- :::Home

- HK Technologies

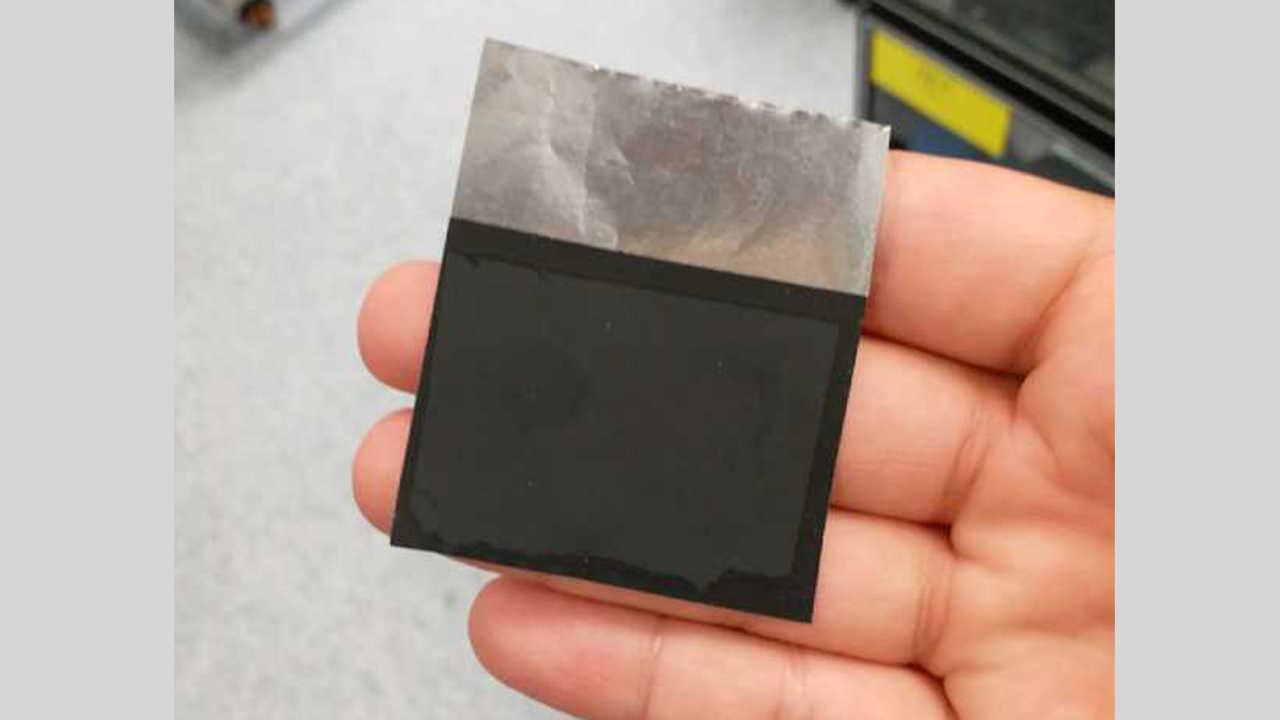

- Solvent-Free Dry Cathode

Solvent-Free Dry Cathode

Unlike the conventional slurry cathode which uses harmful solvents in the fabrication process, NAMI’s dry process is much safer, low-cost and more environmentally friendly without using harmful solvents for cathode and battery fabrication.

- NAMI’s dry process is ideal for high capacity loading cathodes of 5 mAh/cm² and above.

- As a dry process, there is no limitation on the binder variety used in the cathode, enabling easy material optimization for the resultant electrode properties including high stability, high power and high flexibility.

- Easy fabrication

- High capacity loading

- High variety of binder for different electrode properties

- Environmentally friendly and low manufacturing cost

- Any lithium ion batteries including electric vehicle batteries, consumer electronic batteries, energy storage batteries, and special application batteries, etc.

As a Materials Expert, Nano and Advanced Materials Institute (NAMI) has a strong portfolio of innovative technologies to support and collaborate with the industry, offering frontier-applied research on advanced materials as well as technology transfer for commercialization success.

NAMI, incorporated in 2006, is designated by the Innovation and Technology Commission of the Hong Kong Government as a Research and Development Center for nanotechnology and advanced materials. NAMI undertakes and provides support for market-driven research in nanotechnology and advanced materials, and strives for commercialization of the technologies to benefit the industry and the society at large, as well as re-industrialization to promote the economic growth and sustainability of Hong Kong.

