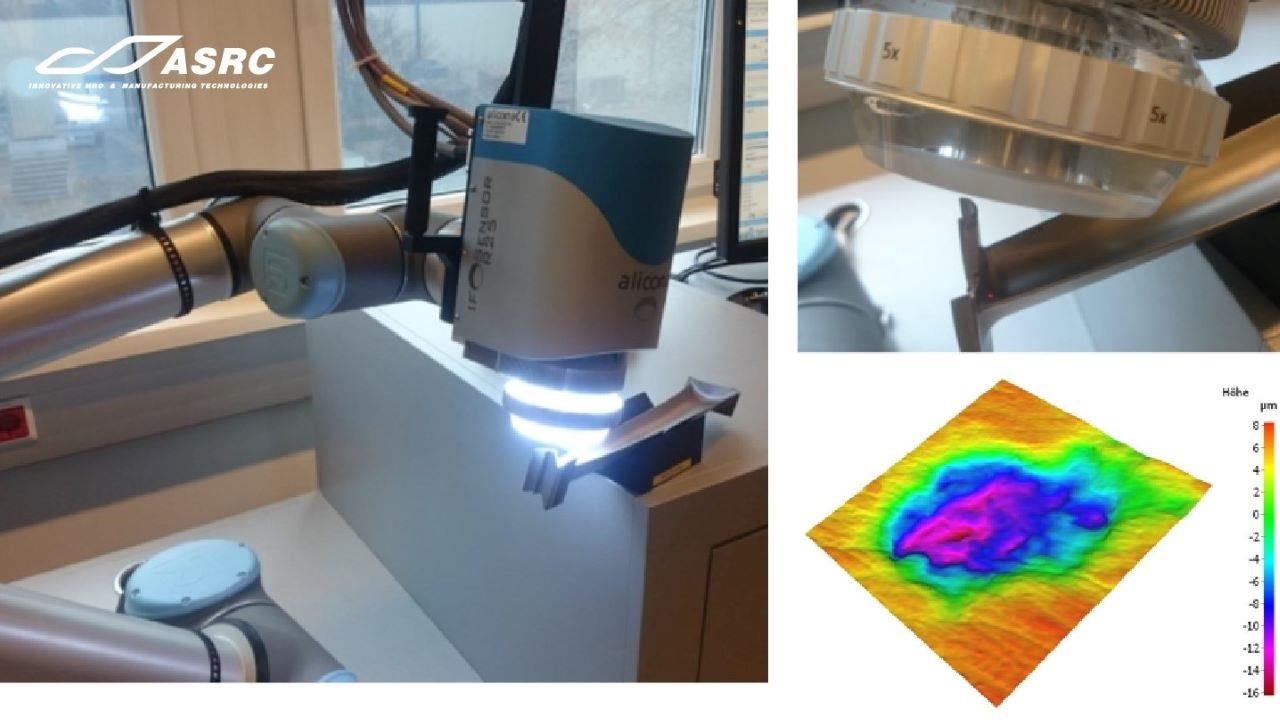

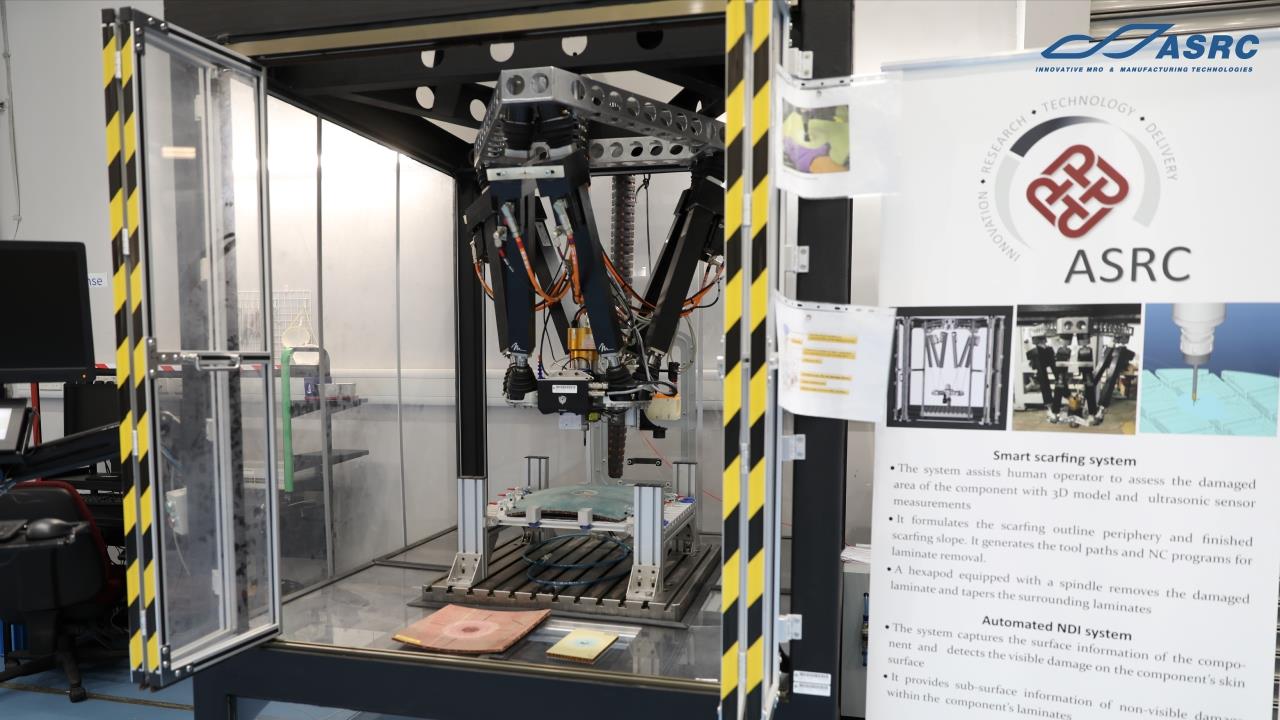

Aircraft Damage Inspection and Assessment

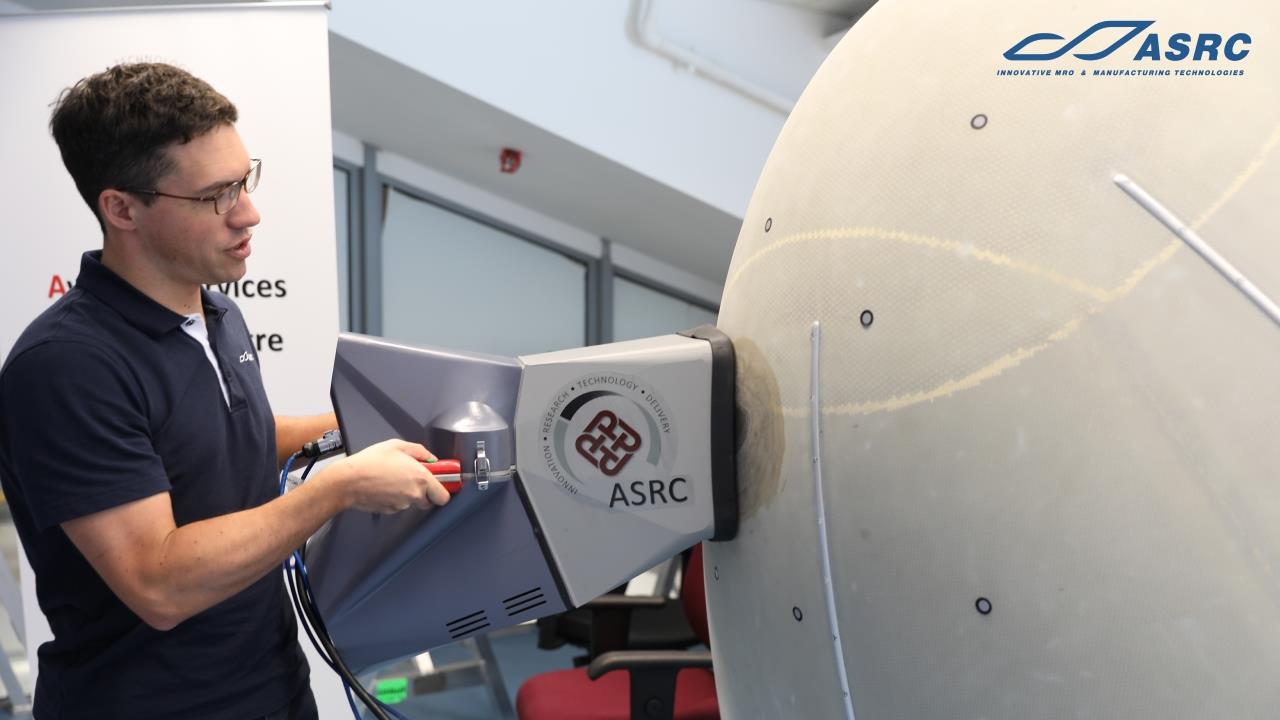

