Hybrid Moulding Technologies with Effective Adhesion/Bonding Mechanism

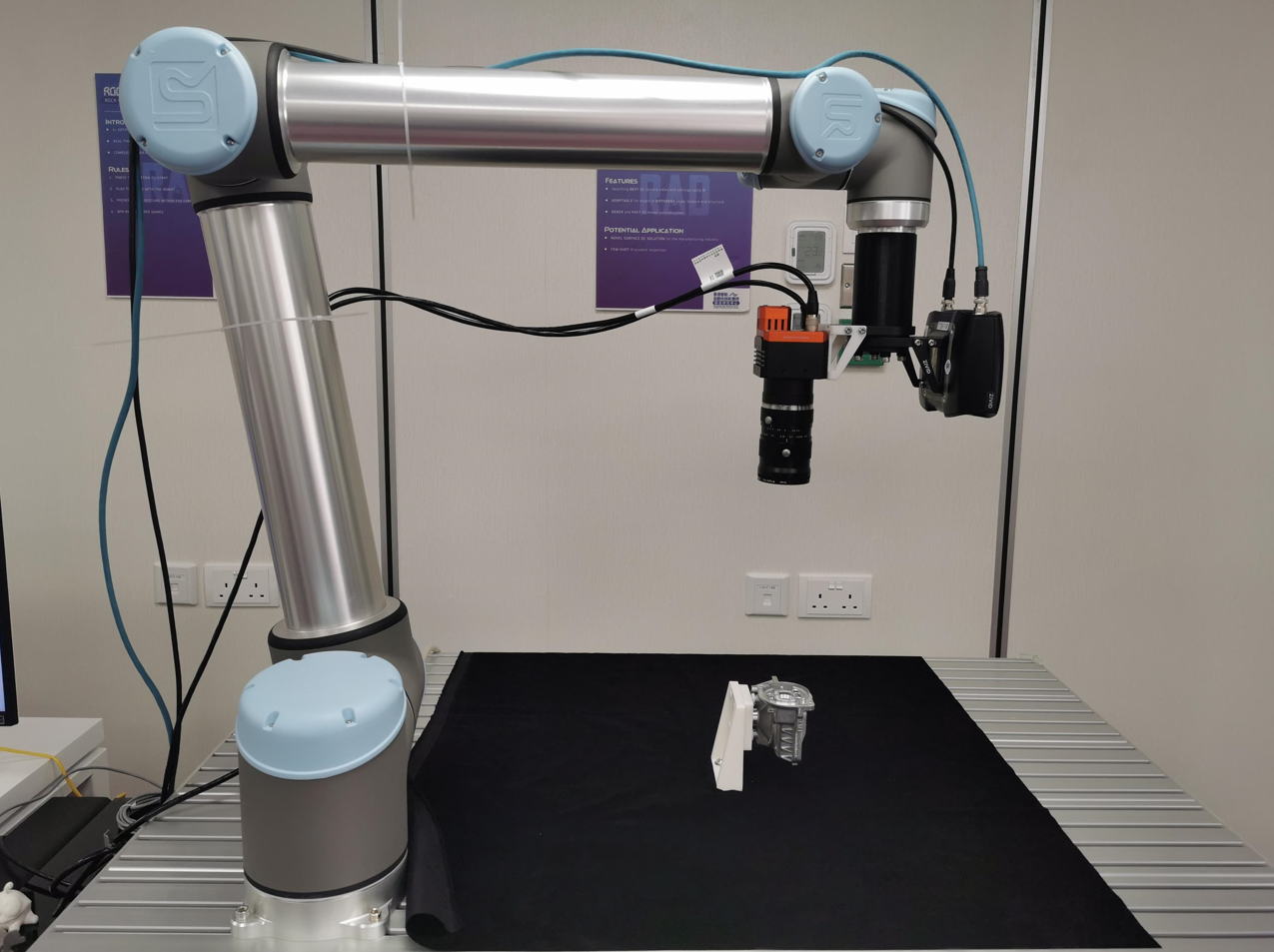

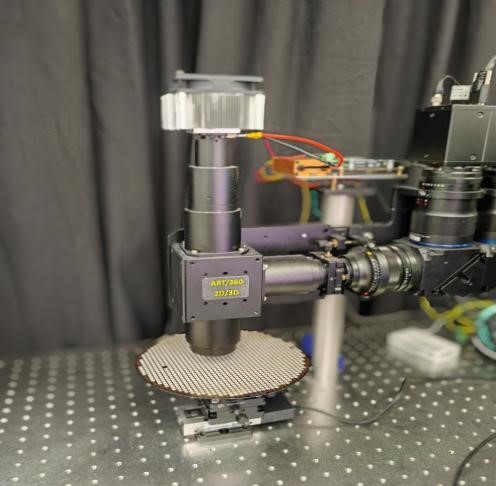

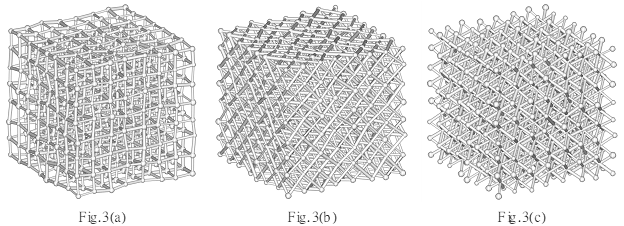

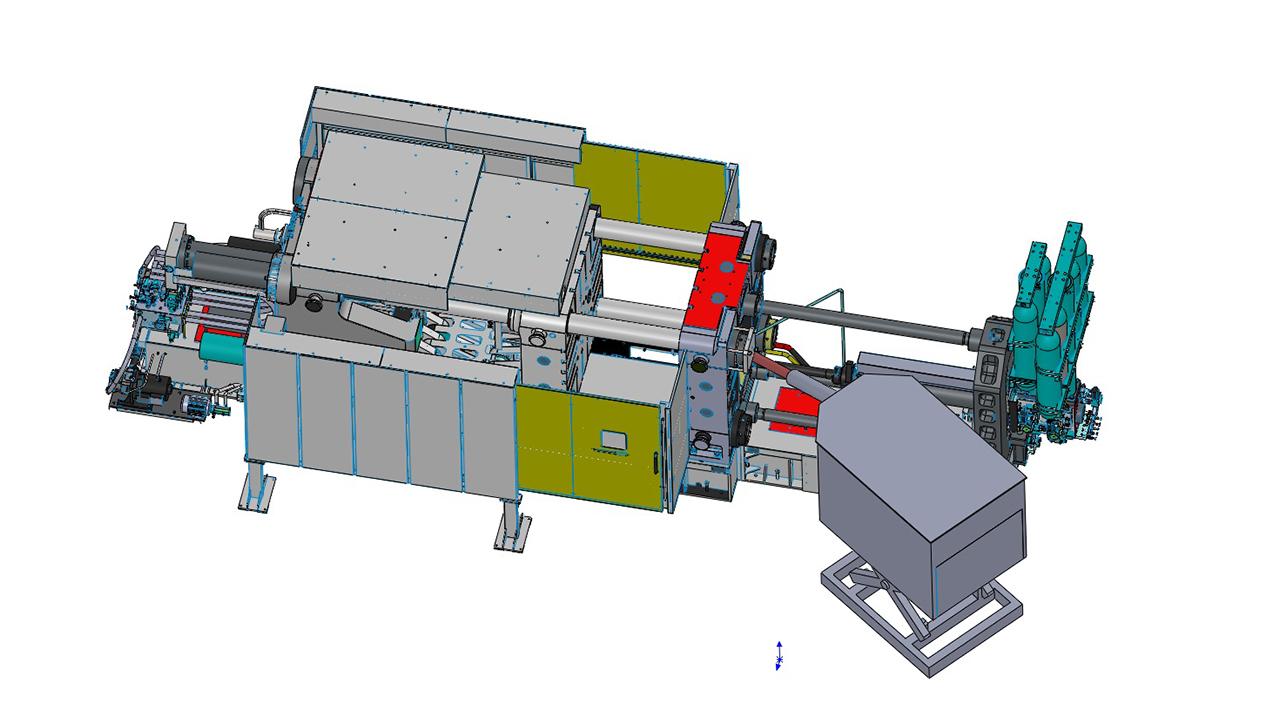

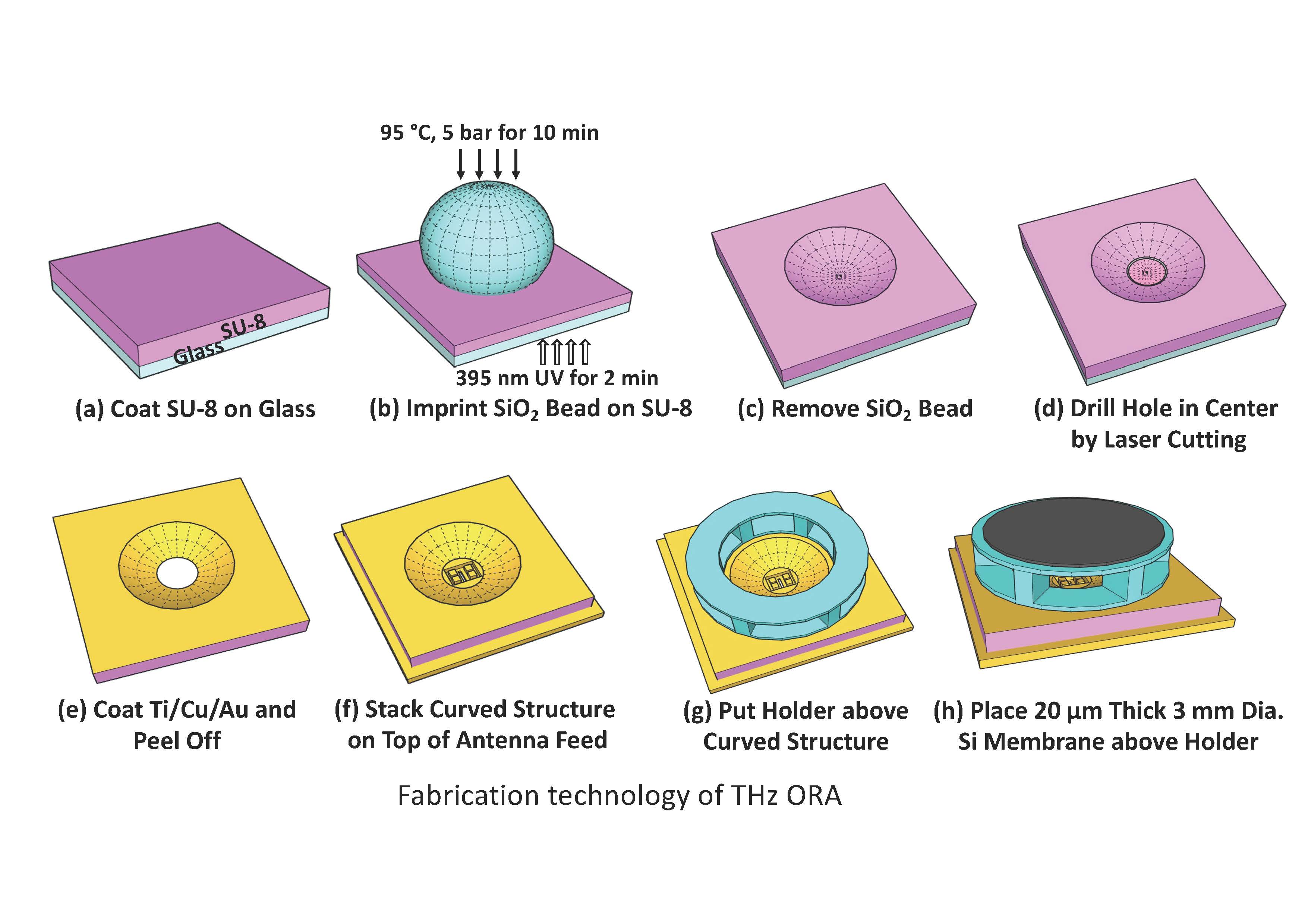

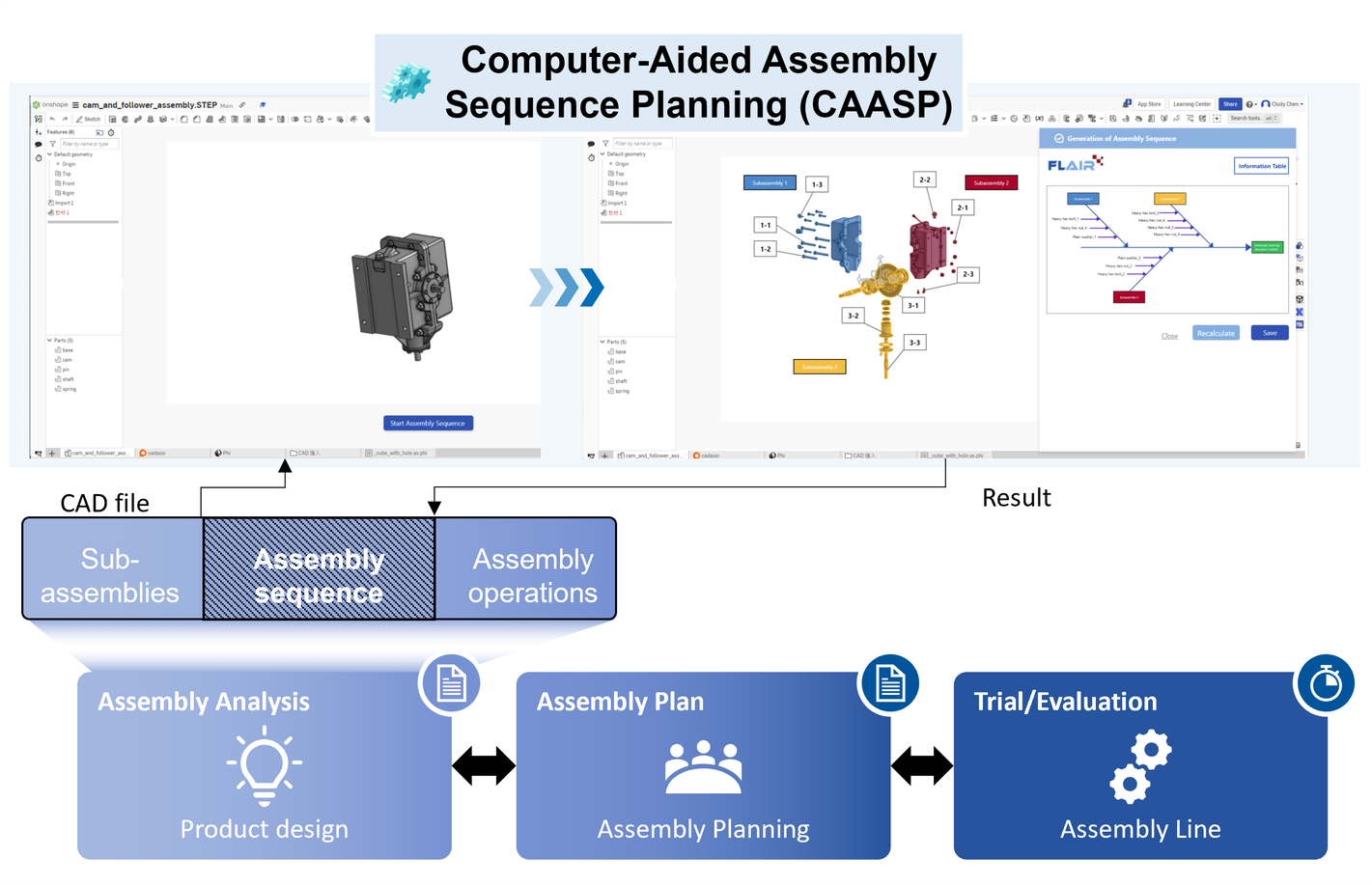

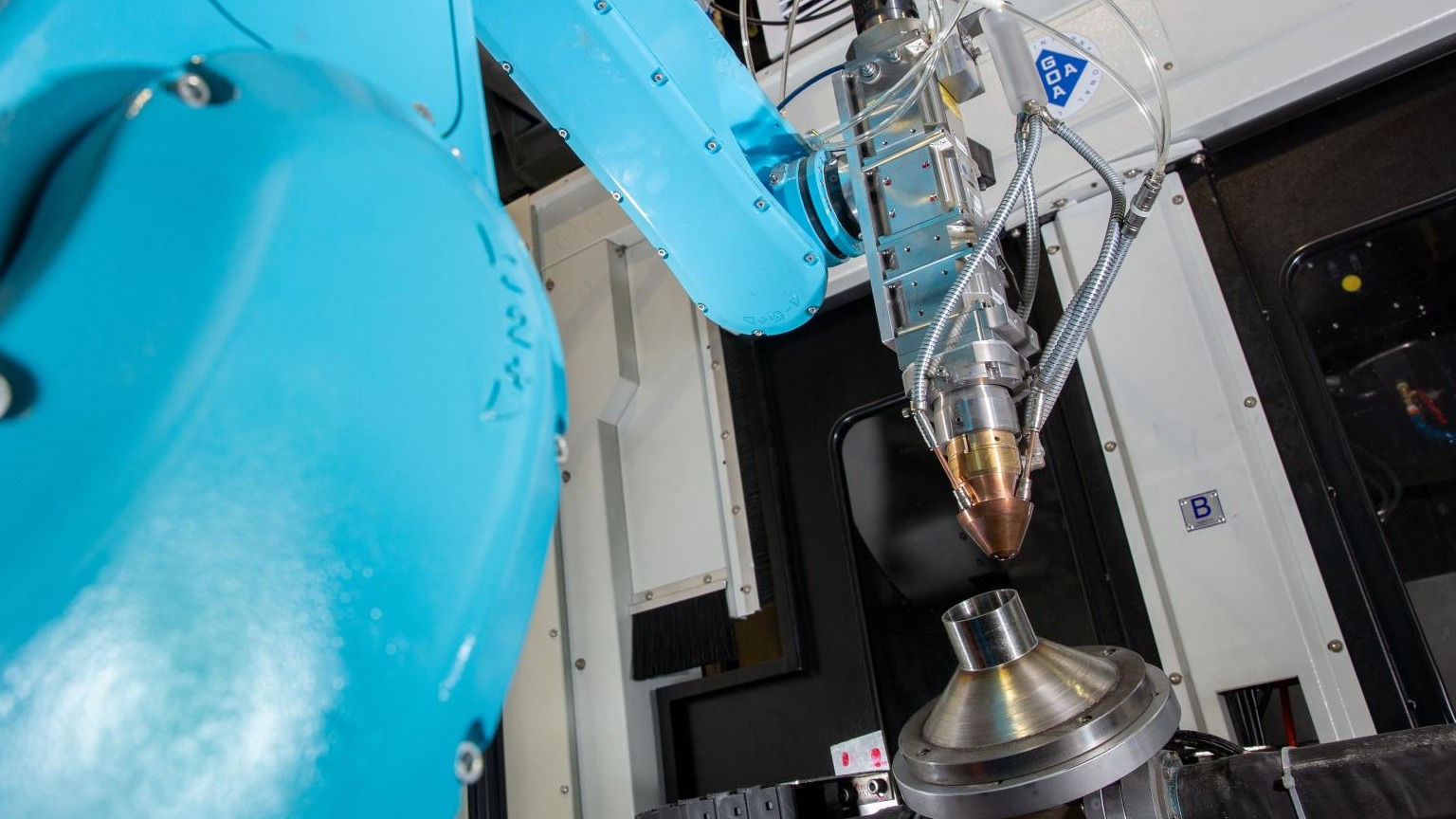

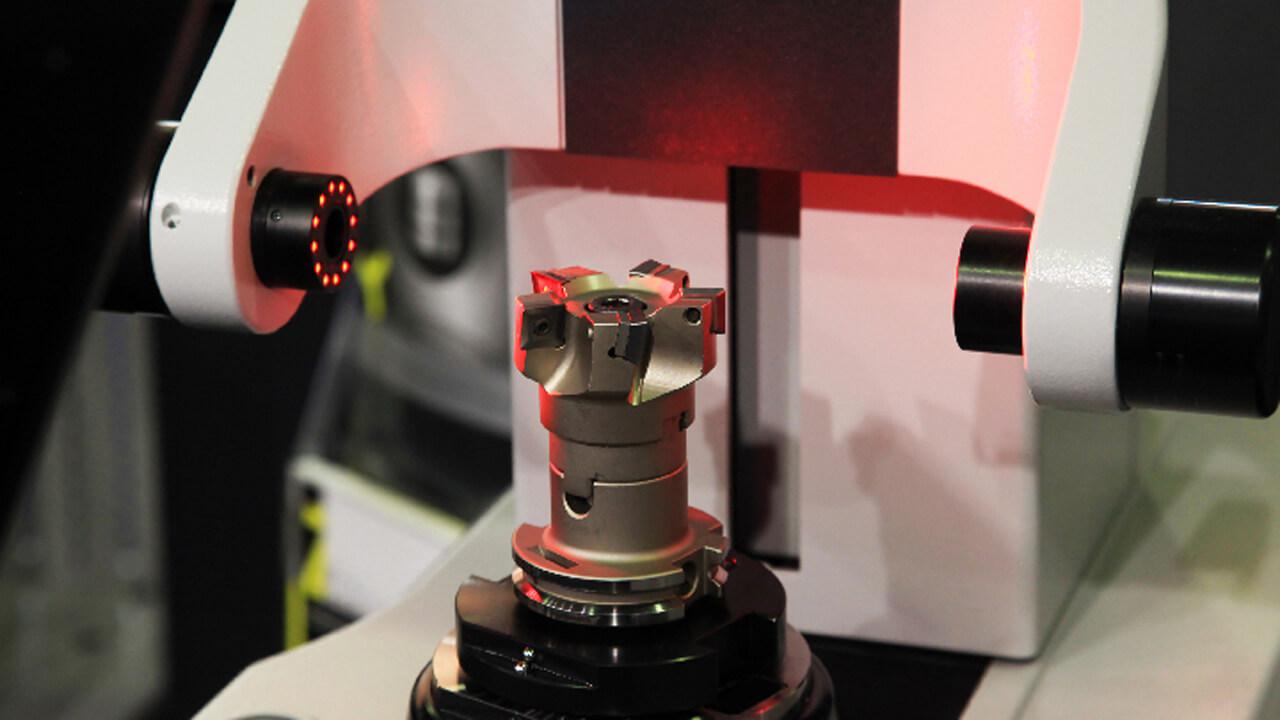

Taking the concept of insert moulding and in-mould labeling of plastic parts, the hybrid moulding technologies enable a more cost-effective production of carbon composite parts. Two low-cost methods for the mass production of carbon composite parts are developed, namely the pre-form insert moulding and pre-heat hybrid moulding.

Carbon fibre reinforced plastic (carbon composite) plays a crucial role in the growing automotive market to produce cosmetic accessories and performance-enhancing parts for automobiles. Existing production methods of composite parts are labour intensive and the production cycles are generally long, increasing the production cost of composite parts and restricting its application to high-class automotives or critical autoparts only.