-

Range Extender Hybrid eCoach

Range Extender Hybrid eCoach -

Smart Glasses

Smart Glasses -

Firm-to-Soft Intelligent Floor Mat for Fall Injury Prevention

Firm-to-Soft Intelligent Floor Mat for Fall Injury Prevention -

Fireproof, Smokeproof and Waterproof Module Stitching System

Fireproof, Smokeproof and Waterproof Module Stitching System -

Plasma-Driven Catalysis (PDC) Air Purification

Plasma-Driven Catalysis (PDC) Air Purification -

All-electric Intelligent Anti-lock Braking System

All-electric Intelligent Anti-lock Braking System -

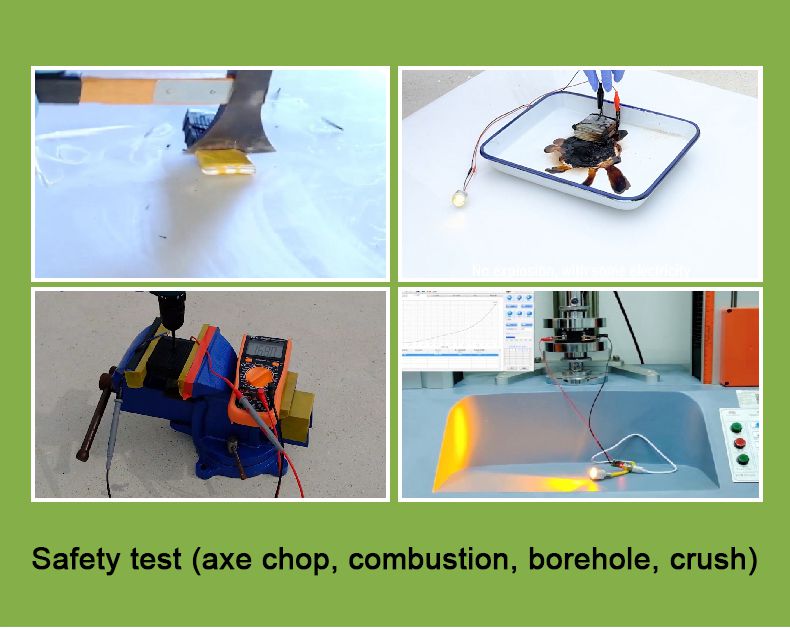

Aqueous Batteries with Ultimate Safety

Aqueous Batteries with Ultimate Safety -

Smart Automatic Parking Module for Electric Vehicles

Smart Automatic Parking Module for Electric Vehicles -

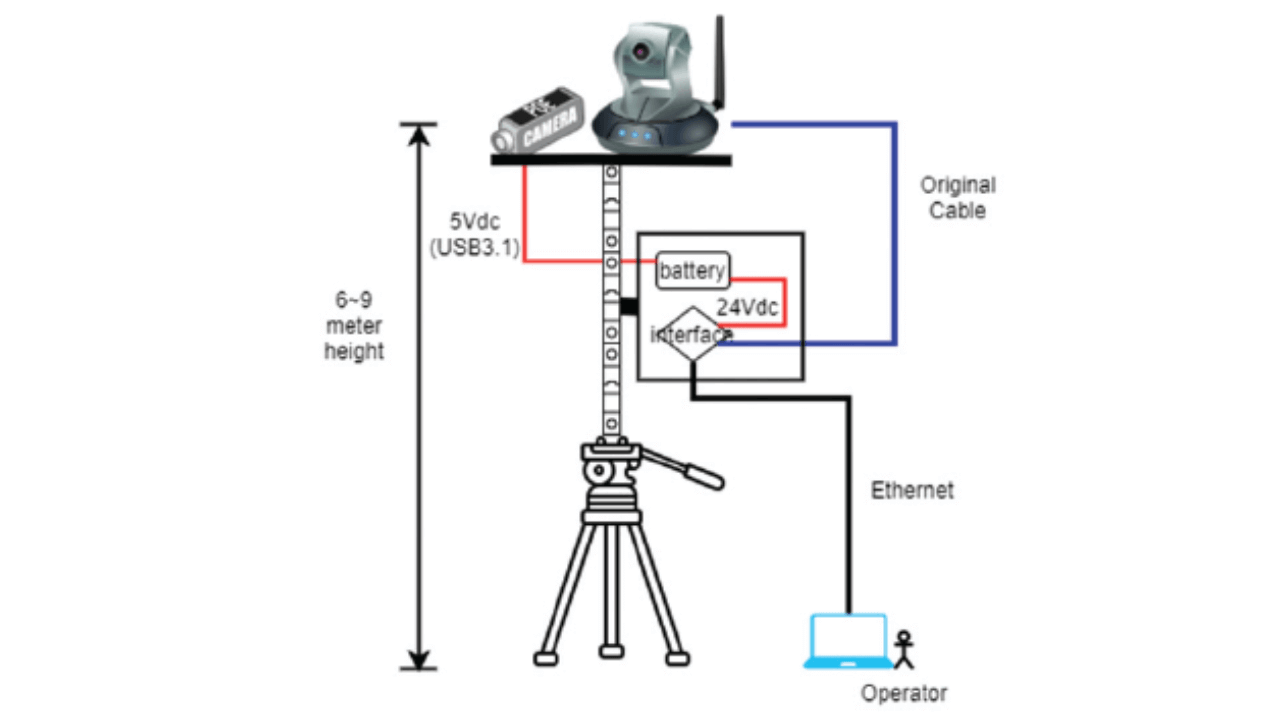

Roadside LIDAR and V2X Communication

Roadside LIDAR and V2X Communication -

Washable Antiviral and Antibacterial Textiles

Washable Antiviral and Antibacterial Textiles -

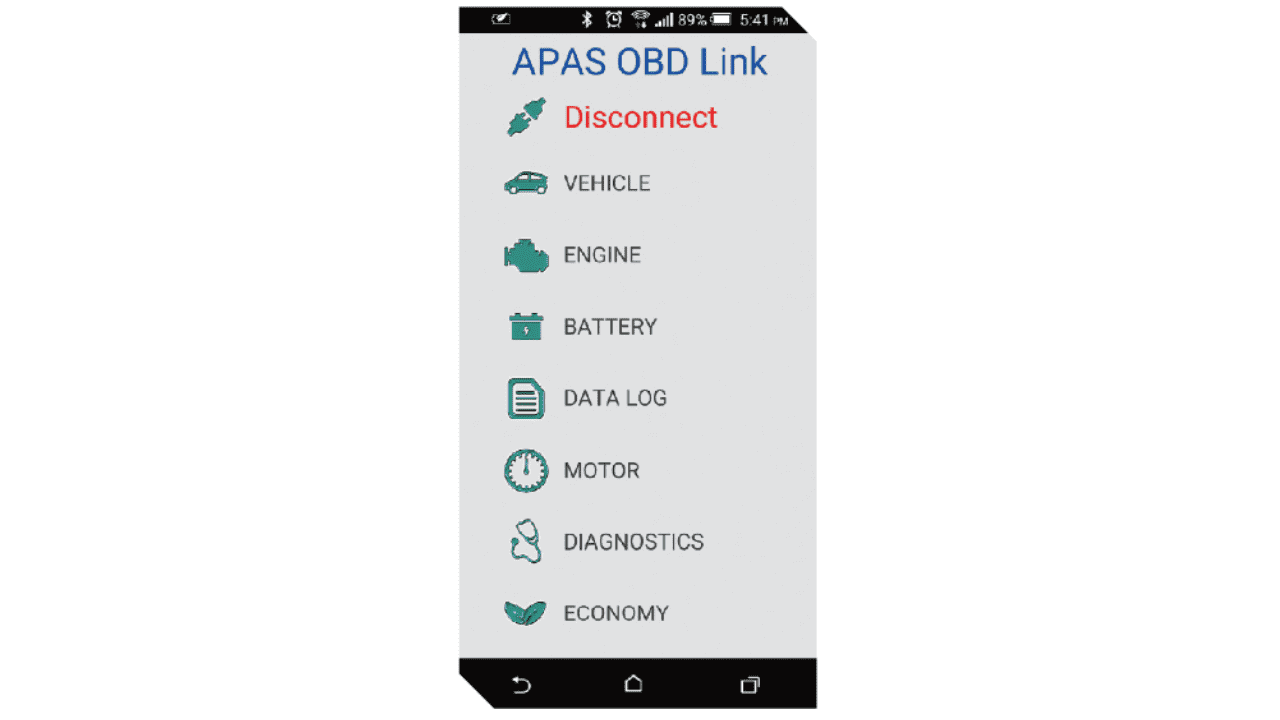

Non-invasive Diagnosis of Internal Combustion Engine Performance

Non-invasive Diagnosis of Internal Combustion Engine Performance -

High Power Density and High Efficiency Motor Controller

High Power Density and High Efficiency Motor Controller -

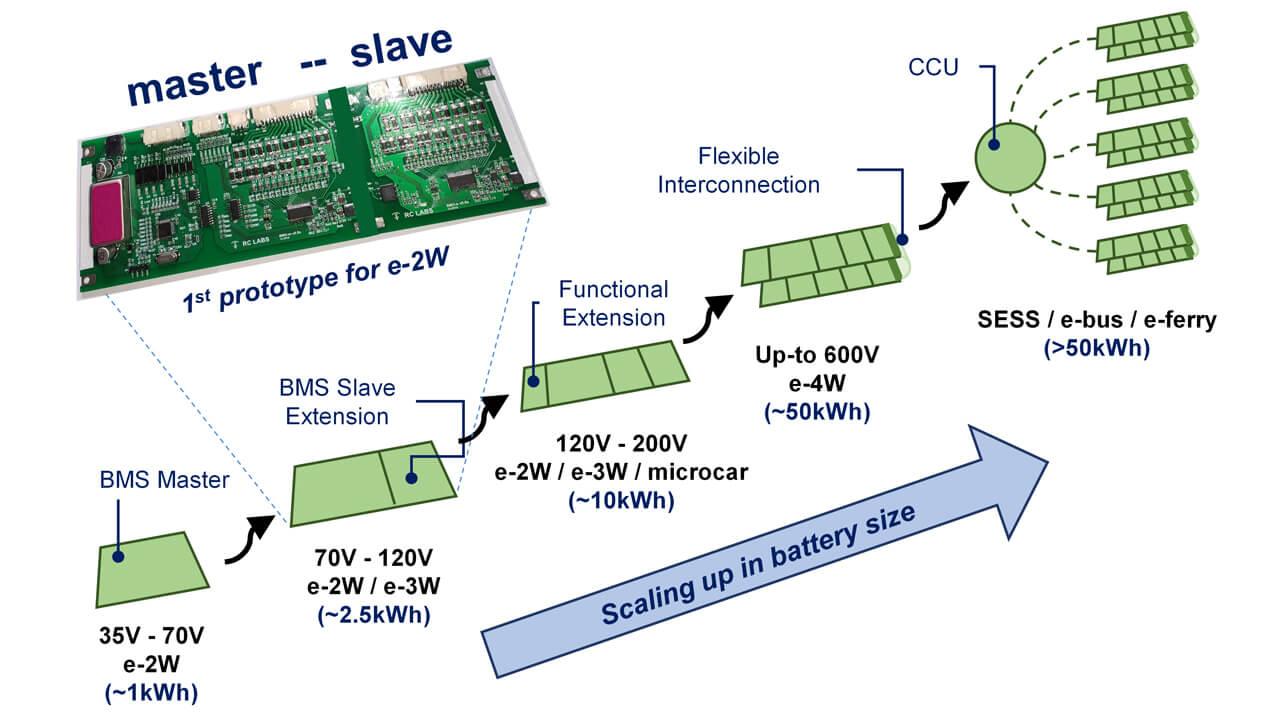

Intelligent battery management system for electric vehicles and stationary energy storage

Intelligent battery management system for electric vehicles and stationary energy storage -

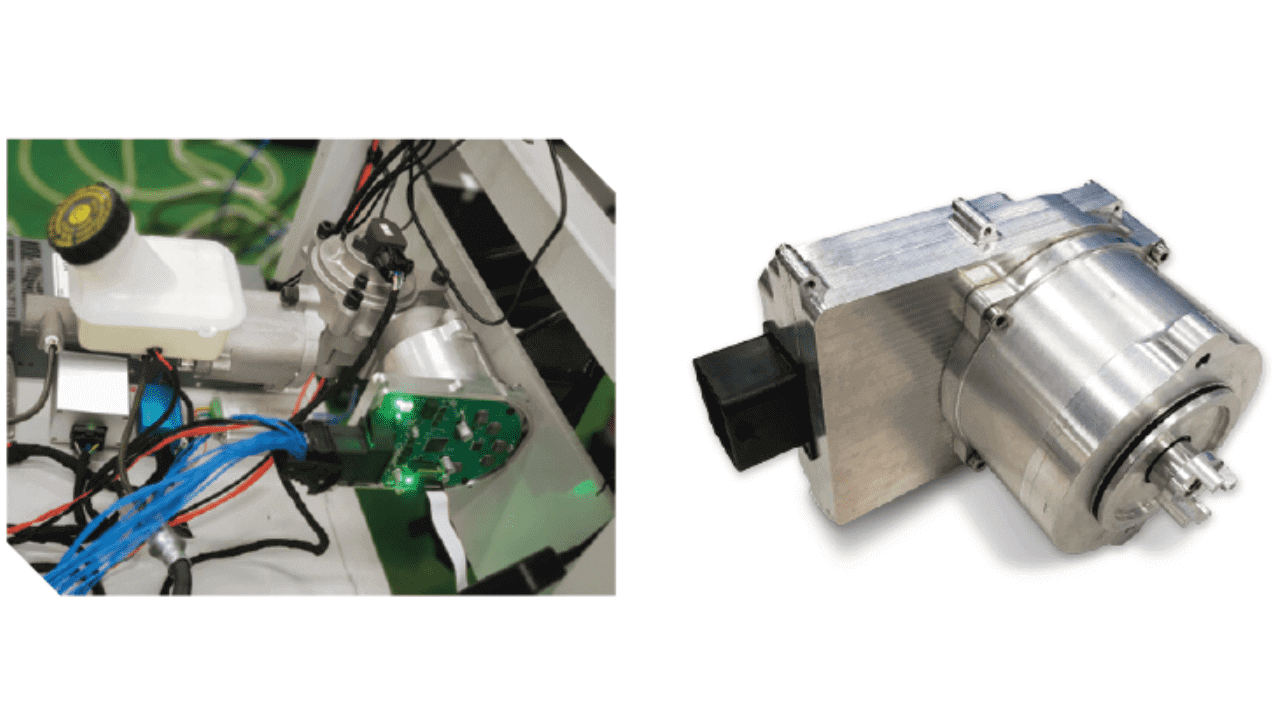

Smart Electric Brake Booster

Smart Electric Brake Booster -

Intelligent Single-deck eBus

Intelligent Single-deck eBus -

Flexible IoT Temperature Patch for Healthcare Application

Flexible IoT Temperature Patch for Healthcare Application -

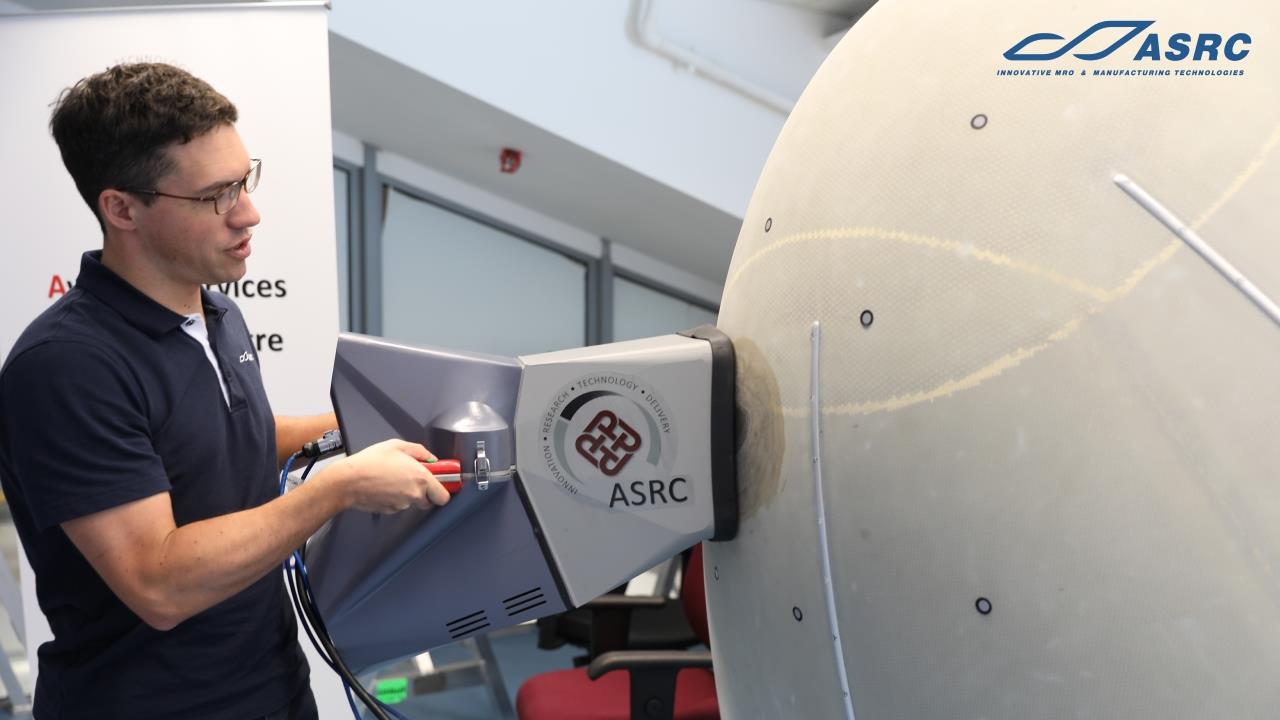

Aircraft Damage Inspection and Assessment

Aircraft Damage Inspection and Assessment -

Pure Electric Minibus with Swappable Batteries

Pure Electric Minibus with Swappable Batteries -

Laser-assisted Progressive Forming (LAPF)