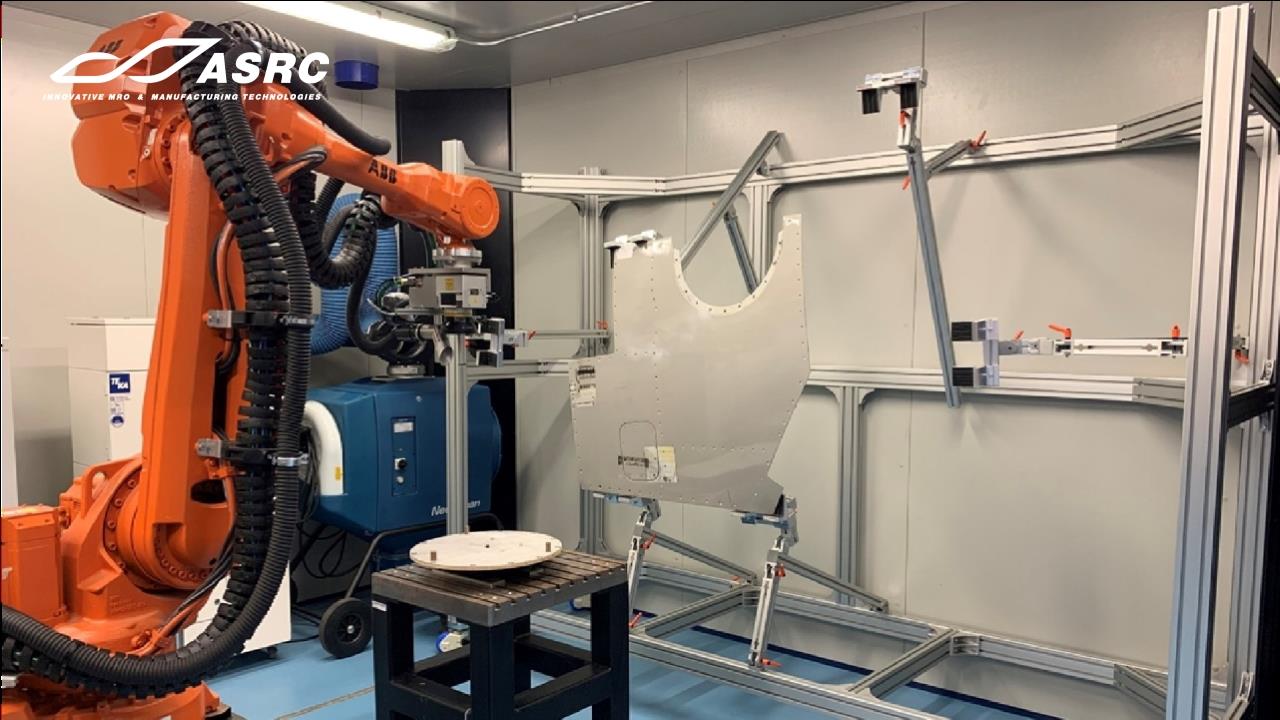

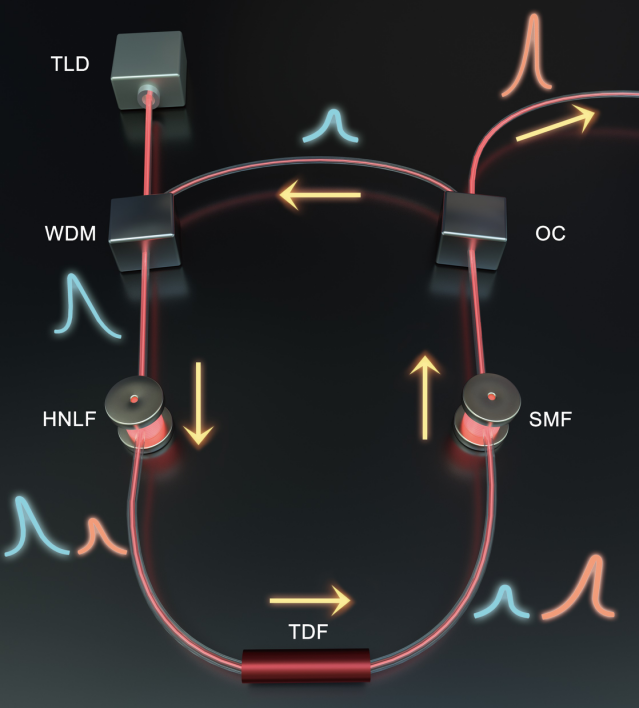

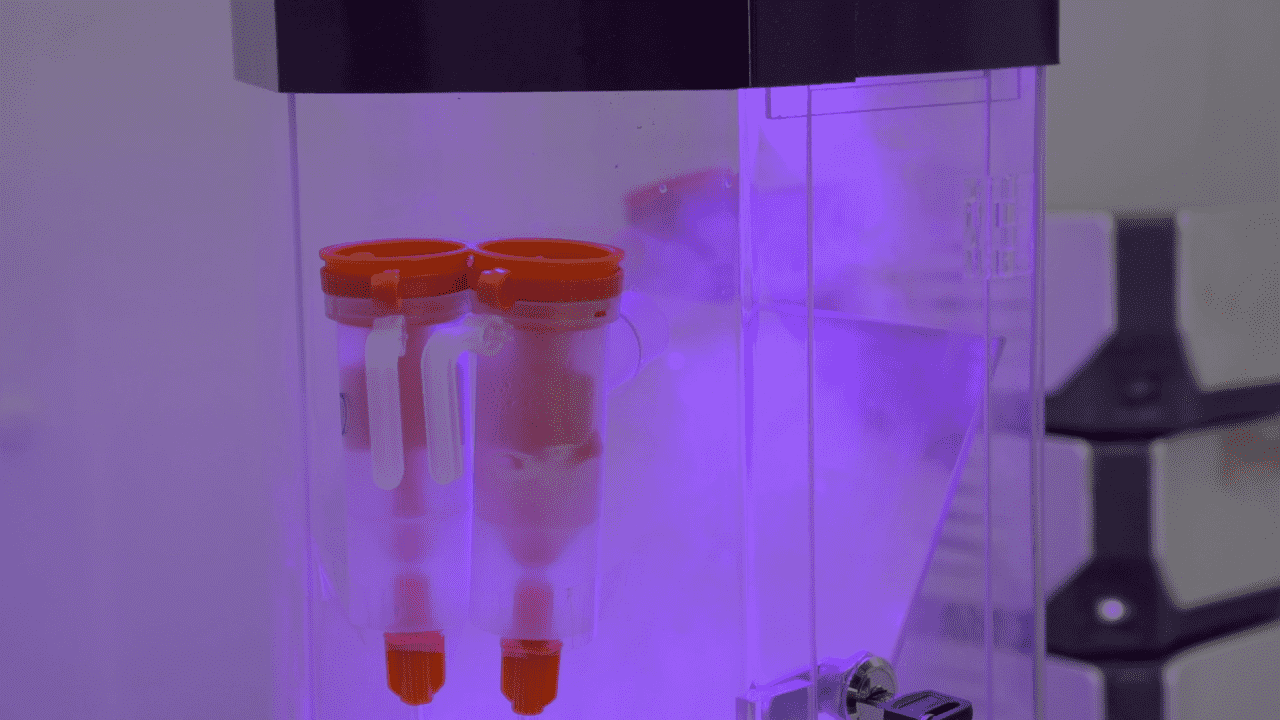

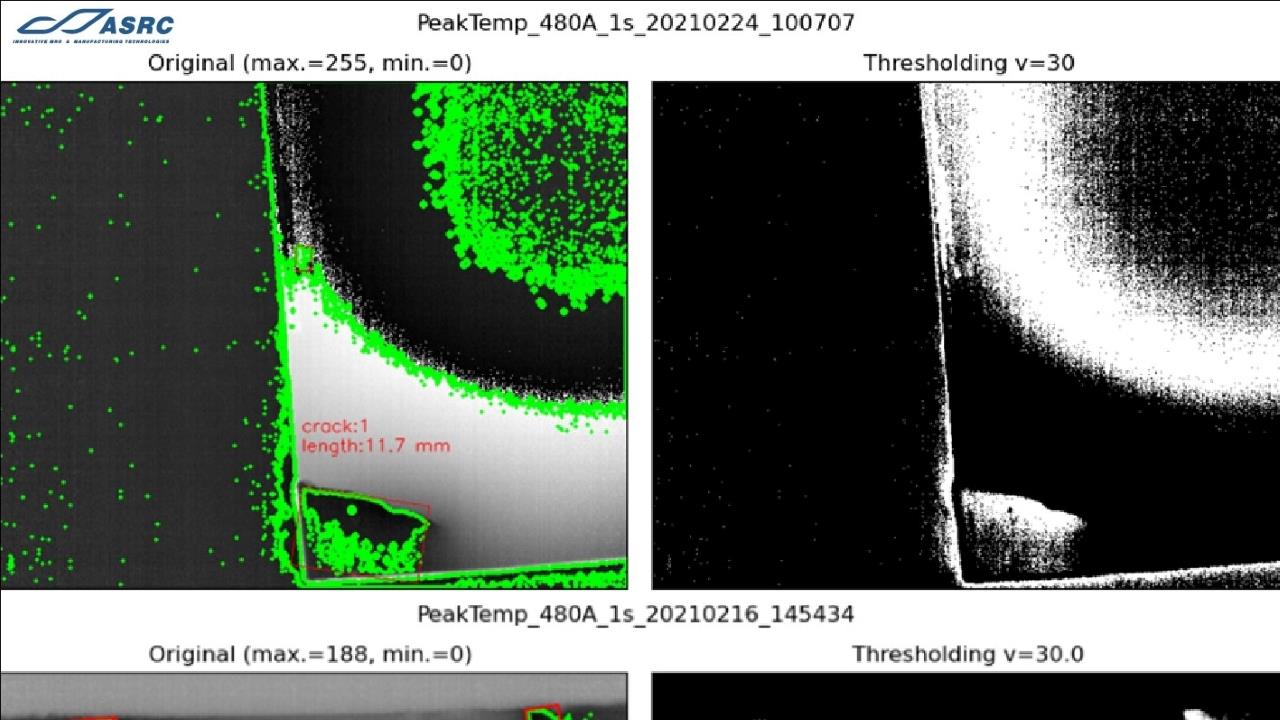