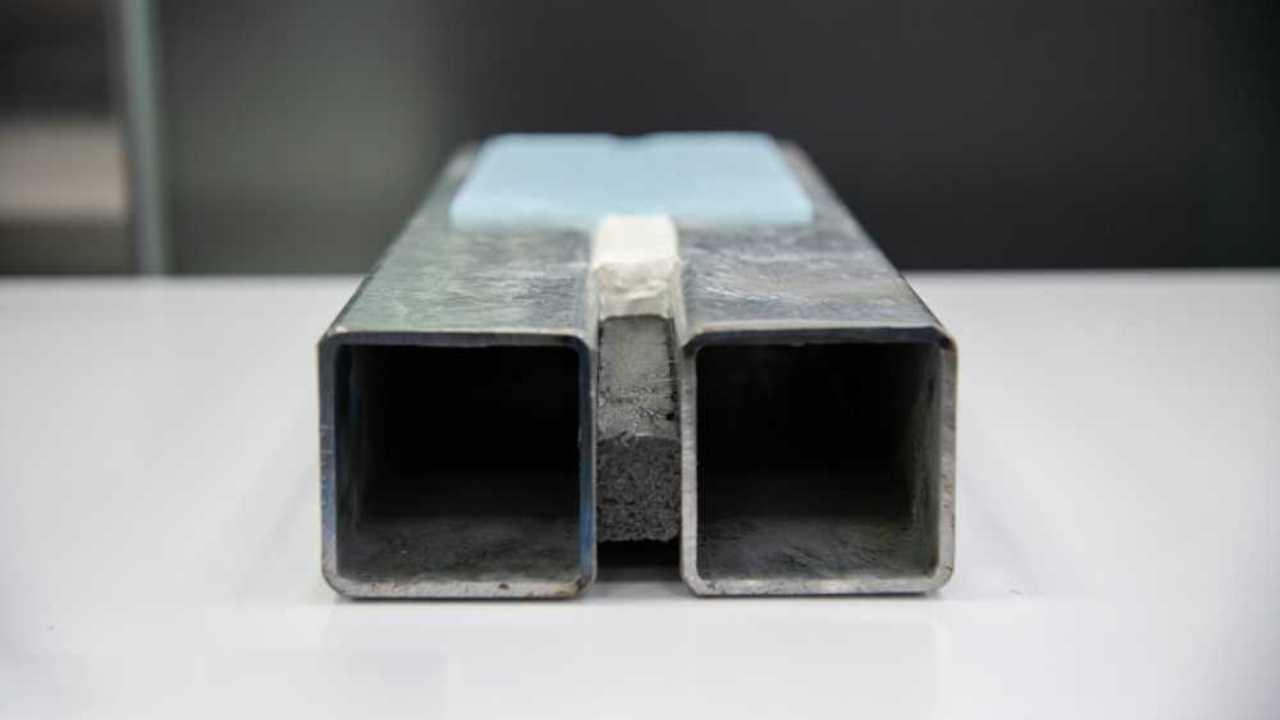

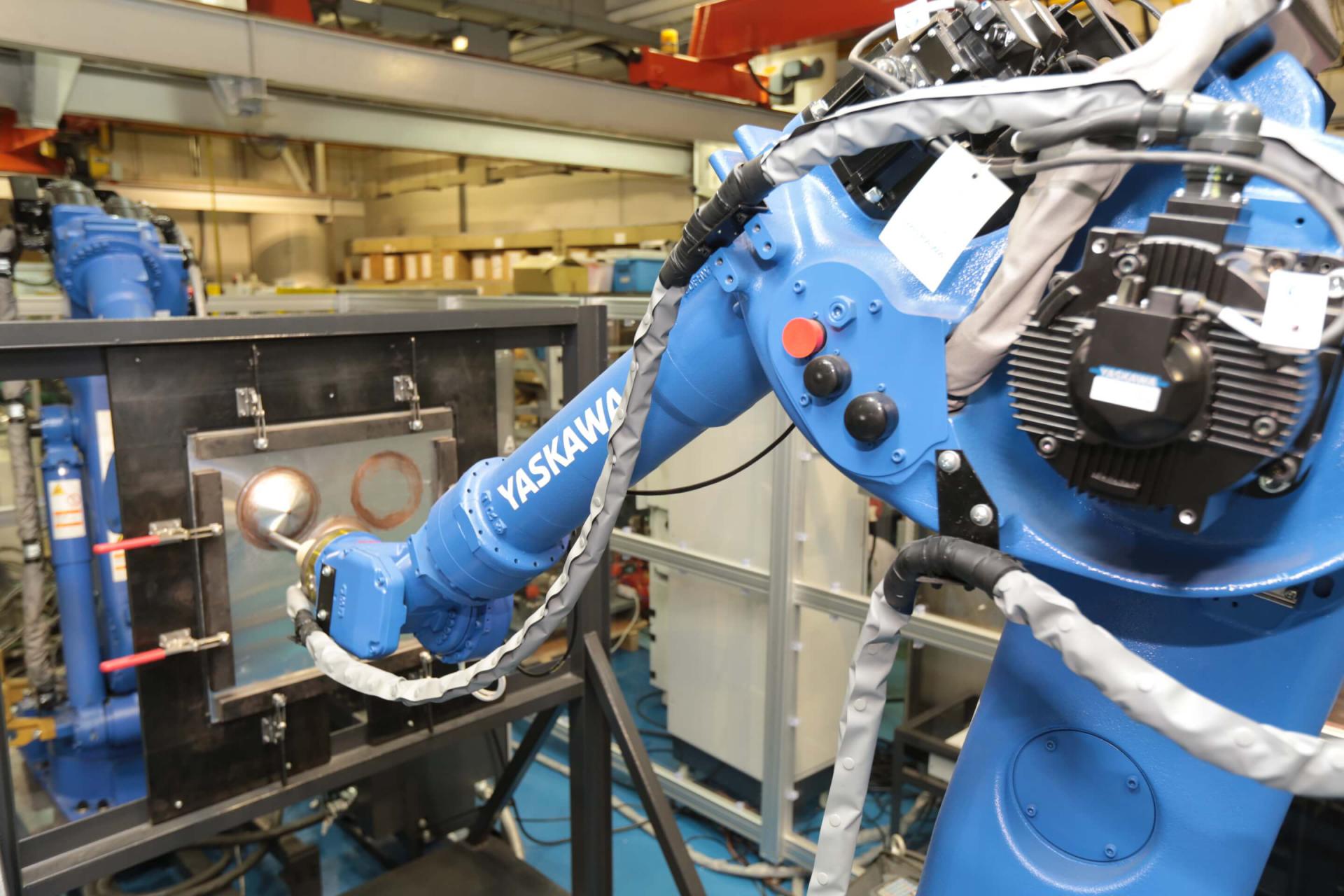

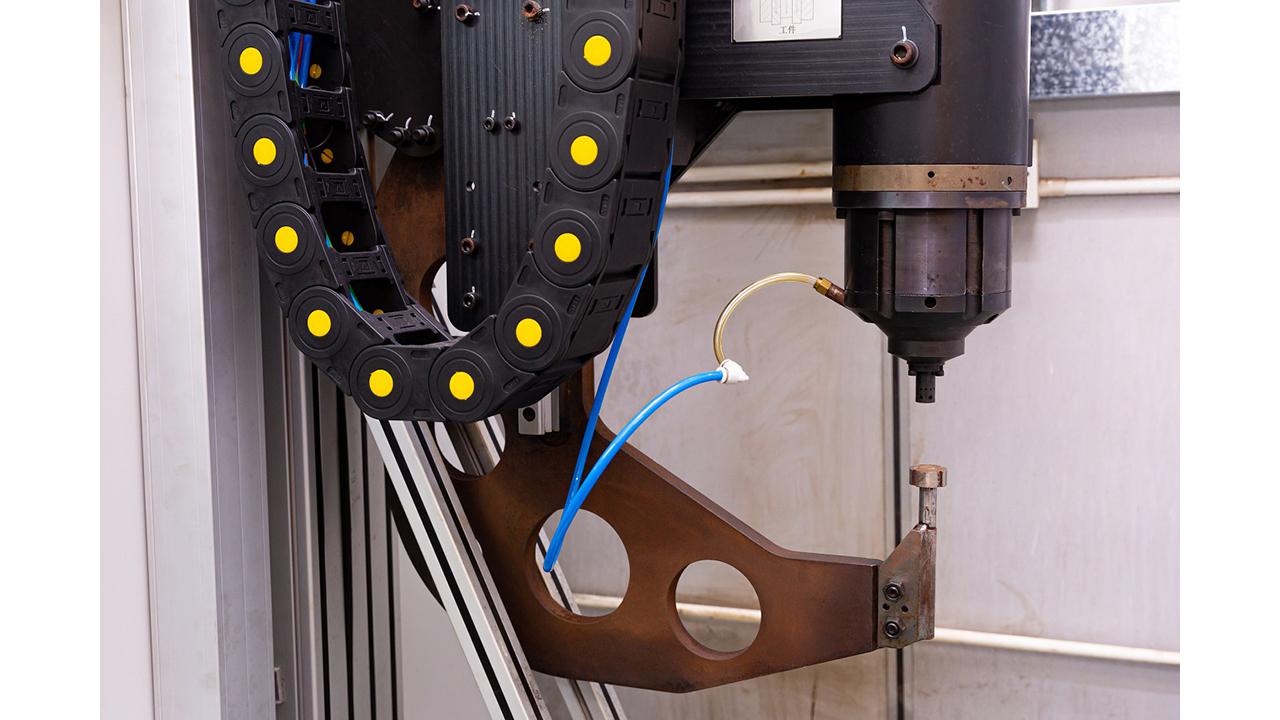

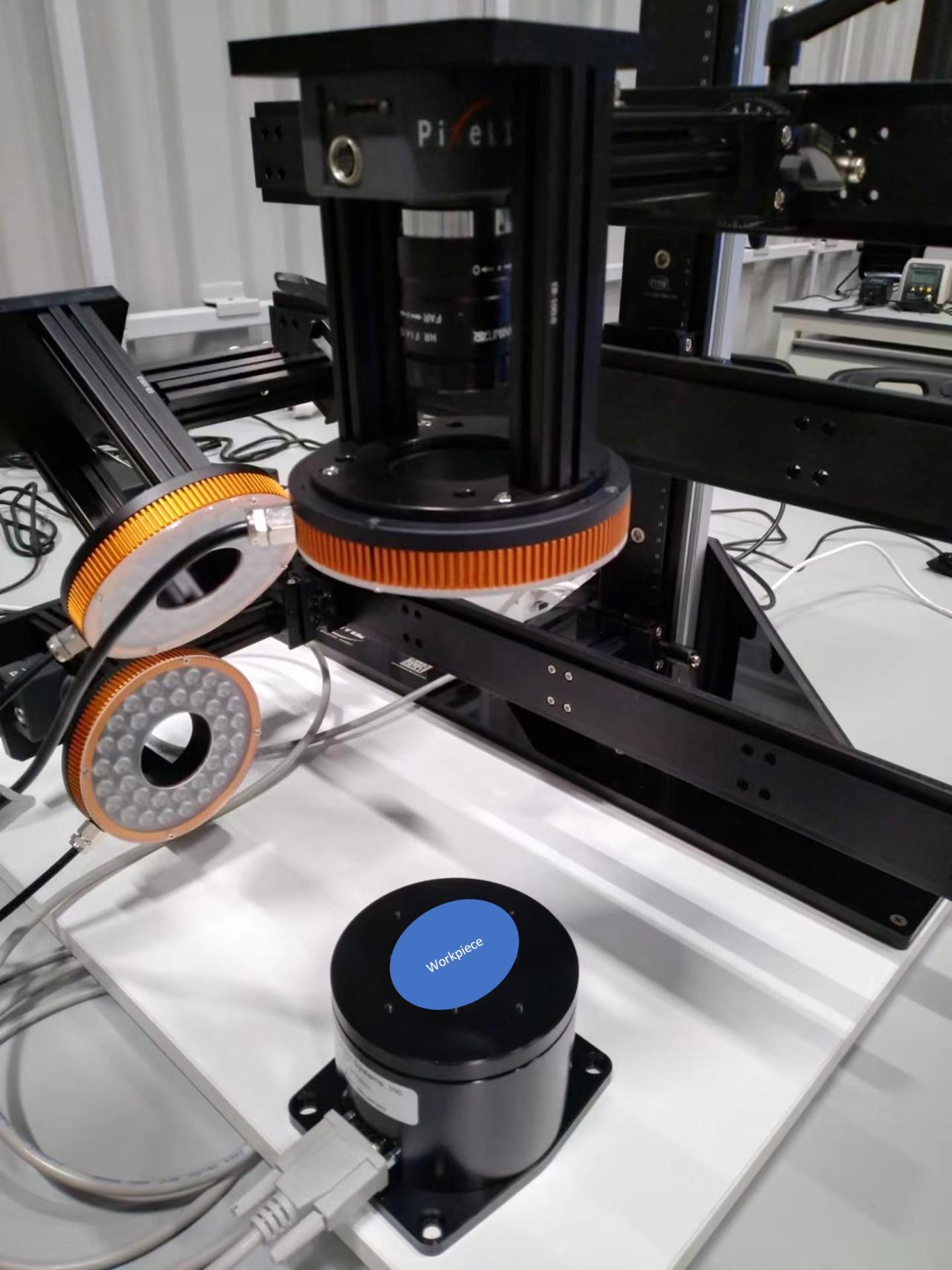

- Pre-form insert moulding comprises the production of carbon composite pre-form with hot press moulding and injection moulding of the finished product using the preform as