Laser-assisted Progressive Forming (LAPF) -

Long-Life Battery Powers Trolley Trackers

Long-Life Battery Powers Trolley Trackers -

Nanostructured Gas Sensors

Nanostructured Gas Sensors -

300kW Pantograph High Power Charging Station & Pure Electric Minibus

300kW Pantograph High Power Charging Station & Pure Electric Minibus -

Antiviral Hydrophobic Surfaces via Laser-Structured Copper Nanoparticles

Antiviral Hydrophobic Surfaces via Laser-Structured Copper Nanoparticles -

Development of Vehicle Platoon Control System Based on V2V Communication

Development of Vehicle Platoon Control System Based on V2V Communication -

Gold(III)-based Emitter Materials for OLED Application

Gold(III)-based Emitter Materials for OLED Application -

The 2nd Generation MOST-150 In-vehicle Infotainment System

The 2nd Generation MOST-150 In-vehicle Infotainment System -

Metal-Heterostructure-Metal (MHM) Ultraviolet Photodetectors

Metal-Heterostructure-Metal (MHM) Ultraviolet Photodetectors -

Functional Atomized Nano-Coating Technology

Functional Atomized Nano-Coating Technology -

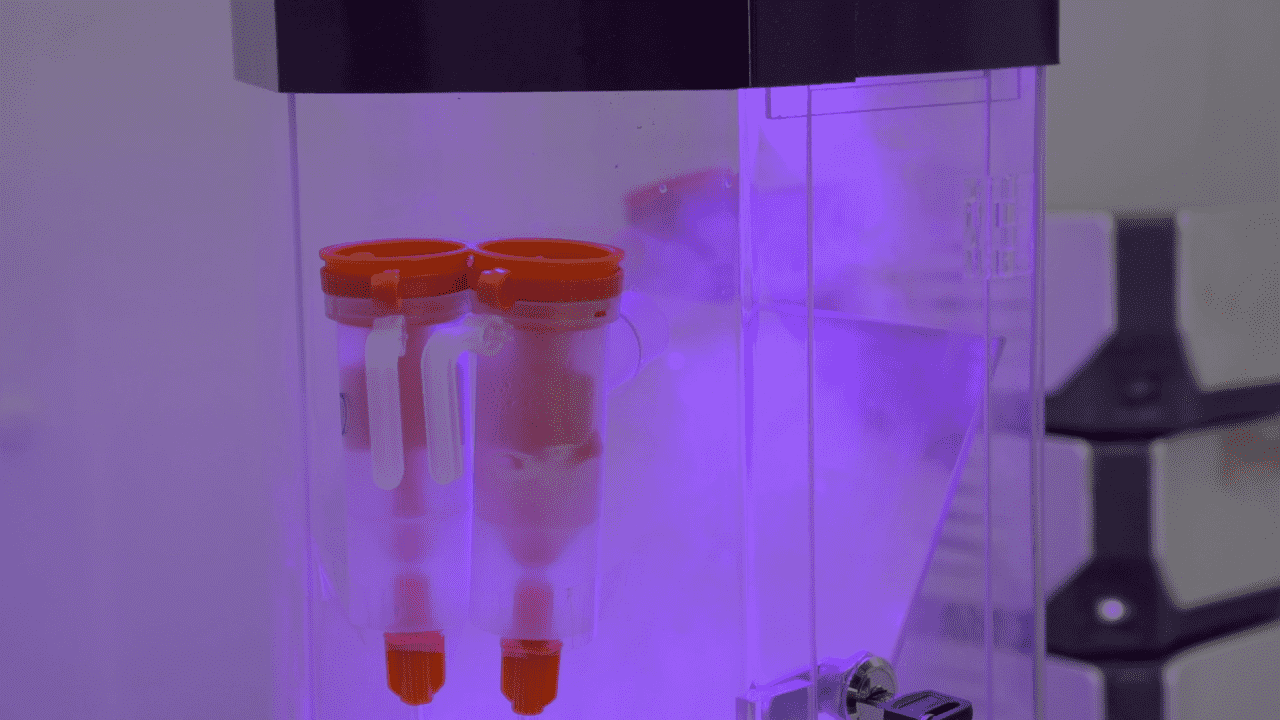

High-performance Two-phase Immersion Coolant for Thermal Management

High-performance Two-phase Immersion Coolant for Thermal Management -

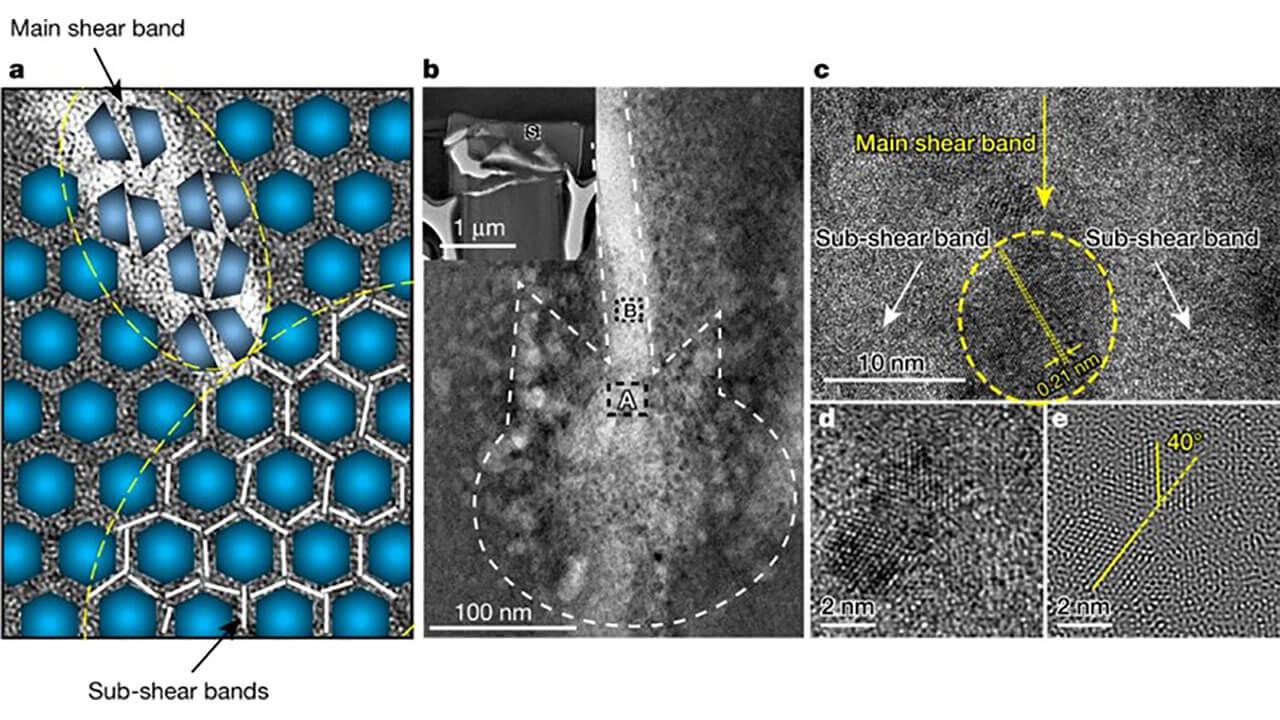

A Nano-dual-phase Glass-crystal with Theoretical Strength and its Fabrication Method

A Nano-dual-phase Glass-crystal with Theoretical Strength and its Fabrication Method -

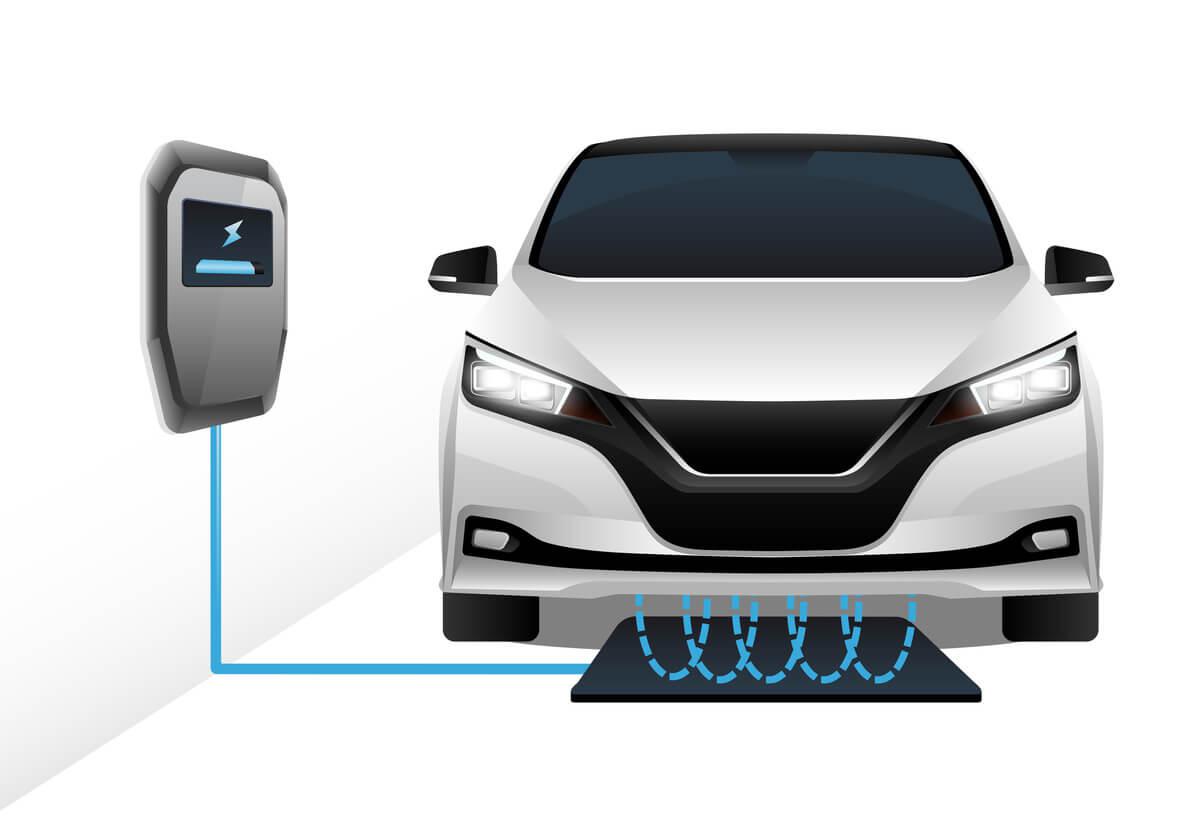

Wireless Battery Charging System with Coordinated Control

Wireless Battery Charging System with Coordinated Control -

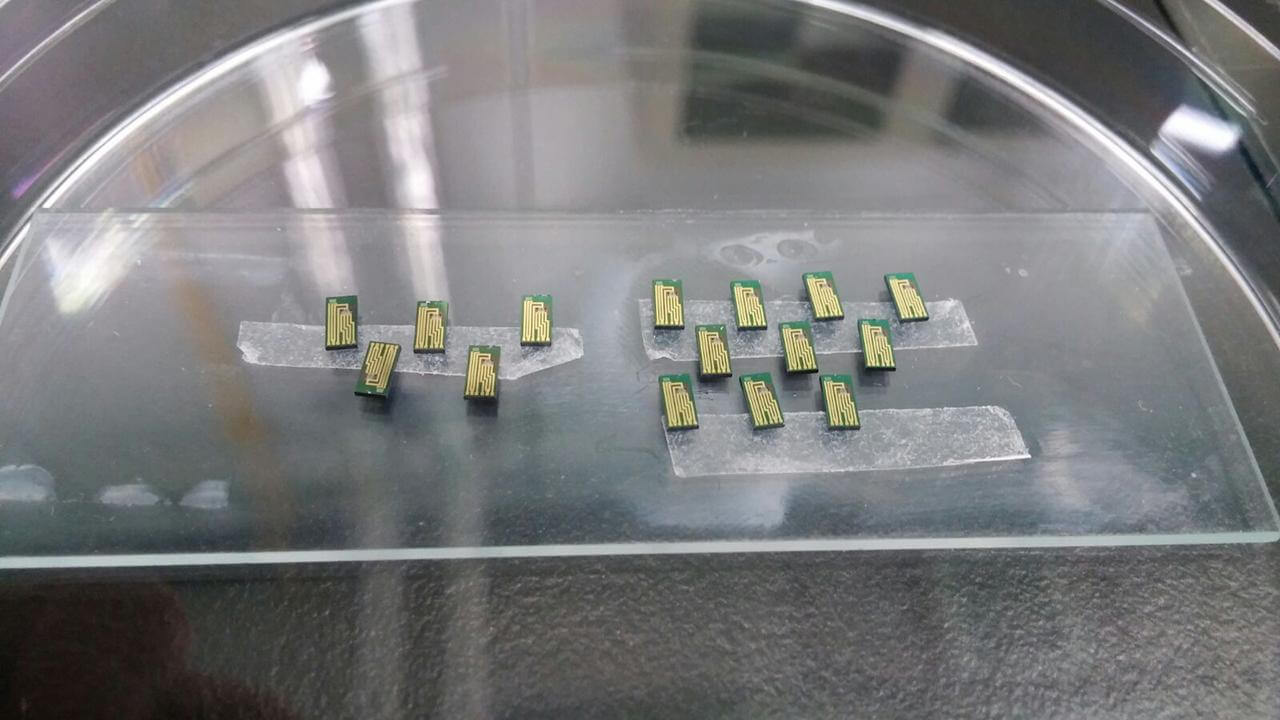

Thermal Radiation Microsensor

Thermal Radiation Microsensor -

16-tonne Full-electric Truck with Hook Lift for Solid Waste Collection

16-tonne Full-electric Truck with Hook Lift for Solid Waste Collection -

Portable Thermal Sterilizer for Surgical Masks with Laser Induced Graphene

Portable Thermal Sterilizer for Surgical Masks with Laser Induced Graphene -

Auto-Fitting Smart Materials and Electronics Platform Technologies

Auto-Fitting Smart Materials and Electronics Platform Technologies -

kNOw Touch - Contactless Elevator Control Panel

kNOw Touch - Contactless Elevator Control Panel -

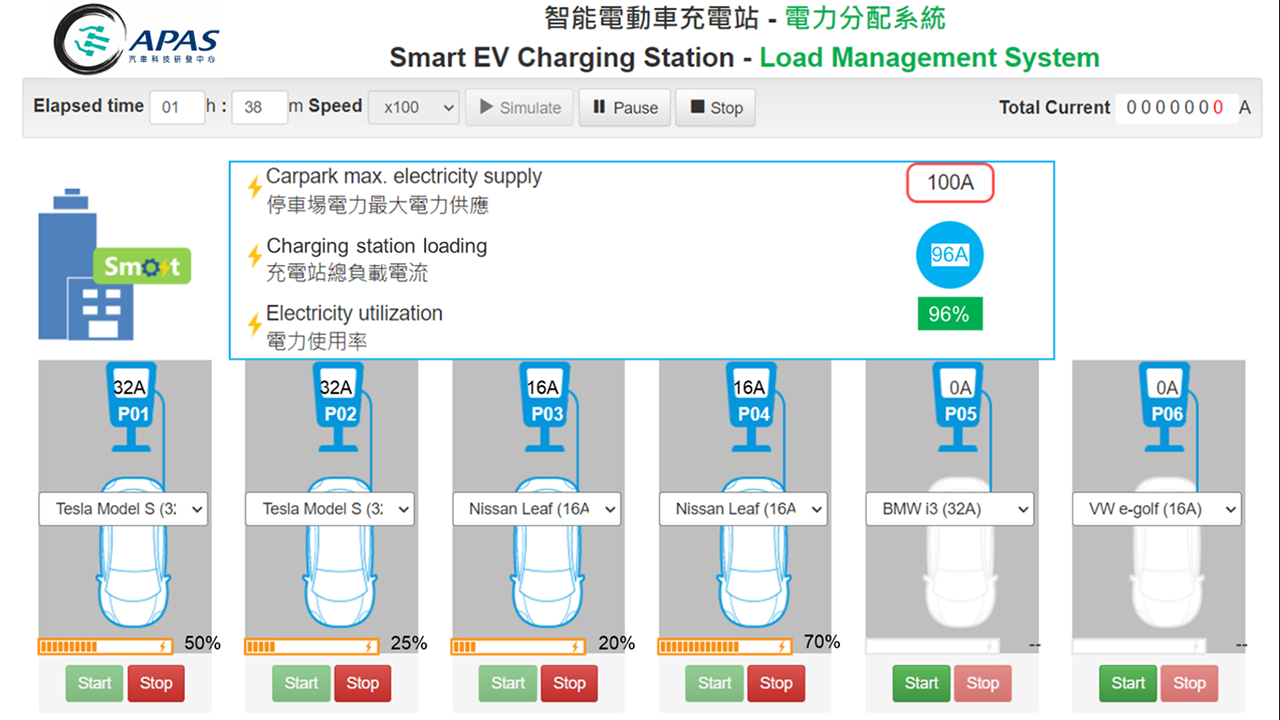

Artificial Intelligence (AI) Load Management Controlled Electric Vehicle Charging System

