Automated Surface Preparation and Inspection

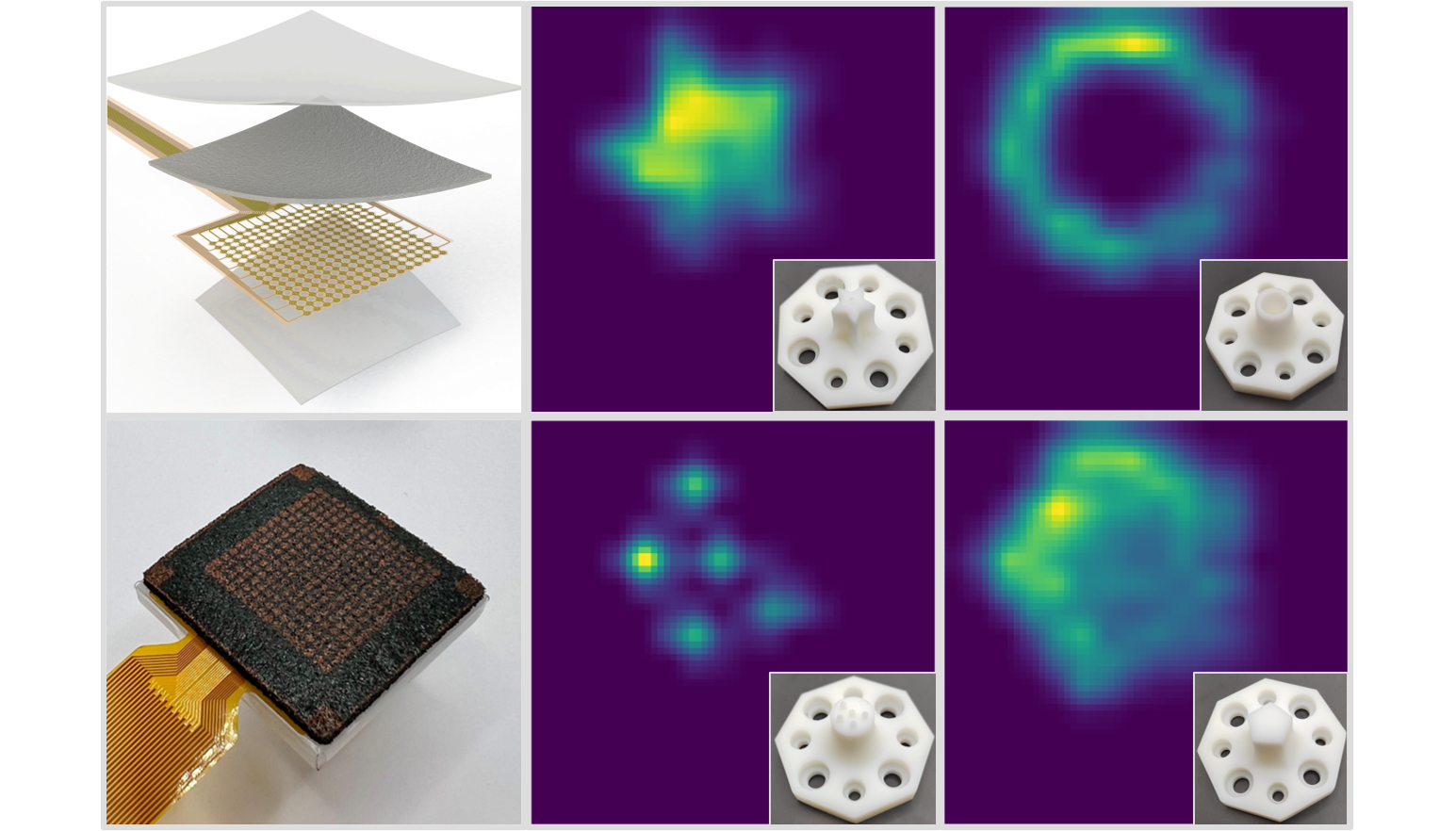

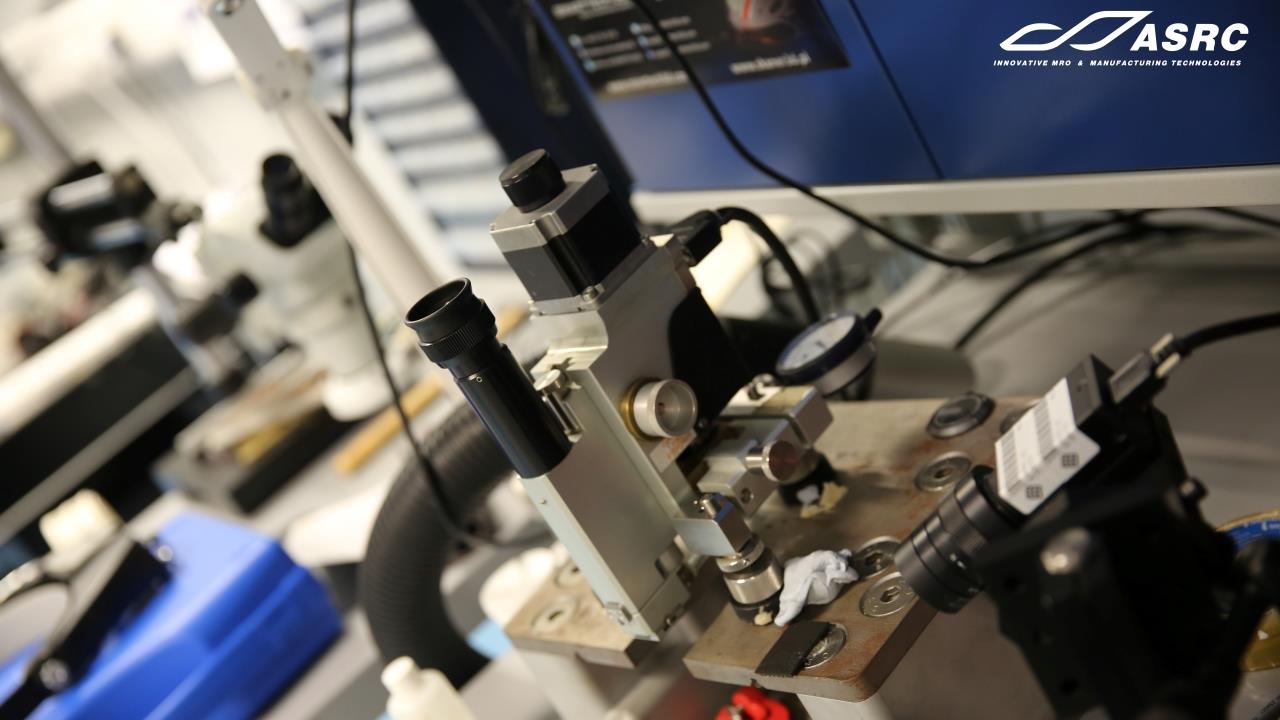

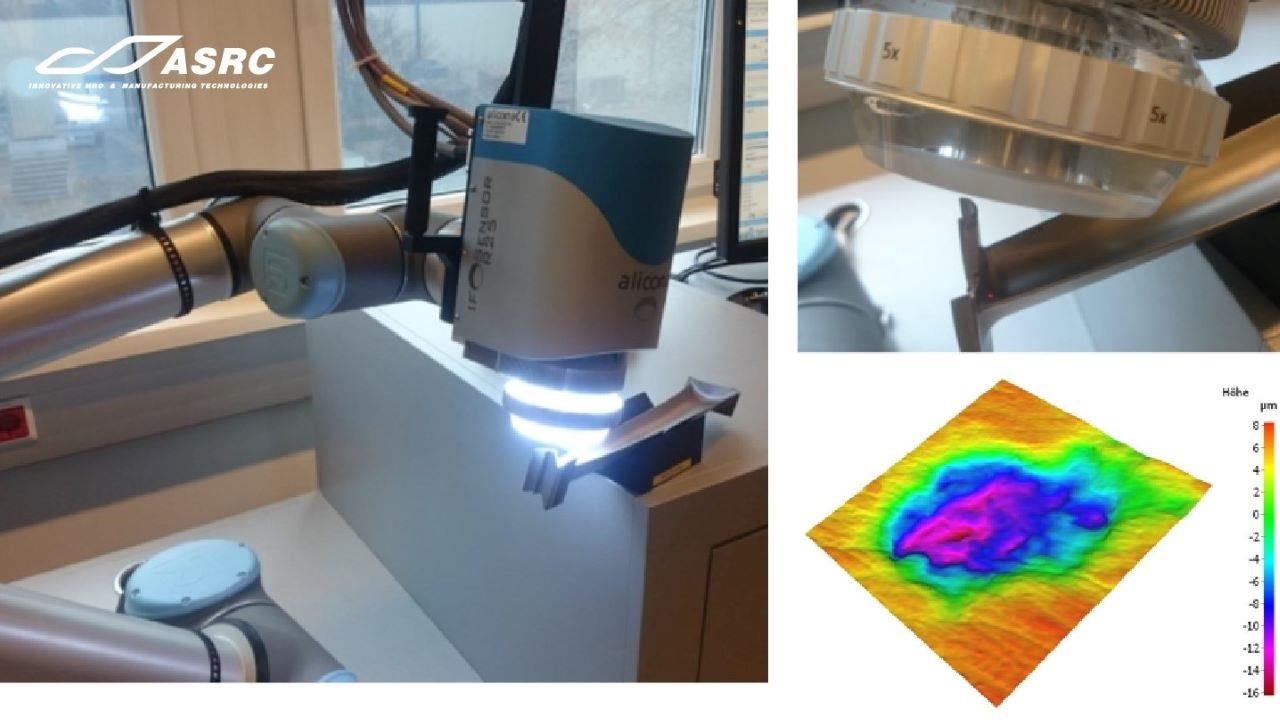

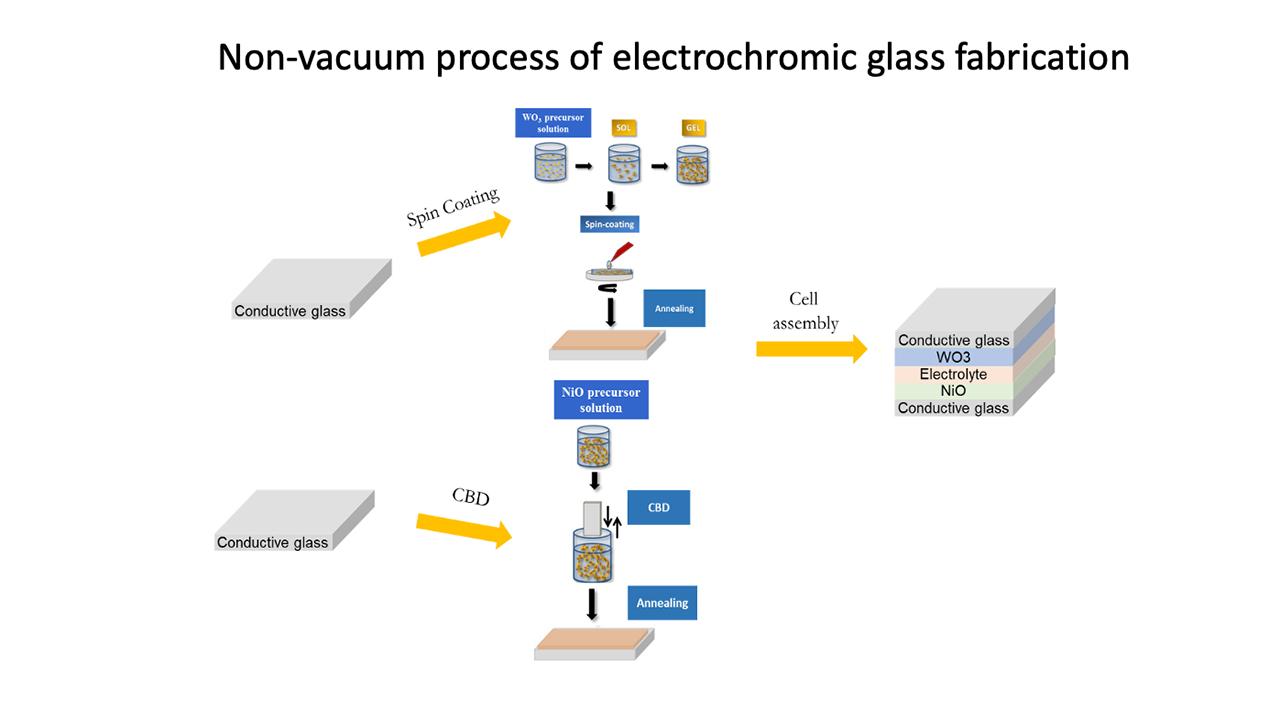

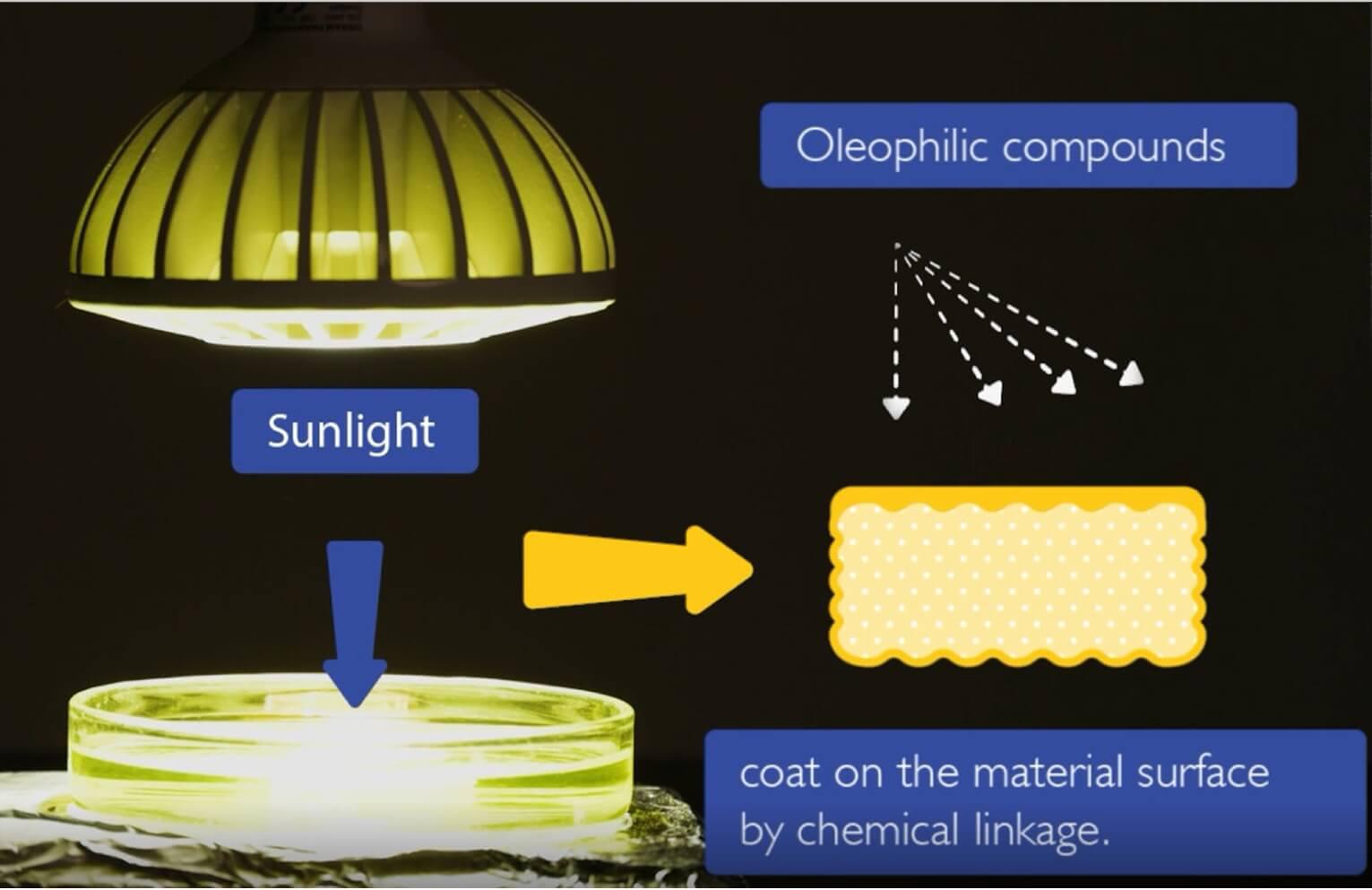

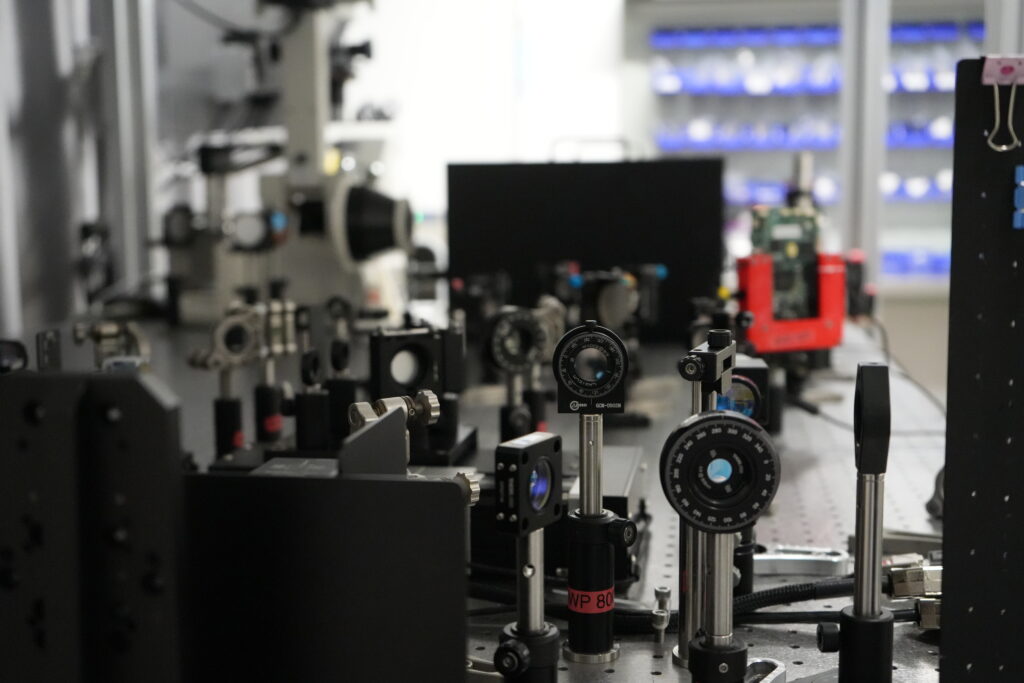

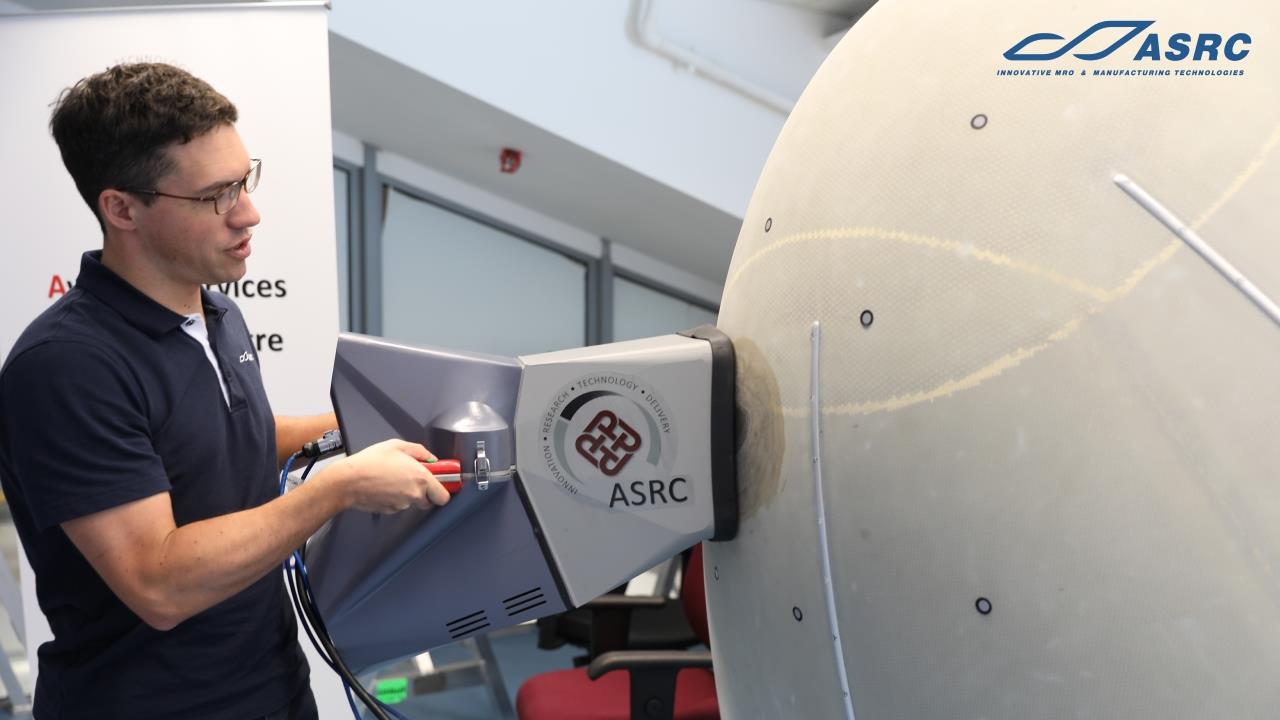

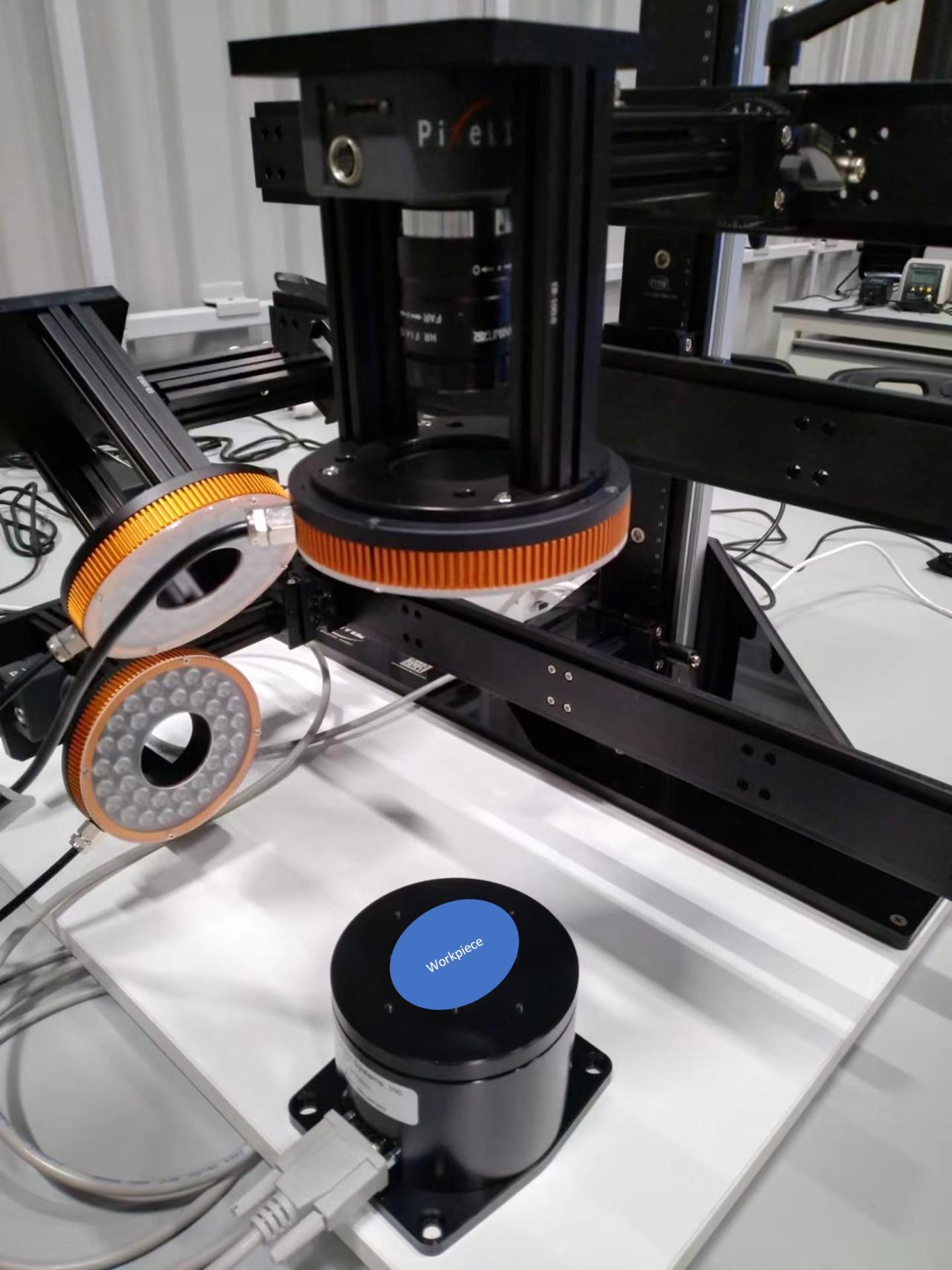