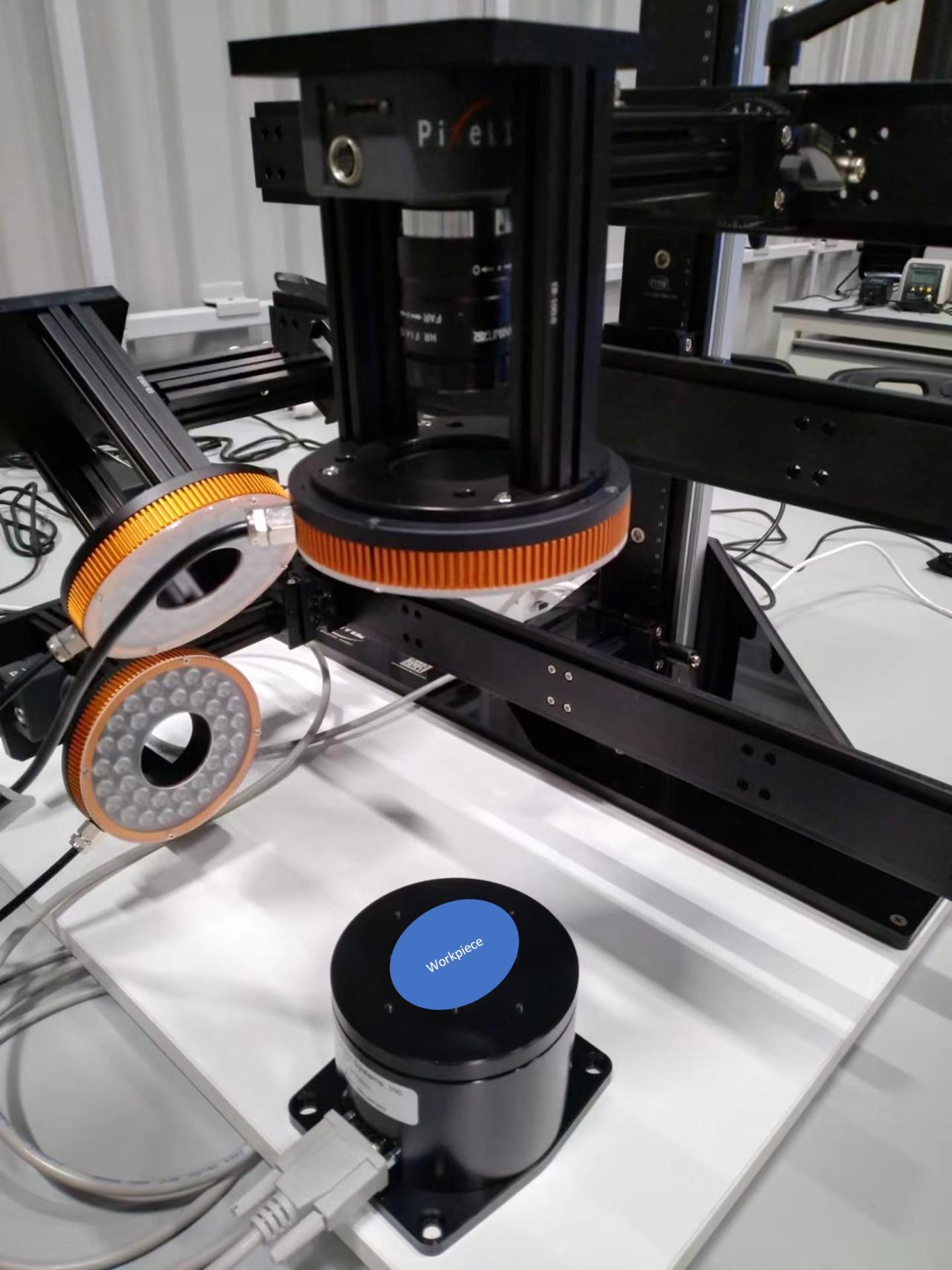

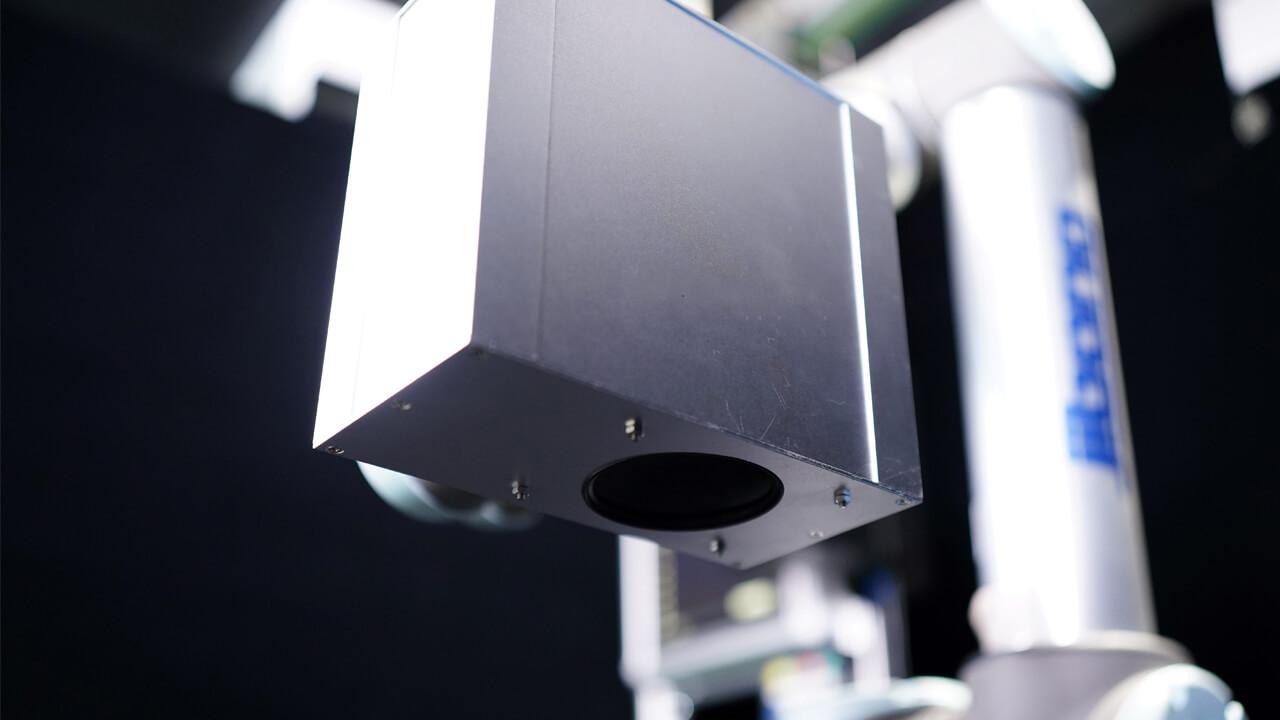

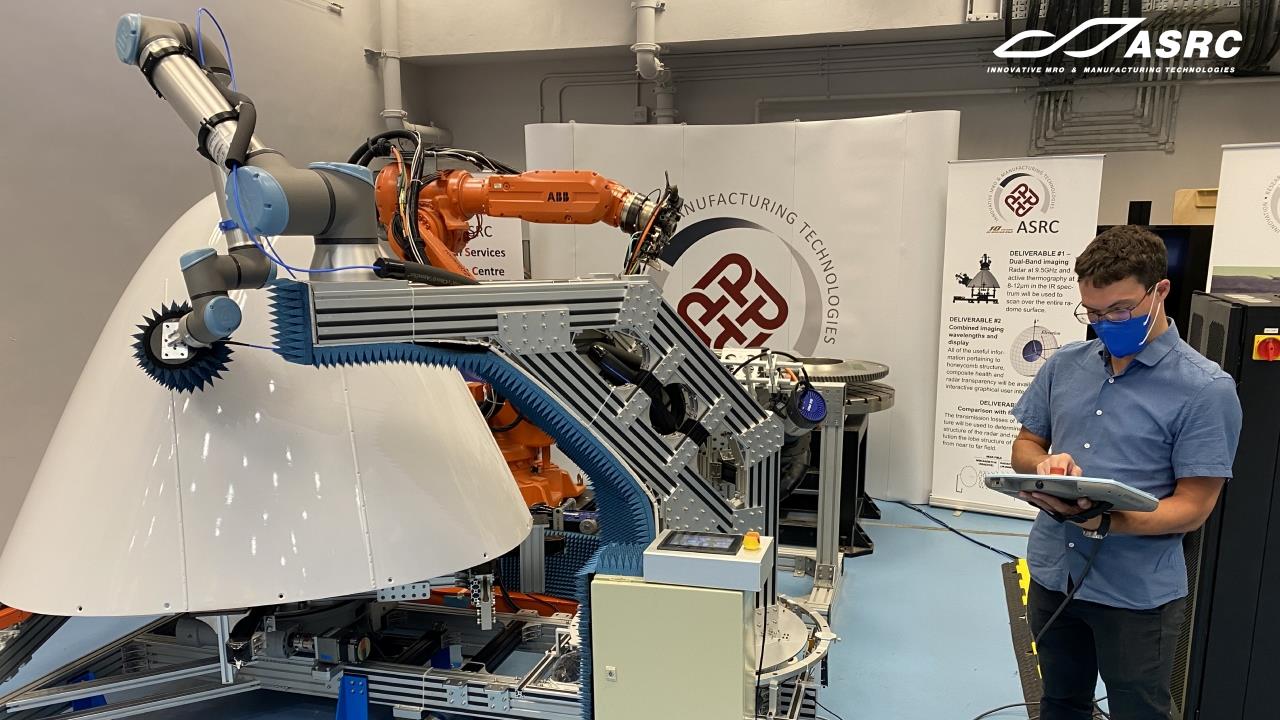

The PolyU Aviation Services Research Centre (ASRC) has developed a device that can produce a 3D model of the surface and subsurface of a region on an aircraft or other area. This technology allows engineers to determine the extent of damage that has occurred. The device uses surface scanning combined with subsurface imaging by active thermography to create the 3D model.

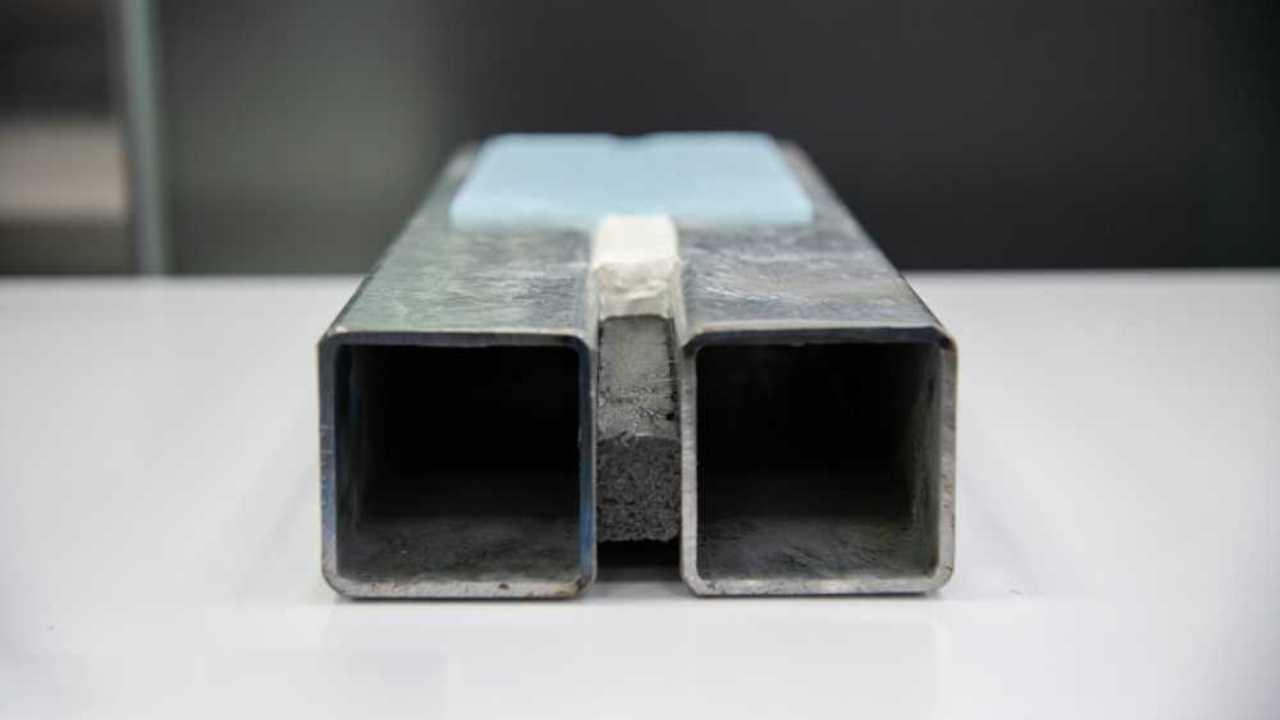

Lightning strikes occur on aircraft roughly once per year. After a lightning strike occurs, the aircraft must be inspected to determine the level of damage that has occurred. It is important to establish whether the damage has broken the electrical connections that make the aircraft lightning safe.