Artificial Intelligence (AI) Load Management Controlled Electric Vehicle Charging System -

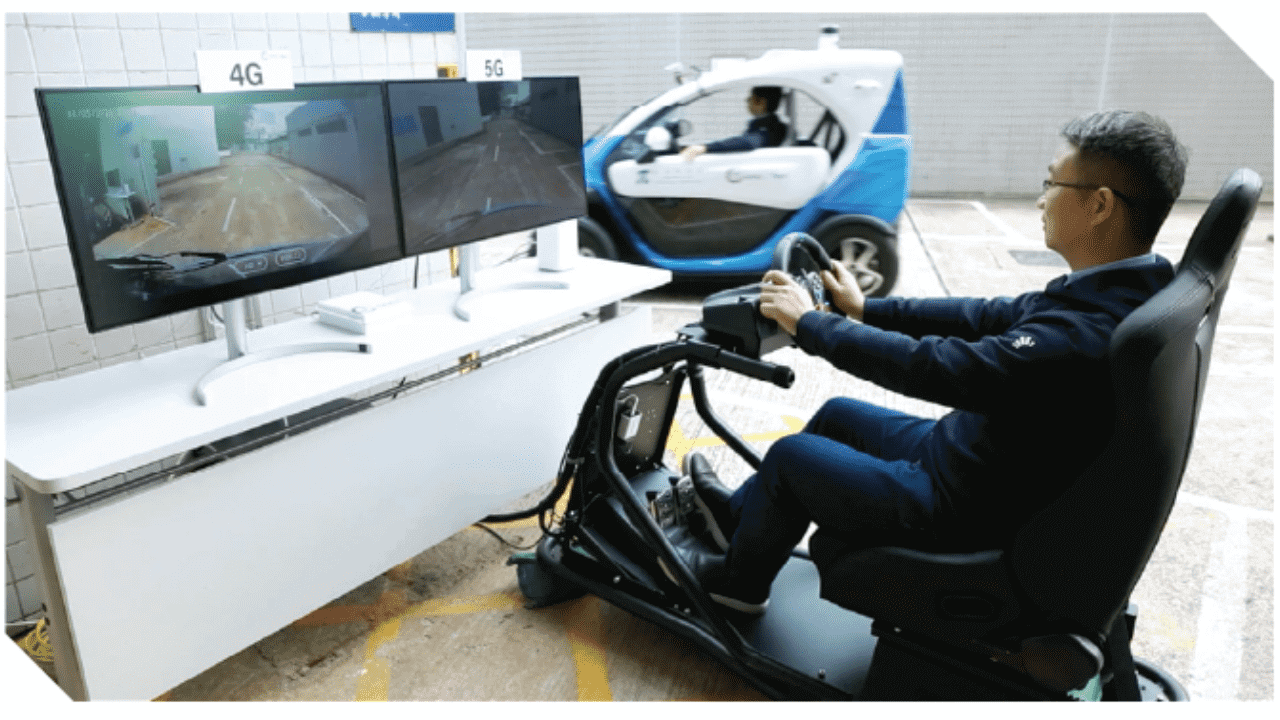

5G Teleoperated-driving

5G Teleoperated-driving -

Optical Soft Skin System for Multimodal Sensing

Optical Soft Skin System for Multimodal Sensing -

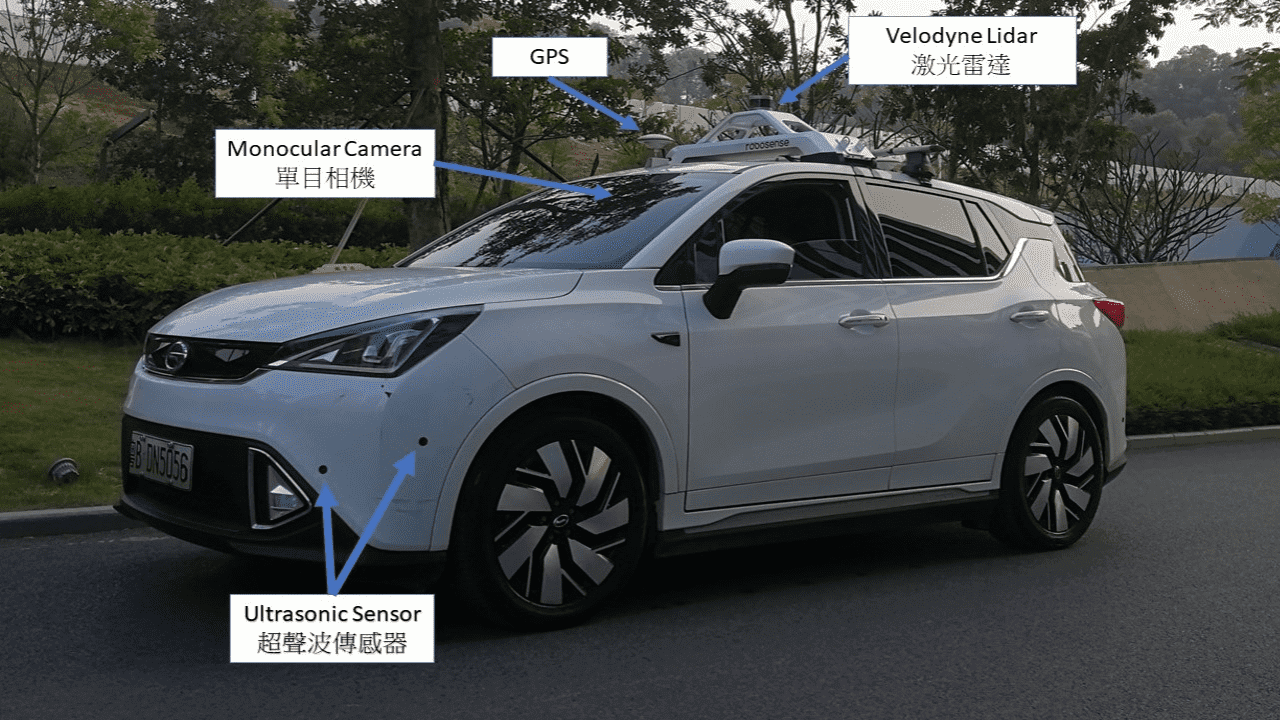

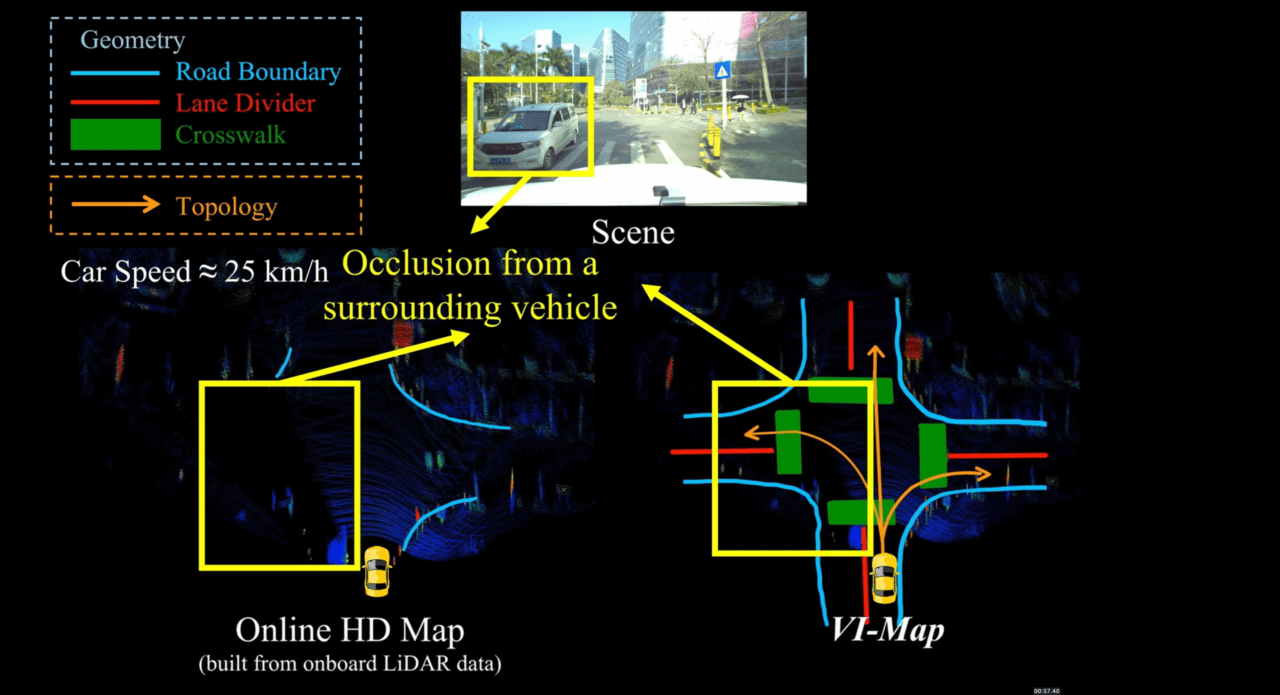

Autonomous Driving High-precision map of vehicle-Infrastructure collaboration

Autonomous Driving High-precision map of vehicle-Infrastructure collaboration -

“OWL” Intelligent Production Line

“OWL” Intelligent Production Line -

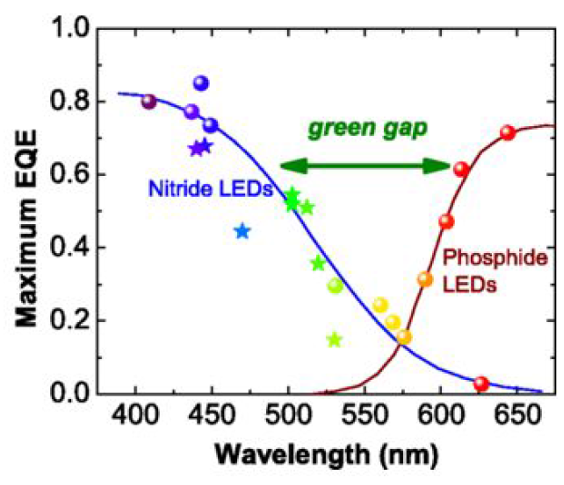

Red-Shifting LED for Monolithium Full-Colour Display and Phosphor Free White LED

Red-Shifting LED for Monolithium Full-Colour Display and Phosphor Free White LED -

Wrinkle-resistant and High-contrast Flexible Screen Material for Spontaneous Pop-Up Display

Wrinkle-resistant and High-contrast Flexible Screen Material for Spontaneous Pop-Up Display -