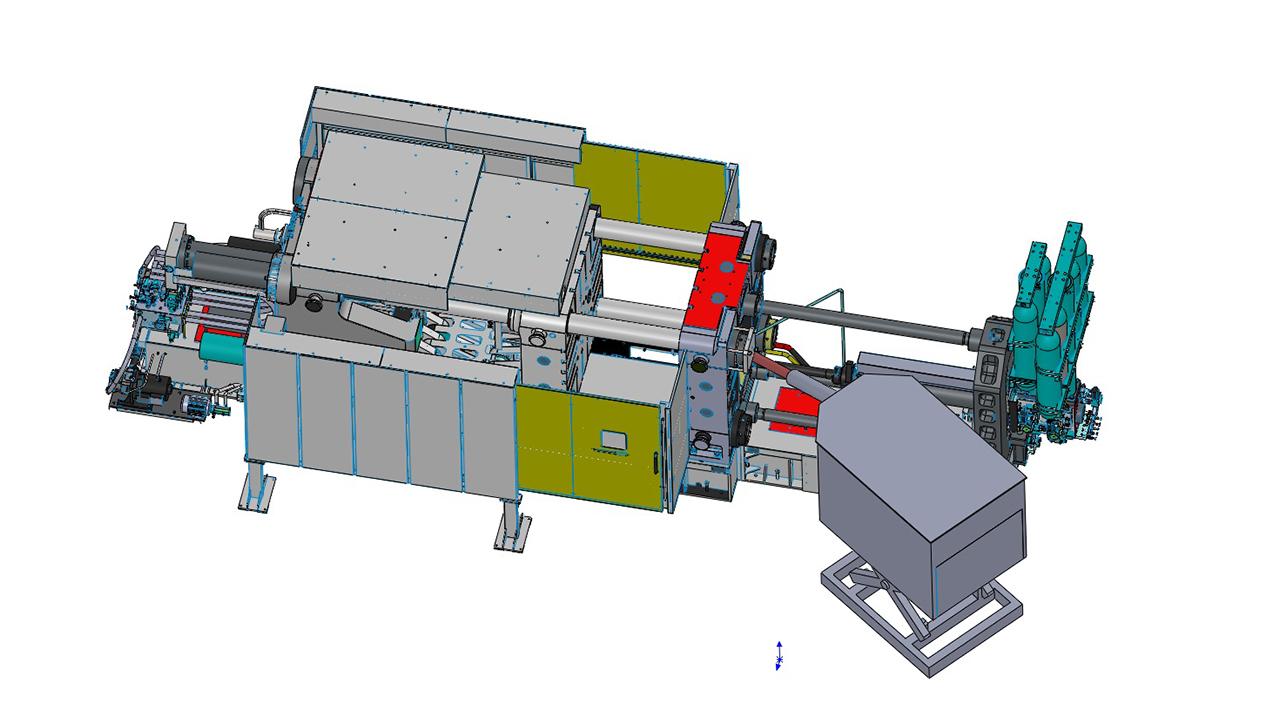

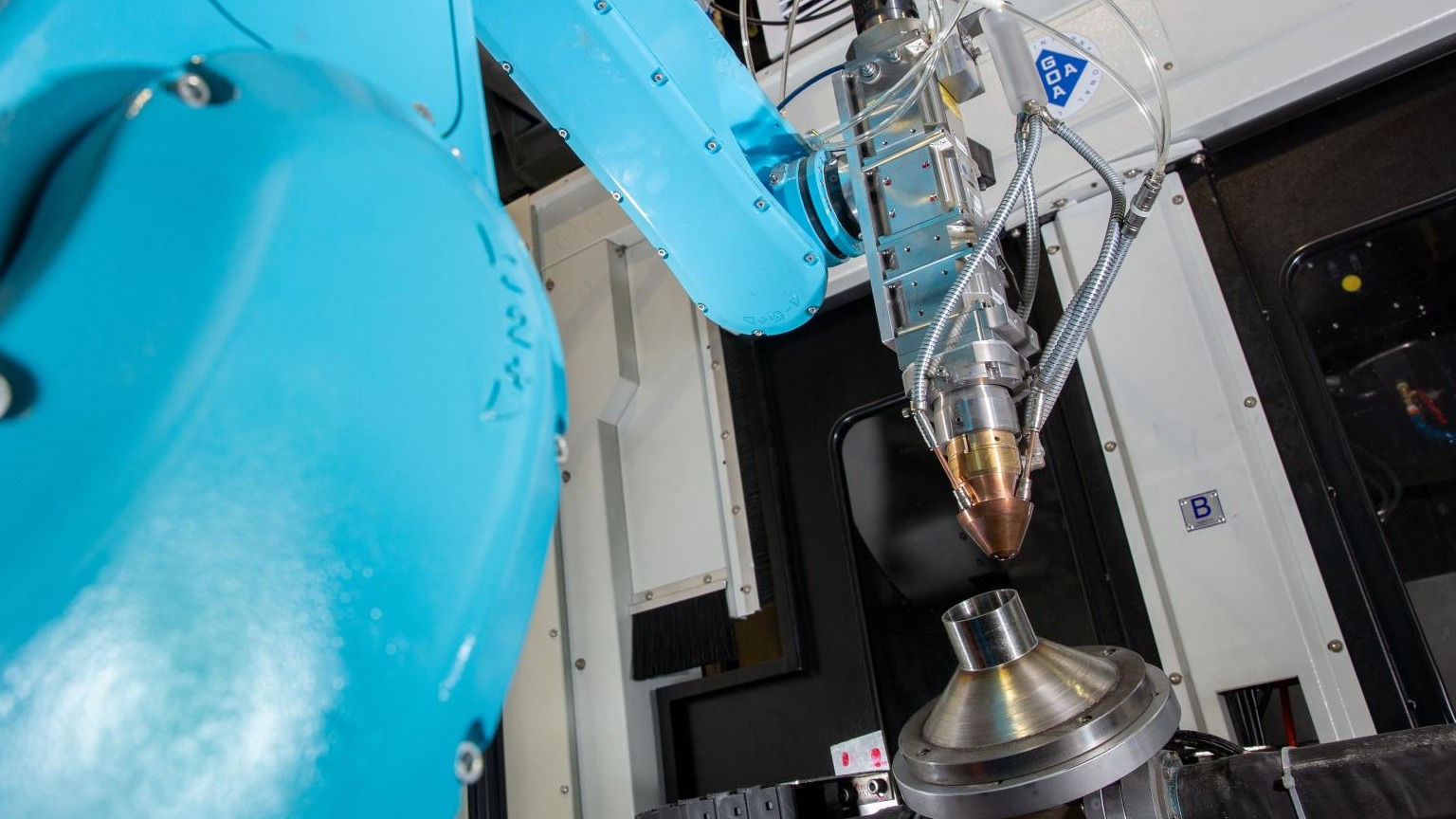

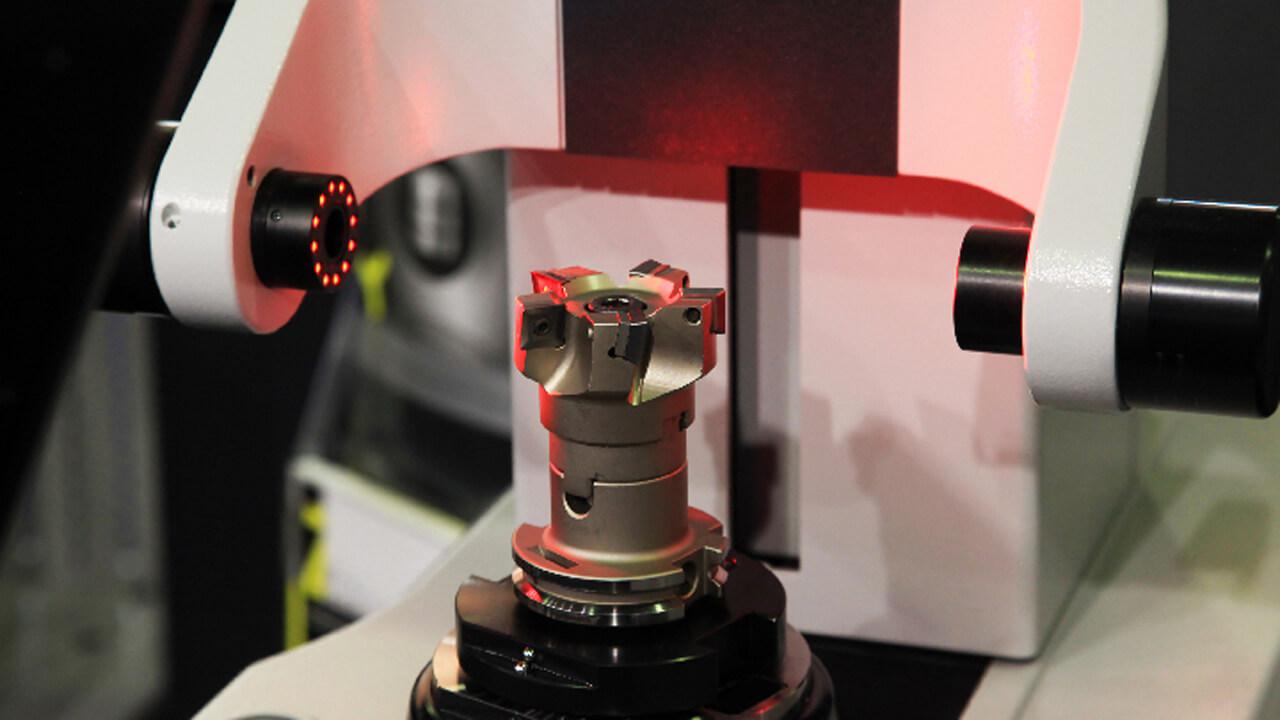

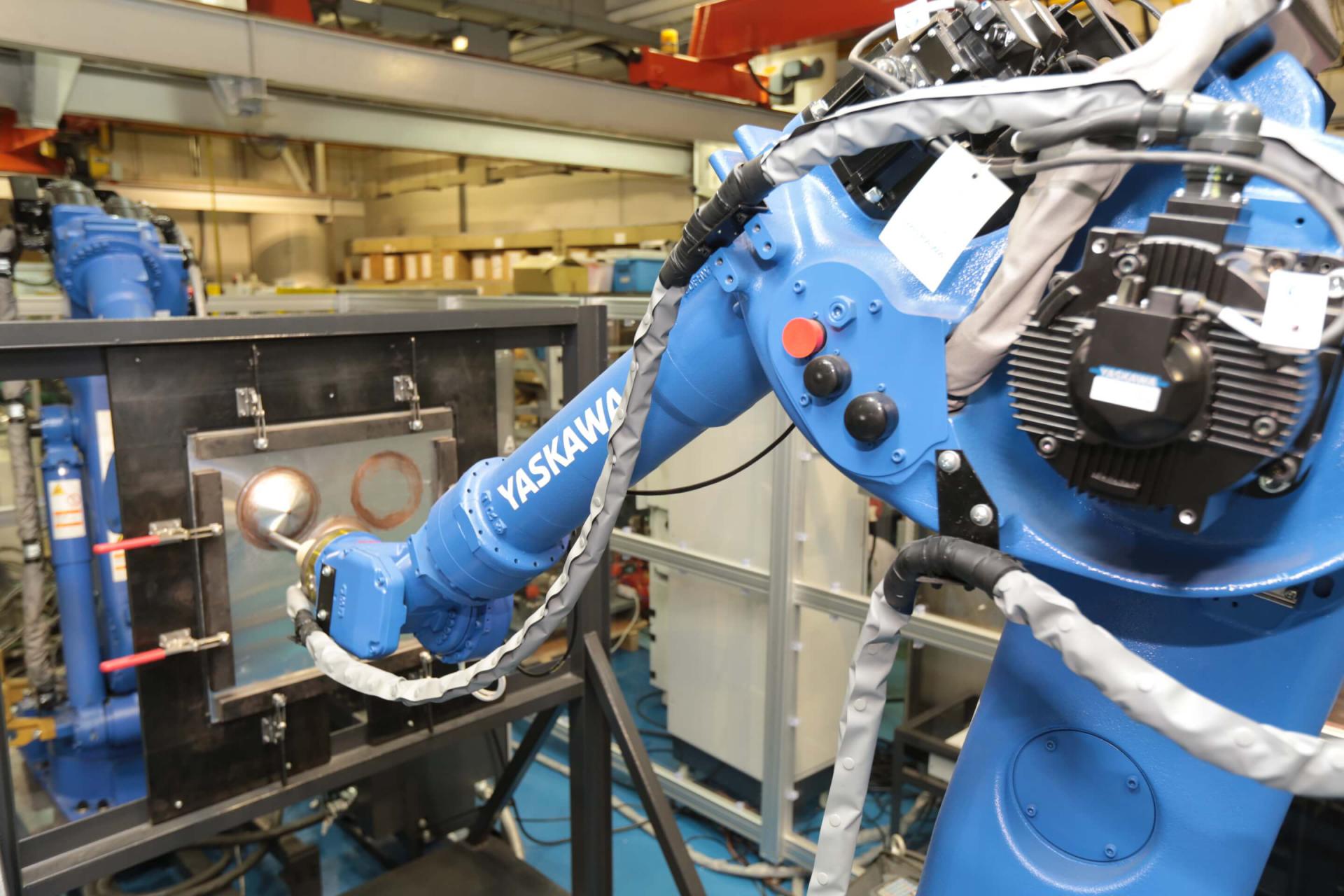

The PolyU Aviation Services Research Centre (ASRC) has developed laser ablation to remove coatings, prepare surfaces before paint application, remove rust, and mark parts. The research focuses on the appropriate automation methods and parameters