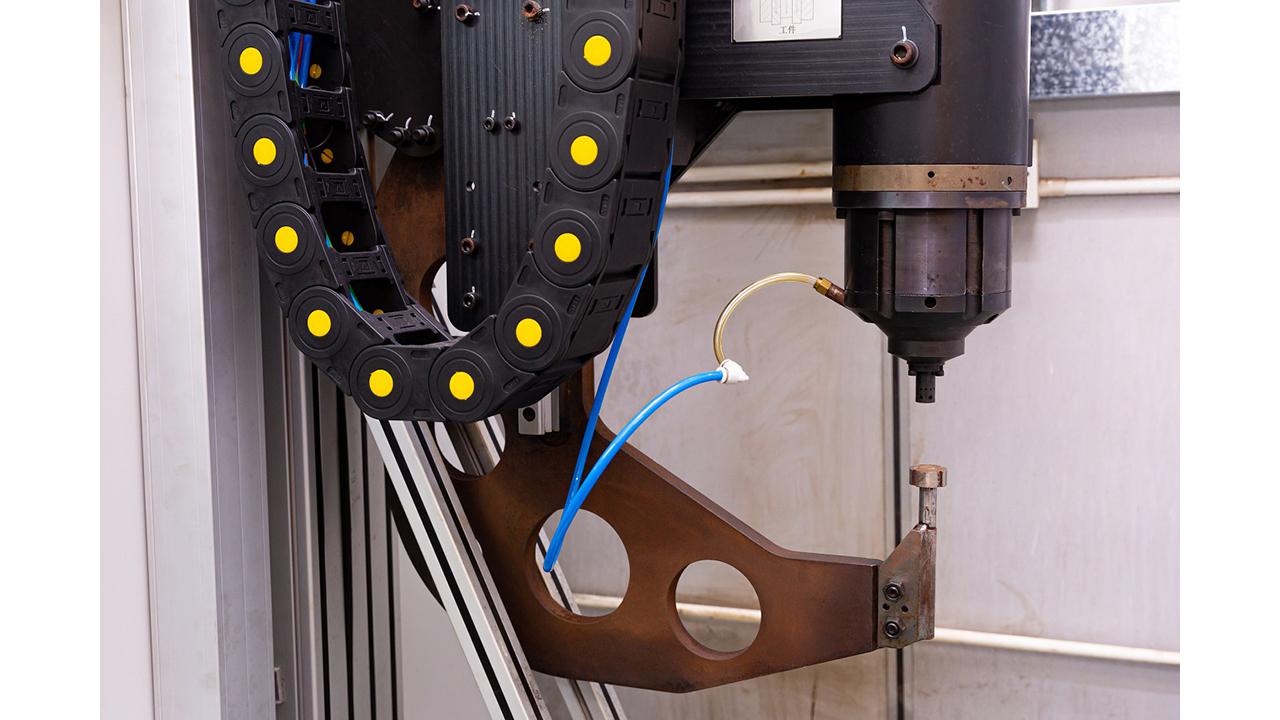

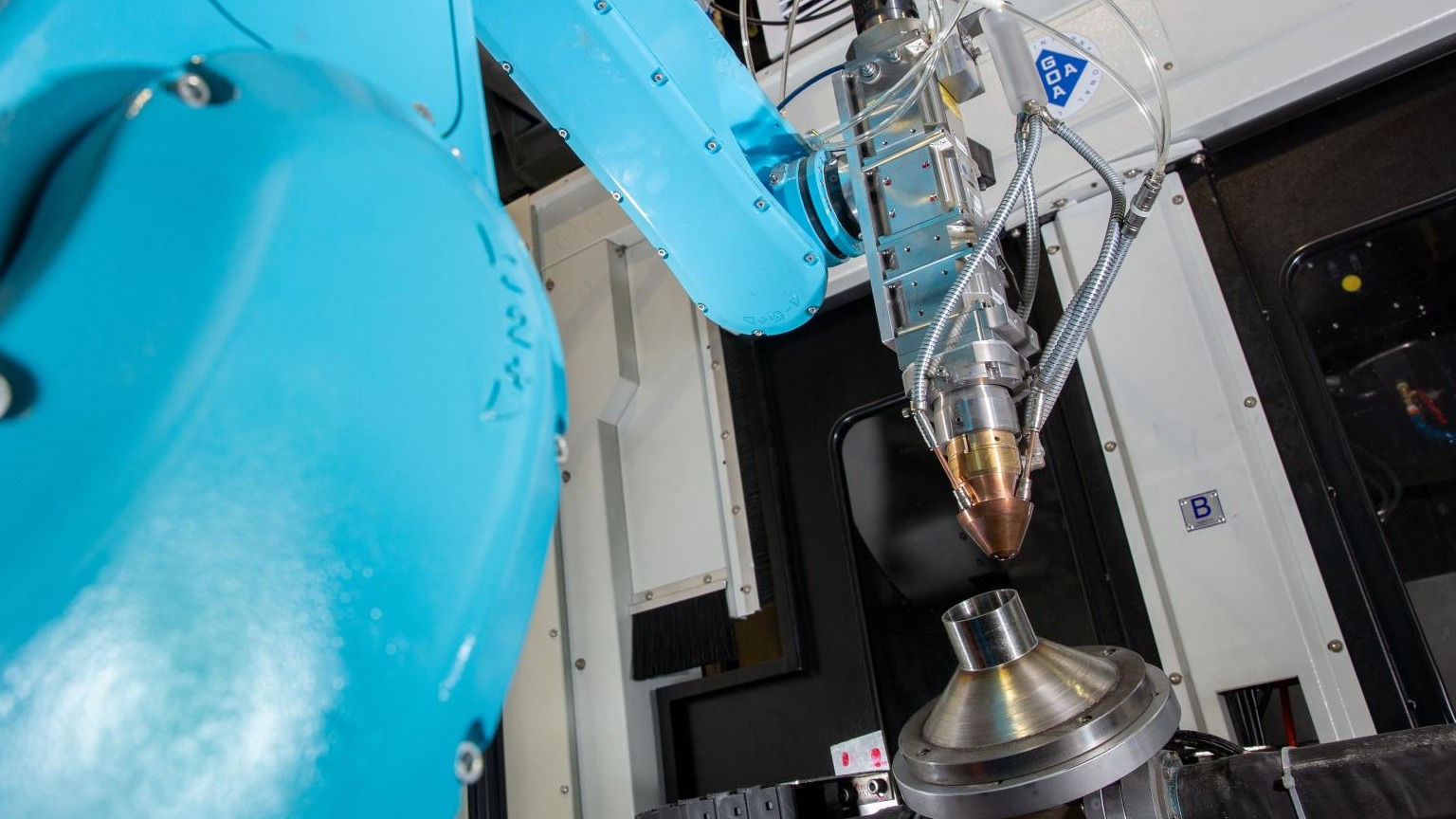

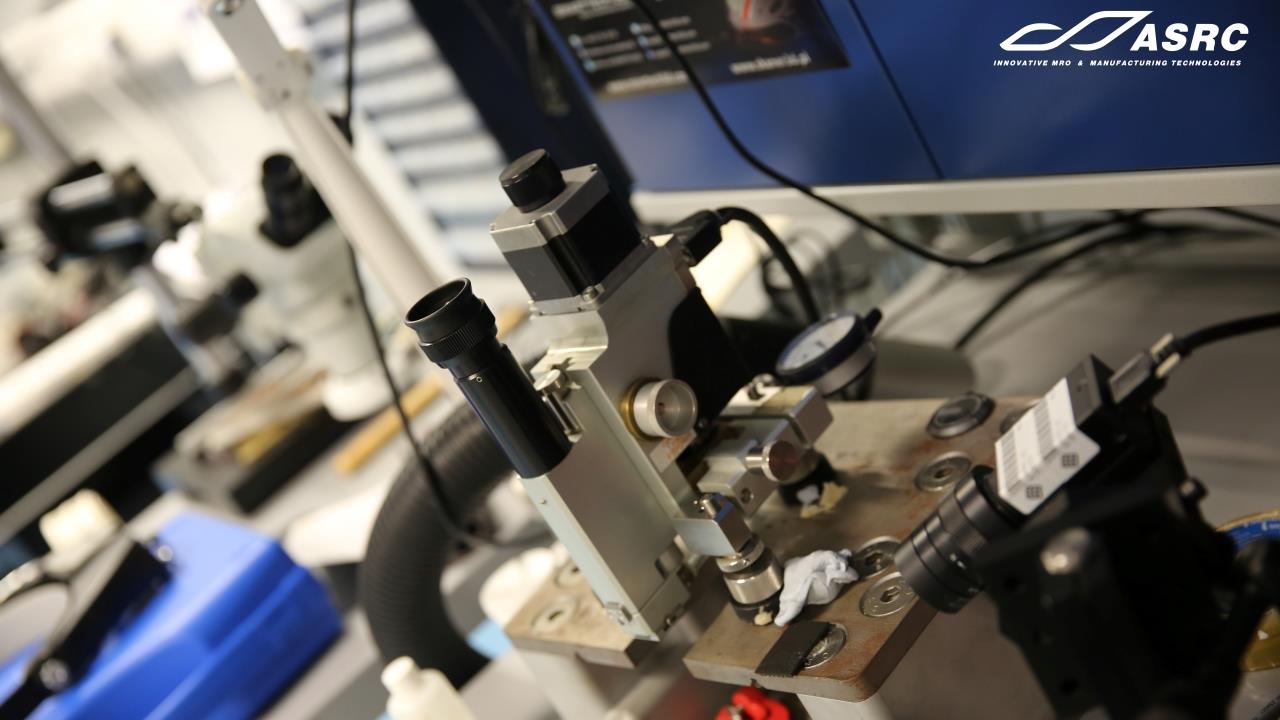

