Innovative Large-scale 3D Metal Printing

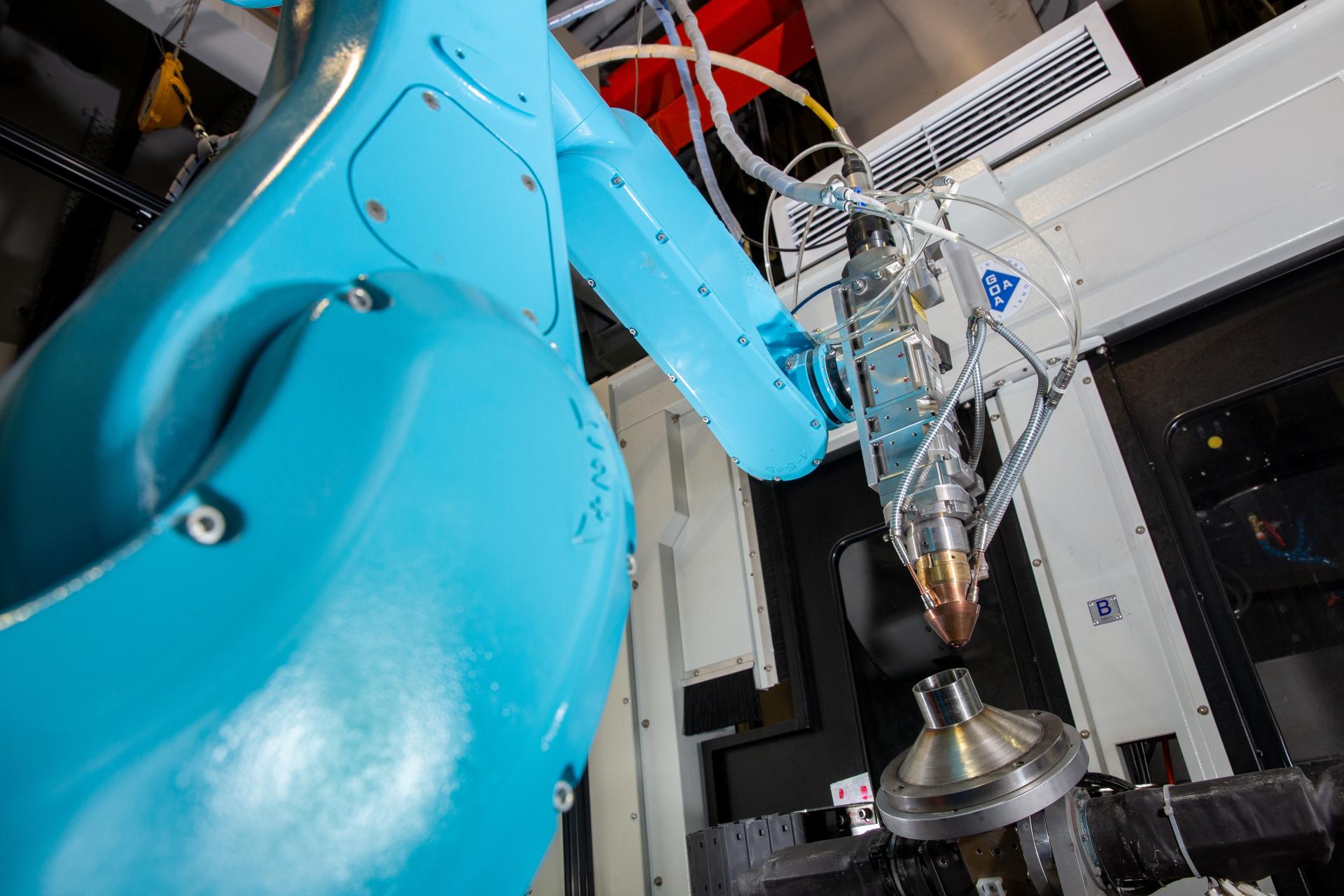

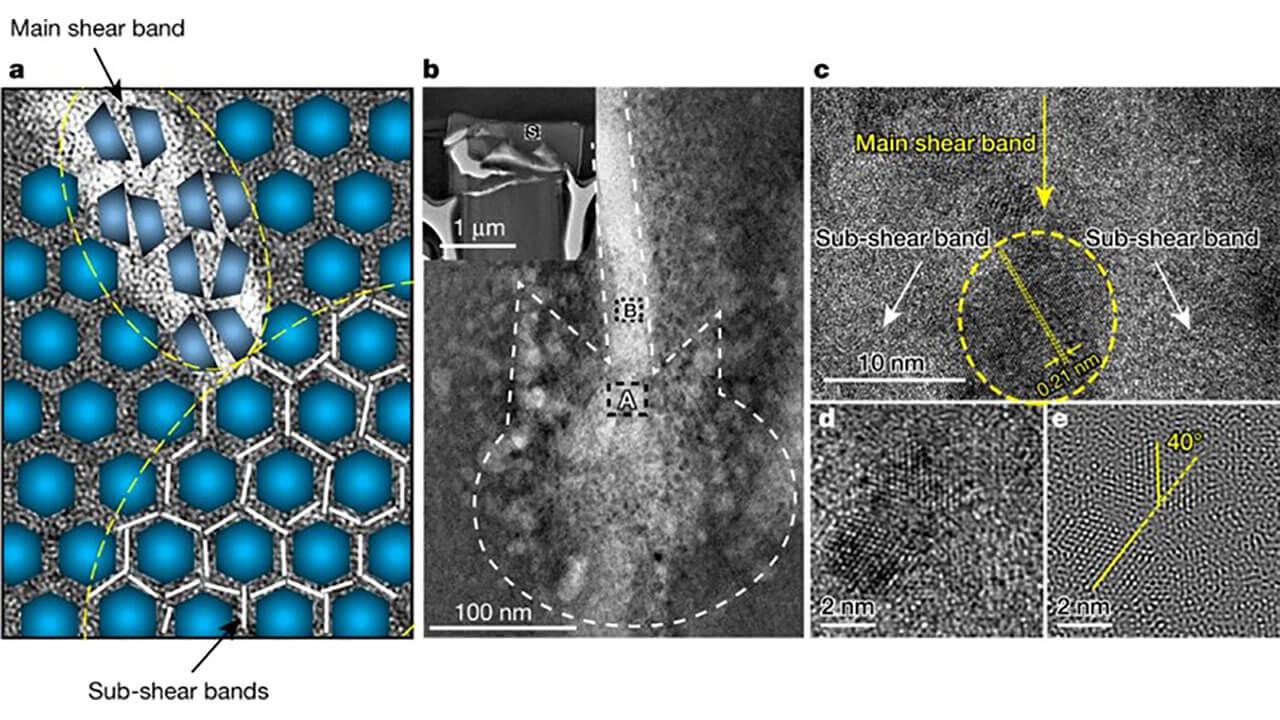

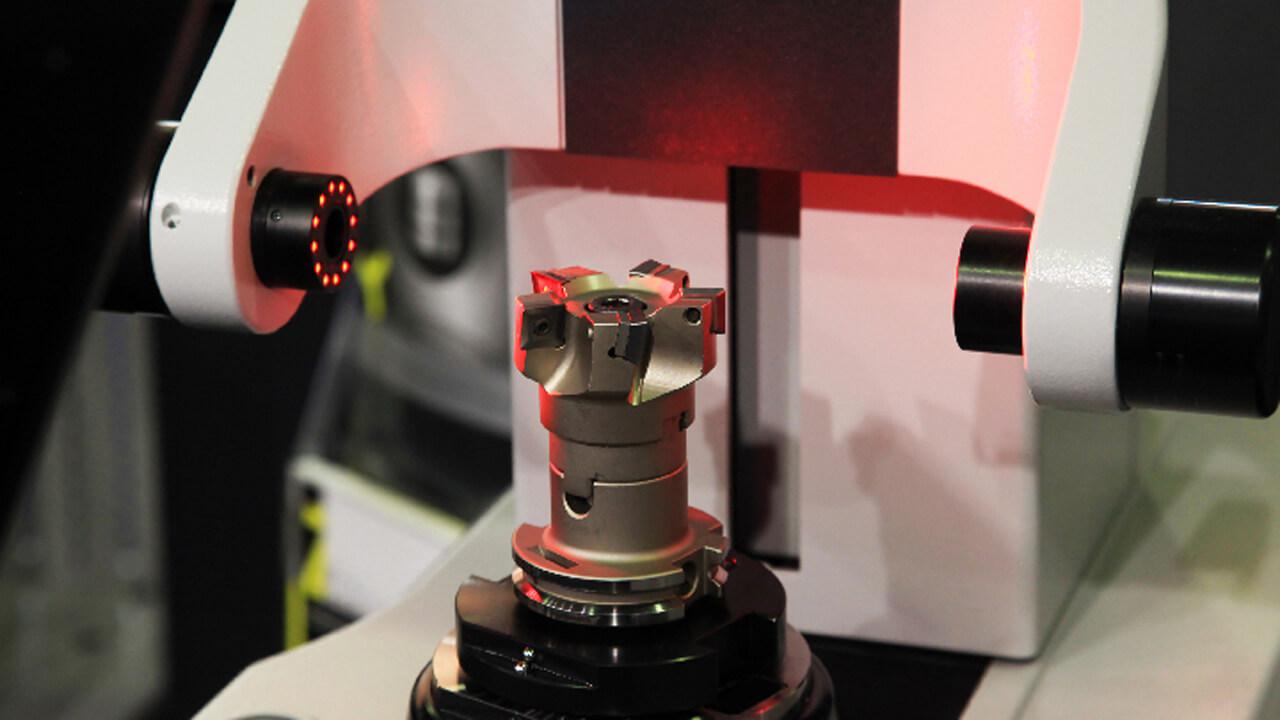

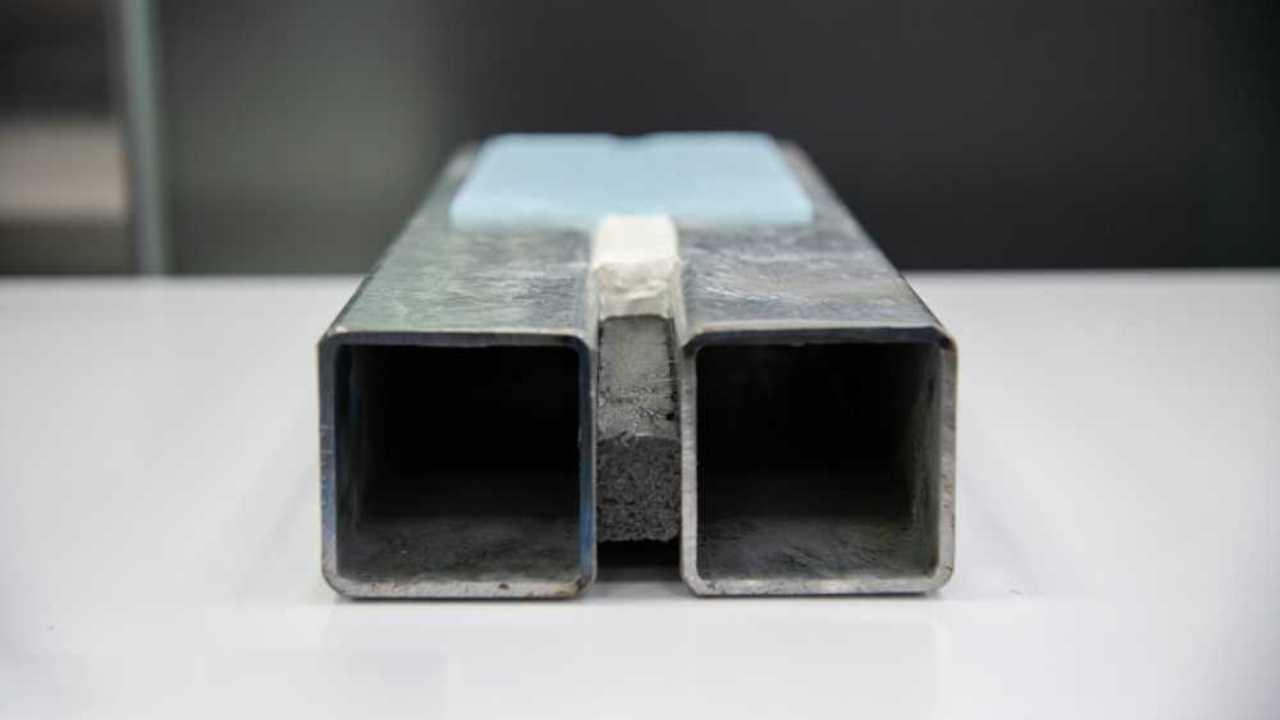

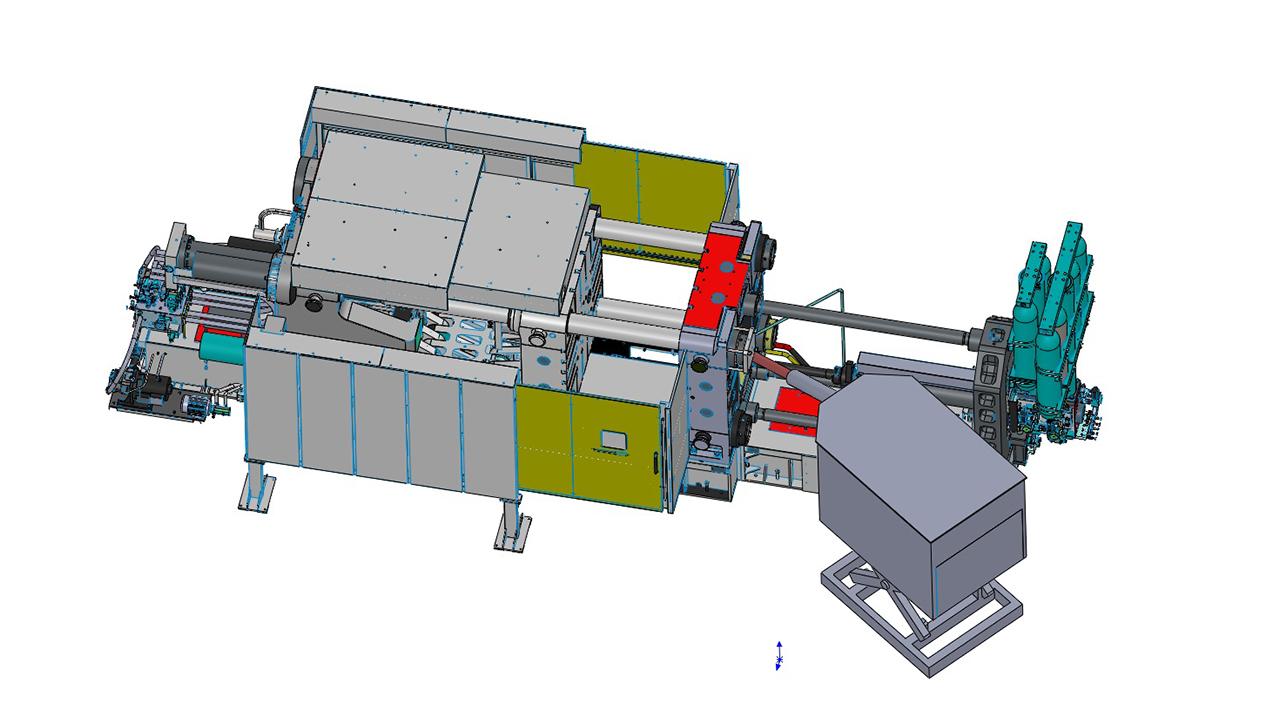

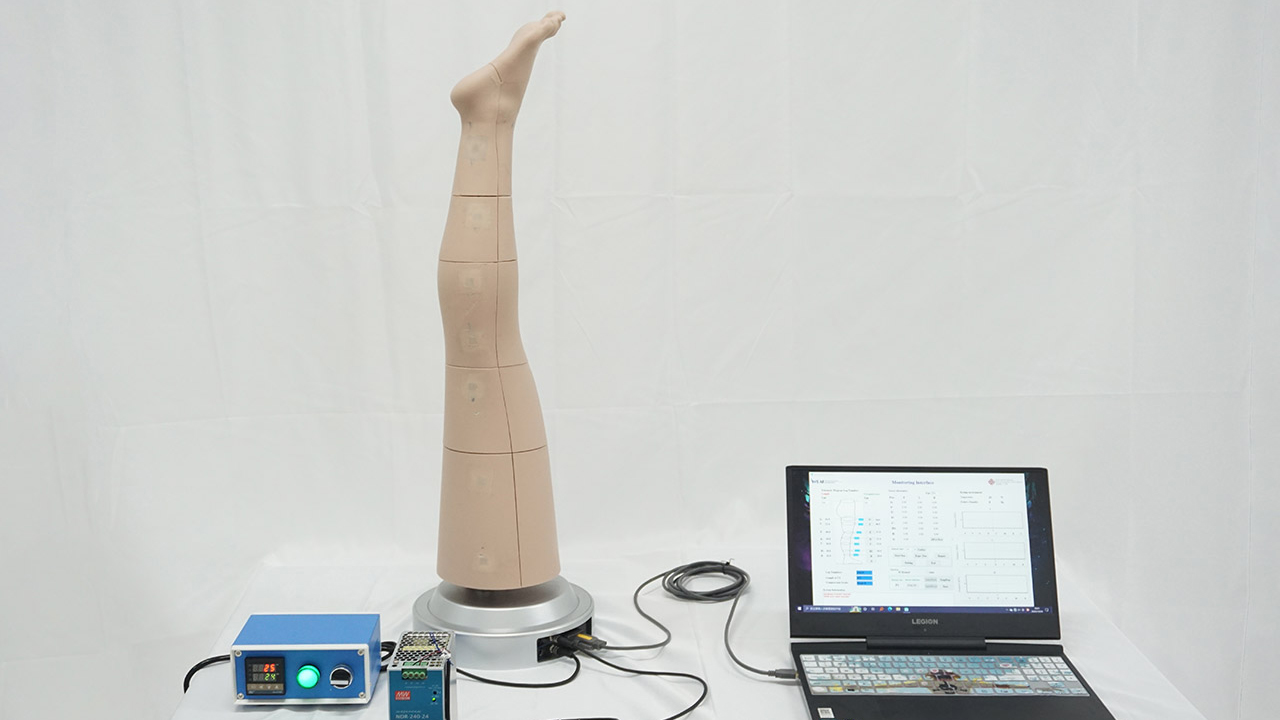

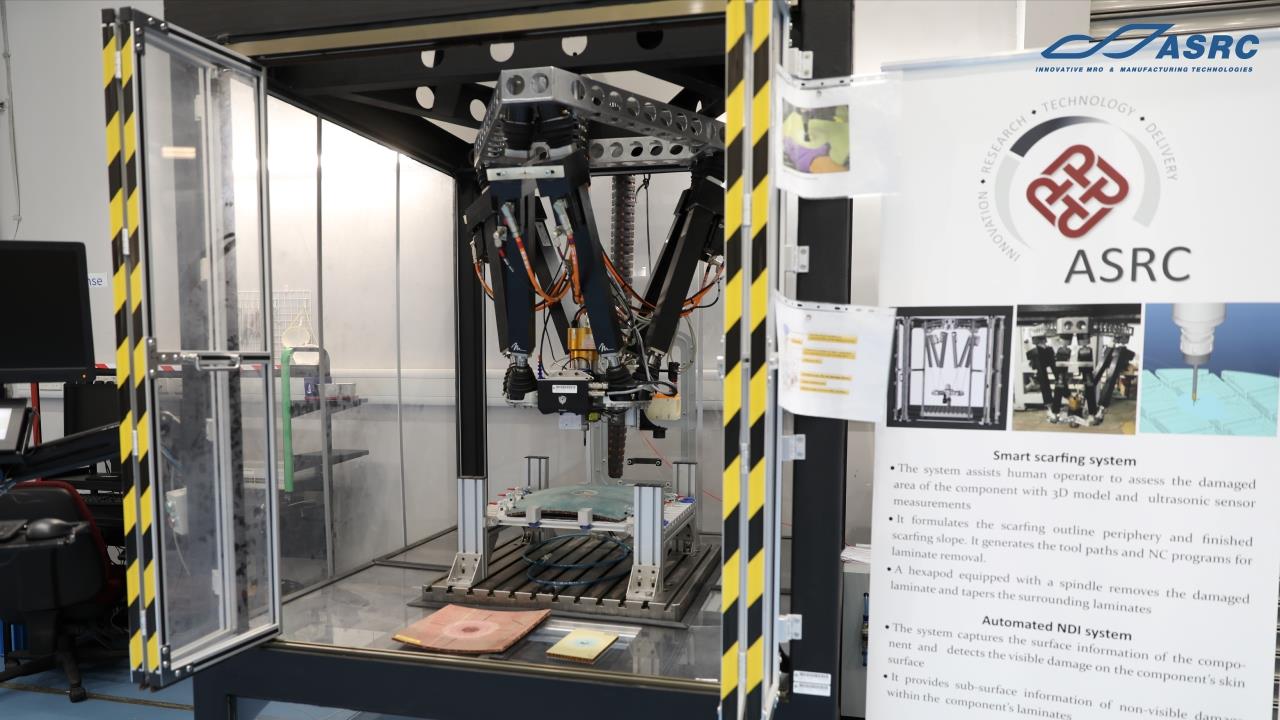