Drain-On-Demand Lithium Battery for Long-Life IoT Devices

Drain-On-Demand Lithium Battery for Long-Life IoT Devices -

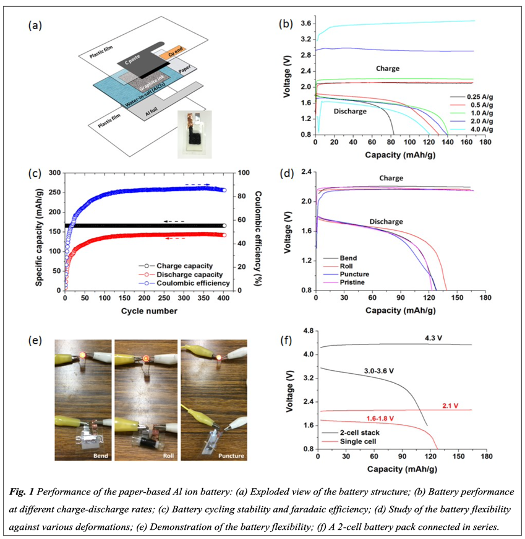

Flexible and Printable Paper-Based Al Ion Batteries

Flexible and Printable Paper-Based Al Ion Batteries -

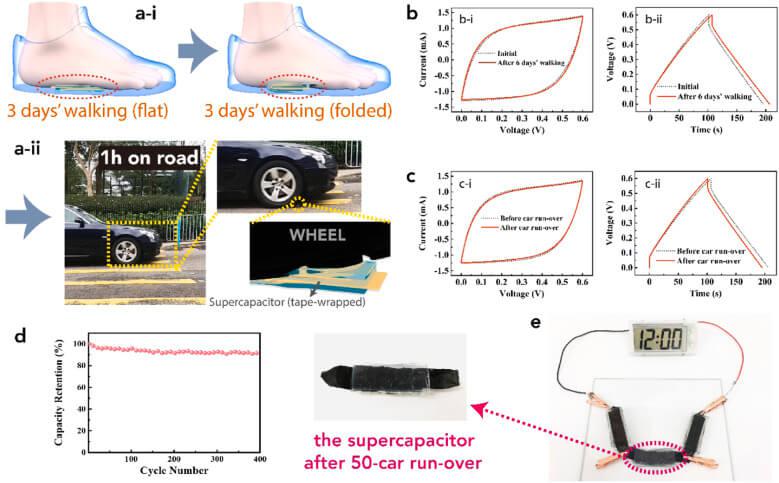

Super Robust and Flexible Wearable Energy Storage Devices

Super Robust and Flexible Wearable Energy Storage Devices -

High speed moving sensing for transportation infrastructure inspection

High speed moving sensing for transportation infrastructure inspection -

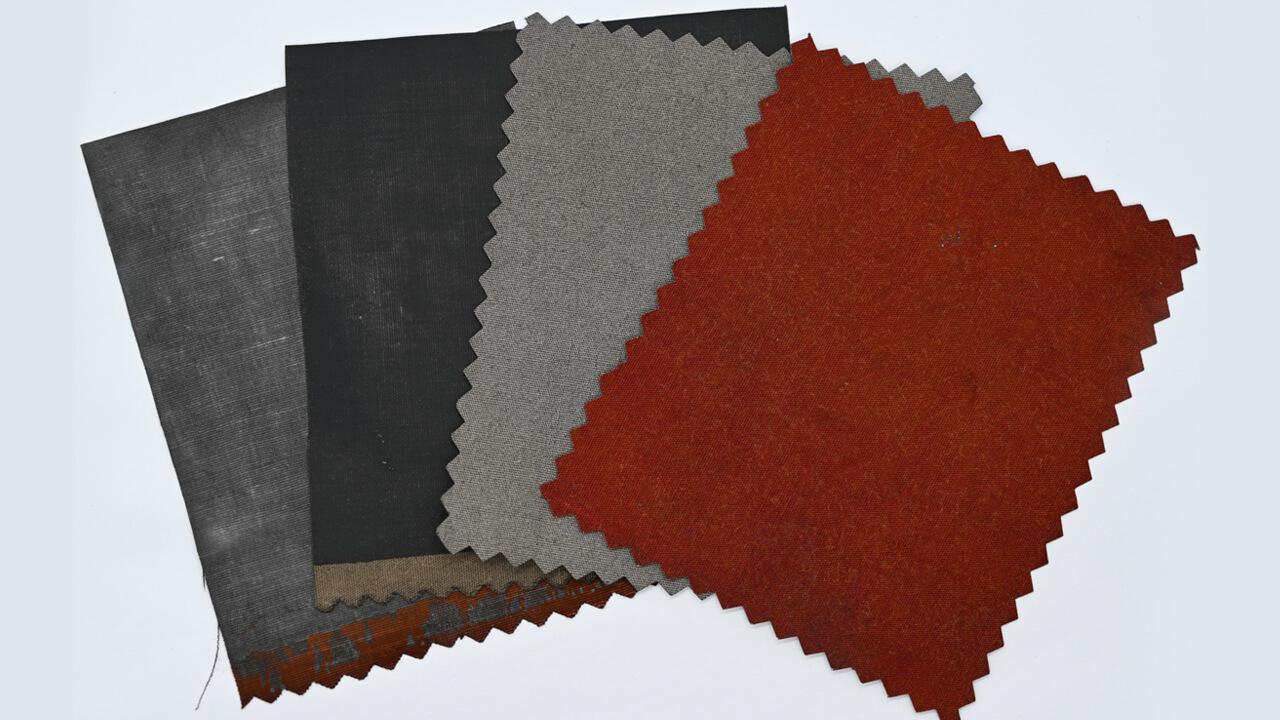

Textile Lithium Battery

Textile Lithium Battery -

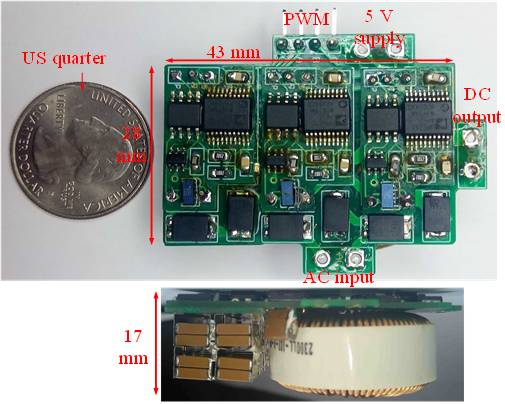

Compact and Efficient Micro-Inverter

Compact and Efficient Micro-Inverter -

Long Lasting Battery for High Power IoT Devices

Long Lasting Battery for High Power IoT Devices -

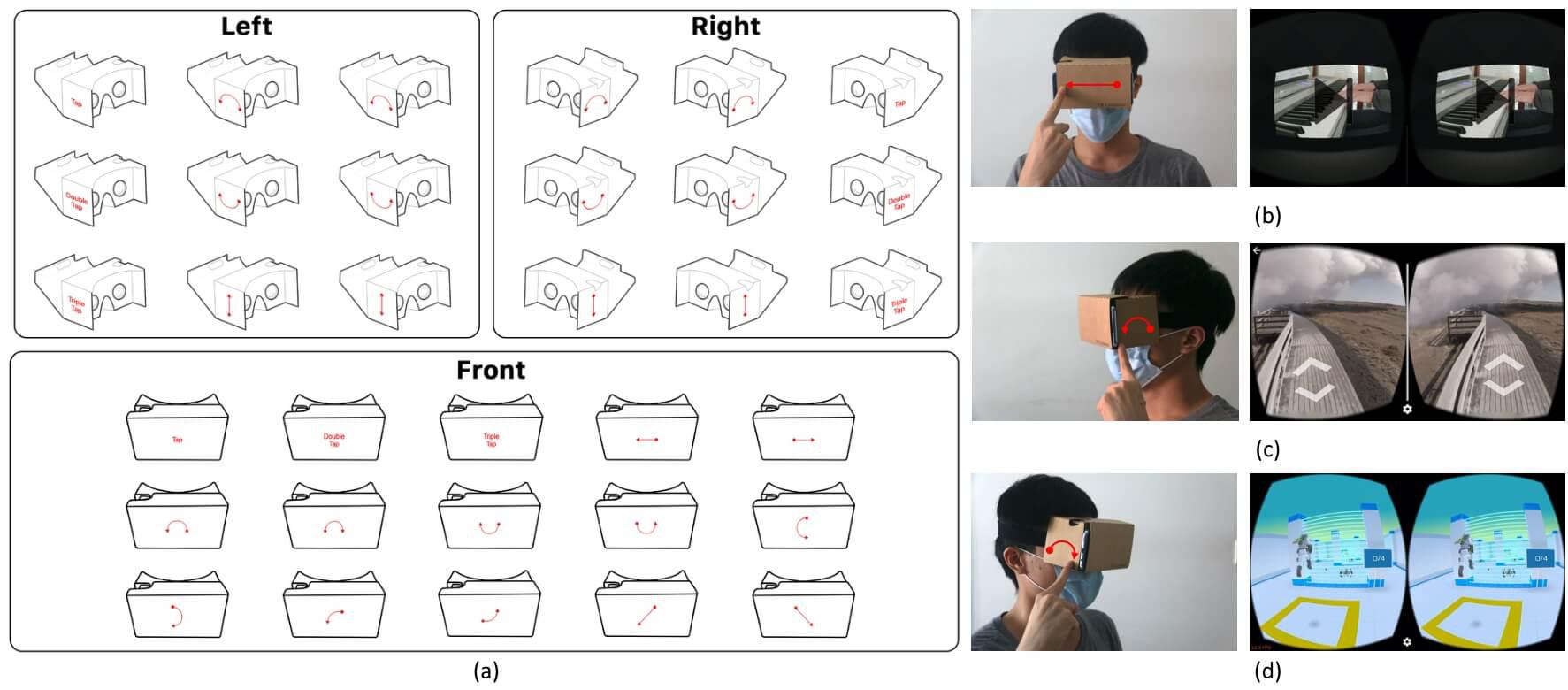

Method of Enabling Gesture-based Interaction on the Surface of a Low-cost VR Head-mounted Display

Method of Enabling Gesture-based Interaction on the Surface of a Low-cost VR Head-mounted Display -