- The combination of 3D surface scanning with subsurface imaging is a novel 'one shot' approach to aircraft inspection. The device also includes a simple visual camera to identify the area on the airframe that has been recorded.

- The software used to create the volumetric image was developed in-house to control the flash thermography process.

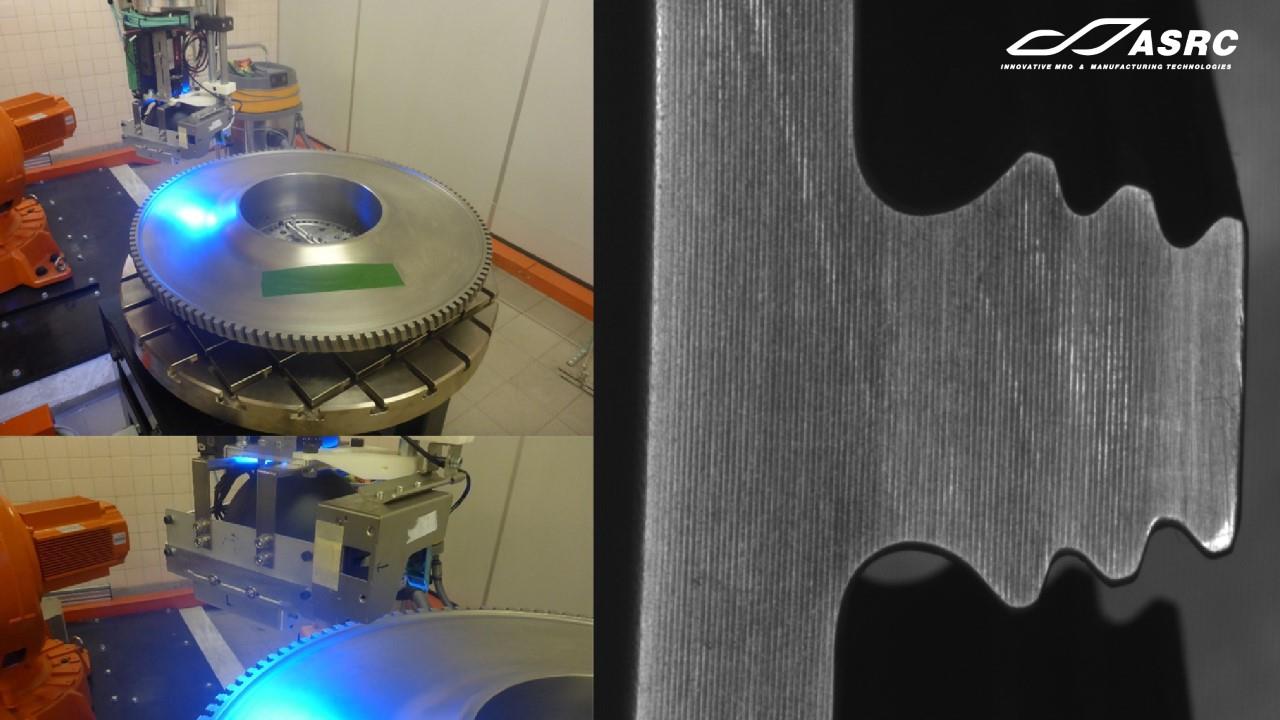

- Engineers can obtain a volumetric image of the damaged site, allowing them to inspect the subsurface condition for delamination, debonding, or other damage.

- The test is fully deterministic, meaning that it does not rely on the skills of an ultrasound technician to interpret the results of the inspection.

- Comapred with an ultrasound test, which requires considerable interpretation, the volumetric image provides a clear picture of damage both on the surface and subsurface.

- Applications go beyond aircraft maintenance: the device can also be used in other industries including automotive tech and marine inspections.

- Can be used for other kinds of aerospace inspections: the flash thermography tech was used on the space shuttle return-to-flight programme.

- Can also be used for generic composite material testing, making it a valuable tool for inspecting the hulls of racing or pleasure yachts. These high-value items can have significant insurance and repair costs.

- The subsurfaces of opaque structures such as walls and other parts of buildings may be investigated if the flash is bright enough.

Patent

- Software and integration of the features with analysis may make this a patentable product.

With over 80 years of proud tradition and ranking among the world’s top 100 institutions, The Hong Kong Polytechnic University (PolyU) aspires to be a leading university with world-class research and education.

PolyU is a home for educating thinkers, discoverers, innovators and communicators in delivering positive impact. We are committed to nurturing tomorrow’s leaders today, through a holistic education that provides graduates unrivaled placements to thrive in communities, industries and businesses.