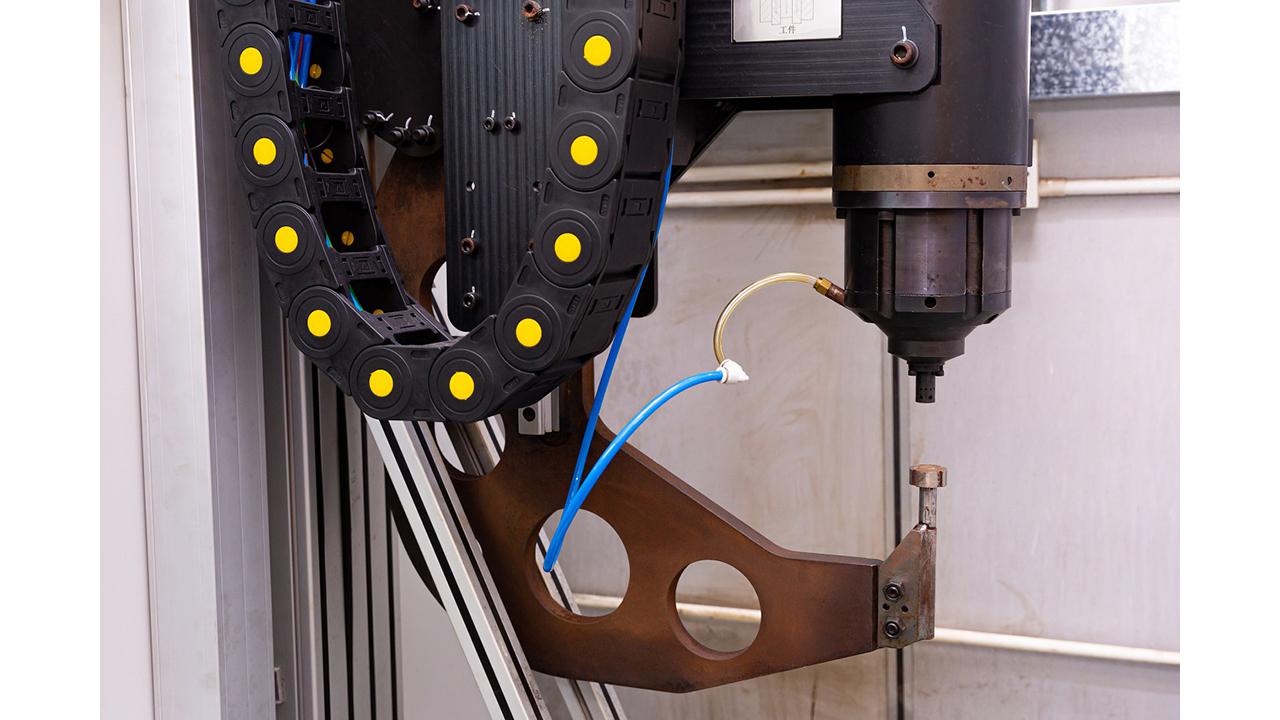

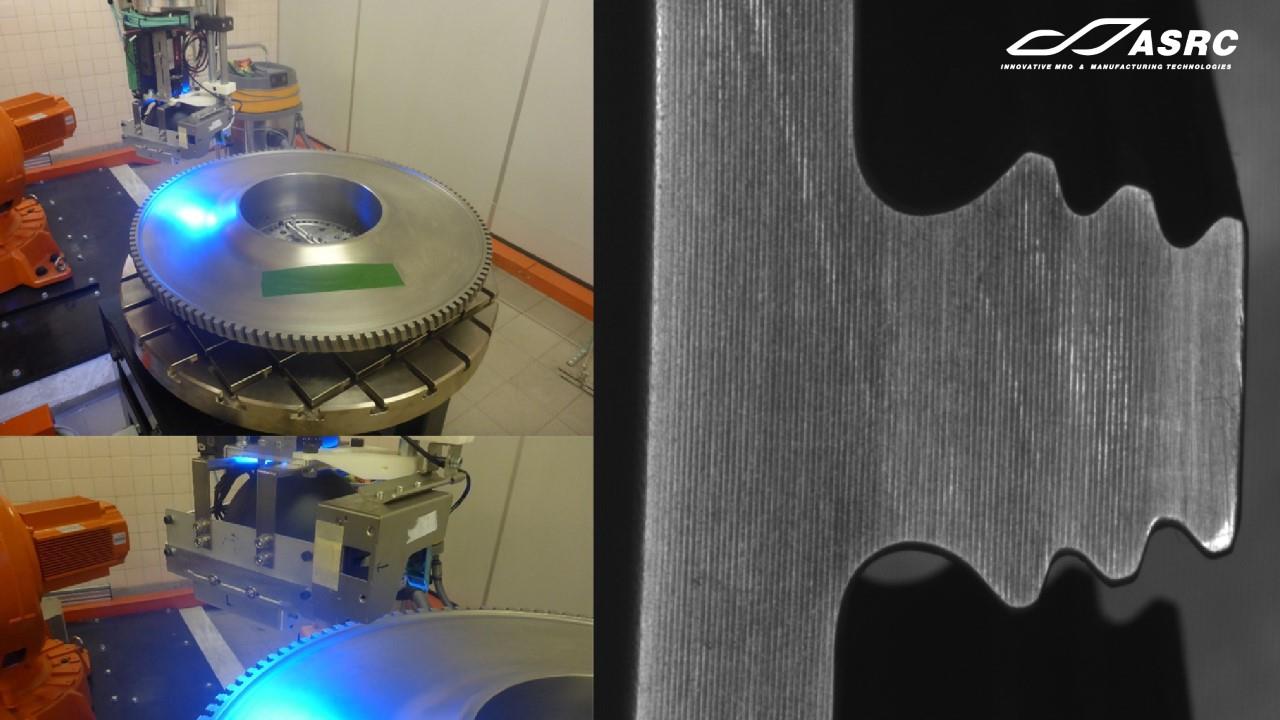

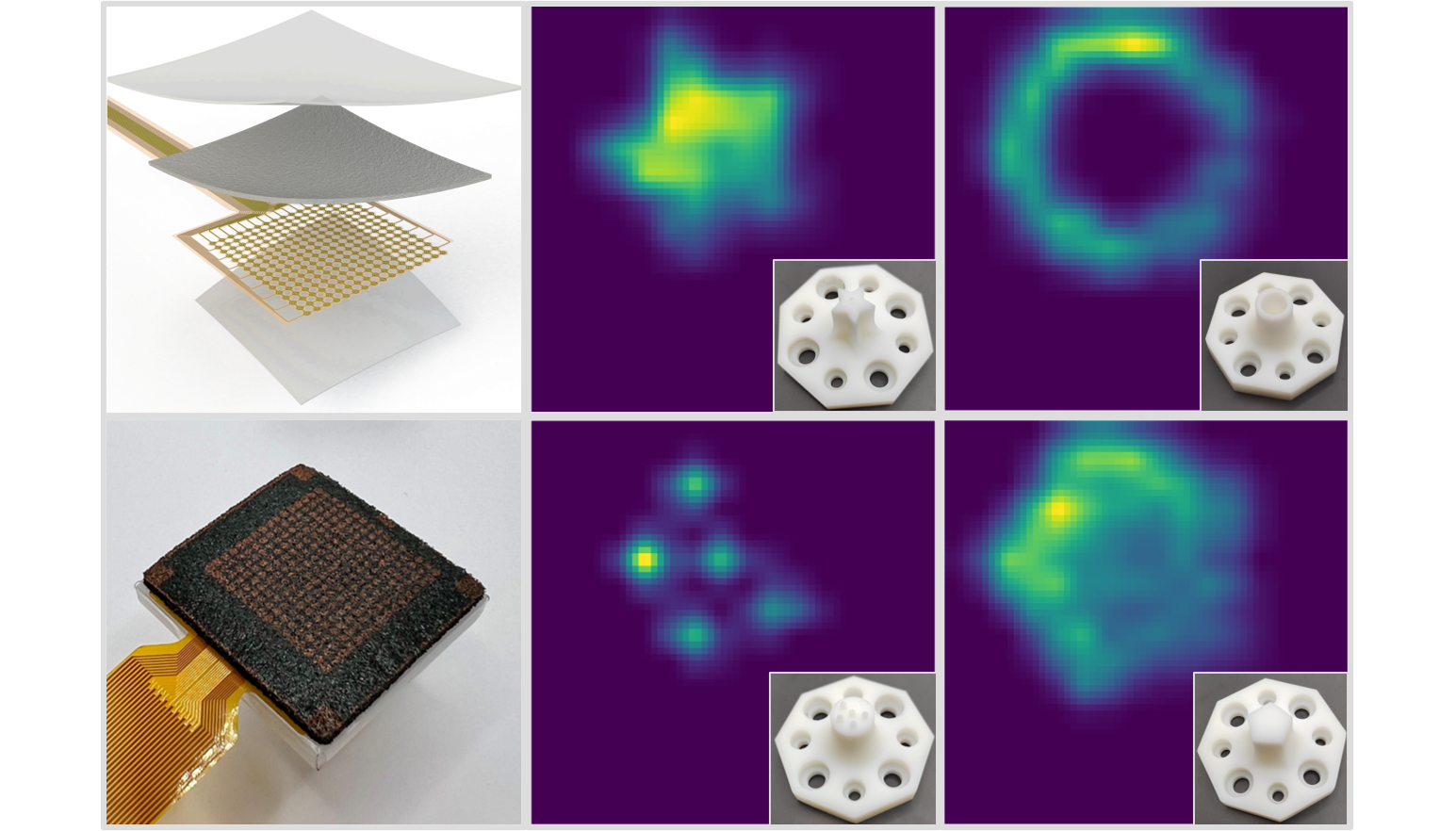

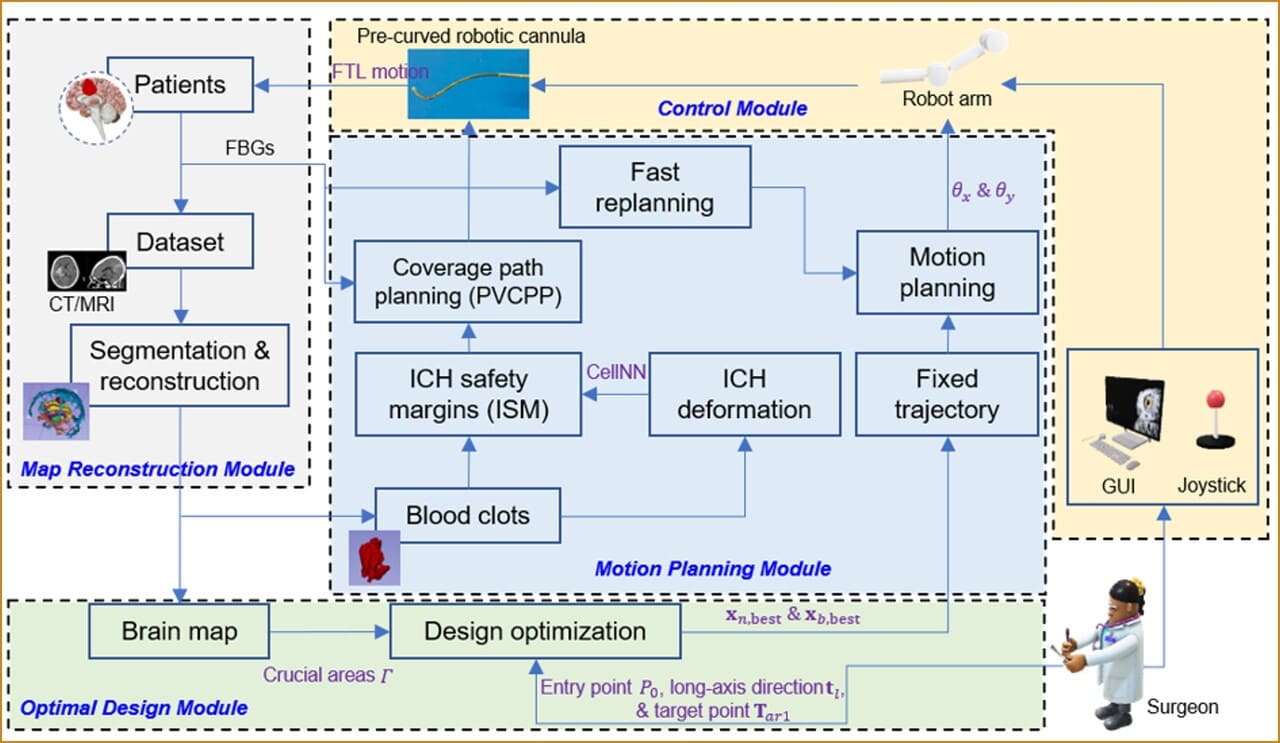

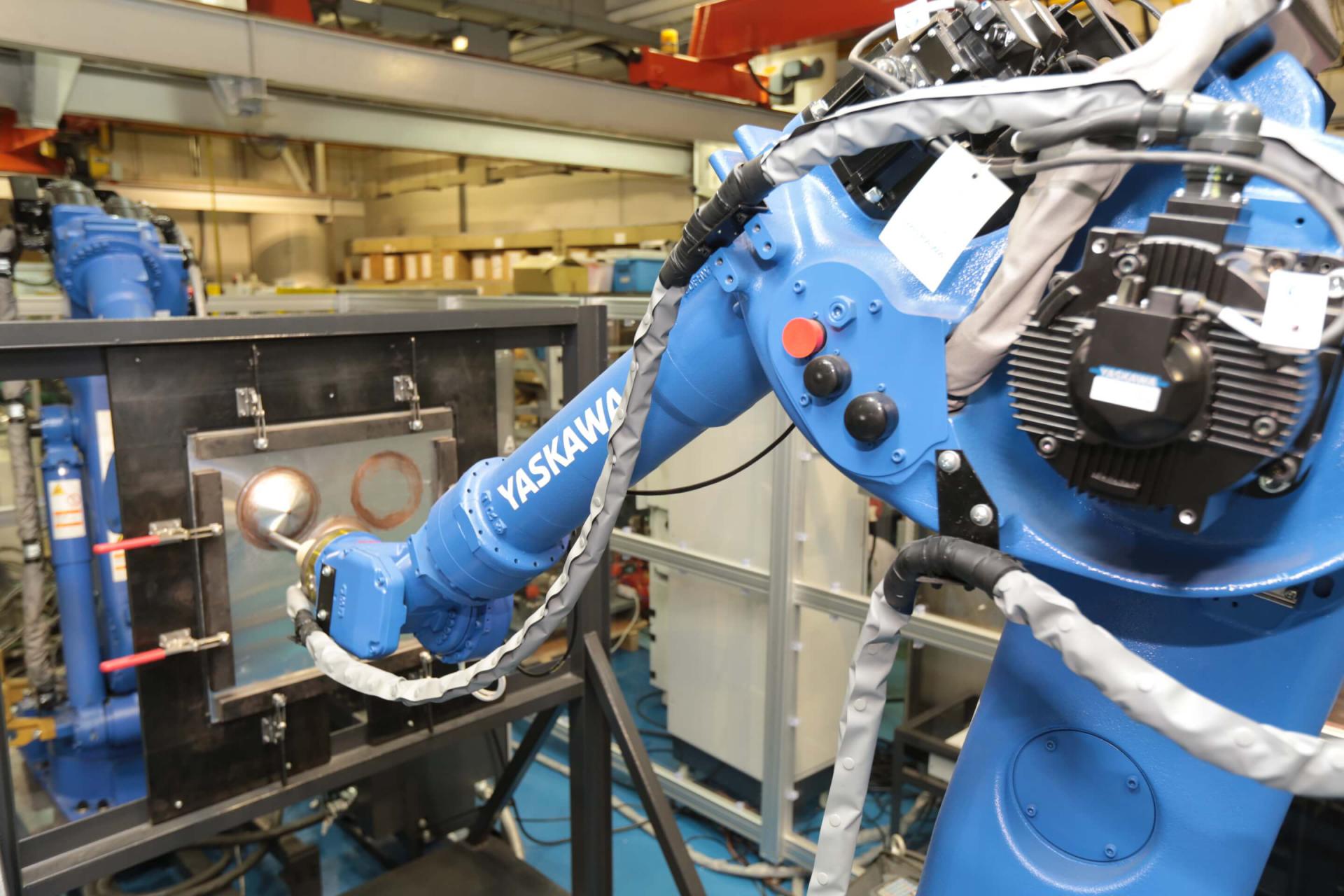

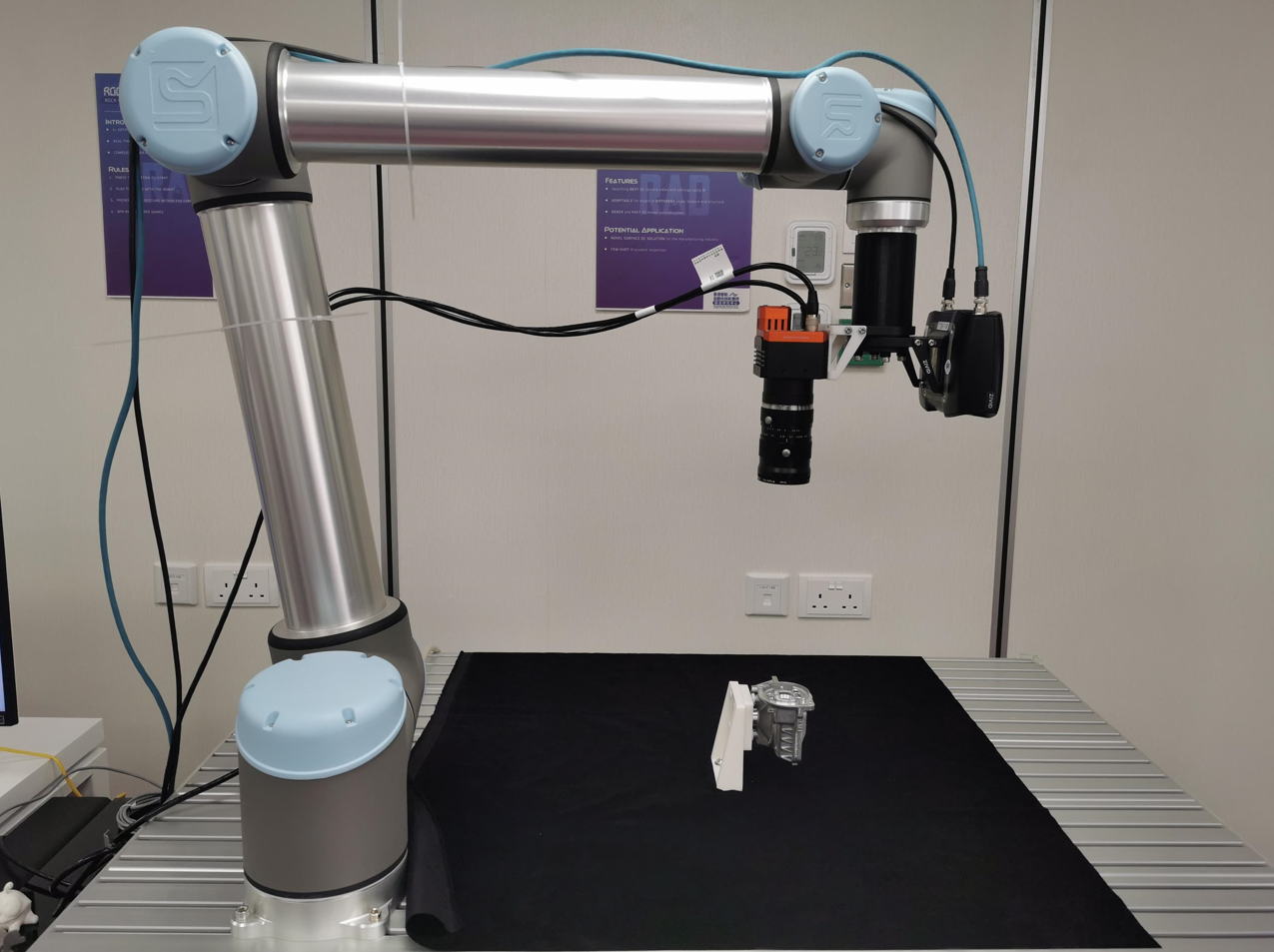

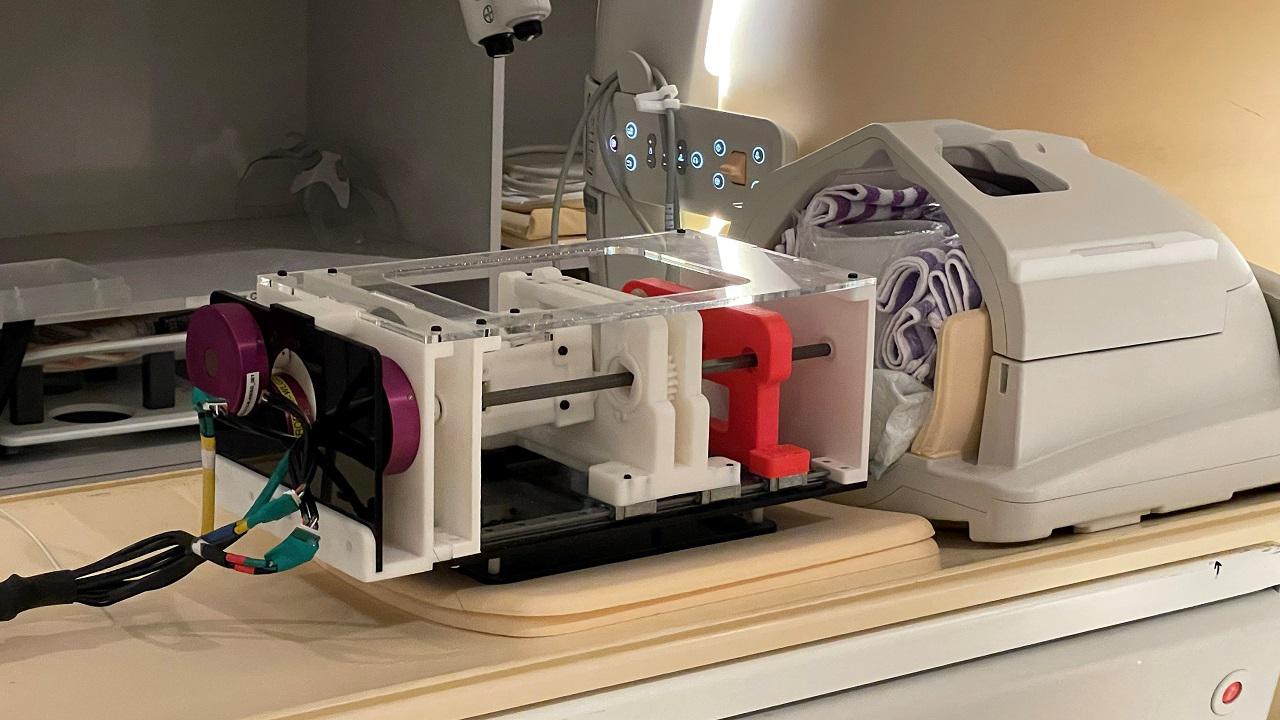

The technology integrates additive and subtractive manufacturing and creates synergy. Laser is utilised to melt the deposited metal powder feedstock excreted by the nozzle to build the near net shape of metal parts. Meanwhile, the milling process will be added in between the laser energy deposition processes to maintain the dimension and the surface quality of the metal parts.

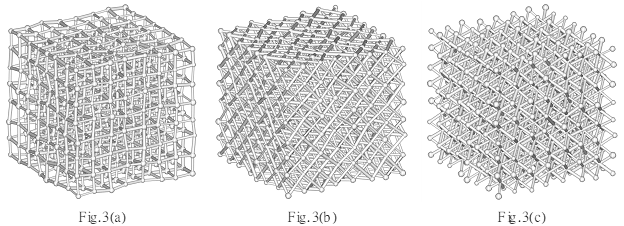

Due to the rising trend of lightweight design on metal parts, the demand for highly complex metal parts is rising. However, the additive and subtractive technology for metal parts have their own drawbacks, which are poor surface finish and dimensional accuracy, and limited geometry respectively, making the production of complex metal parts difficult and costly.