Efficient In-wheel Motor Control

Efficient In-wheel Motor Control -

High-efficient Hydrogen Fuel Cell Hybrid System for Electric Forklifts

High-efficient Hydrogen Fuel Cell Hybrid System for Electric Forklifts -

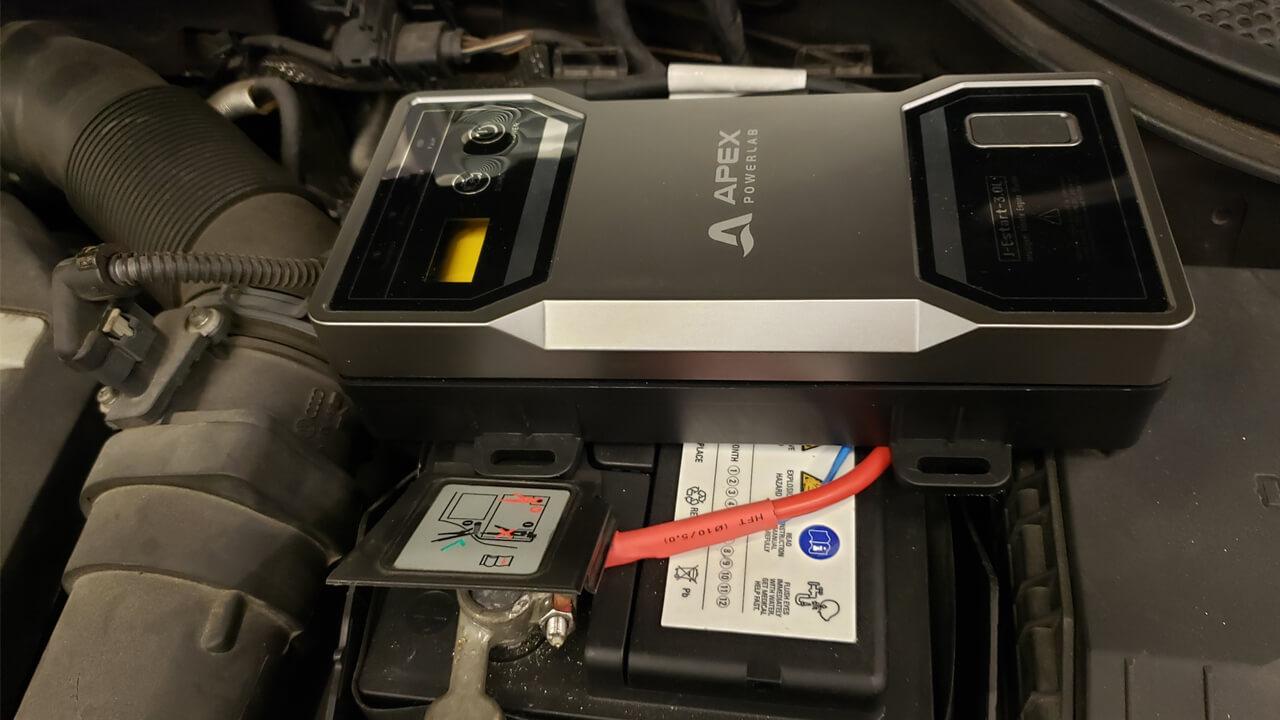

Intelligent Vehicle Engine Starter

Intelligent Vehicle Engine Starter -

Anti-fouling Coating for Electronics

Anti-fouling Coating for Electronics -

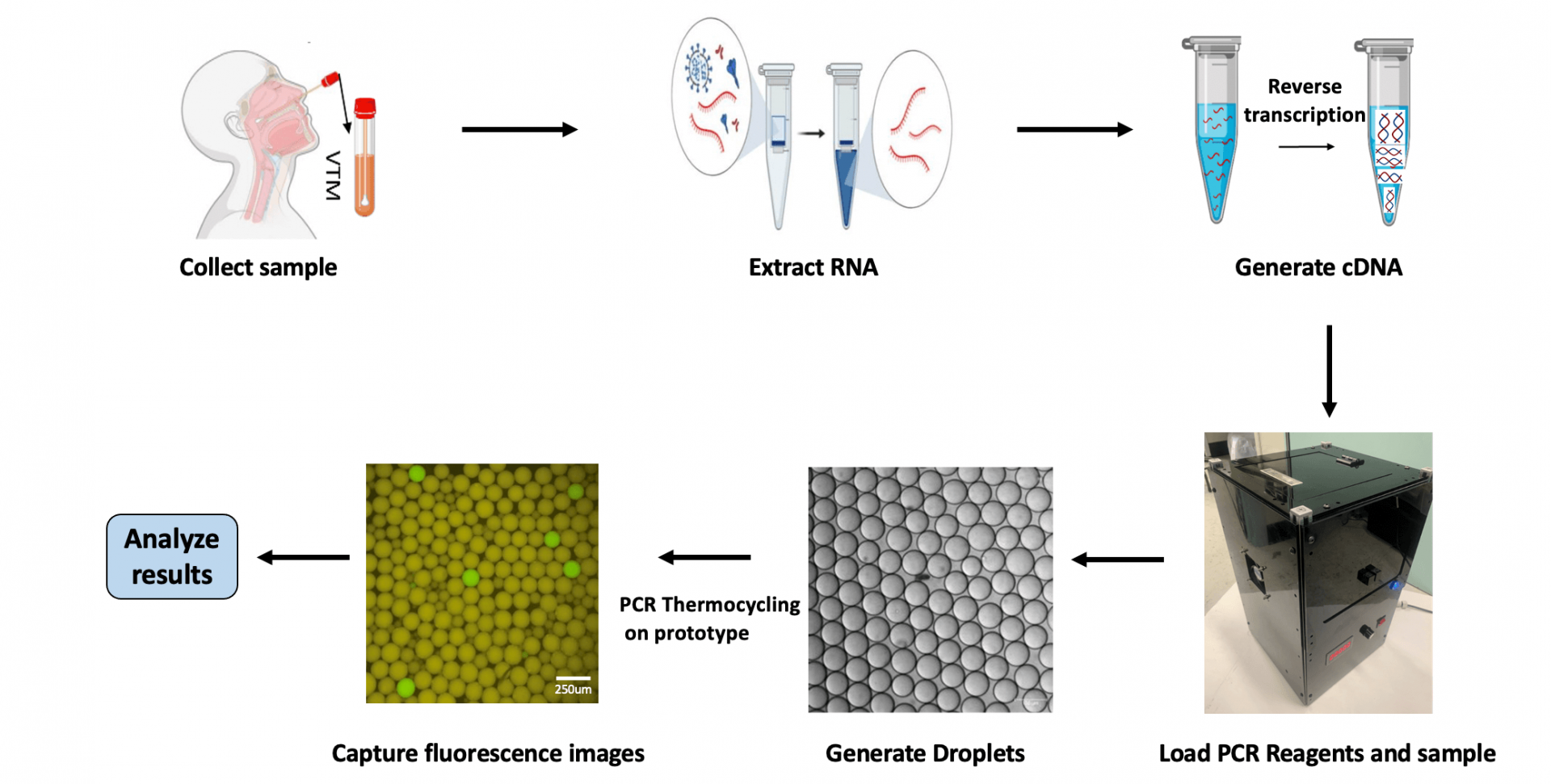

Integrated Digital-PCR-on-a-disc Device

Integrated Digital-PCR-on-a-disc Device -

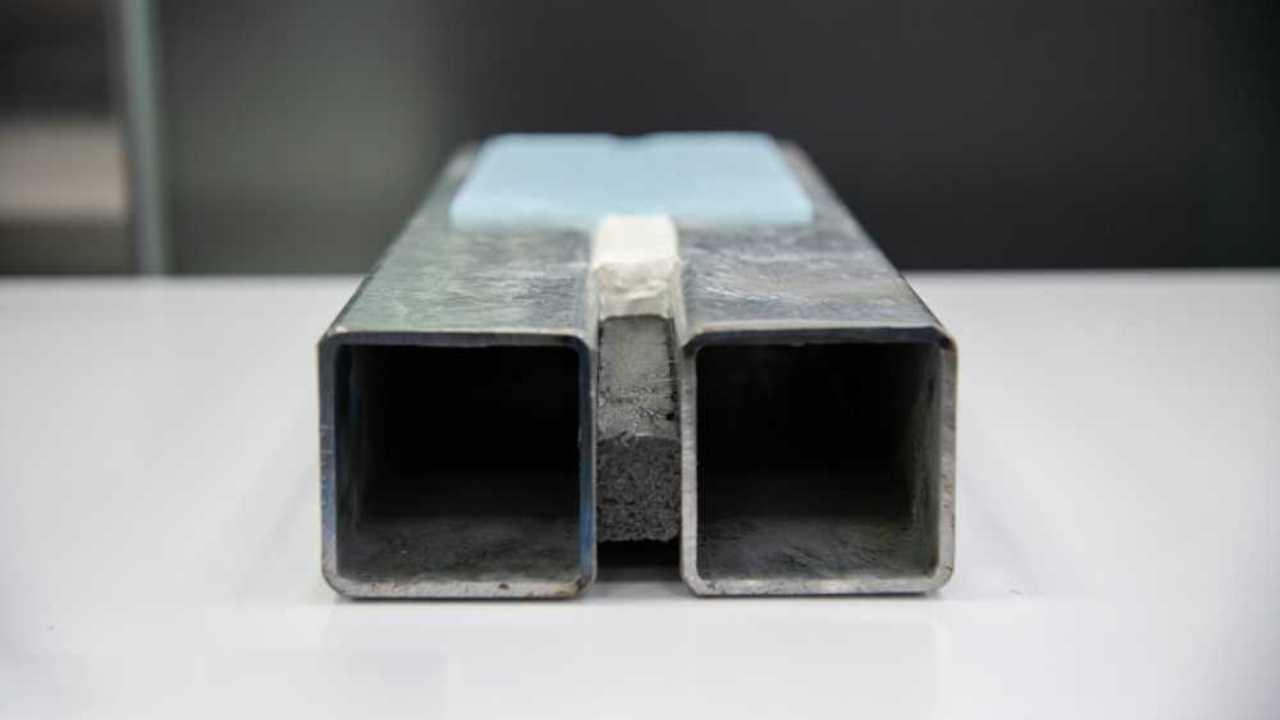

Modular Integrated Construction (MiC) Innovations

Modular Integrated Construction (MiC) Innovations -

High Strength Lightweight Concrete

High Strength Lightweight Concrete -

Fault Tolerant Steer-by-Wire System

Fault Tolerant Steer-by-Wire System -

Anti-reflective, scratch-resistant coating for glasses and plastics

Anti-reflective, scratch-resistant coating for glasses and plastics -

Super Hard nCoating for Multiple Substrates

Super Hard nCoating for Multiple Substrates -

Machining Distortion Minimisation

Machining Distortion Minimisation -

MY-O-Analyser

MY-O-Analyser -

Development of Visible Light Anti-bacteria and Anti-odour Coating Materials for Vehicle Interiors

Development of Visible Light Anti-bacteria and Anti-odour Coating Materials for Vehicle Interiors -

Self-Compacting Backfill Material

Self-Compacting Backfill Material -

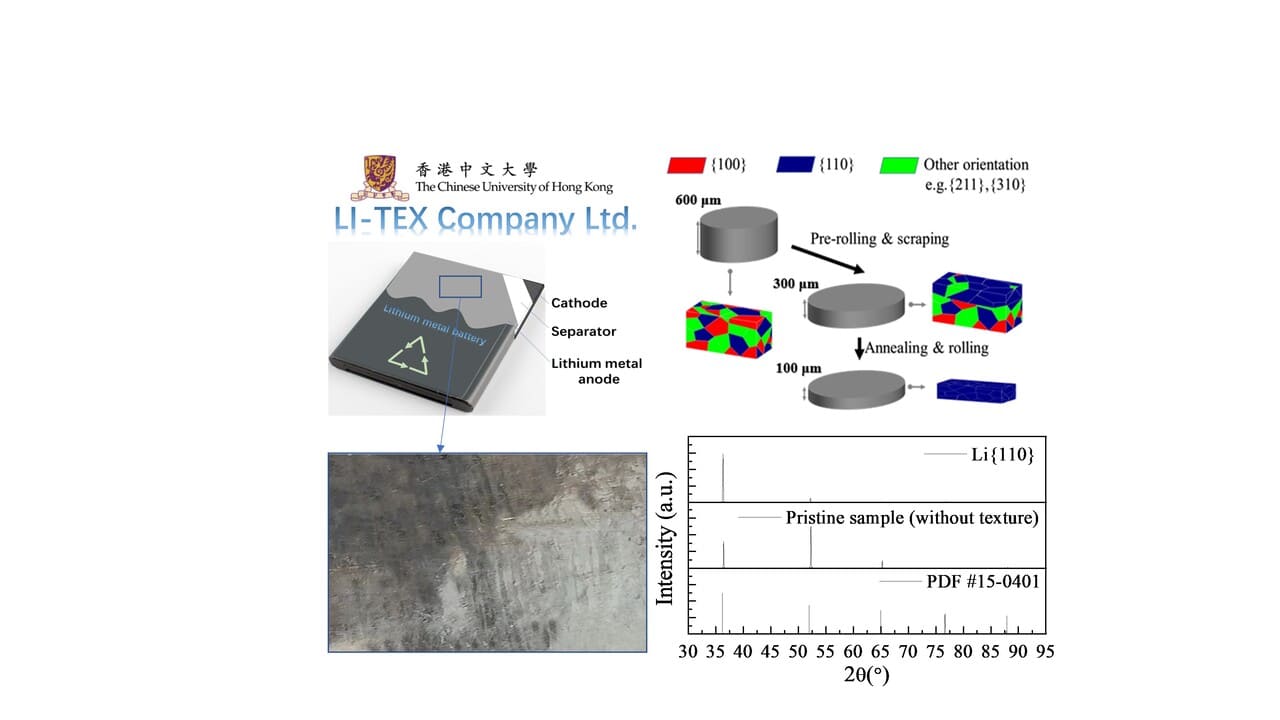

Breaking Barriers in Li-based Energy Storage: {110} Textured Li Metal Foil Anode

Breaking Barriers in Li-based Energy Storage: {110} Textured Li Metal Foil Anode -

