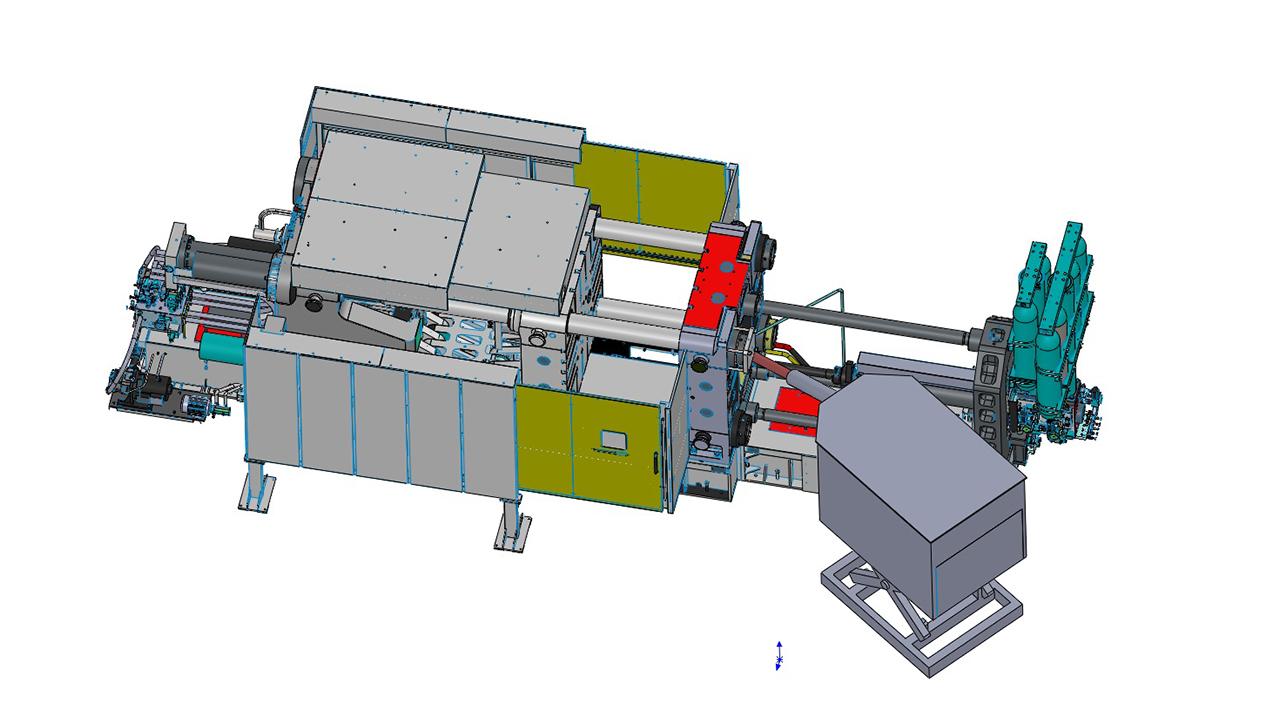

Accumulative Roll Bonding (ARB) for Multi-Metal Sheets Fabrication

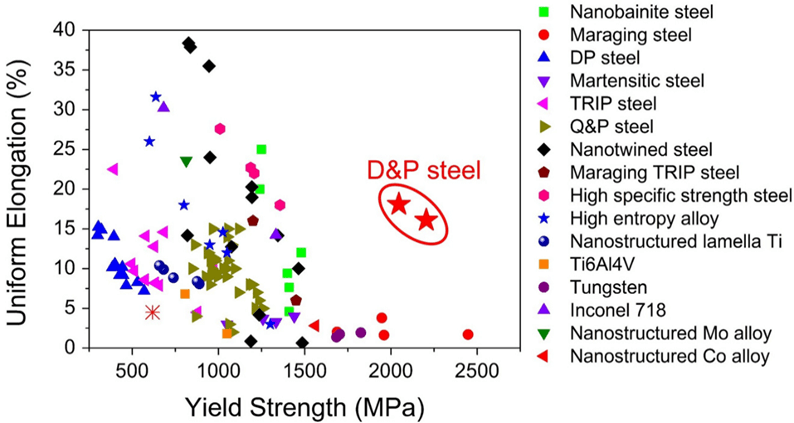

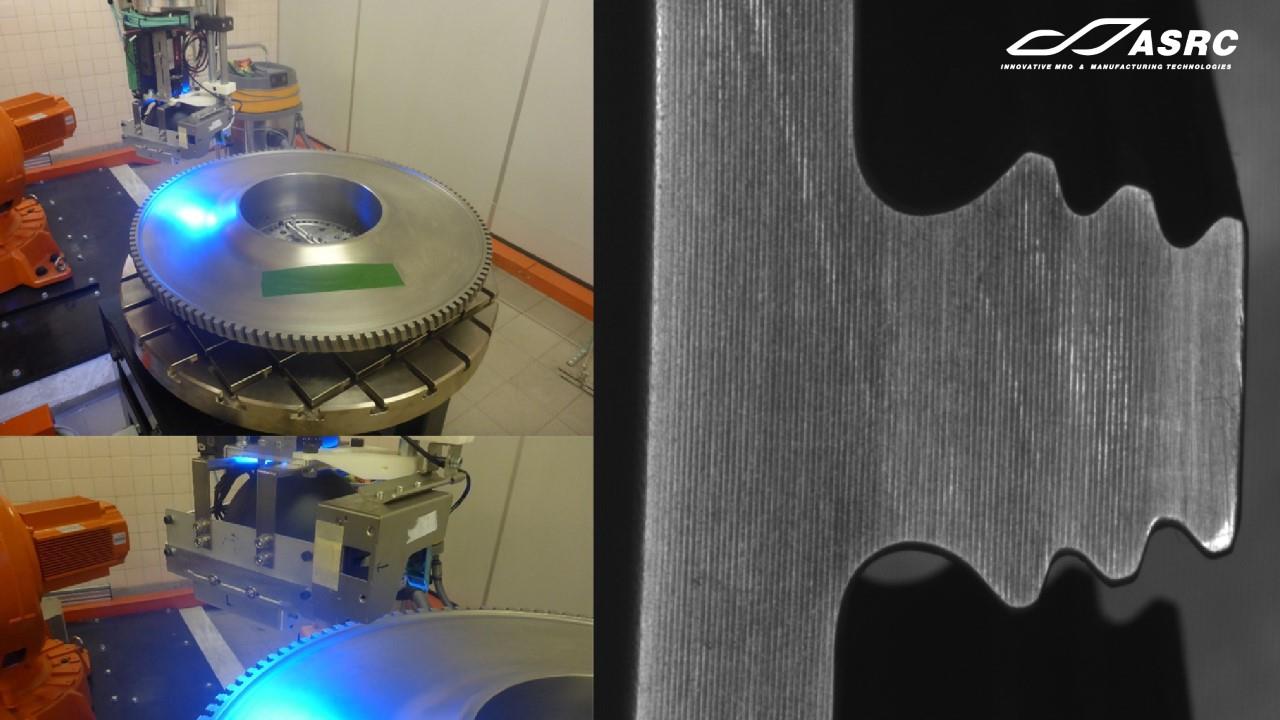

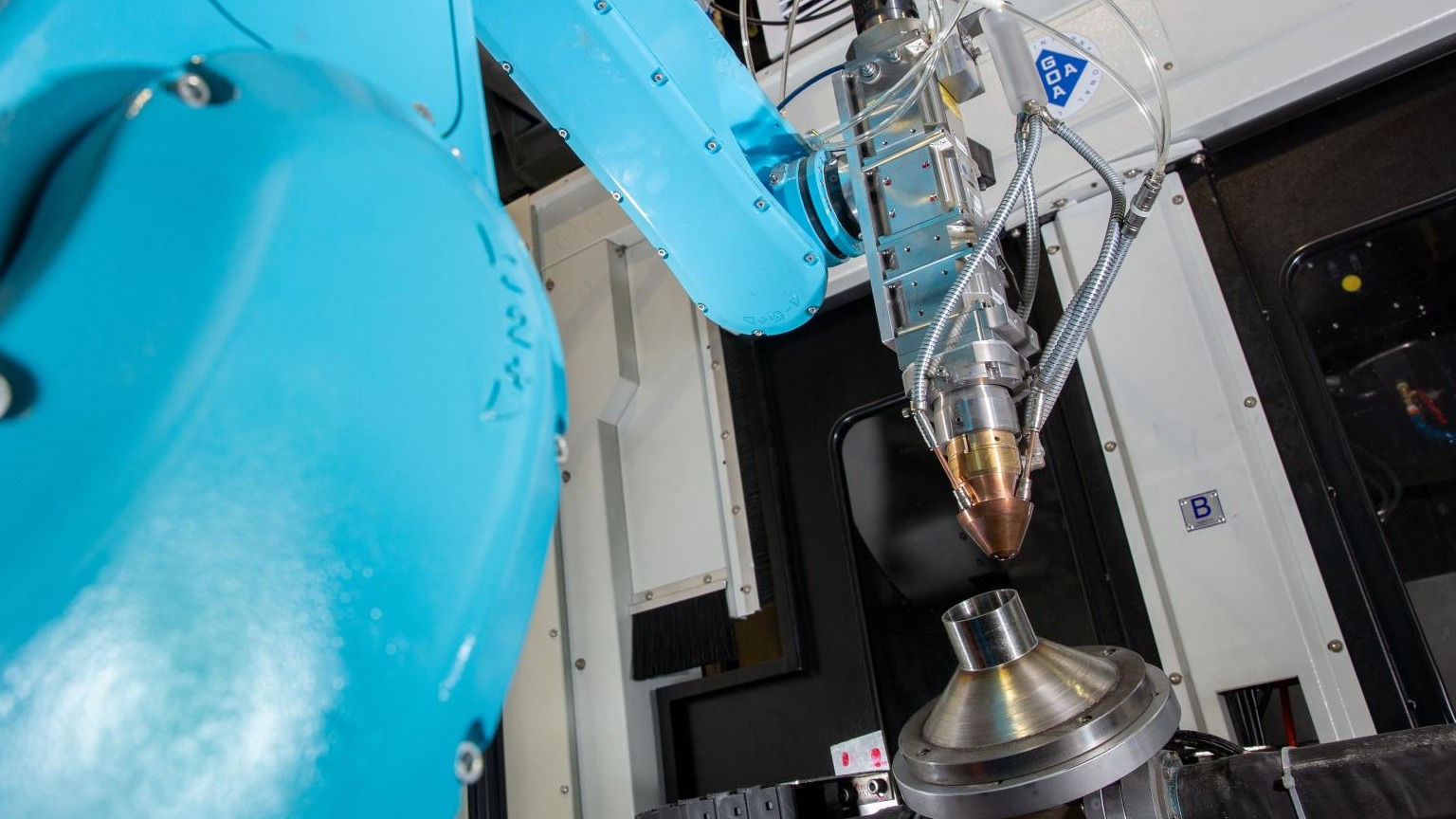

This ARB technology provides greater flexibility for the bonding of different metallic materials and more cost-effective in-house batch production of composite alloy sheets. Sheets with customised and enhanced mechanical properties can be volume produced for stamping of products, and the stamped products combine the characteristics and advantages of different metals, such as steel, aluminum, copper, magnesium, etc., to meet the requirements for various functionality enhancements.

Conventional single material metallic sheet cannot meet the growing requirement of high strength, good anti-corrosion and thermal conductivity at the same time. Moreover, the manufacturing process of conventional composite materials fabrication process is relatively more complex and environmentally harmful.