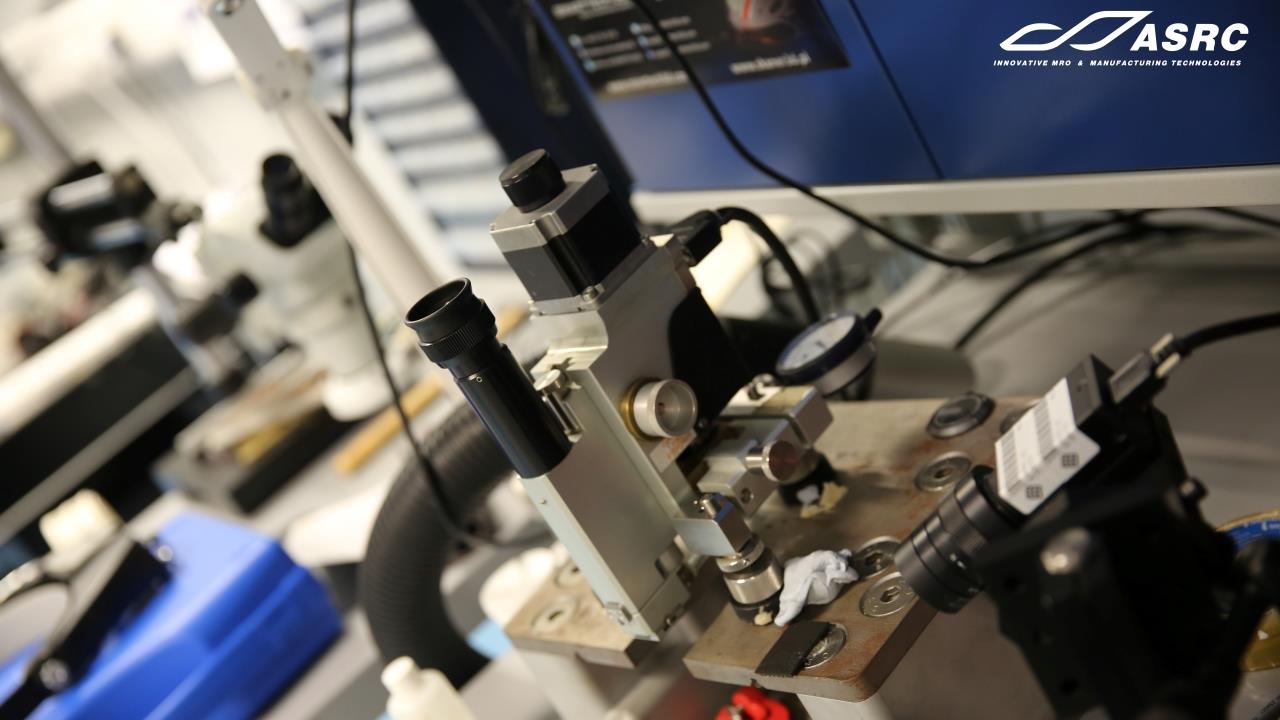

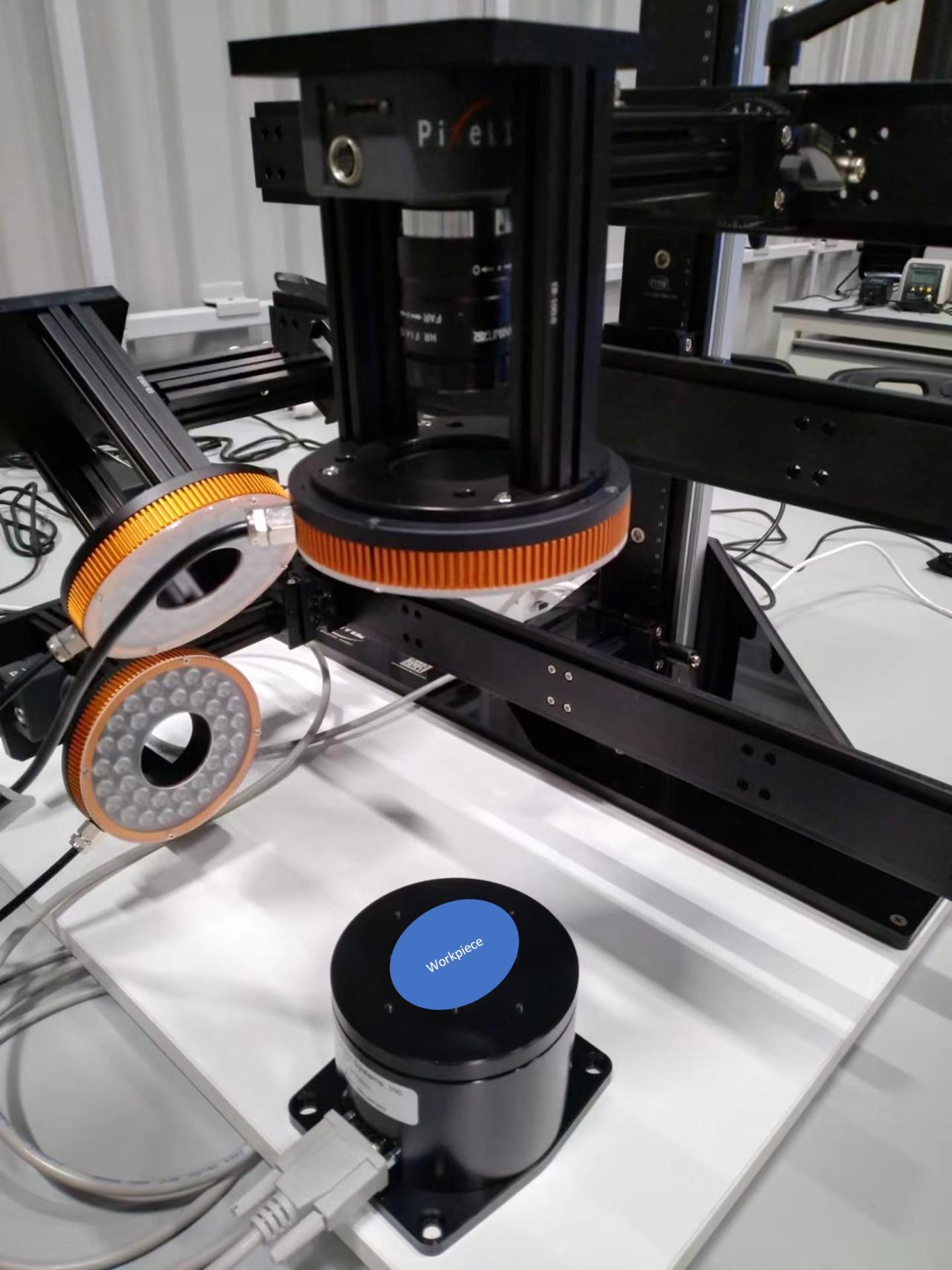

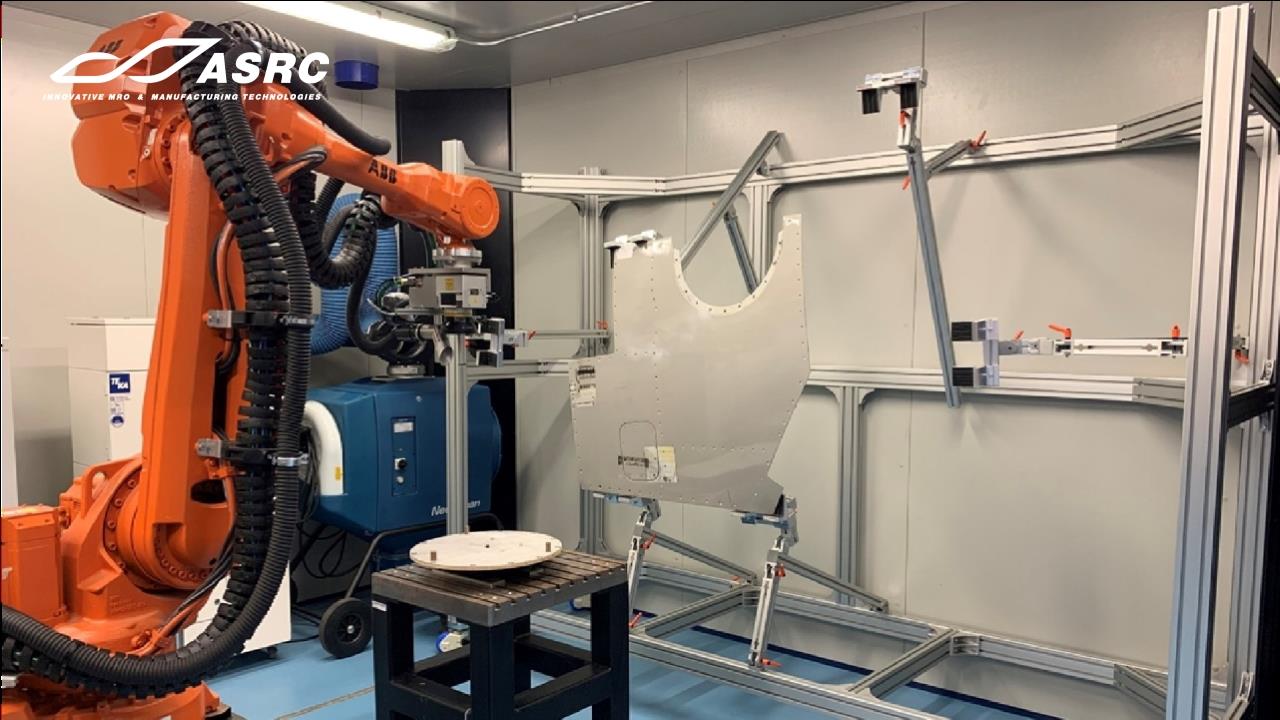

- The technology utilises a 3-axis rotary telescopic arm and standardised fixtures for the exchange of the laser energy deposition and milling process.

- Unlike traditional metal 3D printing processes, this mechanism enables simultaneous production of two metal parts with minimal machine footprint. Hence, the production speed can be greatly enhanced.