Smart Street Lighting System

Smart Street Lighting System -

Copper-based Air Filter with Fast Virus Inactivation Ability

Copper-based Air Filter with Fast Virus Inactivation Ability -

Hydrogen Fuel Cell EV Charger

Hydrogen Fuel Cell EV Charger -

NAMI's Smart Protection Materials

NAMI's Smart Protection Materials -

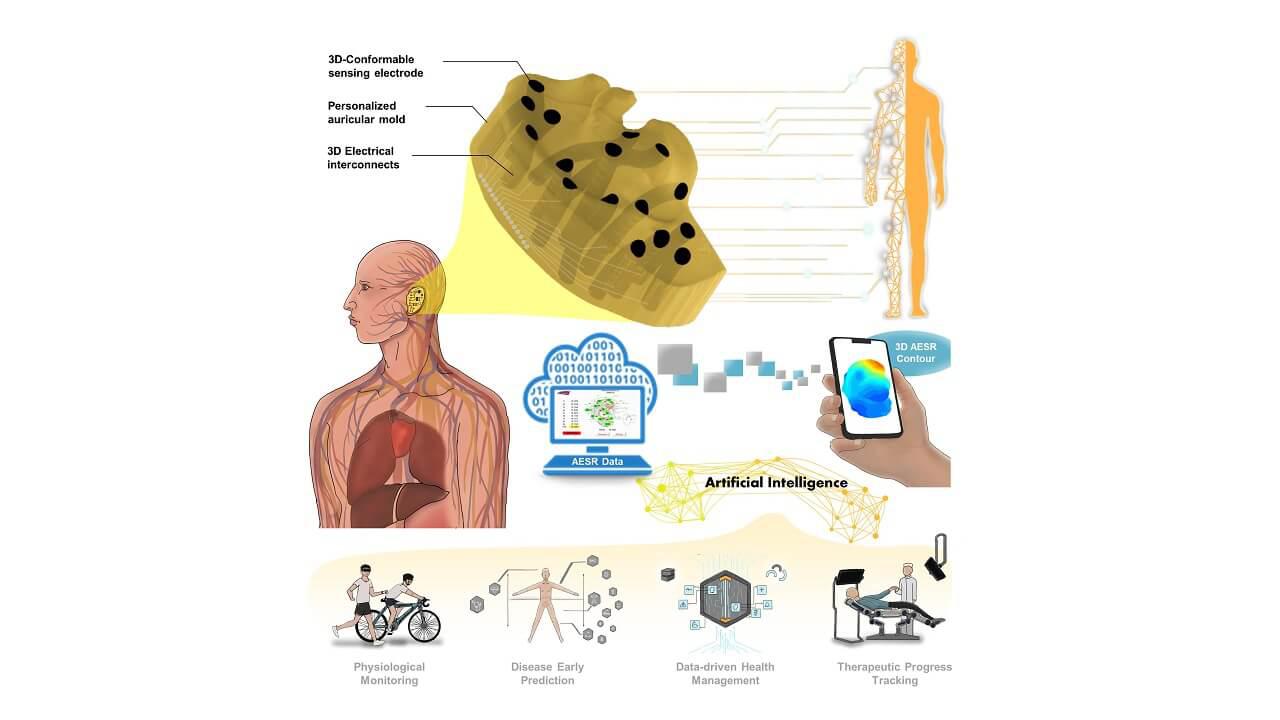

Wearable Full-Auricle Diagnostic and Therapeutic Device

Wearable Full-Auricle Diagnostic and Therapeutic Device -

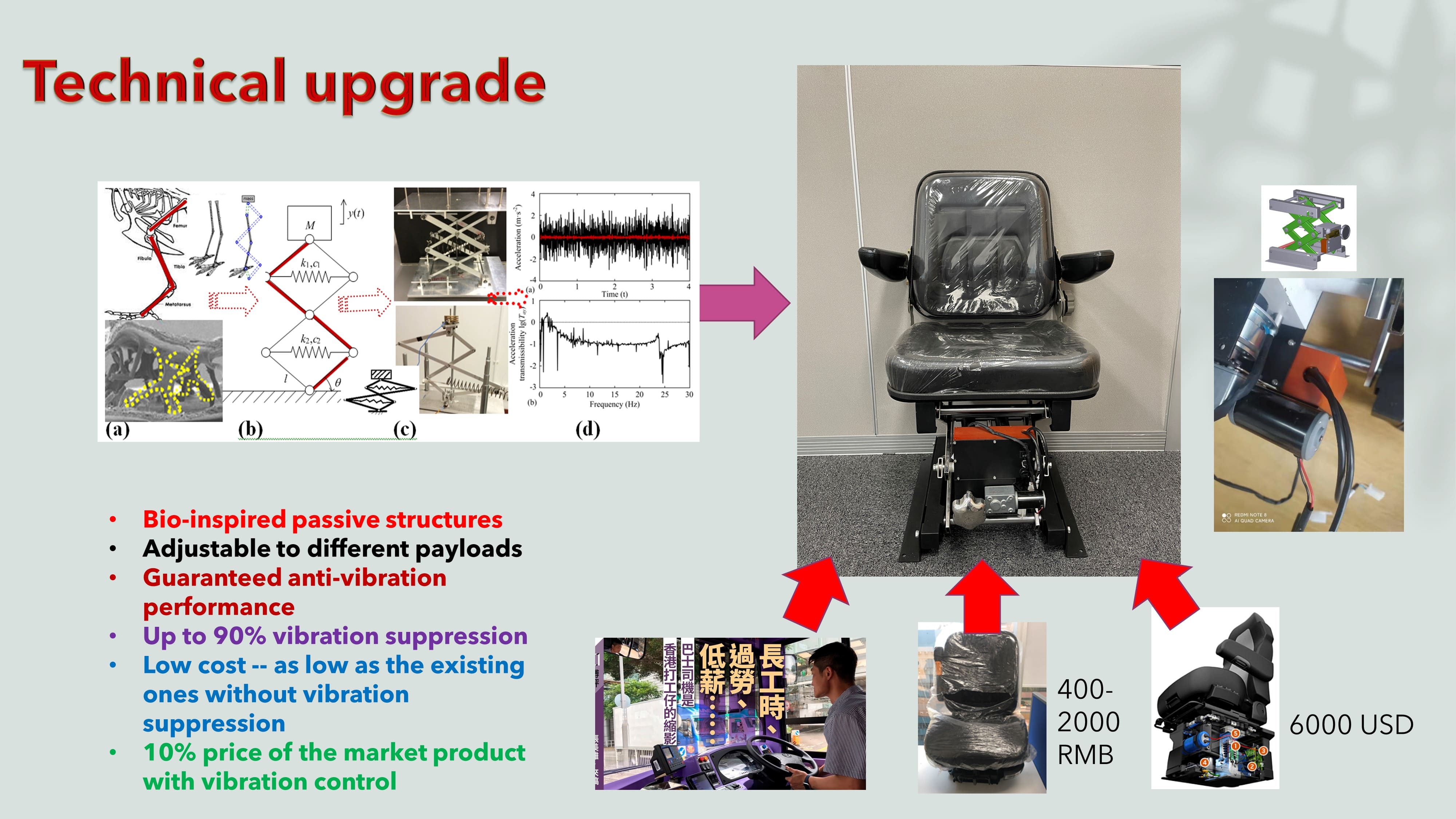

New-Gen Anti-Vibration X-Seating Technology

New-Gen Anti-Vibration X-Seating Technology -

Solid-state Electrolyte for Lithium Batteries

Solid-state Electrolyte for Lithium Batteries -

Flexible transparent electrode

Flexible transparent electrode -

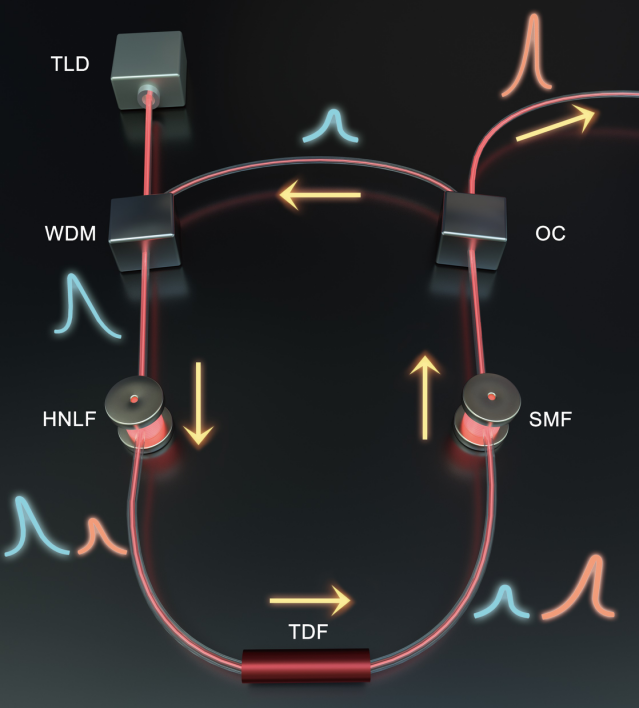

Hybrid Optical Parametrically-Oscillating Emitter (HOPE)

Hybrid Optical Parametrically-Oscillating Emitter (HOPE) -

Non-invasive Cable Energization Status Identification and Operation State Monitoring System

Non-invasive Cable Energization Status Identification and Operation State Monitoring System -