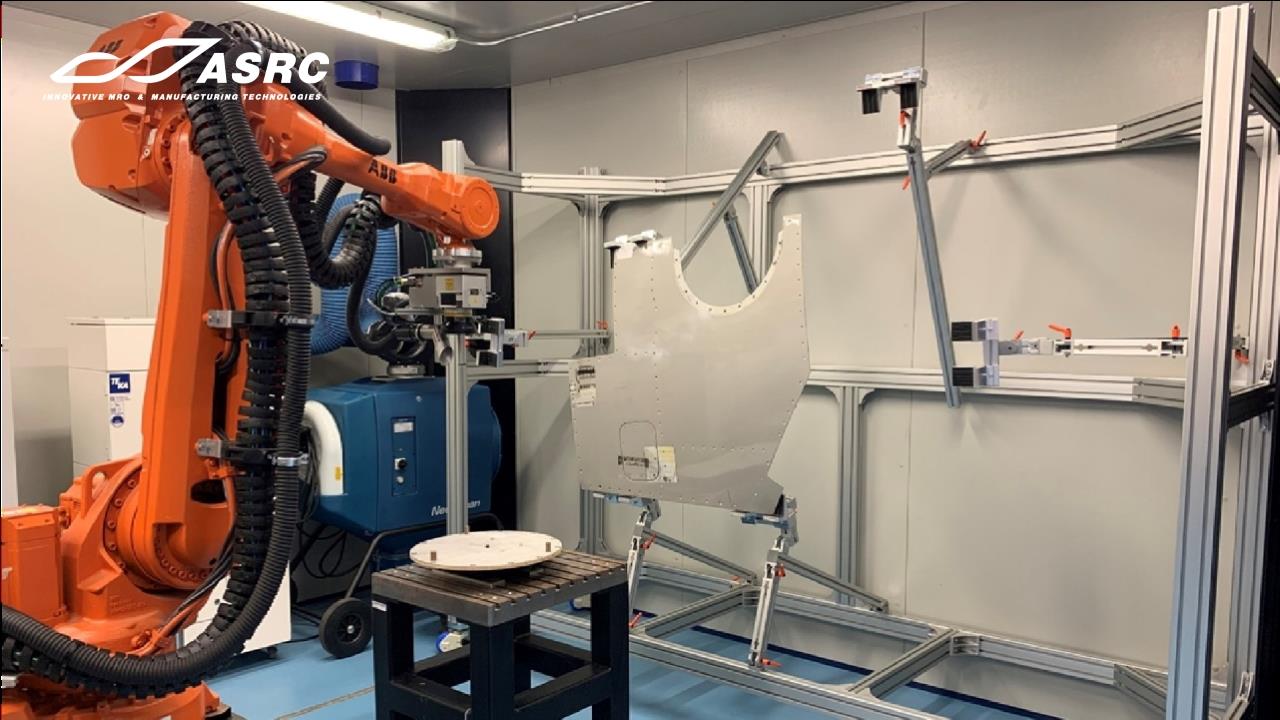

Laser-assisted Progressive Forming (LAPF)