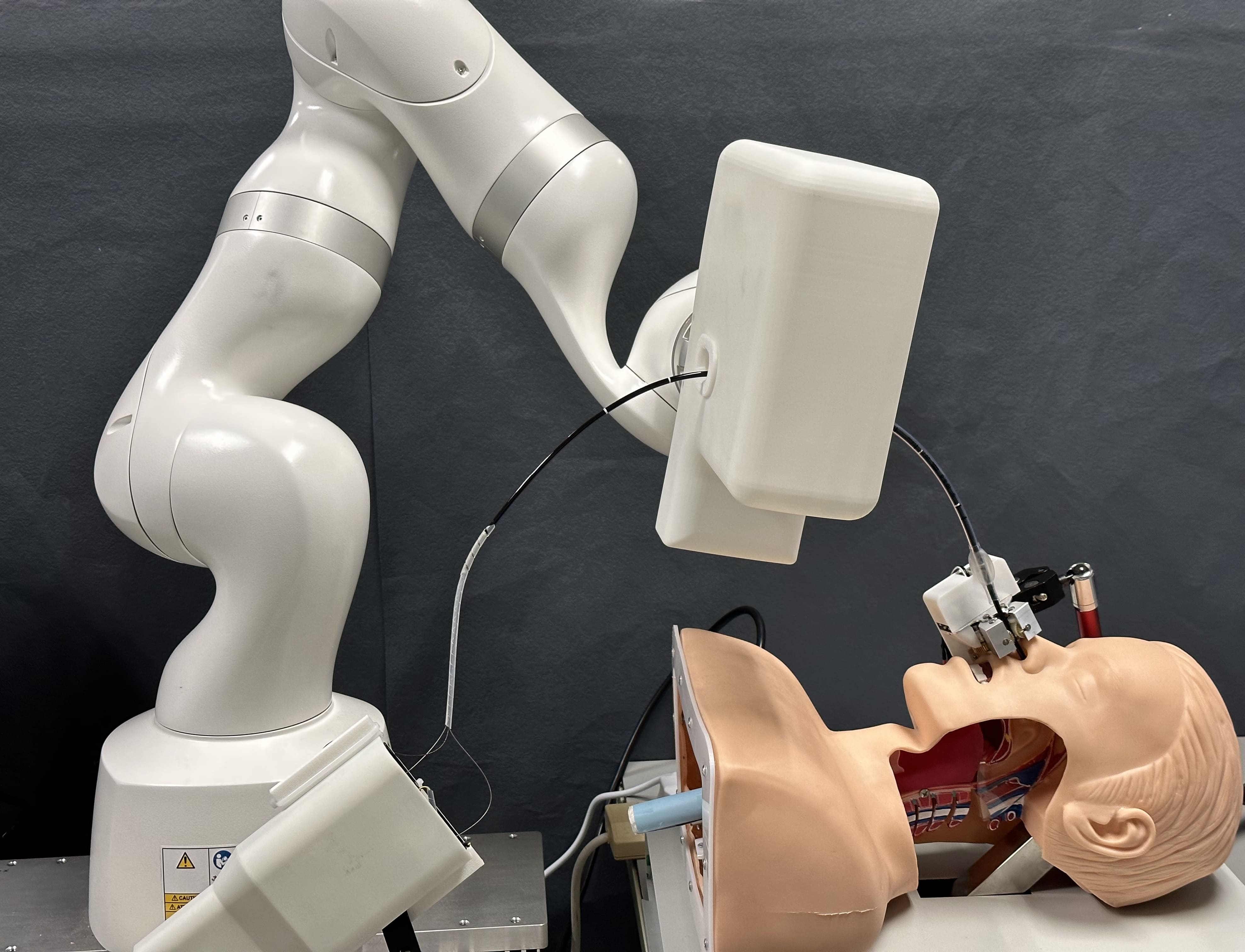

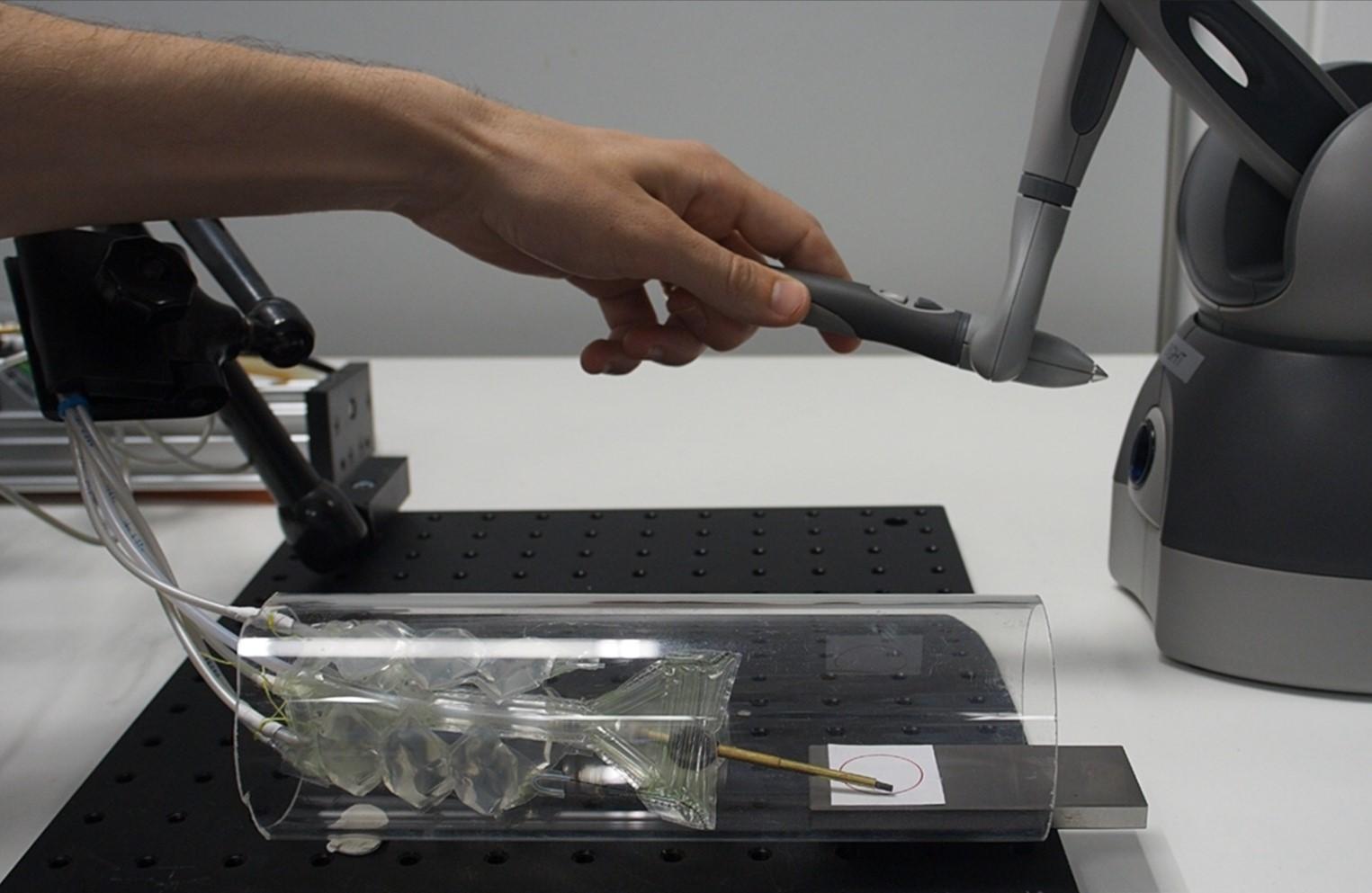

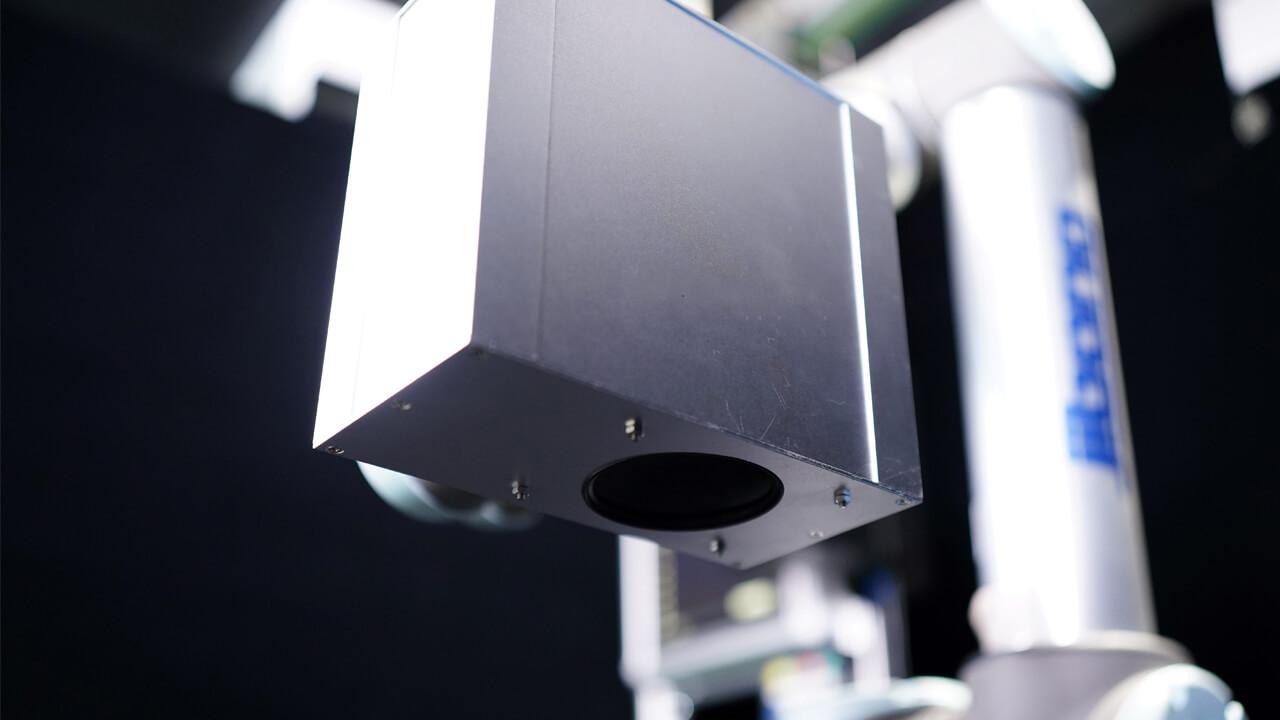

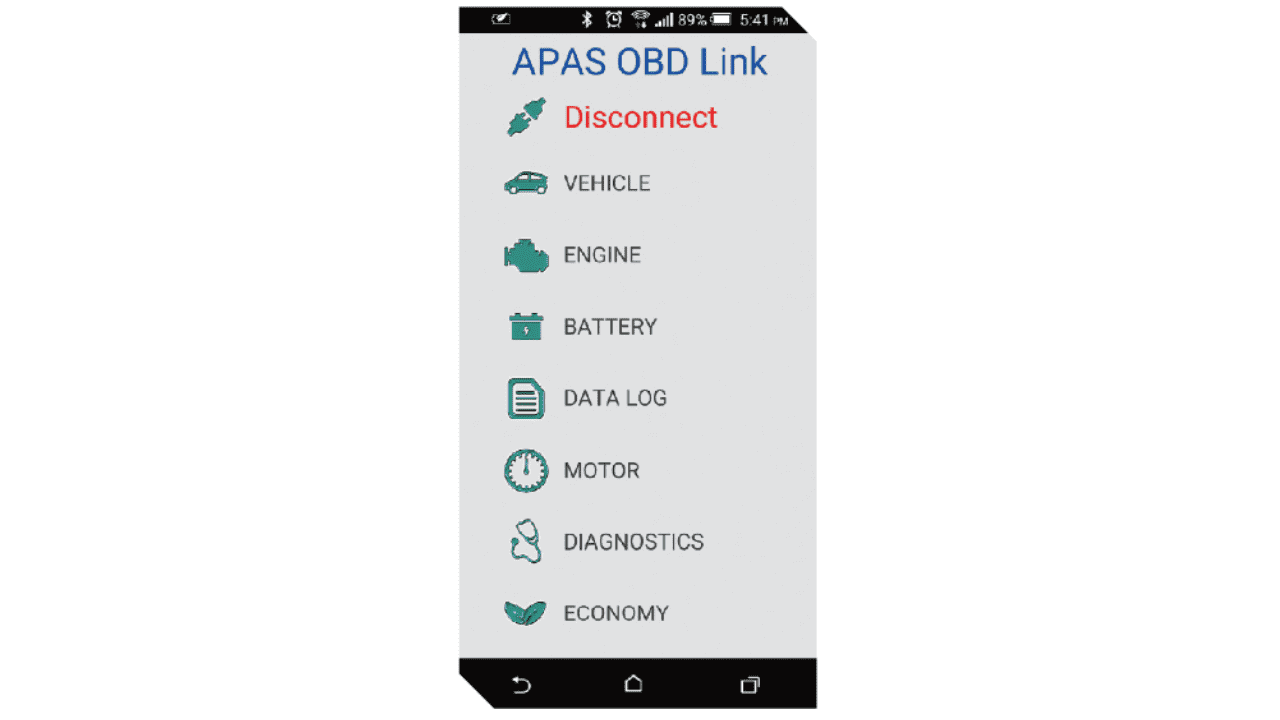

- Instead of a Computer Numerical Control (CNC) system, a robot arm is used fr holding the nozzle. The working space of the laser energy deposition process is greatly increased from the confined space of the CNC system to the working space of the robot arm.