required for effective laser ablation. The lasering process can be applied to a wide range of metal and composite materials without damaging the substrate material.

Currently, the aviation industry relies on either the application of chemicals such as paint strippers or sanding operations for coating removal and surface preparation. These methods are time-consuming, environmentally unfriendly, and often involve tedious manual labour. Chemical application creates a significant amount of waste material that is difficult to treat and recycle, leading to environmental concerns.

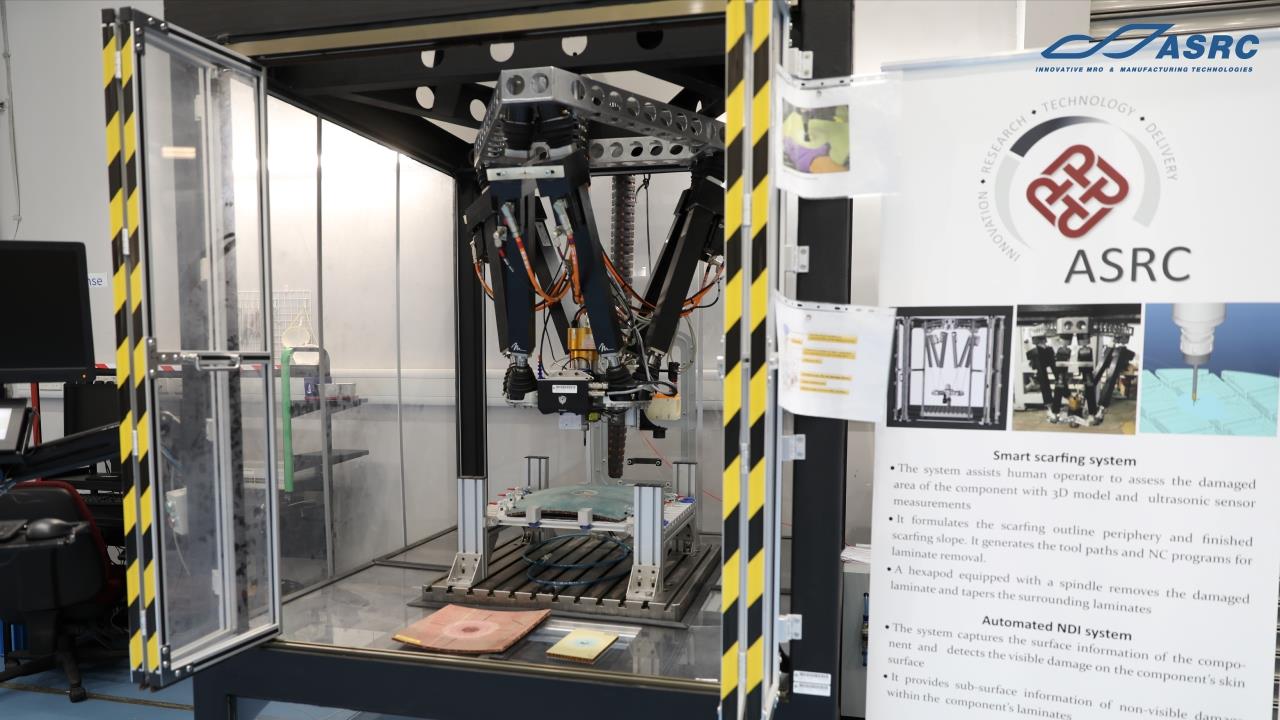

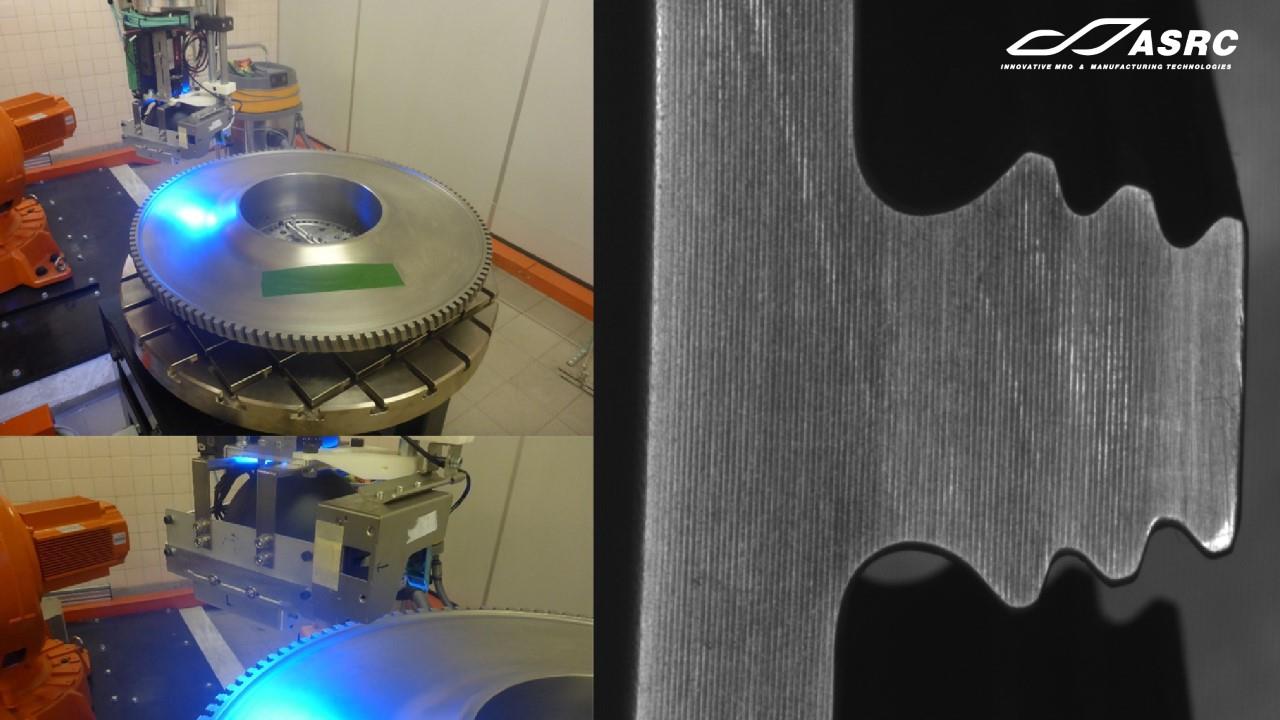

- The ASRC has developed, tested and demonstrated an environmentally friendly process to remove coatings and clean rust without creating waste and without damaging the processed components. It has been tested on both metals (aluminium, titanium), and on composite parts (CFRP and GFRP).

- The parameters of the system such as its power, scan frequency, laser point size, and working distance can be adapted. This level of control allows for selective removal of only the top coating layer, without damaging the substrate material.