inserts, with the assistance of an loading and unloading system.

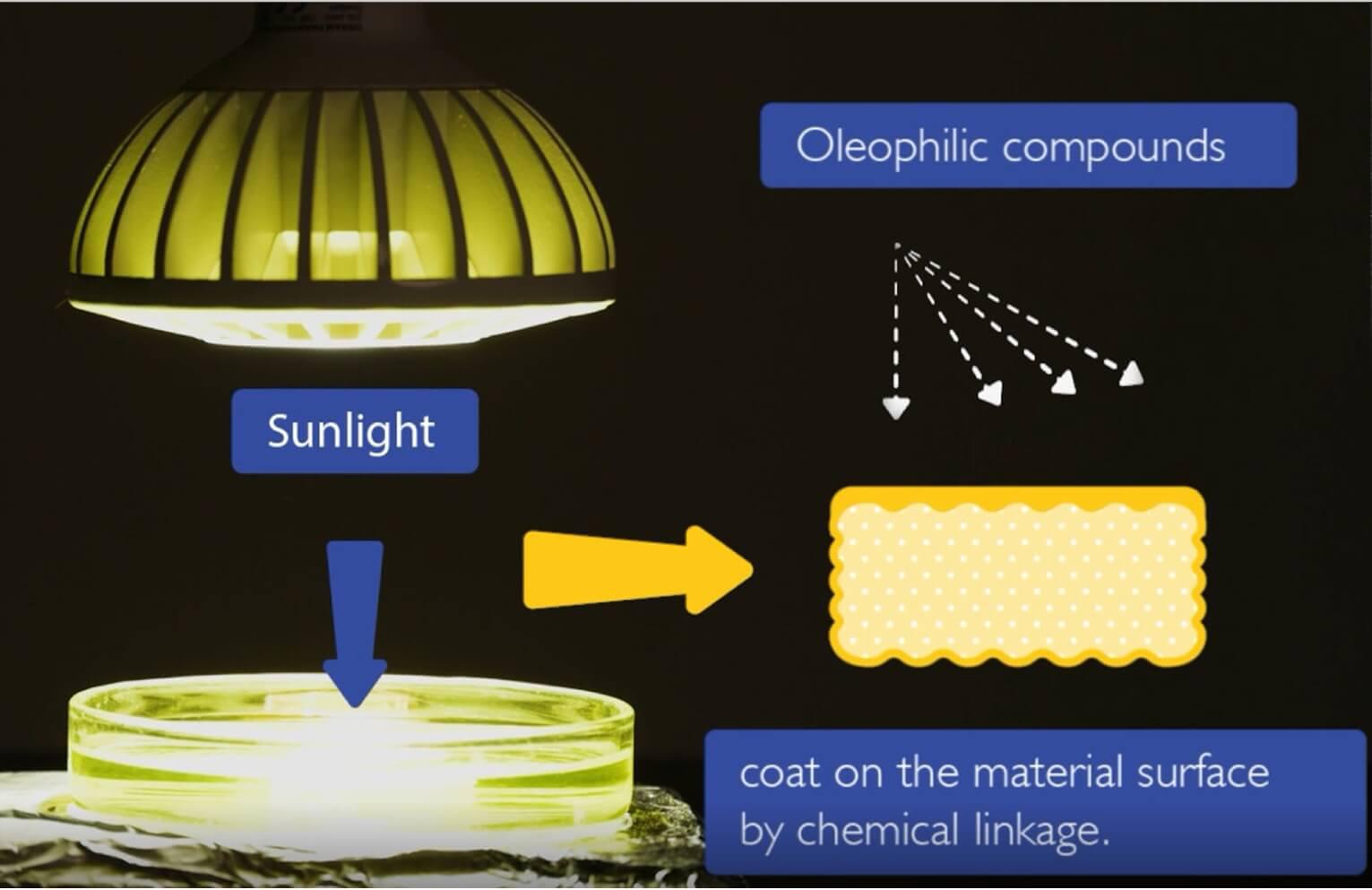

- Pre-heat hybrid moulding comprises the pre-heating of a carbon fibre/thermoplastic prepreg, forming of the prepreg in a mould and injection moulding of the finished product with appropriate clamping and holding systems for the prepeg.