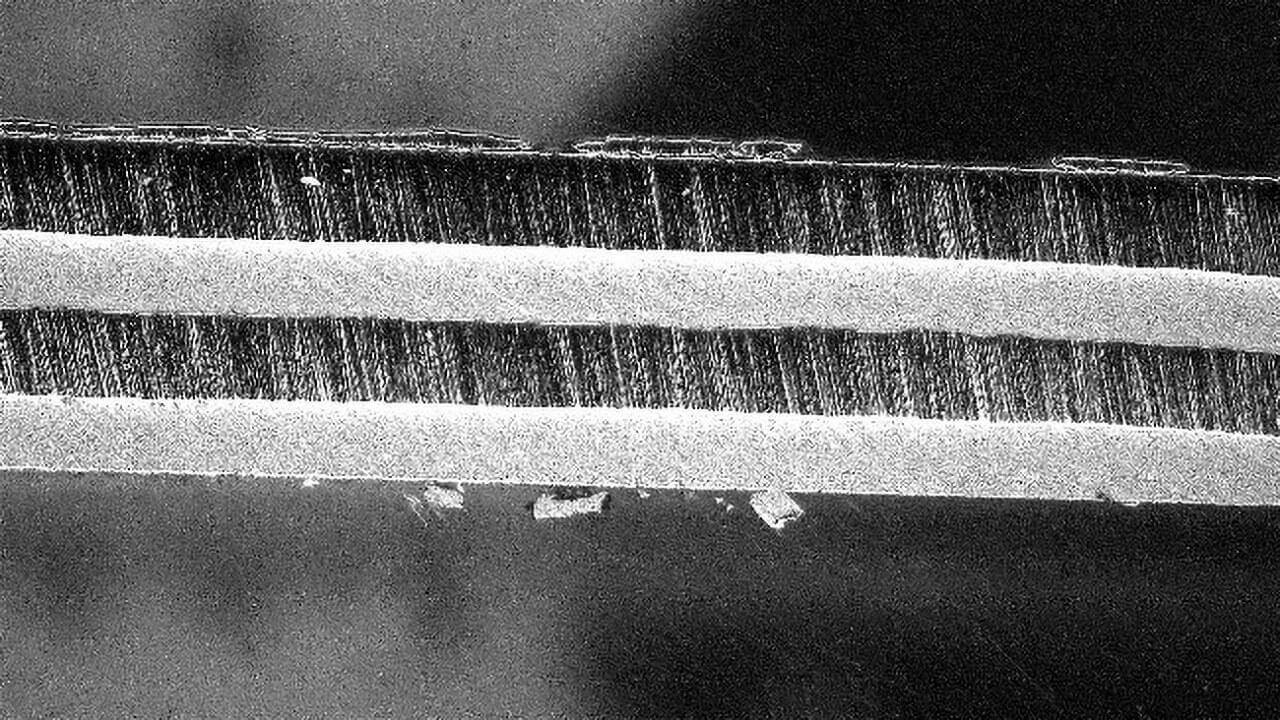

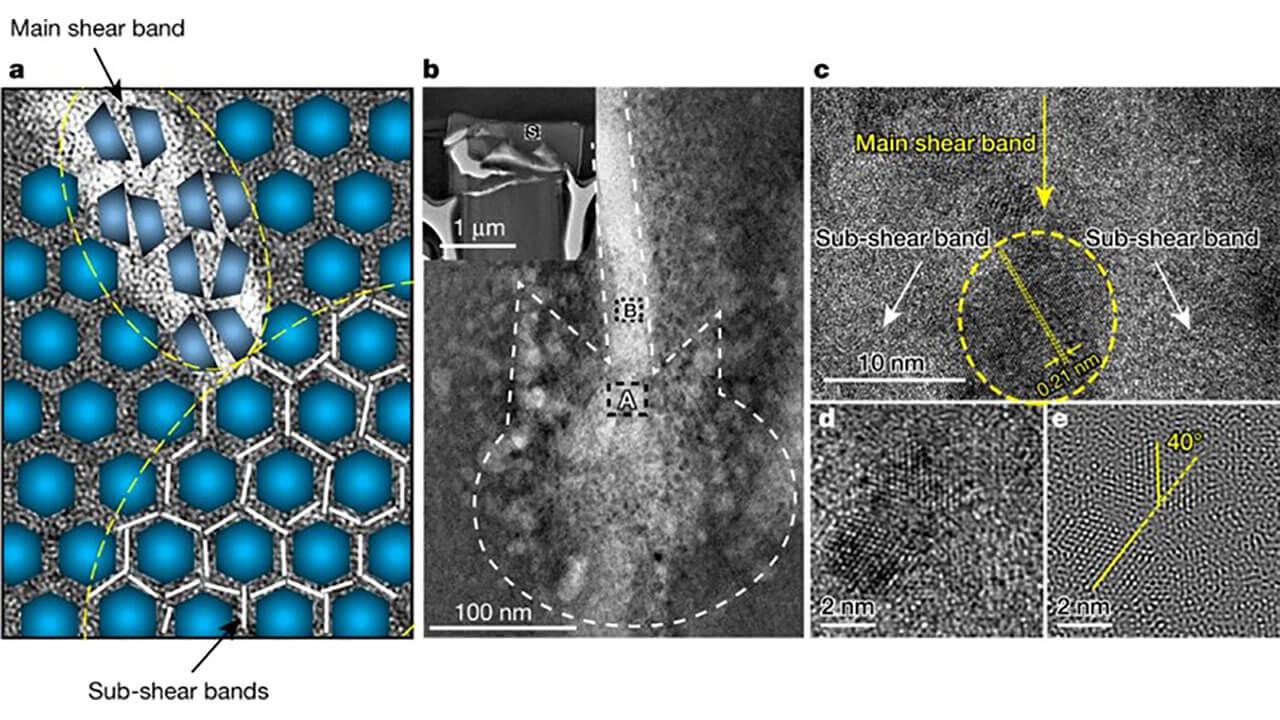

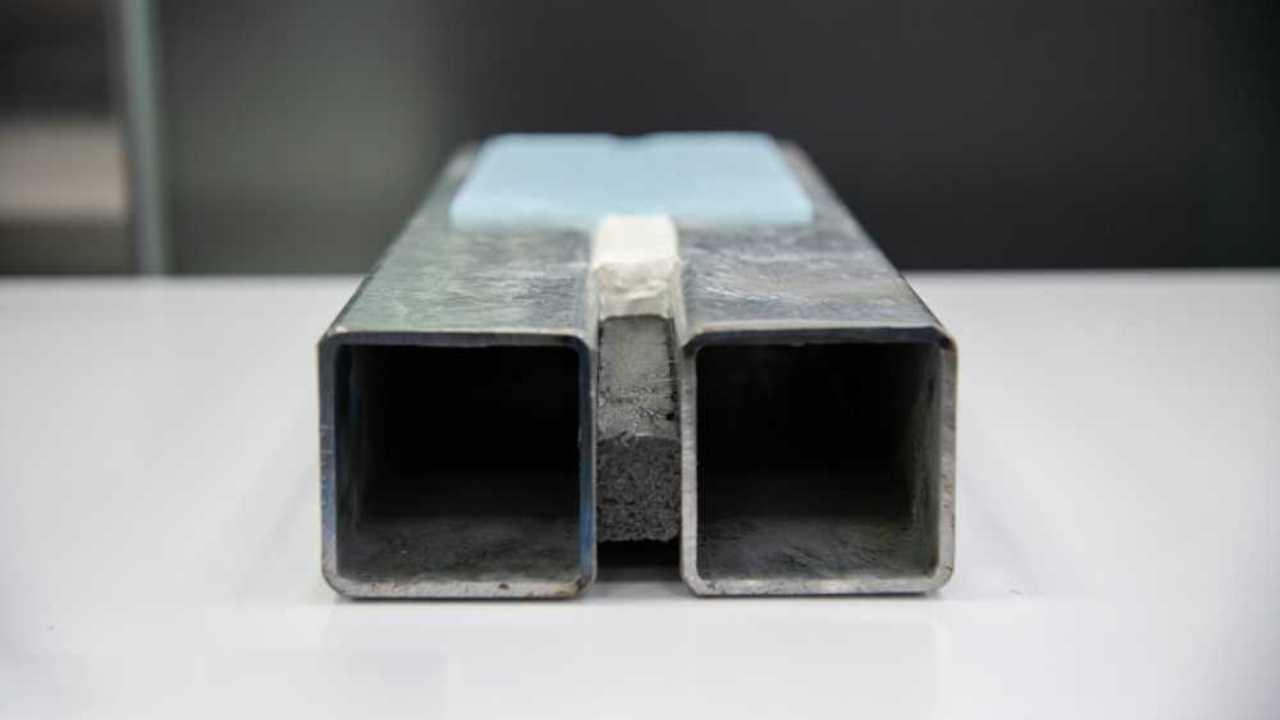

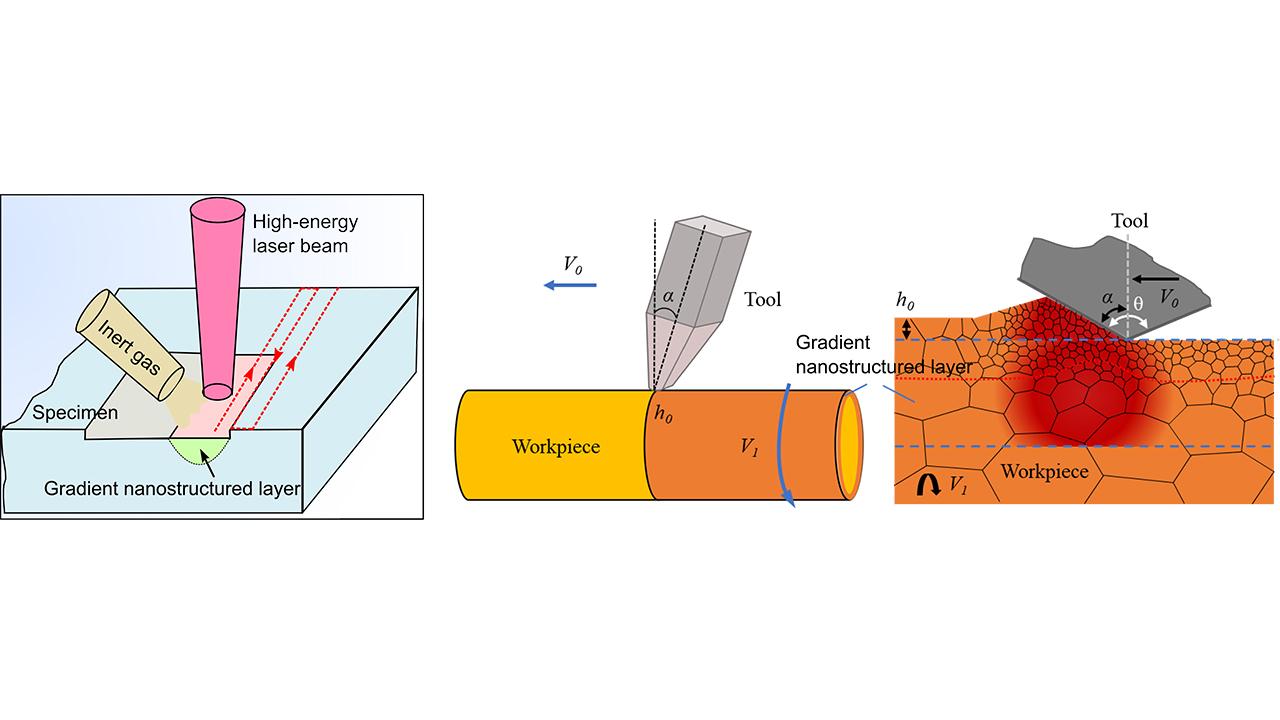

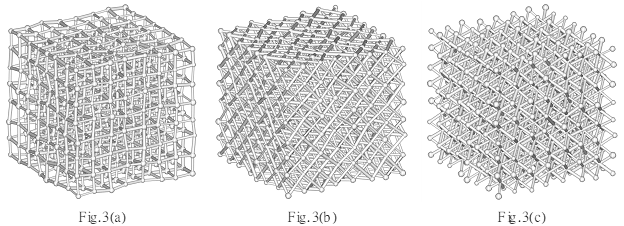

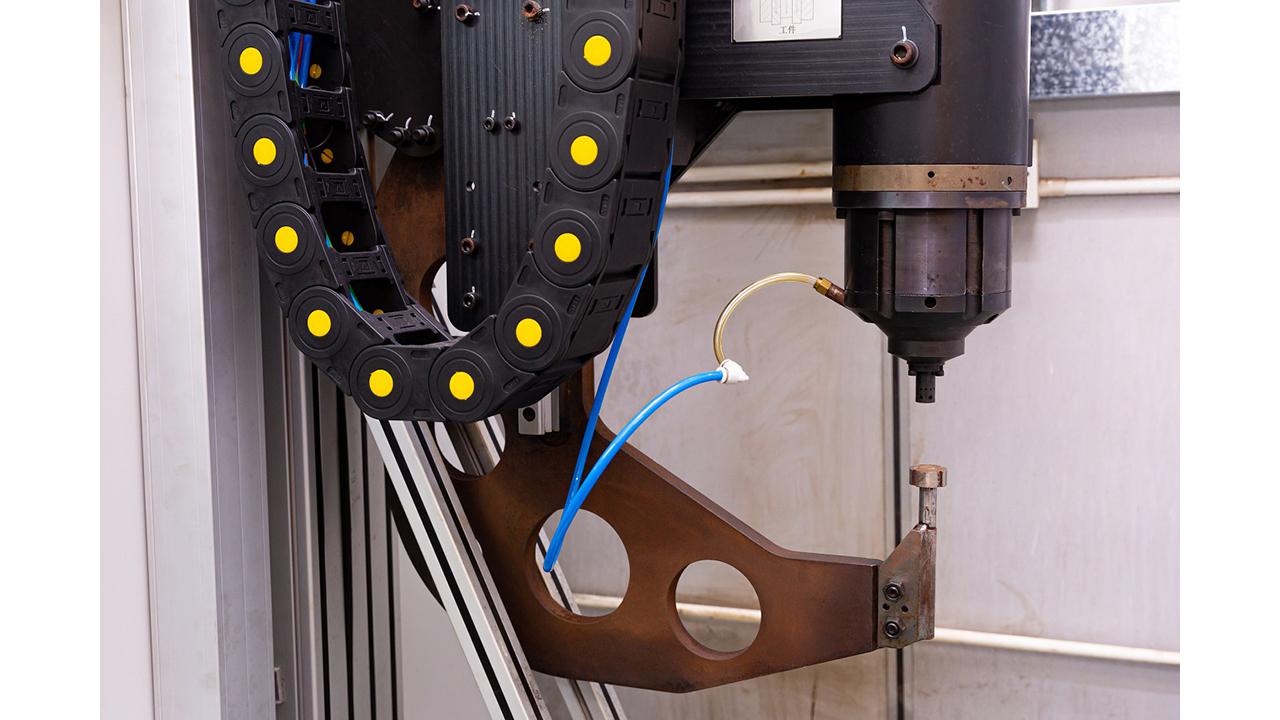

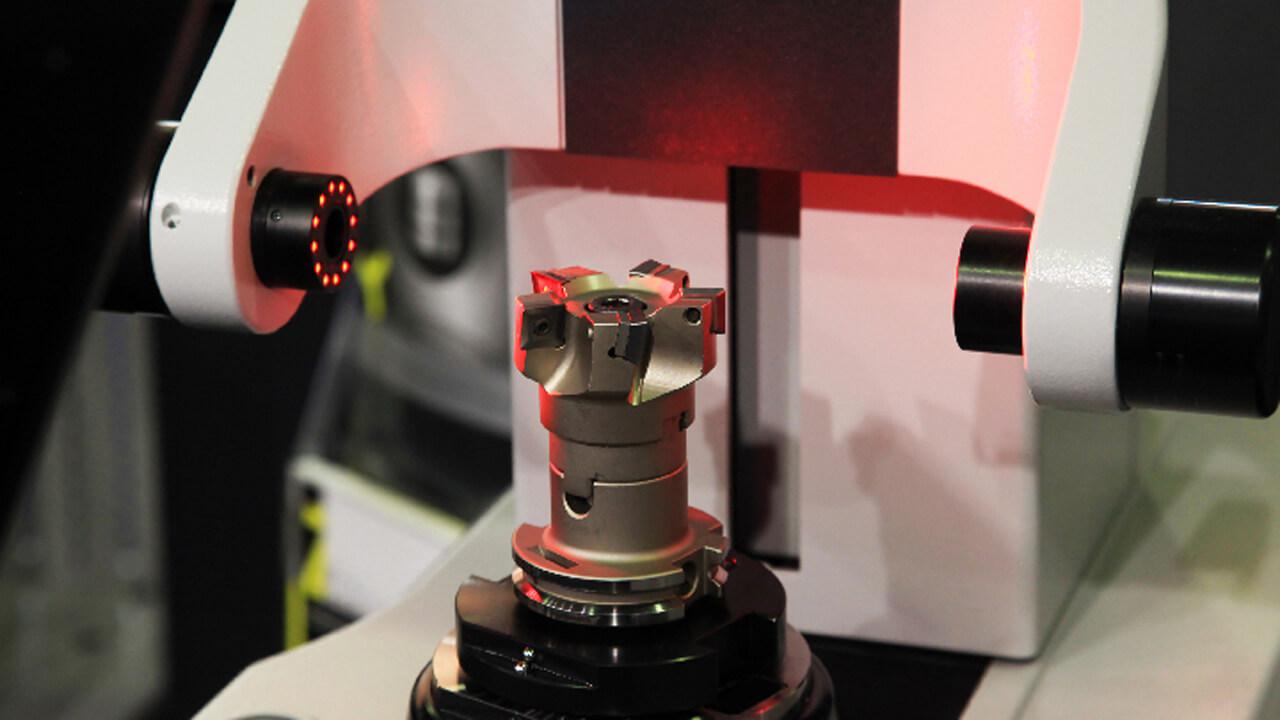

- The ARB process can form strong mechanical bonds among aluminum, copper, steel and other metal materials through severe plastic deformation (SPD), to produce multi-layer and sheet metal parts of multiple layers and materials.

- The composite metal sheet has the advantages of high-strength, lightweight and corrosion resistant, and also has thermal conductivity.

- Improve the versatility and work performance of metal fittings as critical components, which can enhance safety and save energy.

- New high-performance materials can enhance product value, such as increased strength, lightweight, thermal conductivity and corrosion resistance.

- The fabrication process is under atmospheric environment without causing air, liquid or solid pollution.

- Geneva International Exhibition of Inventions 2022 - Gold

- Produce composite alloy sheets with the combination of two or more metals, such as steel-aluminium, steel-copper, magesium-copper, and steel-aluminium-copper.

- Fabricate stamping products with different combinations of enhanced functional requirements, such as high-strength, lightweight, good heat dissipation, excellent electrical conductivity, and magnetic shielding.