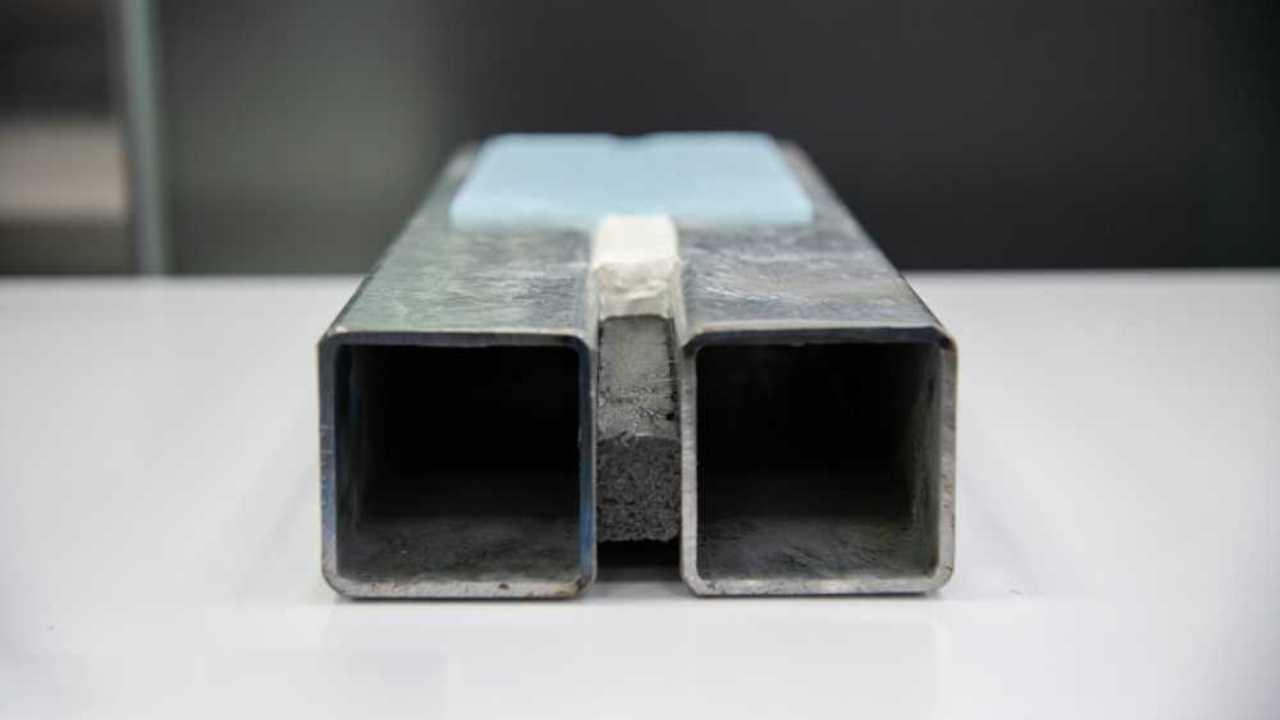

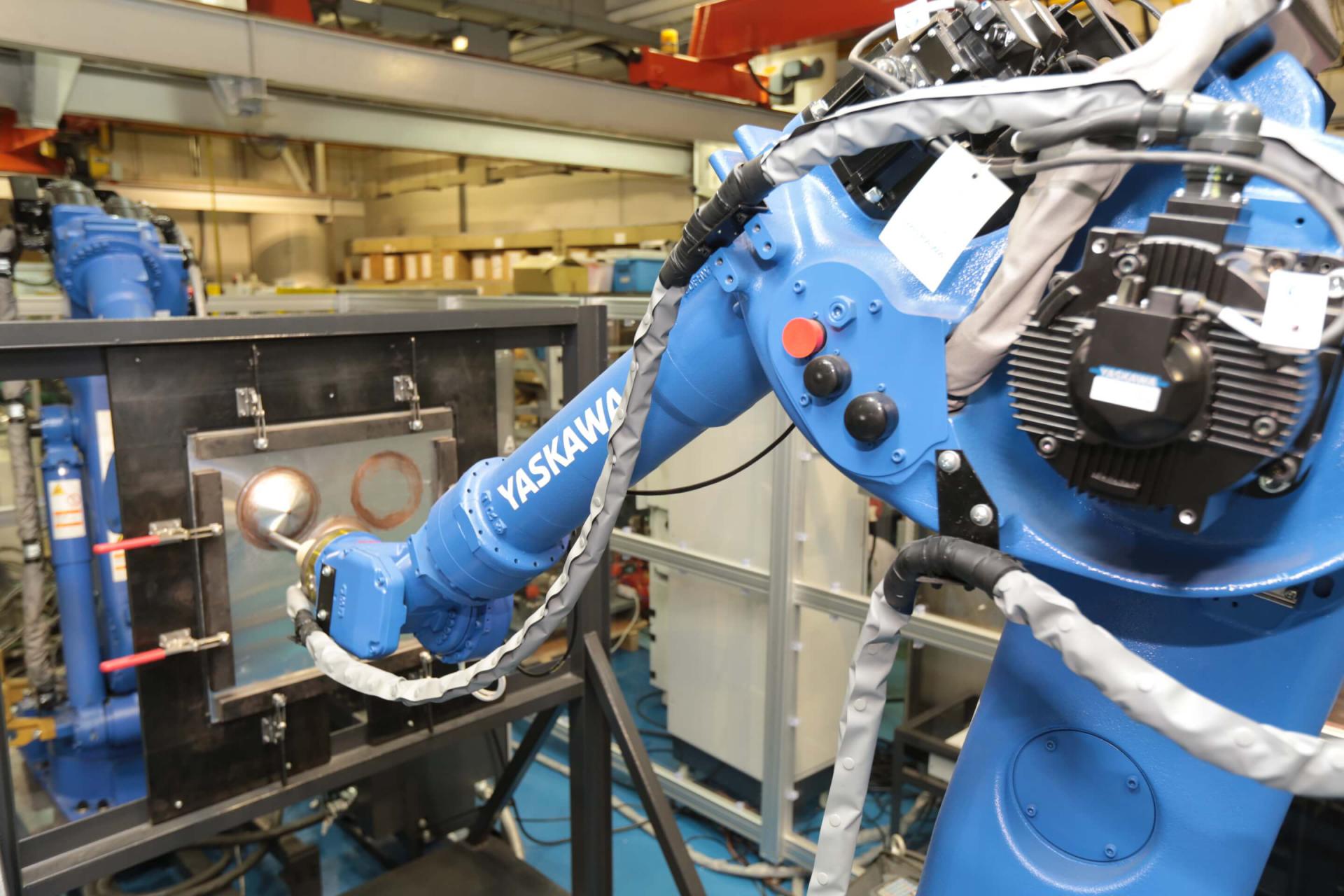

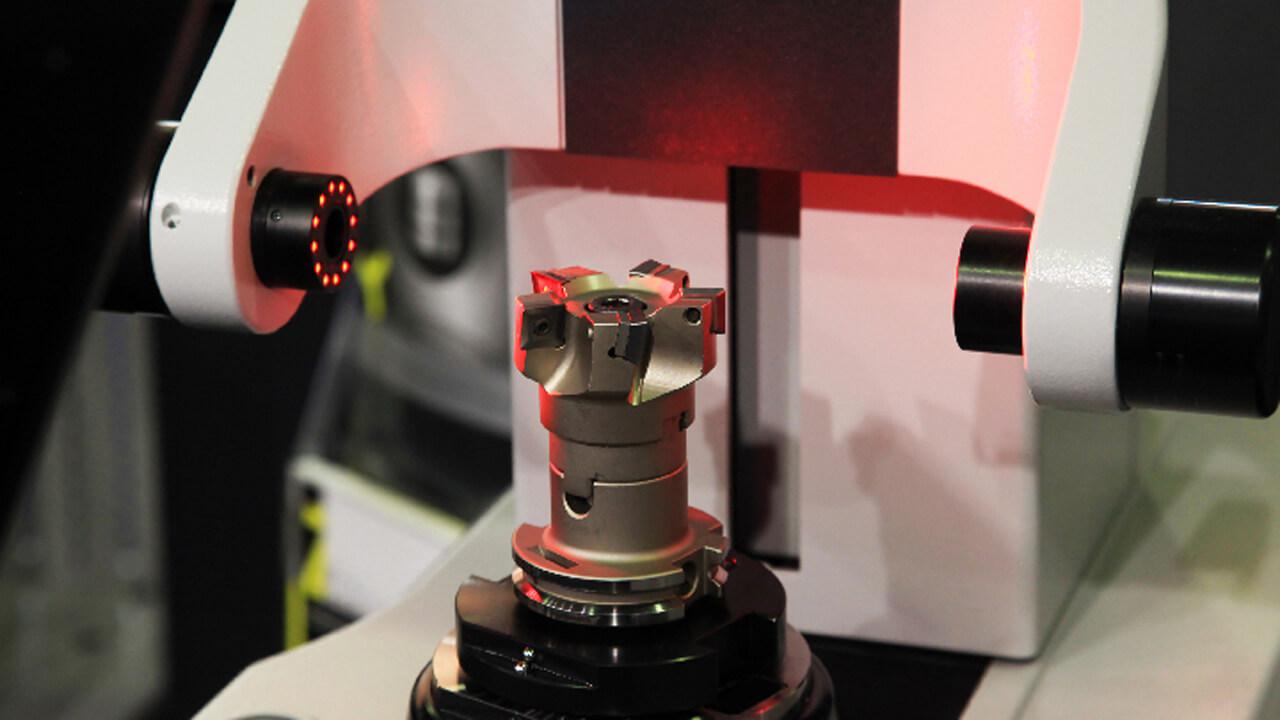

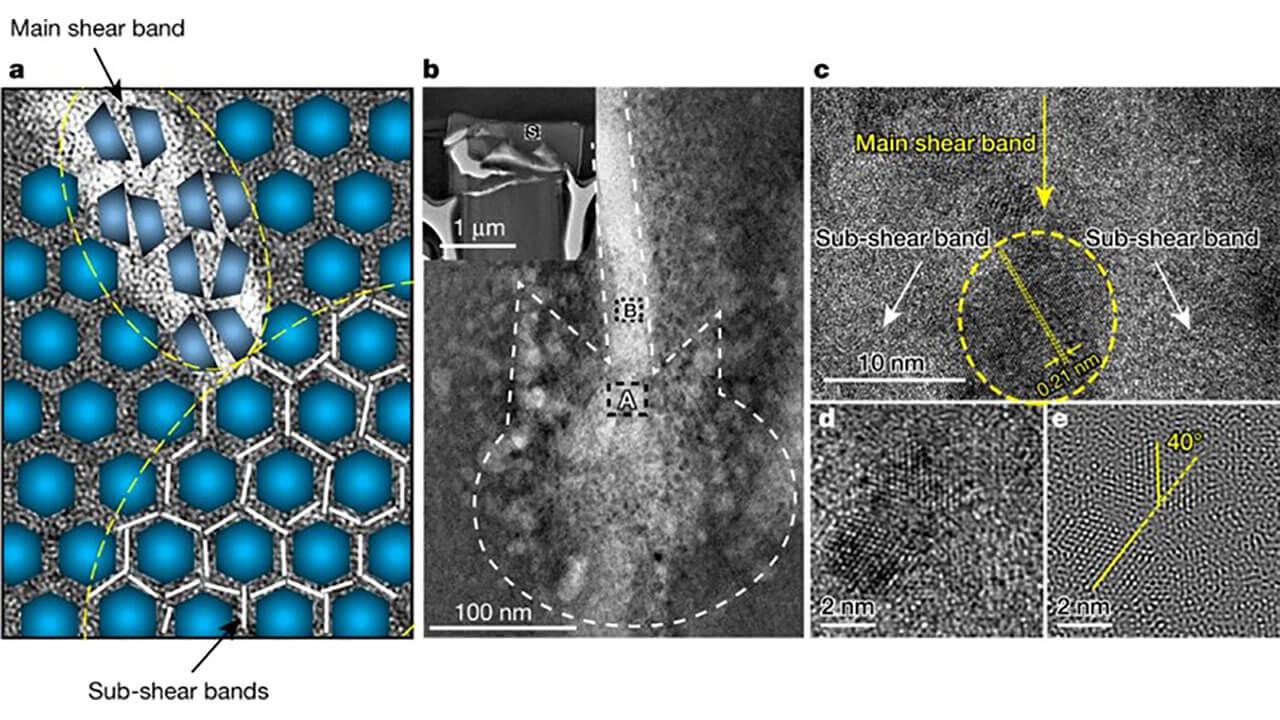