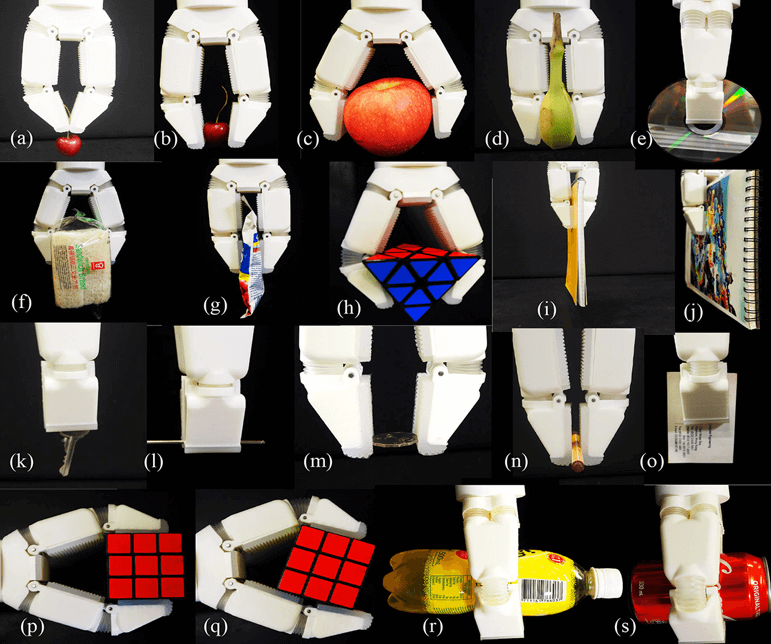

- The technology creates a synergy of both additive and subtractive manufacturing by combining their advantages, complementing the disadvantages. In other words, the technology can produce huge and highly complex metal parts via laser energy deposition process and maintain the surface finishing and dimensional accuracy by using precision milling.