Patent

- Hong Kong Short Term Patent: HK30027293

- China Utility Patent: ZL 20202 1895460.2

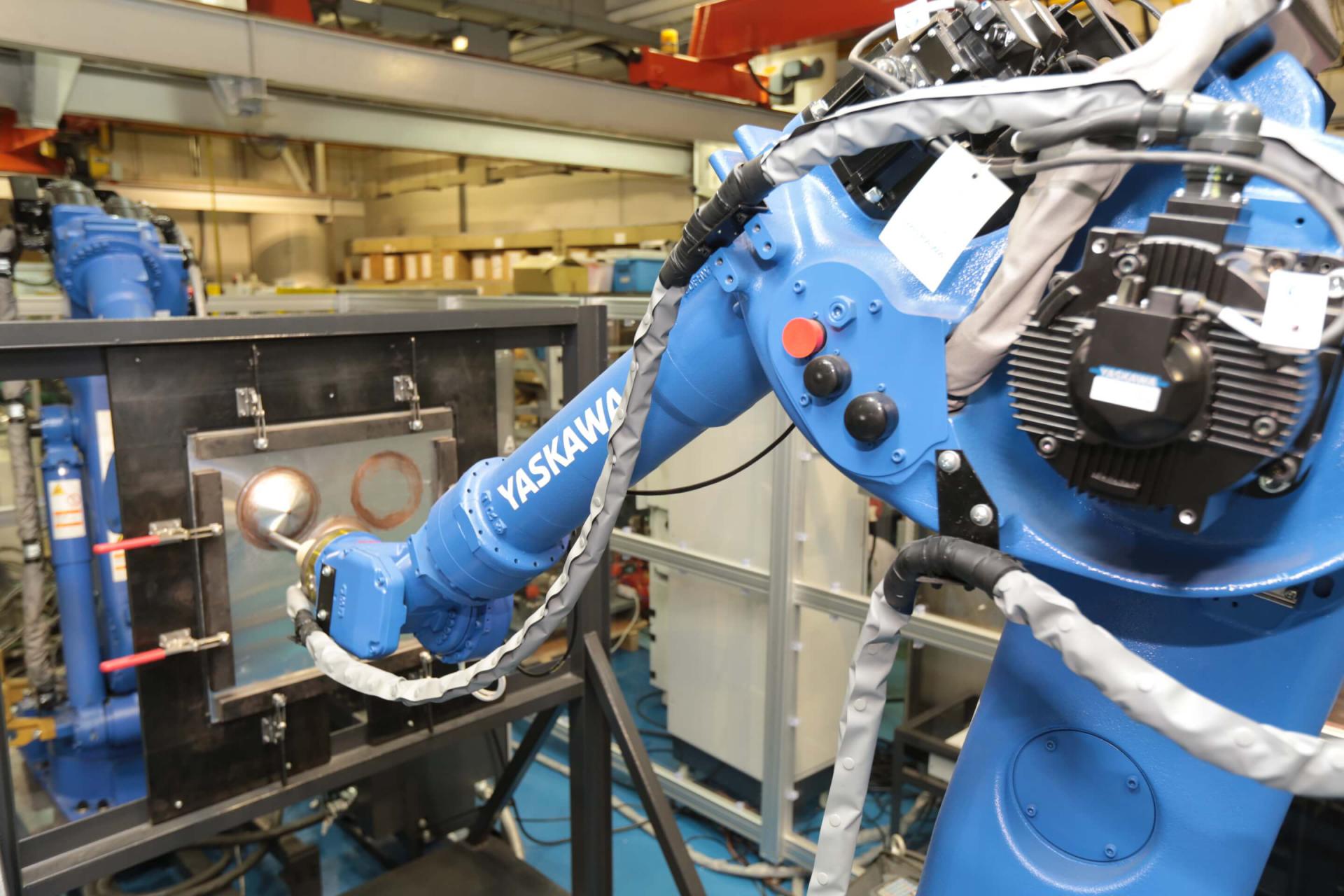

The Hong Kong Productivity Council (HKPC) is a multi-disciplinary organisation established by statute in 1967, to promote productivity excellence through integrated advanced technologies and innovative service offerings to support Hong Kong enterprises. HKPC is the champion and expert in facilitating Hong Kong's new industrialisation empowered by i4.0 and e4.0 - focusing on R&D, IoT, big data analytics, AI and Robotic technology development, digital manufacturing, etc., to help enterprises and industries upgrade their business performance, lower operating costs, increase productivity and enhance competitiveness.

The Council is a trusted partner with comprehensive innovative solutions for Hong Kong industries and enterprises, enabling them to achieve resources and productivity utilisation, effectiveness and cost reduction, and enhanced competitiveness in both local and international marketplace. It offers SMEs and startups immediate and timely assistance in coping with the ever-changing business environment, accompanying them on their innovation and transformation journey.