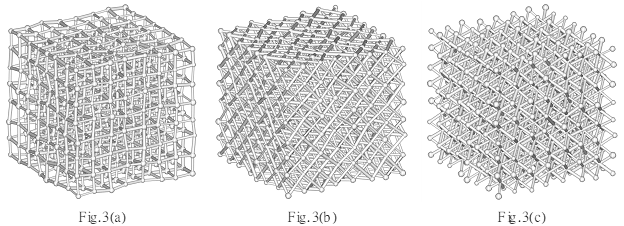

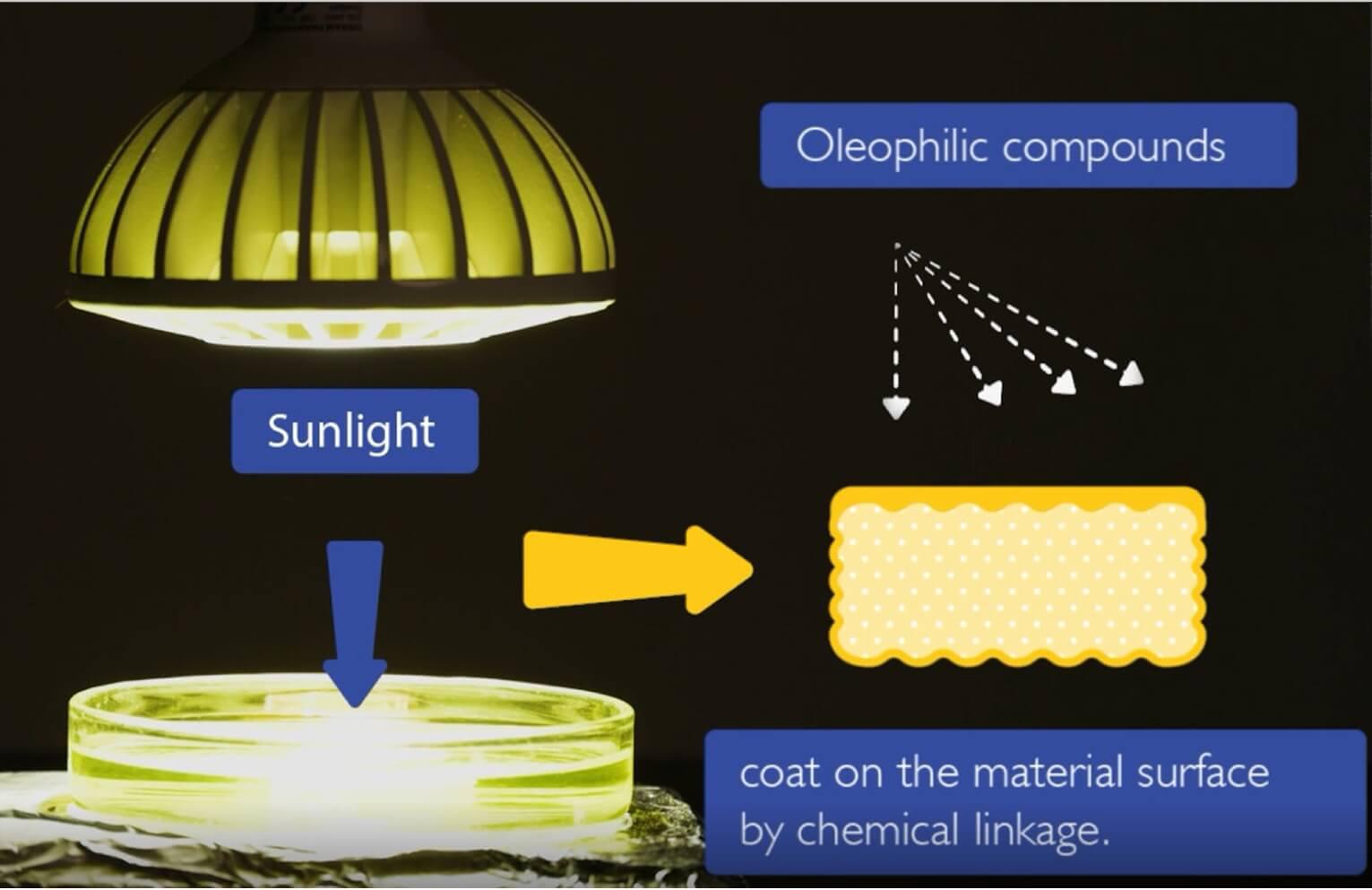

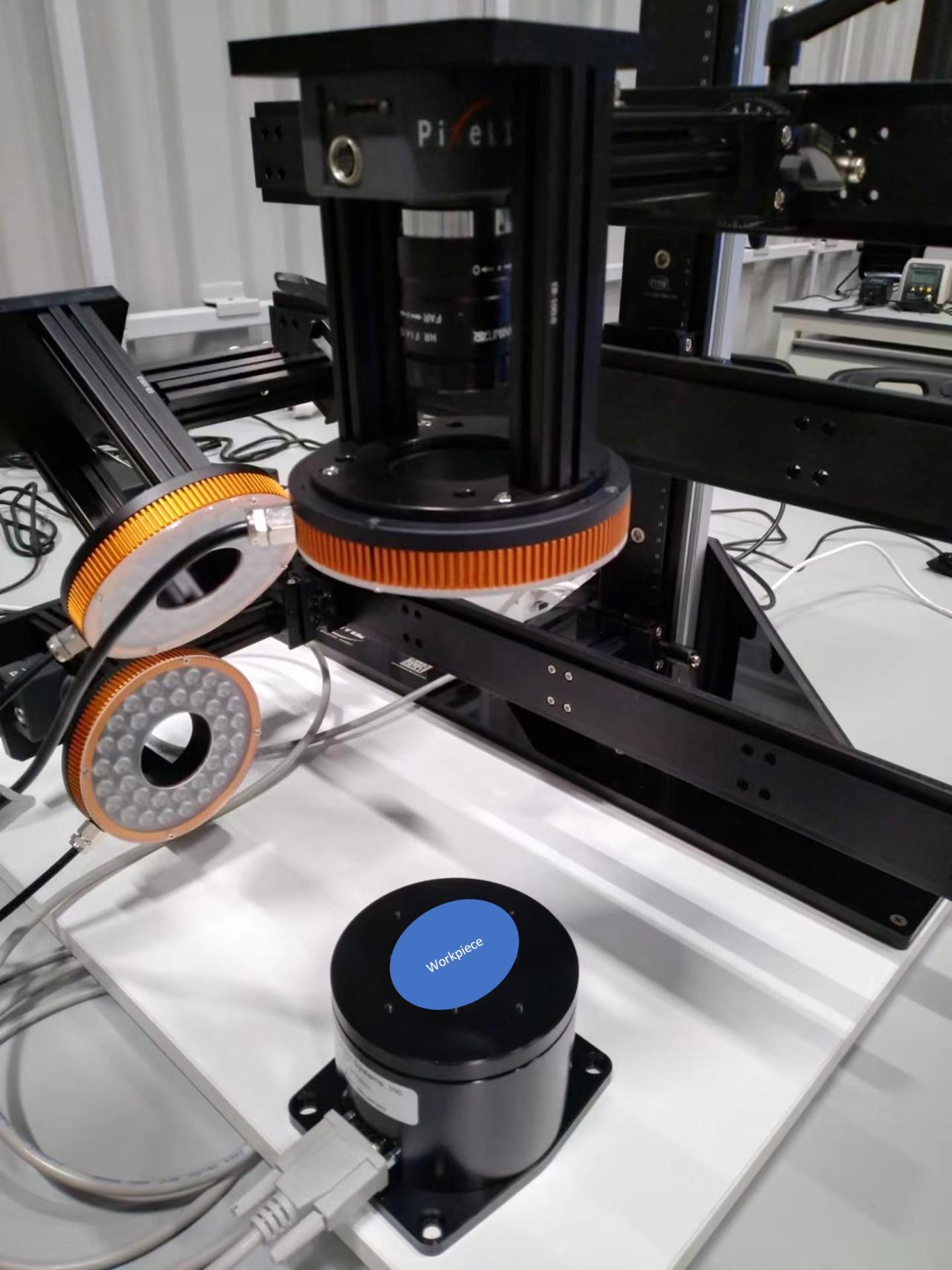

In the LAPF process, the sheet metal is heated and softened locally by laser. The workpiece is then deformed as usual by the forming die immediately after the heating process. Better formability, dimensional accuracy and surface finish can be achieved as compared with the conventional forming. This allows the forming of products with complex geometry, enabling lightweight design.