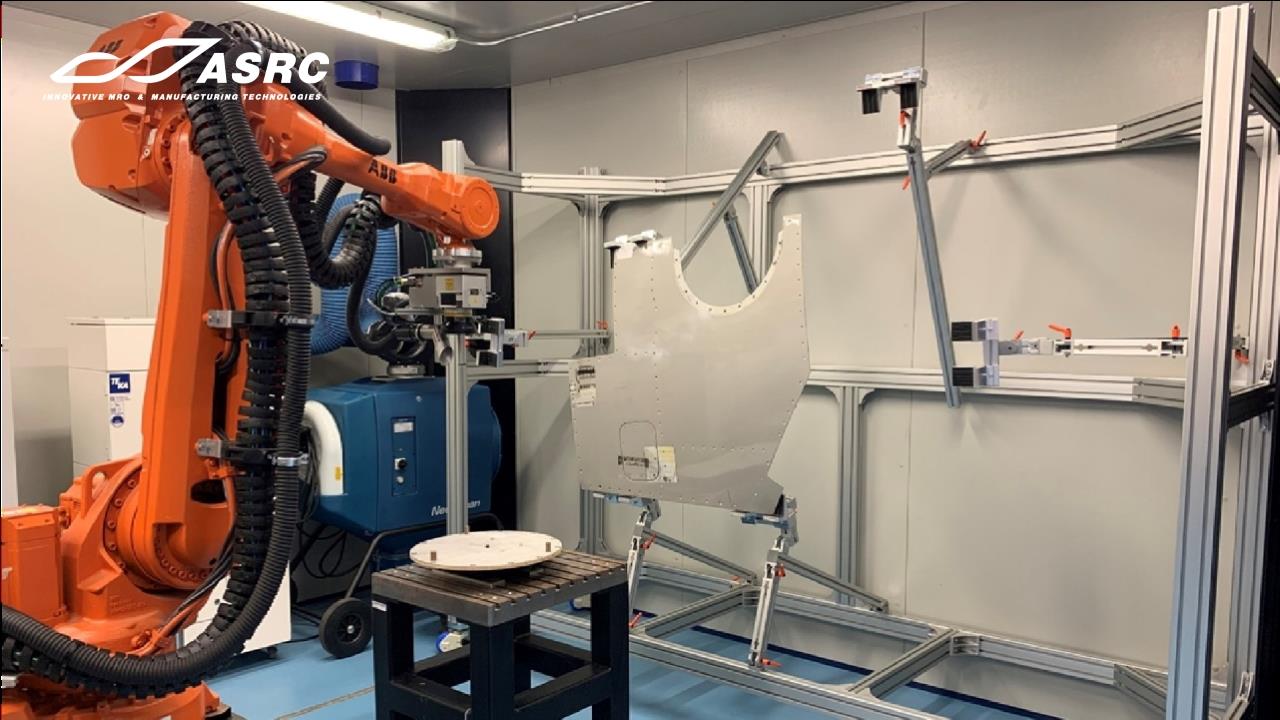

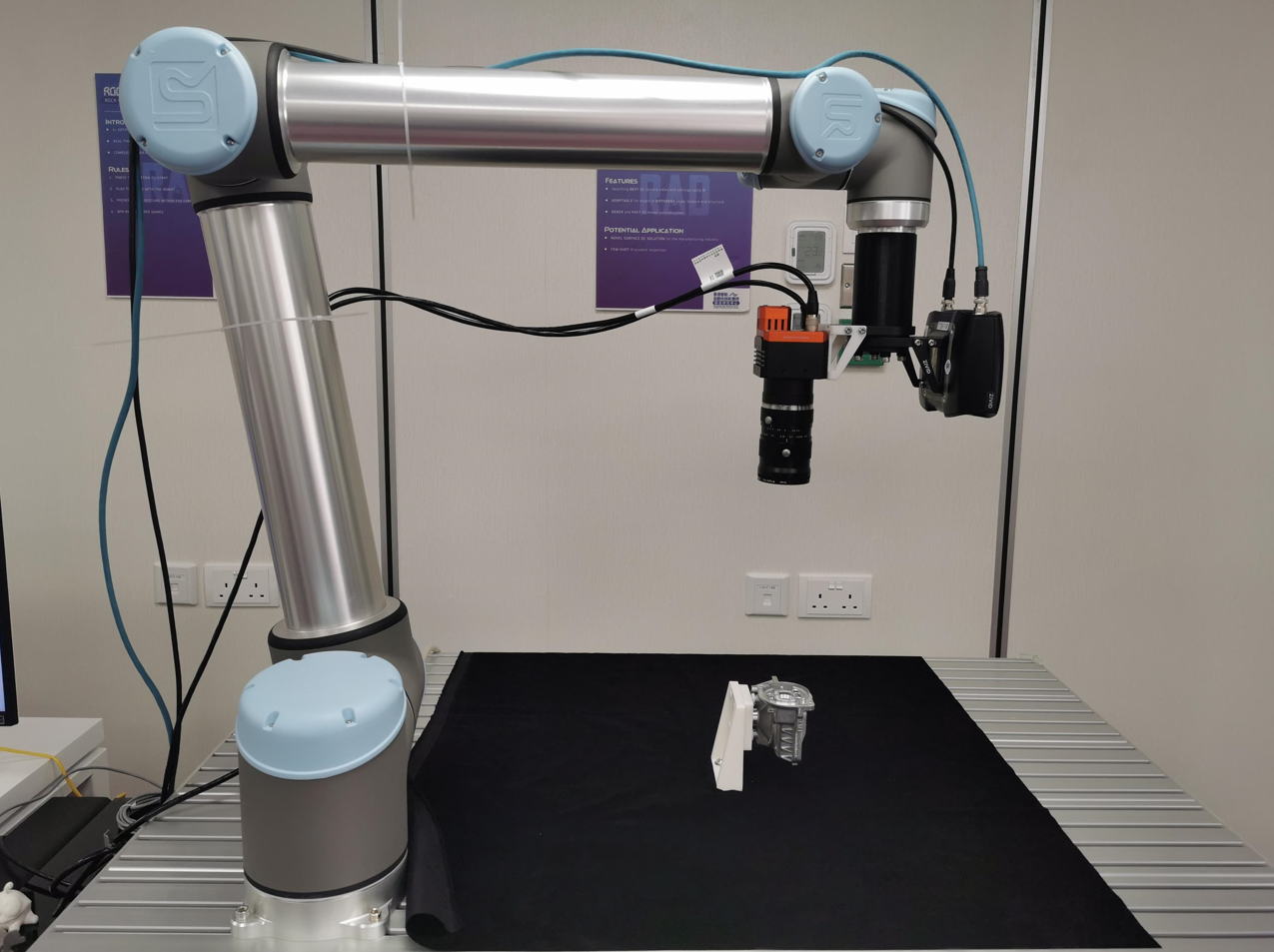

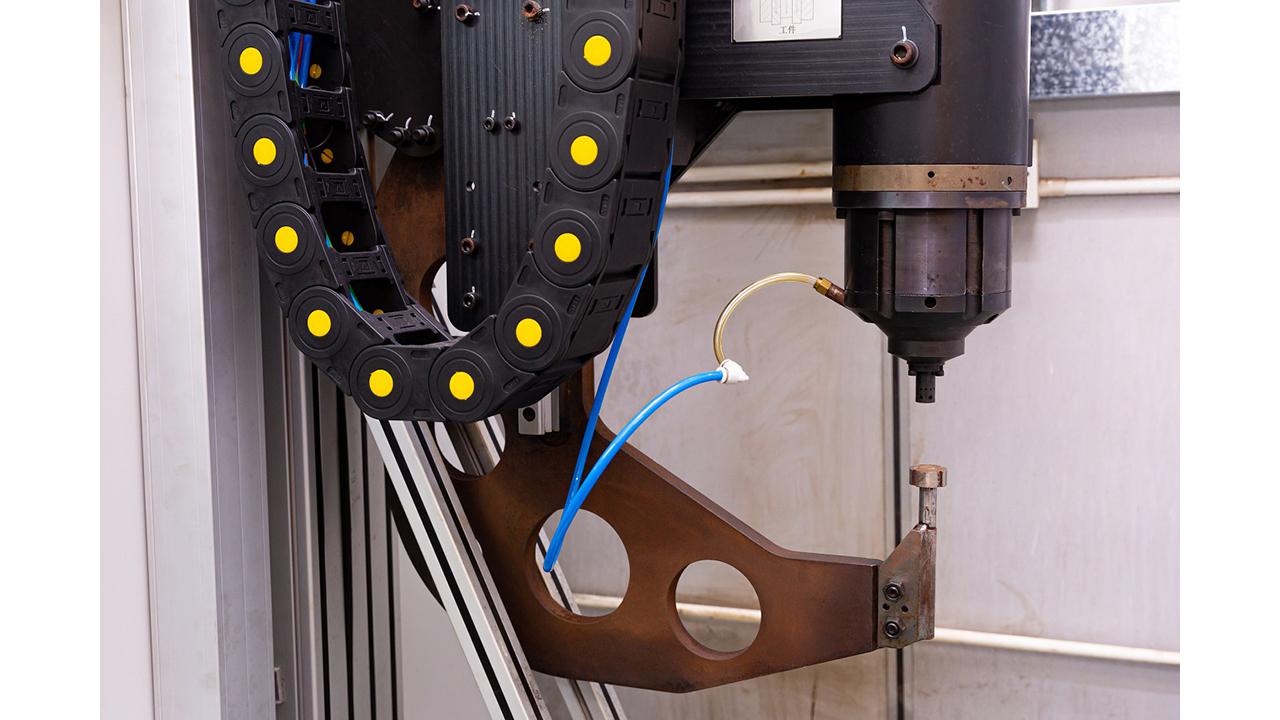

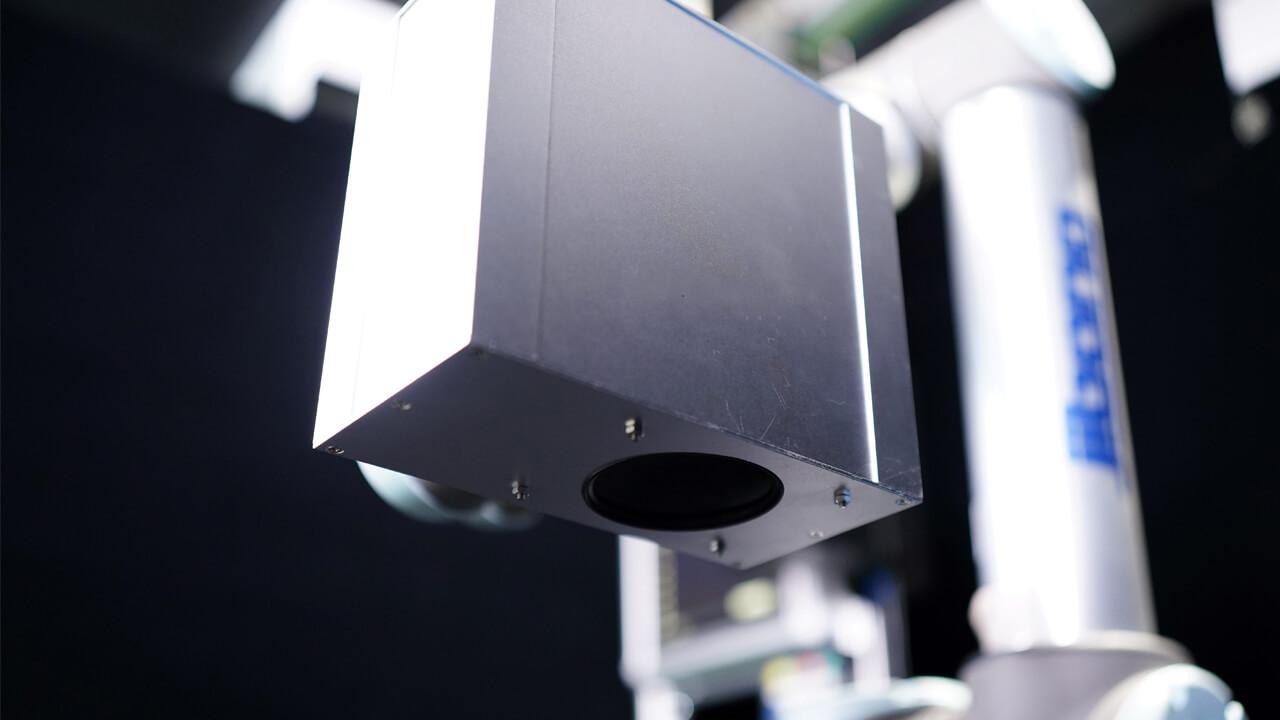

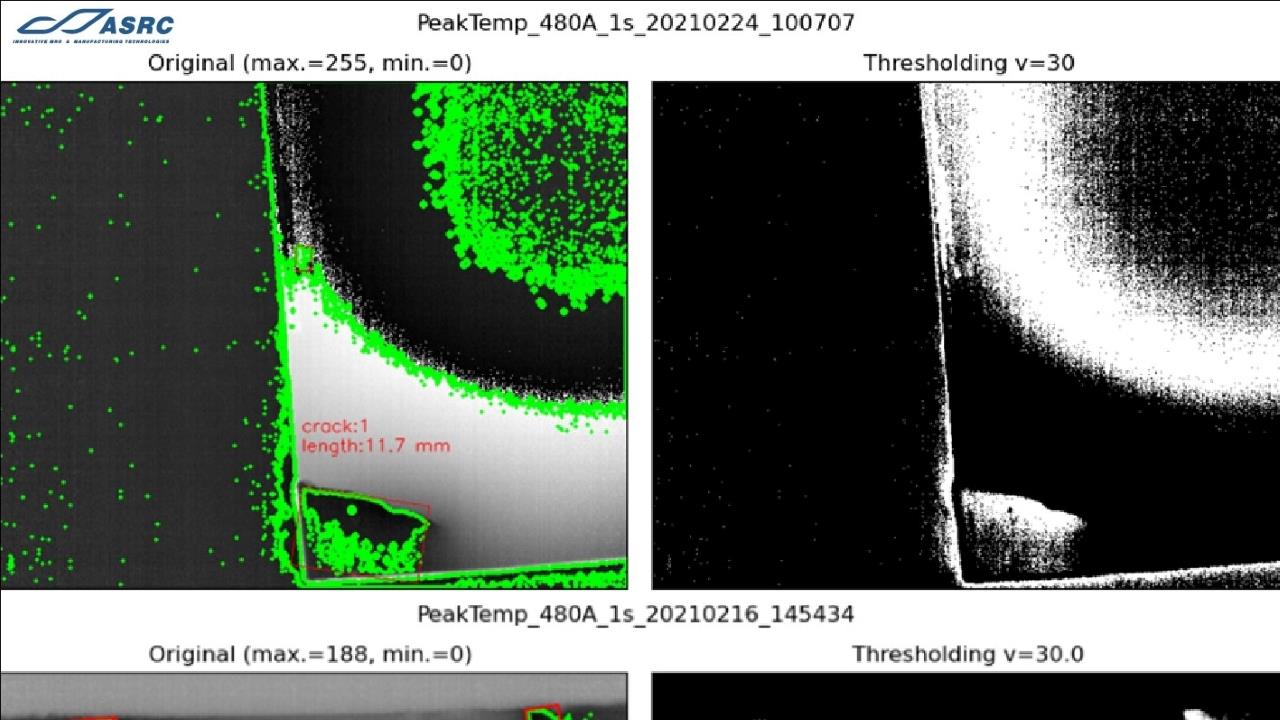

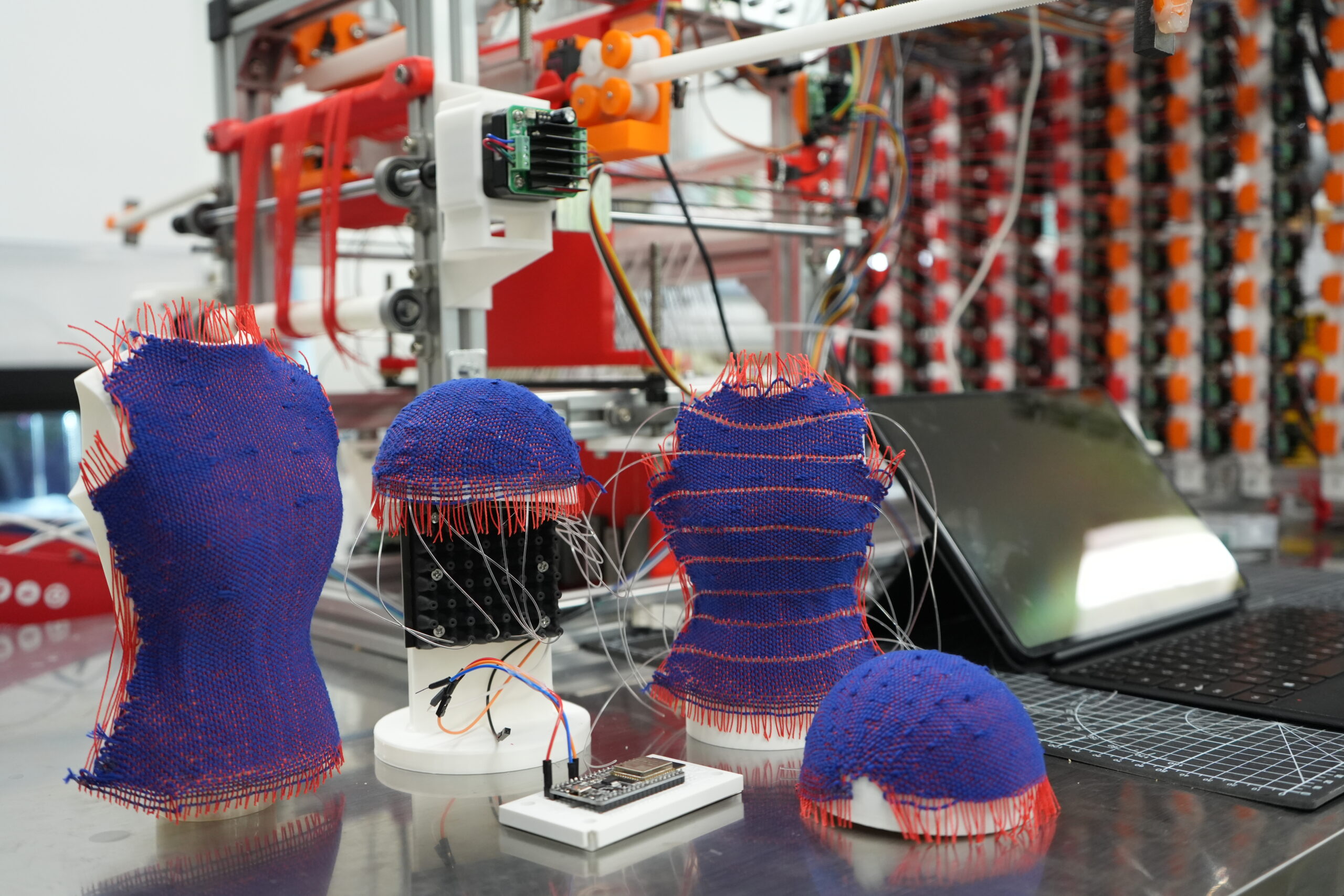

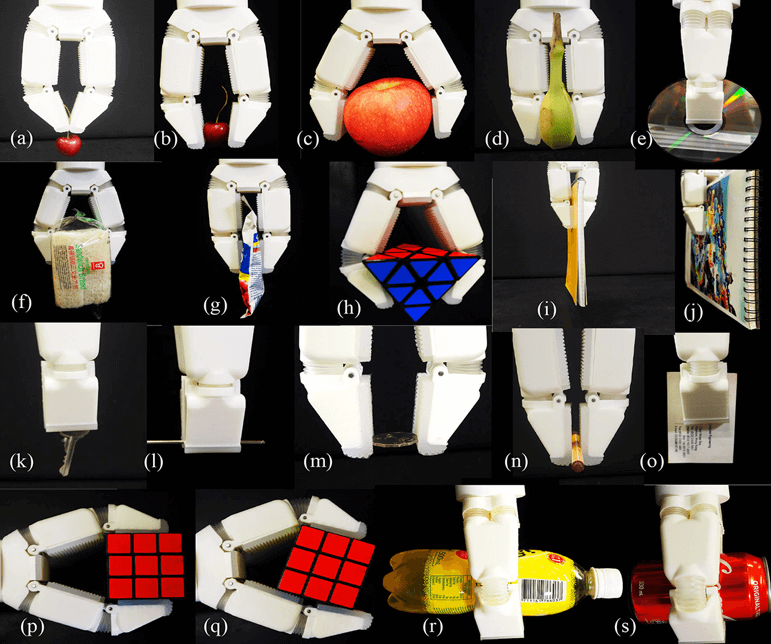

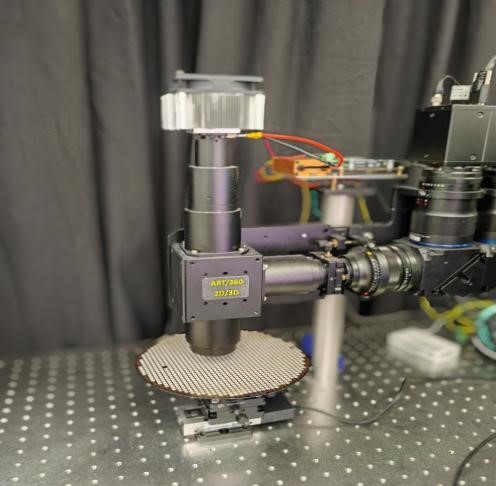

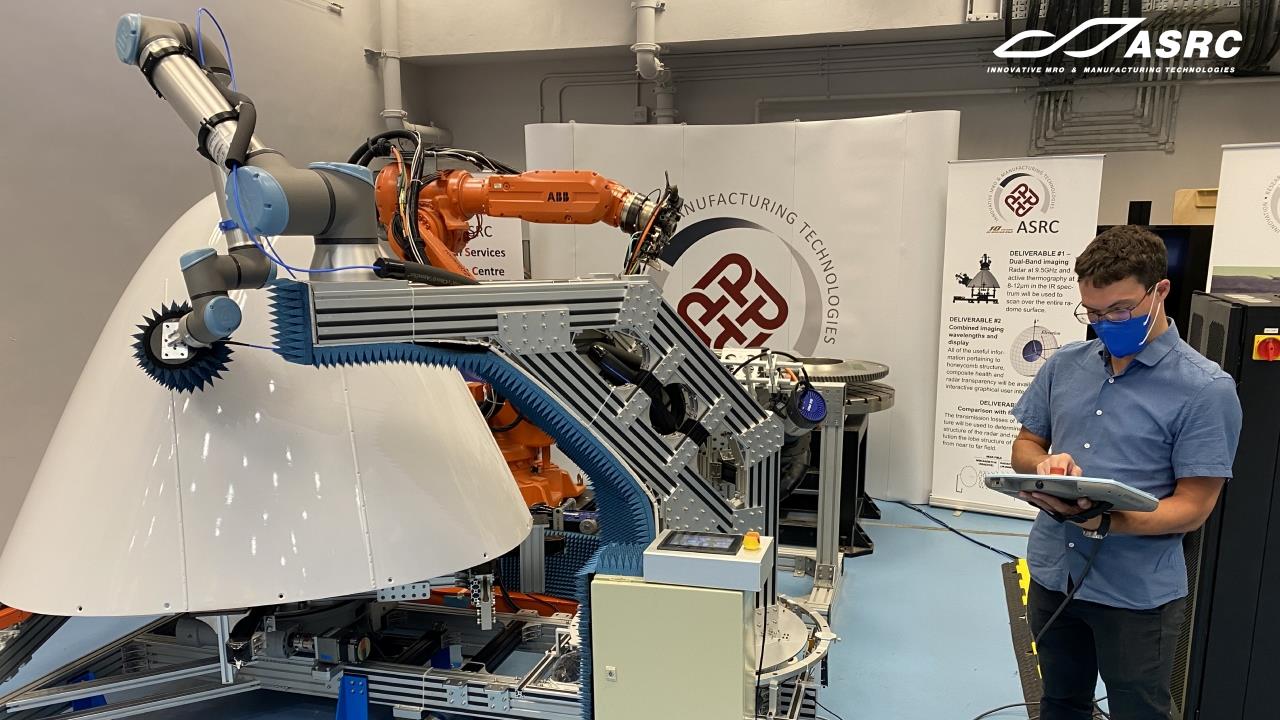

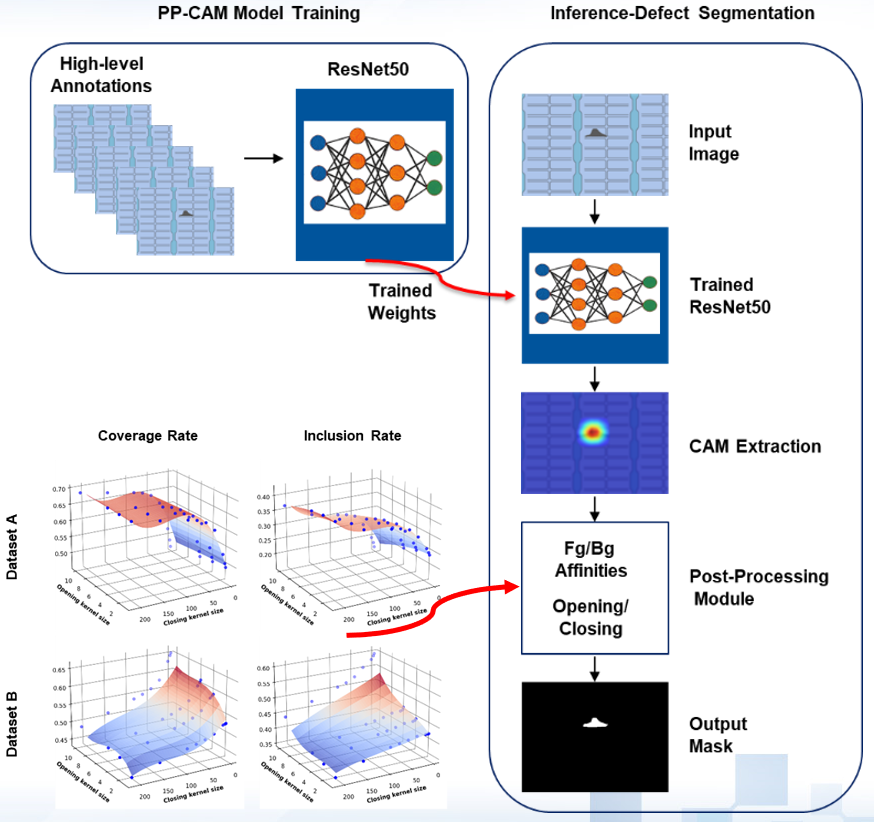

- The end effector is mounted on a robot arm, making the laser processing fully automated and scalable. The process result is checked automatically by camera for assessment and feedback to the system.

- A new coating removal system based on laser ablation technology provides a more efficient and effective solution for coating removal. This system replaces traditional chemical stripping and manual stripping methods without damaging the substrate material of components.

- The automated process requires fewer manual operations, reducing the exposure of operators to paint residues. The robot arm accommodates the shape of various components.

- The laser ablation process is environmentally friendly as it does not generate waste, does not require any consumables, and generates only ablated particles, which are gathered in-process by vacuum. This ensures that most resources are directed towards adding value.

- Automated inspection during the lasering process ensures that the process stops when the necessary ablation level is reached. This makes the process more efficient.

- Paint and coating removal from metal and composite materials primarily in the aviation industry, but also applicable to any other industry where components need to be repainted.

- Rust removal from metal materials and surface preparation before further processes such as welding.

With over 80 years of proud tradition and ranking among the world’s top 100 institutions, The Hong Kong Polytechnic University (PolyU) aspires to be a leading university with world-class research and education.

PolyU is a home for educating thinkers, discoverers, innovators and communicators in delivering positive impact. We are committed to nurturing tomorrow’s leaders today, through a holistic education that provides graduates unrivaled placements to thrive in communities, industries and businesses.