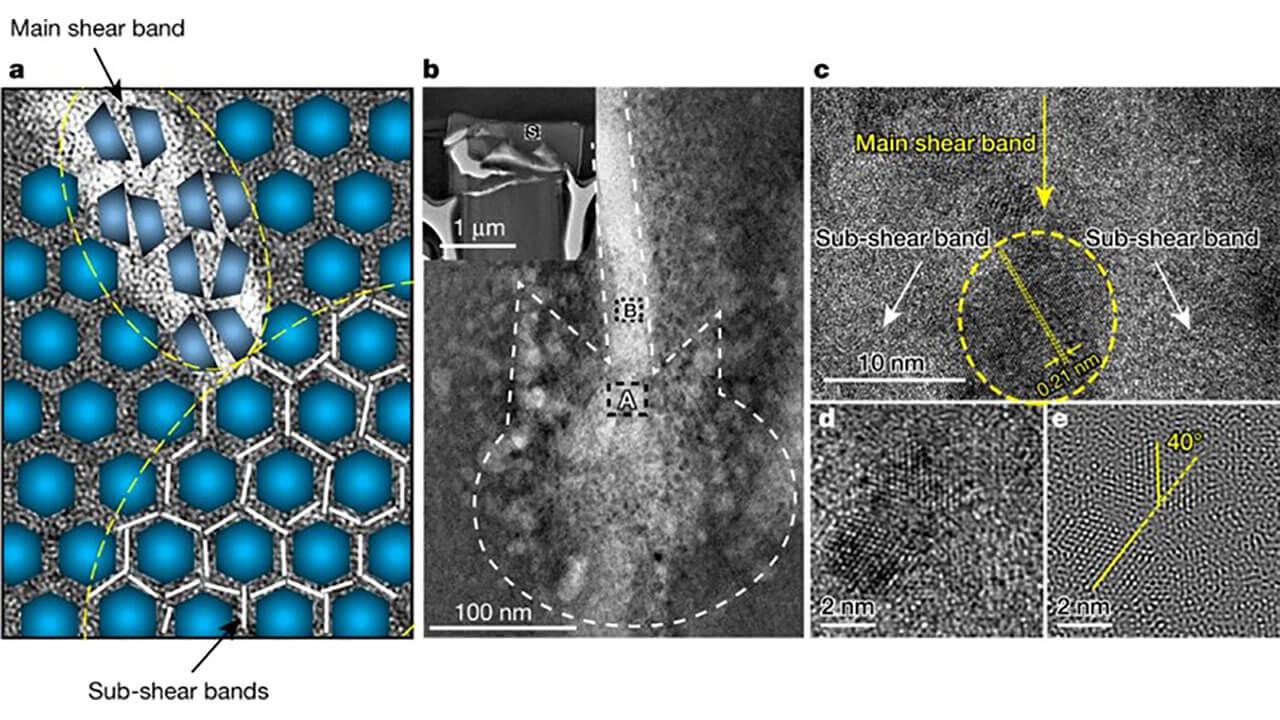

- Enhance the quality of parts, achieve high mechanical strength, and improve surface quality.

- Reduce the size and weight of the final product, as the carbon composite inserts are integrated to the plastic parts without the use of fasteners or connectors.

- Enhance design flexibility, allowing almost unlimited configurations and material combinations of carbon fibre prepreg and injected plastic.

- Reduce the operation cost and tool cost for post-processing and machining of the carbon composite, lowering assembly costs as the parts are integrated during the moulding process.