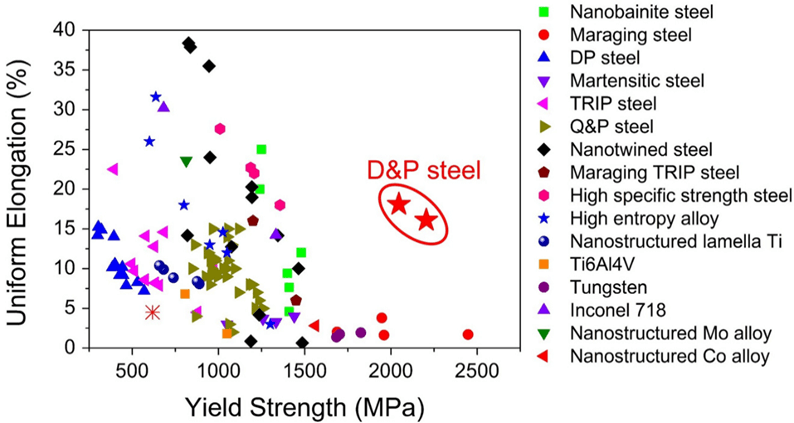

Vehicle weight reduction can be realised by using high-strength materials. However, the forming of complex geometry with high-strength materials is extremely difficult, and it usually leads to cracking defect on the formed parts, leading to short die fatigue life. A complicated process route is now generally required, resulting in high cost and low productivity.

- The synergic integration of the metal forming process with laser heating technology can improve the quality of formed parts, lower production cost and enhance productivity.

- By using localised heating approach, better dimensional accuracy and surface finish can be achieved as compared with the heating of the whole workpiece during conventional hot forming. On the other hand, the materials can have better formability and sheared surface quality as compared with the conventional cold forming process.

- With the better formability and reduction of deformation load, forming steps can be simplified, and die fatigue life can be lengthened, resulting in a higher cost-competitiveness.

- As laser is used to conduct rapid heating, machine downtime caused by die repairing is reduced, and thus productivity can be enhanced.

- High-strength and lightweight sheet metal parts for automobile

Patent

- China Invention Patent: A method and its device of laser-assisted stamping of high-strength and lightweight parts

- China Invention Patent: A method and its device of hybrid induction and laser heating for stamping

- HK Standard Patent: A method and its device of laser-assisted stamping of high-strength and lightweight parts

- HK Standard Patent: A method and its device of hybrid induction and laser heating for stamping