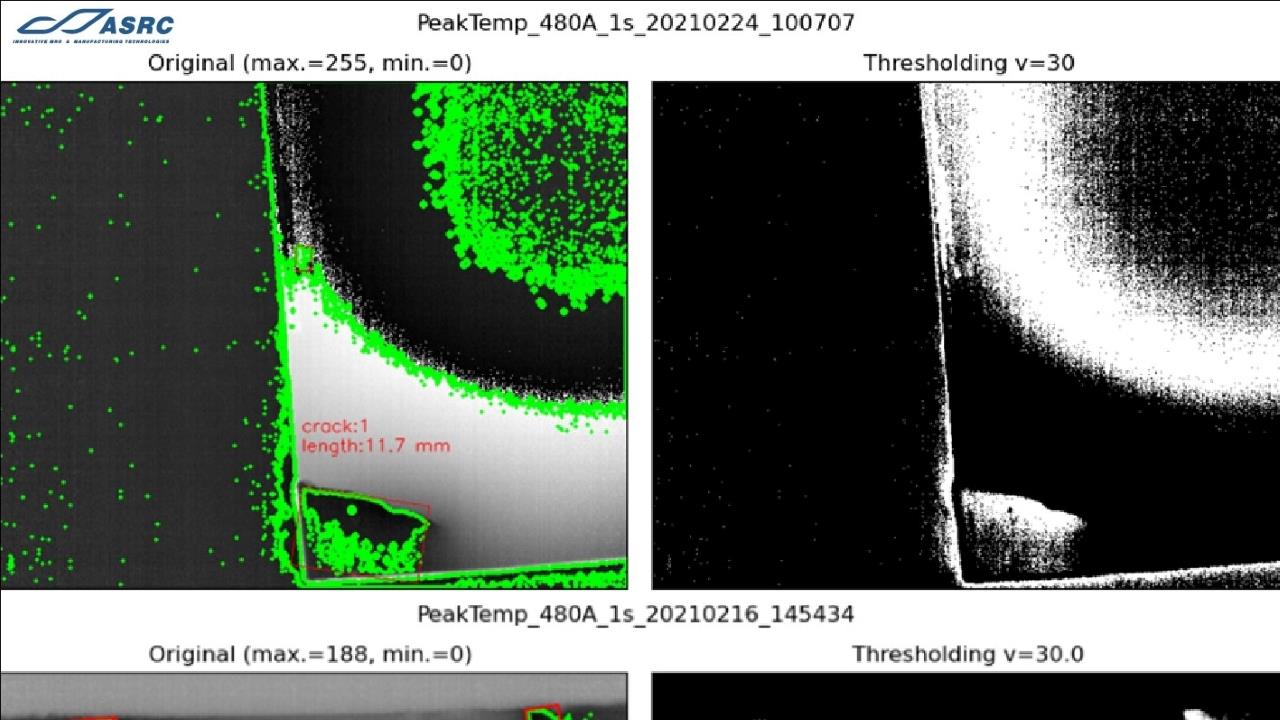

- It can repair metal parts by cladding metal on the cracks.

- The design of this machine enables the simultaneous production of two metal parts, greatly enhancing the production efficiency of the machine by doubling its output. The space utilisation ratio of the machine is also higher than traditional machines.

- Unlike traditional metal 3D printing technologies, this innovation greatly enhances the efficiency of metal 3D printing. Also, as the system only deposits the necessary metal powder during production, its material utilisation rate is also higher when compared with traditional technology.

- 2021 Geneva International Exhibition of Inventions - Gold Medal

- Automotive and aerospace components

- Critical components

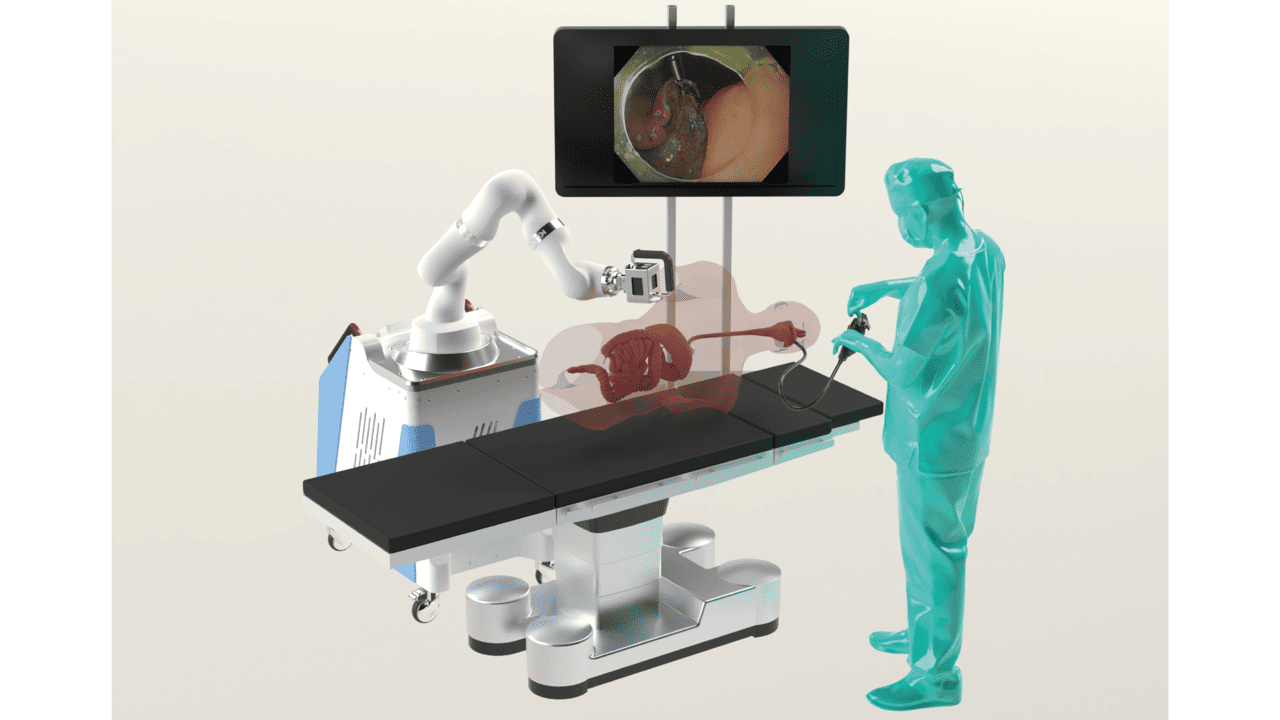

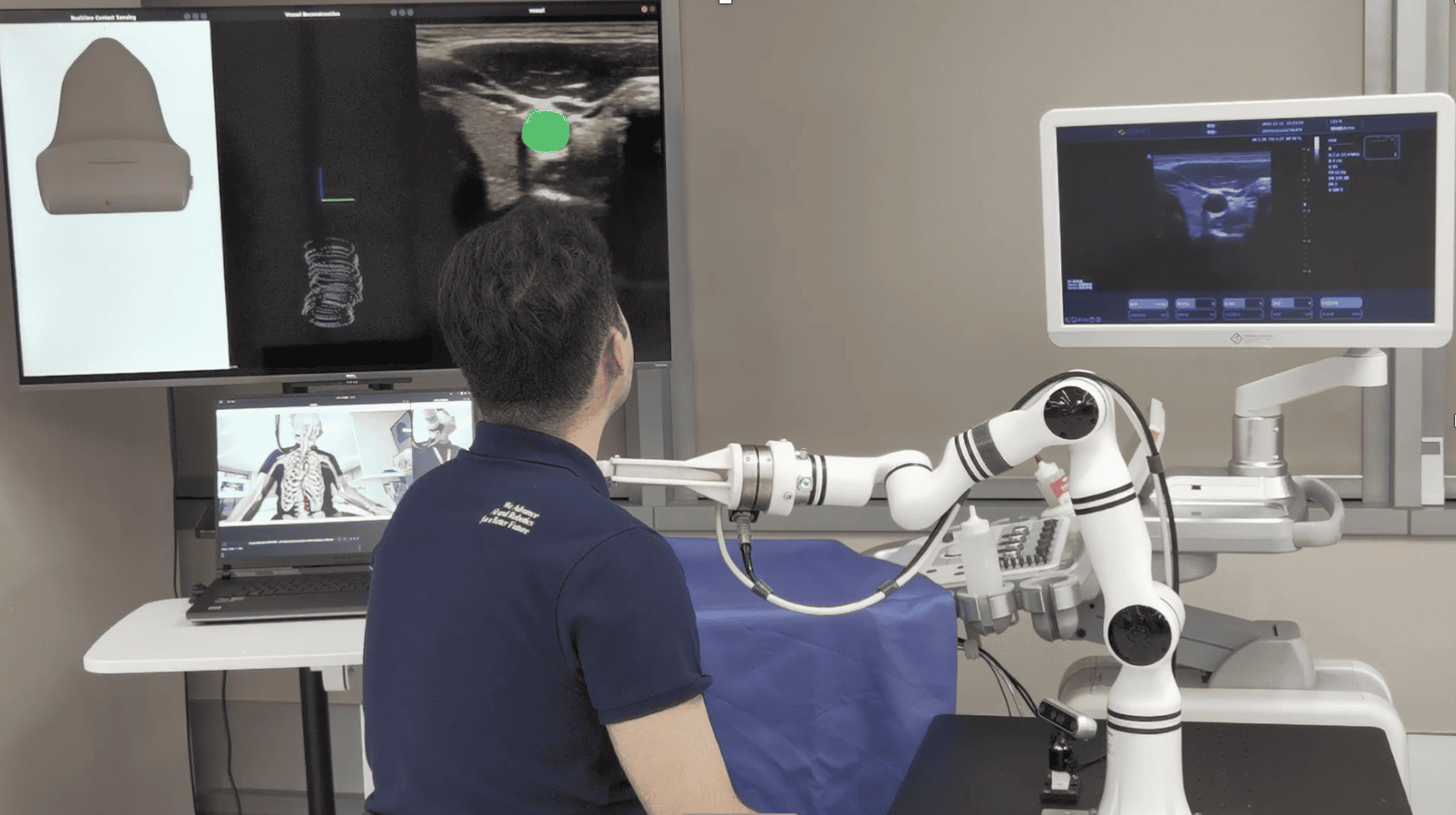

- Medical implants

- Mould

Patent

- China Utility Patent: 201820313859.1

- Hong Kong short term: HK1243275A

The Hong Kong Productivity Council (HKPC) is a multi-disciplinary organisation established by statute in 1967, to promote productivity excellence through integrated advanced technologies and innovative service offerings to support Hong Kong enterprises. HKPC is the champion and expert in facilitating Hong Kong's new industrialisation empowered by i4.0 and e4.0 - focusing on R&D, IoT, big data analytics, AI and Robotic technology development, digital manufacturing, etc., to help enterprises and industries upgrade their business performance, lower operating costs, increase productivity and enhance competitiveness.

The Council is a trusted partner with comprehensive innovative solutions for Hong Kong industries and enterprises, enabling them to achieve resources and productivity utilisation, effectiveness and cost reduction, and enhanced competitiveness in both local and international marketplace. It offers SMEs and startups immediate and timely assistance in coping with the ever-changing business environment, accompanying them on their innovation and transformation journey.