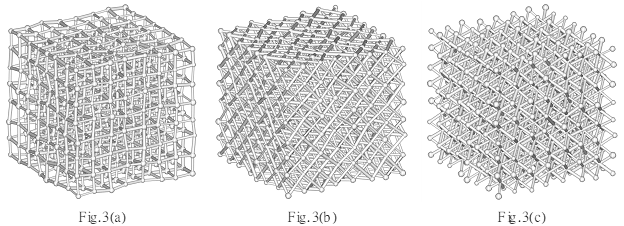

High-entropy Lattice achieved by 3D printing

High-entropy Lattice achieved by 3D printing -

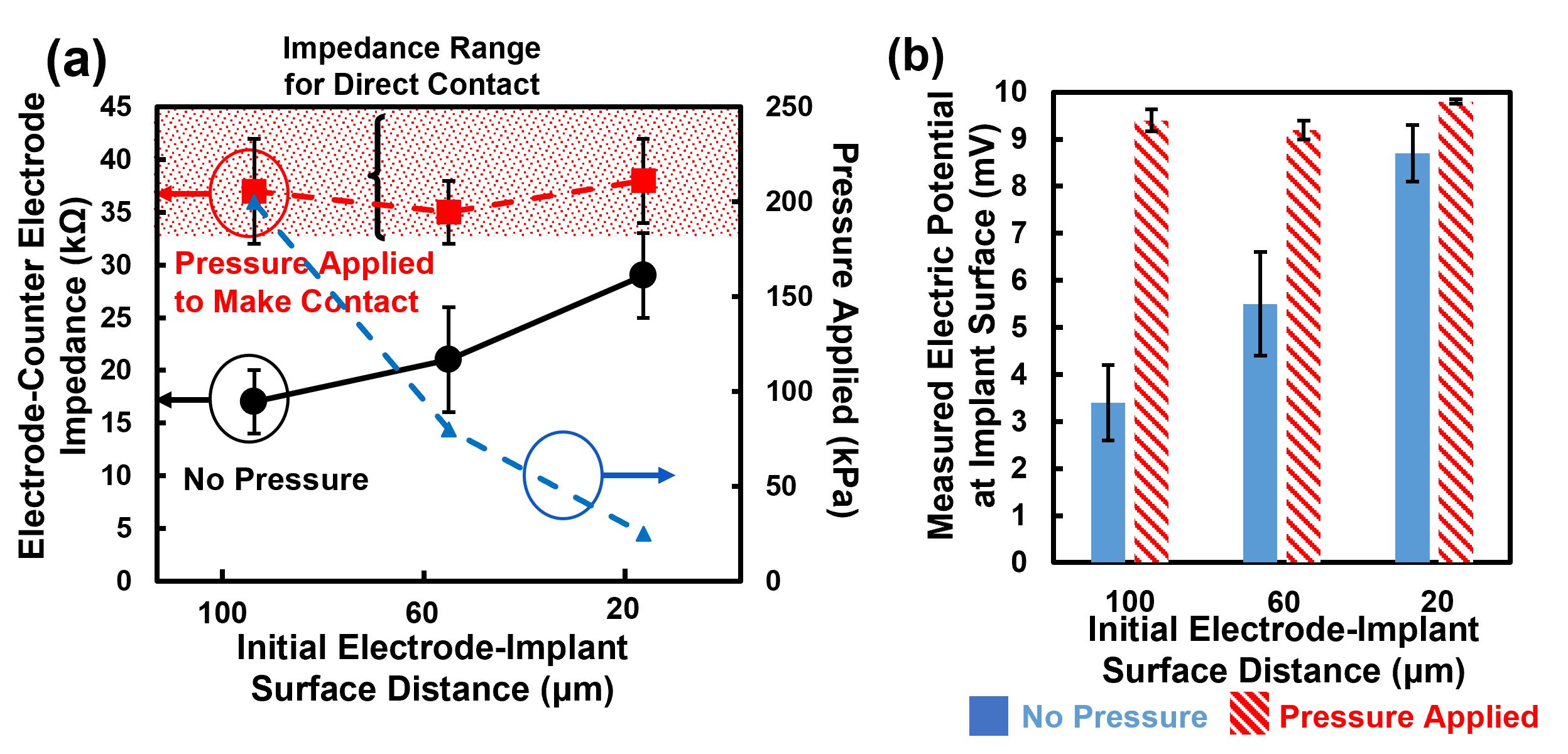

Neural Implant with Dynamic Electrode Position Control

Neural Implant with Dynamic Electrode Position Control -

MagiCurl – A STEM Kit for Learning Shape Memory Materials

MagiCurl – A STEM Kit for Learning Shape Memory Materials -

Mobilised EV Charging Service Vehicle and Combo Fast Charging Station

Mobilised EV Charging Service Vehicle and Combo Fast Charging Station -

Smart EV Charging Station

Smart EV Charging Station -

Ultra-hard, Anti-scratch Sapphire Thin Film Technology

Ultra-hard, Anti-scratch Sapphire Thin Film Technology -

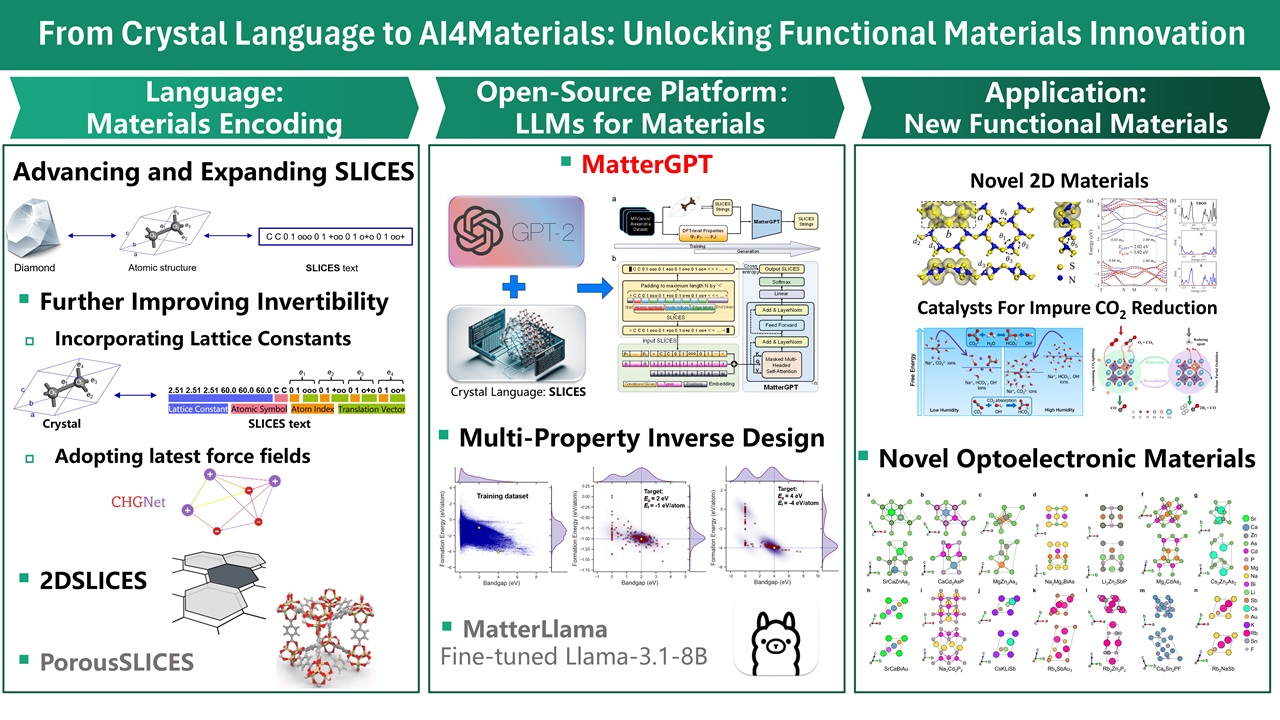

MatterGPT: AI-Powered Platform for Smart Material Design and Innovation

MatterGPT: AI-Powered Platform for Smart Material Design and Innovation -

Micro-LED Full Colour Micro-display Technology

Micro-LED Full Colour Micro-display Technology -

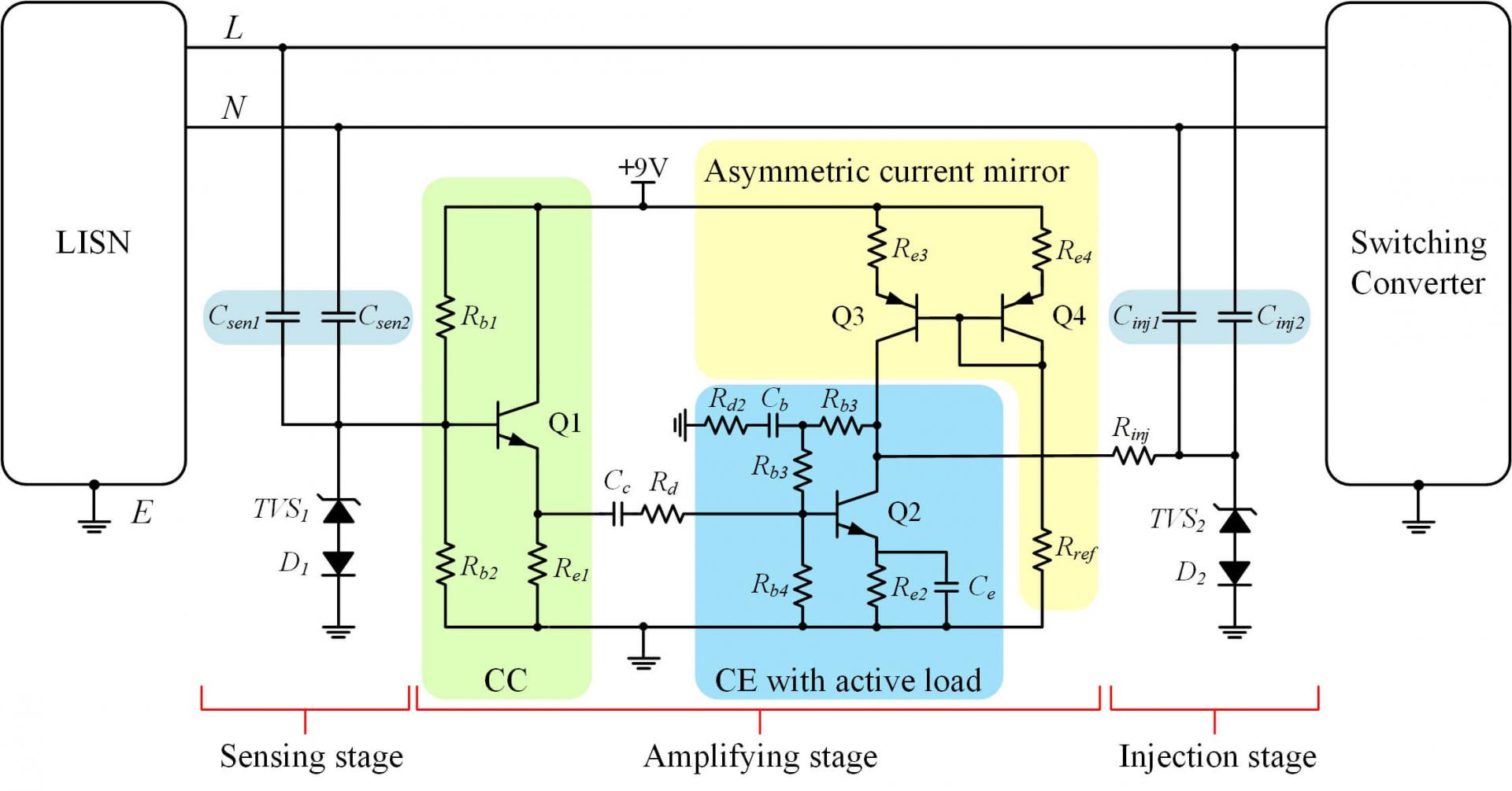

High-Attenuation Wideband Active Common-Mode EMI Filter Section

High-Attenuation Wideband Active Common-Mode EMI Filter Section -

Smart Pier and Coastal Structure Monitoring System

Smart Pier and Coastal Structure Monitoring System -

Large Area, Highly-Flexible Metamaterials for Potential Application in Organic Electronics

Large Area, Highly-Flexible Metamaterials for Potential Application in Organic Electronics -

New Generation Advanced Motorcycle Electronic Fuel Injection System

New Generation Advanced Motorcycle Electronic Fuel Injection System -

All-Liquid Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Device

All-Liquid Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Device -

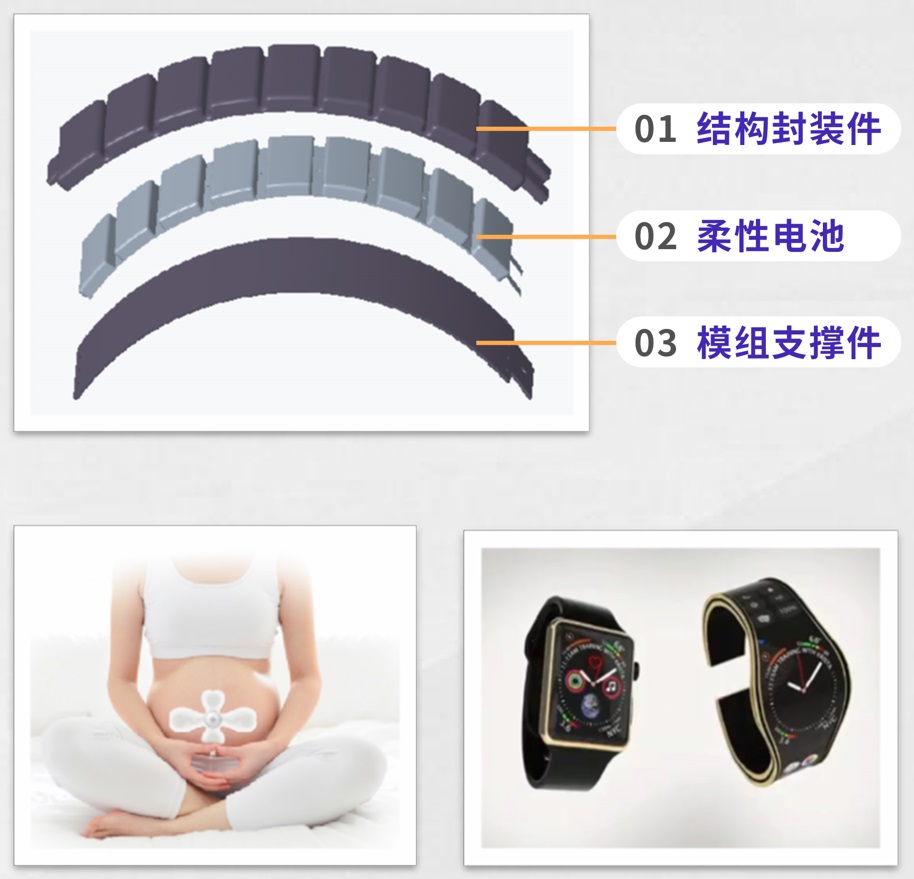

Flexible battery

Flexible battery -

Acoustic Metamaterials

Acoustic Metamaterials -

Electric Powertrain with Integrated Three-speed Automatic Transmission

Electric Powertrain with Integrated Three-speed Automatic Transmission -

Autonomous Vehicle

Autonomous Vehicle -

Hybrid Moulding Technologies with Effective Adhesion/Bonding Mechanism

Hybrid Moulding Technologies with Effective Adhesion/Bonding Mechanism -

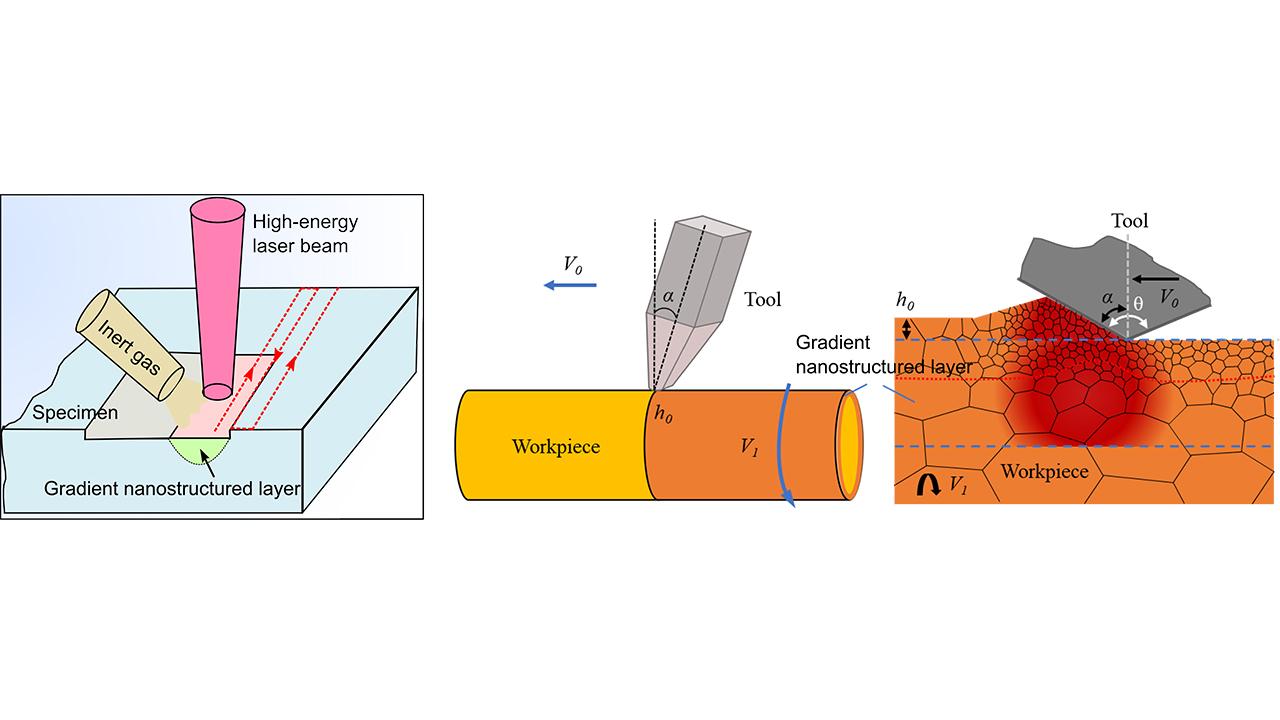

Advanced Surface Treatment Platforms for Superior-performance Gradient Nanostructured Steels

Advanced Surface Treatment Platforms for Superior-performance Gradient Nanostructured Steels