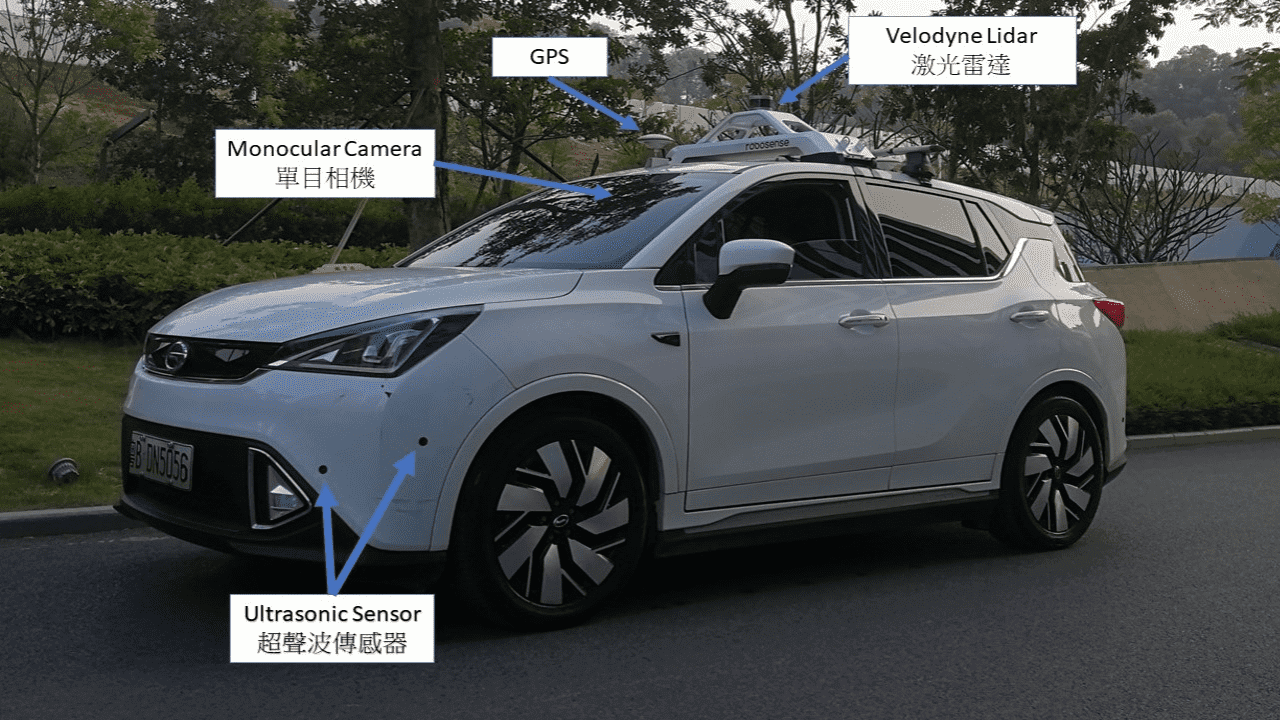

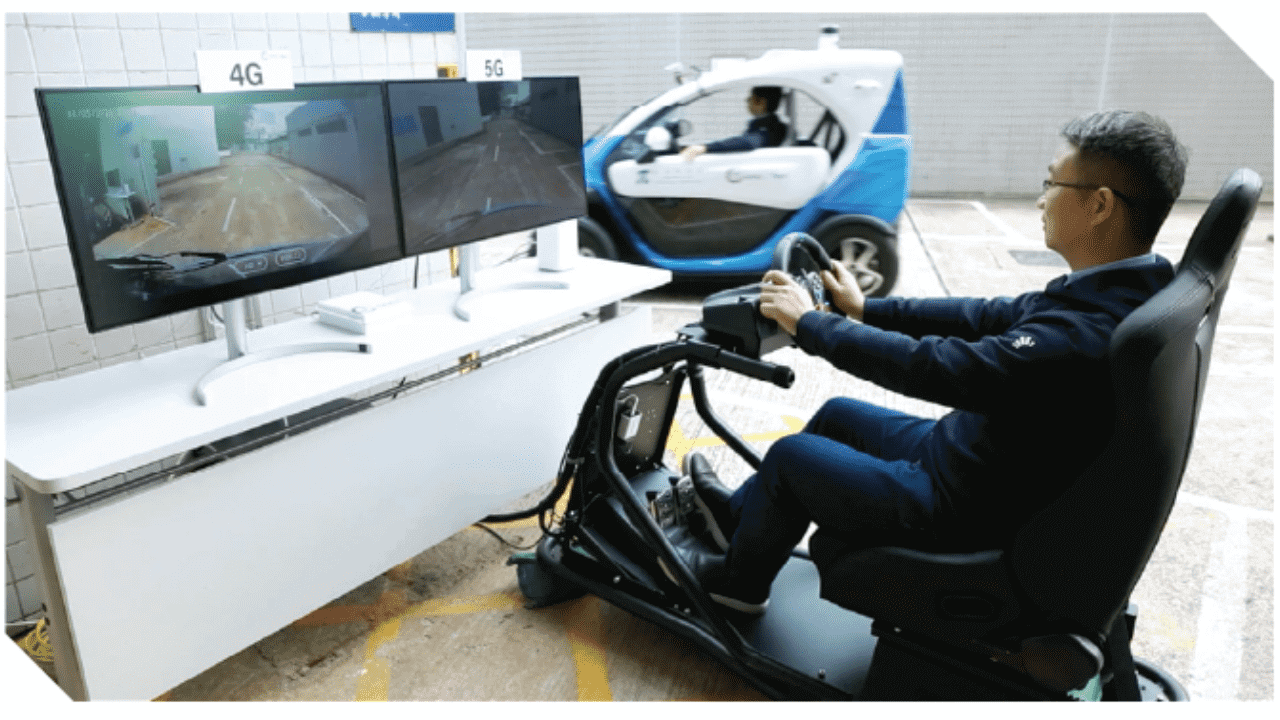

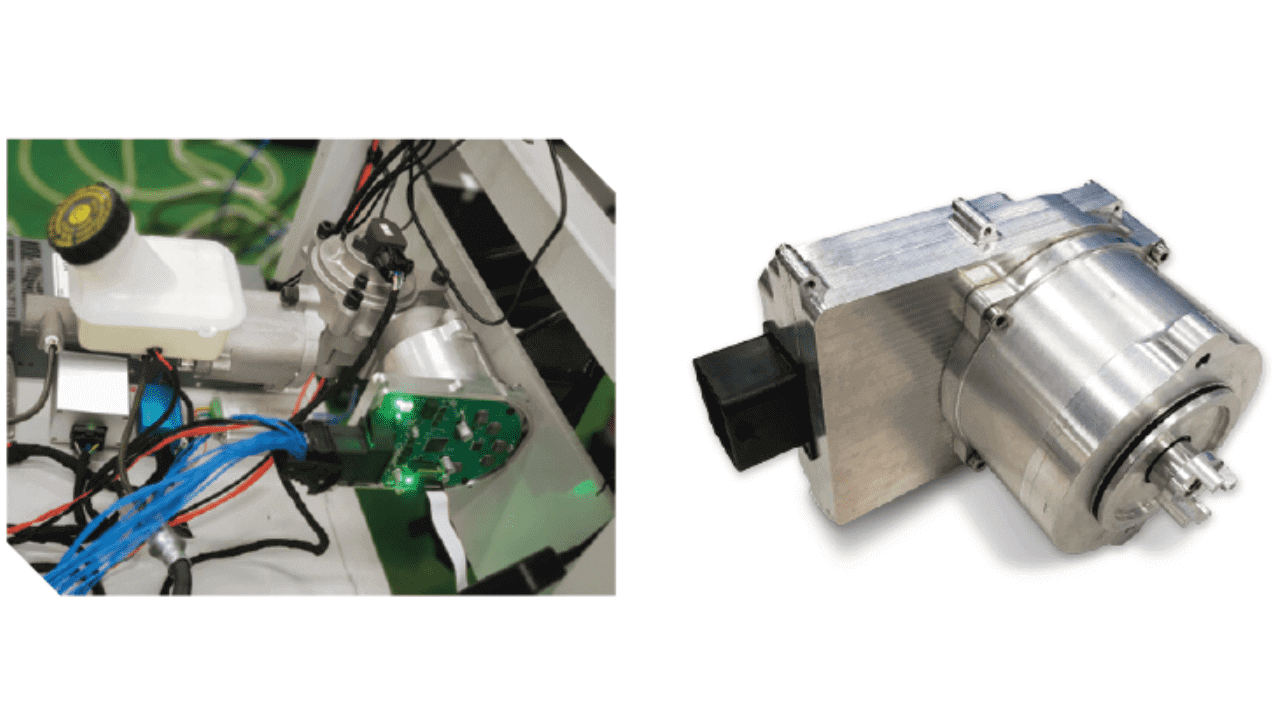

Centre of Advanced Power and Autonomous Systems (APAS) (formerly Automotive Platforms and Application Systems R&D Centre) was established in 2006 and is fully integrated as a business division under HKPC on 1 April 2025. APAS continues to undertake market-led R&D programmes spanning green transportation, smart mobility, intelligent systems and emerging applications, as well as commercialises R&D results in collaboration with industry, universities and technology institutes to enhance the competitiveness of Hong Kong's automotive and other transportation sectors in new energy and smart driving.