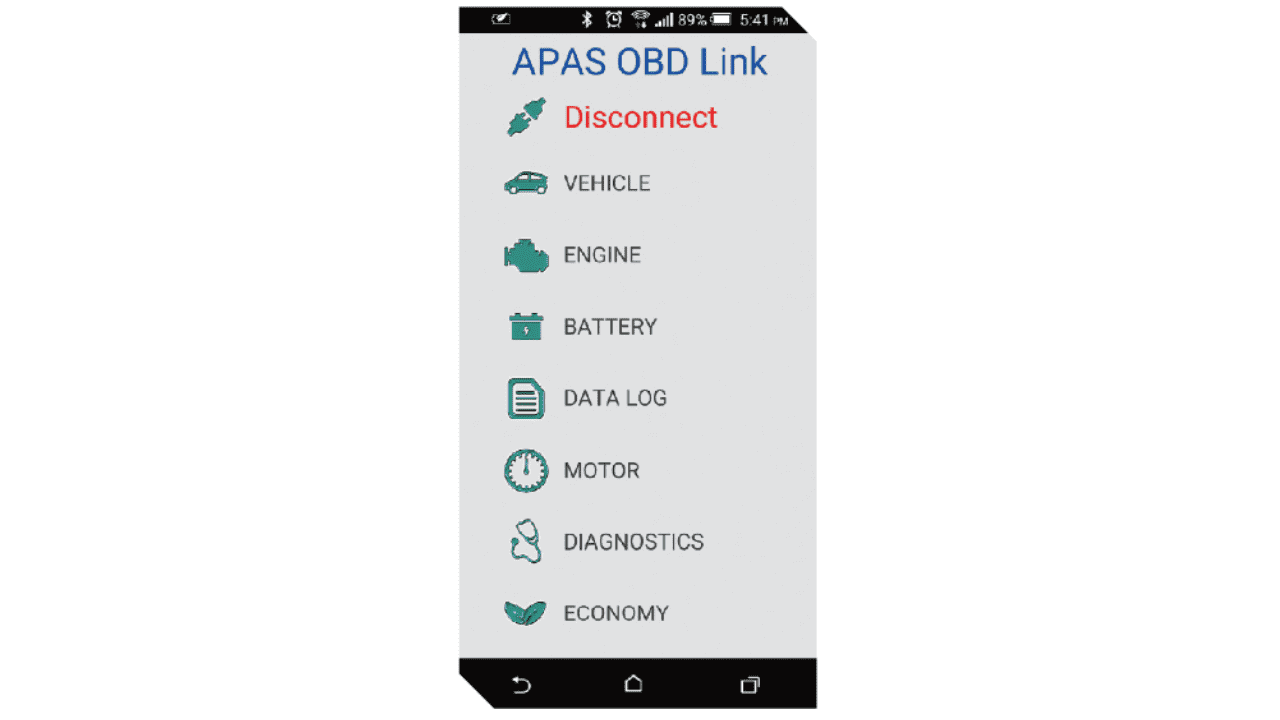

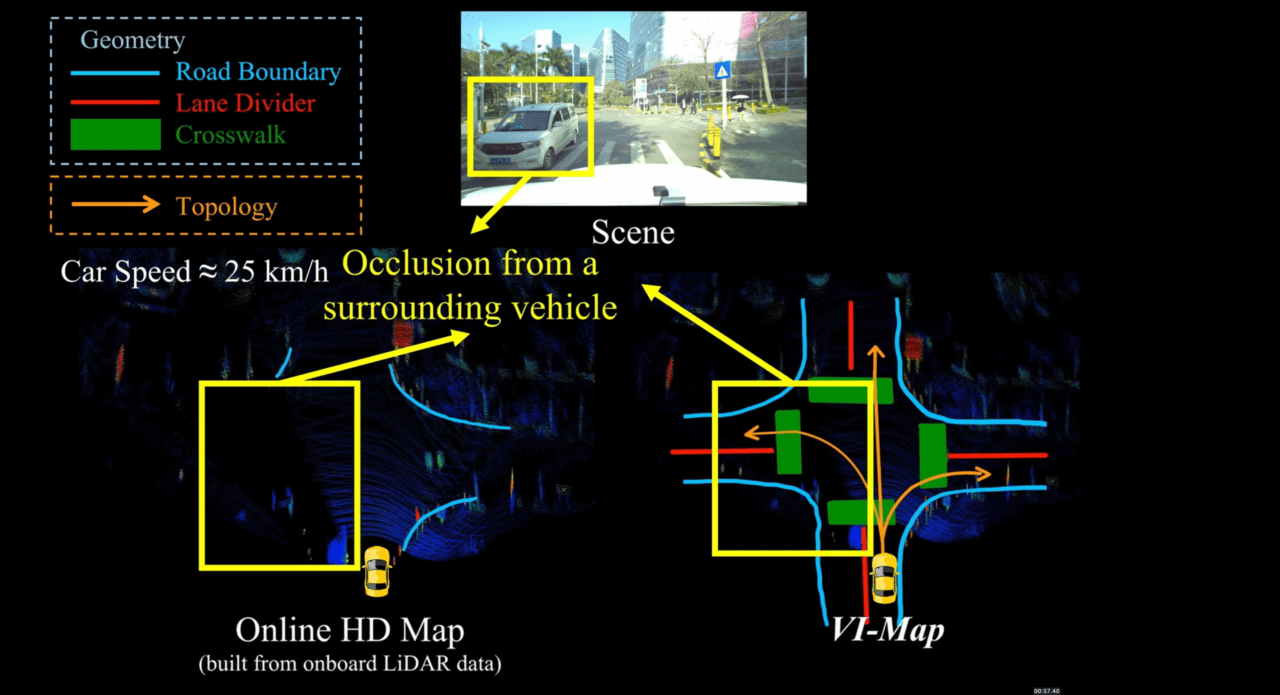

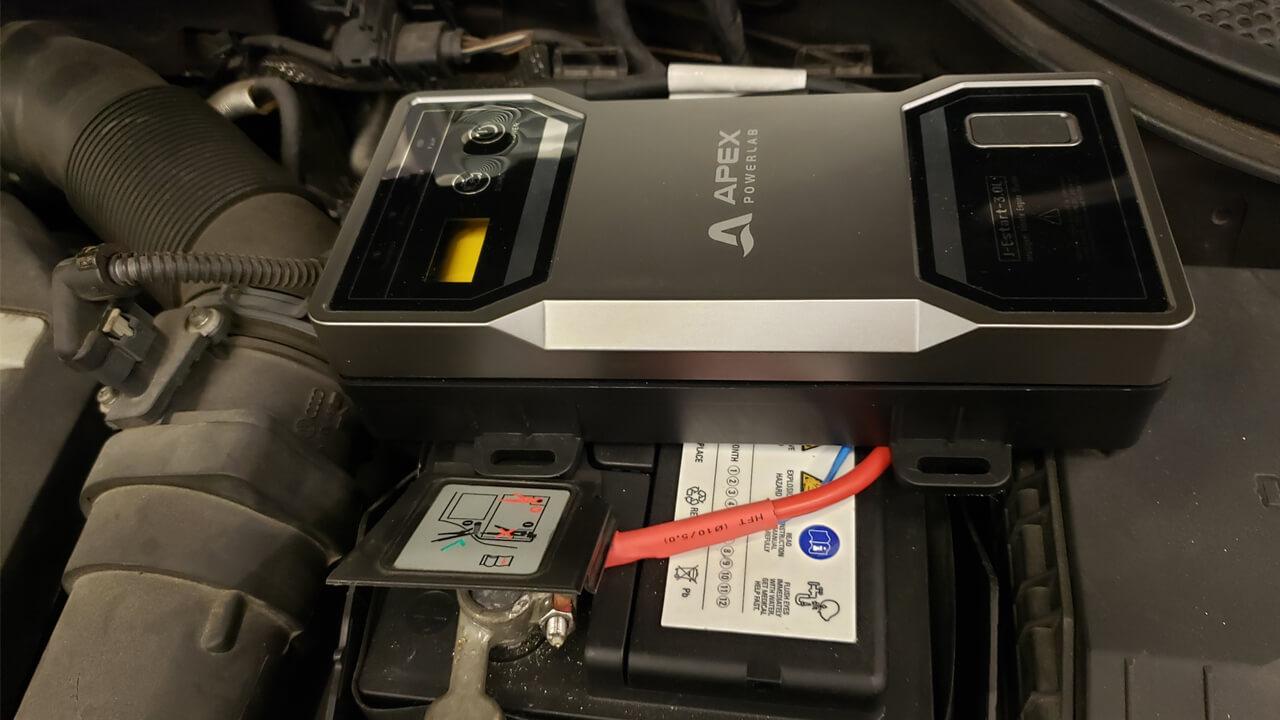

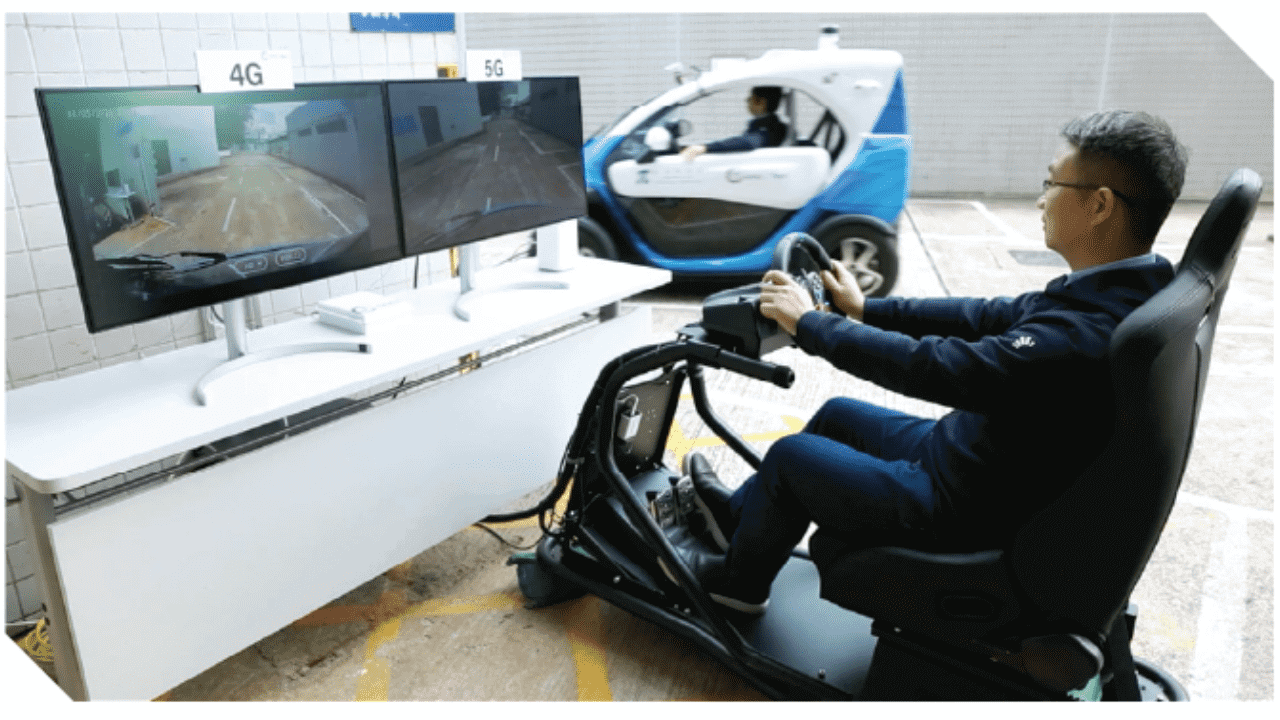

Centre of Advanced Power and Autonomous Systems (APAS) (formerly Automotive Platforms and Application Systems R&D Centre) was established in 2006 and is fully integrated as a business division under HKPC on 1 April 2025. APAS continues to undertake market-led R&D programmes spanning green transportation, smart mobility, intelligent systems and emerging applications, as well as commercialises R&D results in collaboration with industry, universities and technology institutes to enhance the competitiveness of Hong Kong's automotive and other transportation sectors in new energy and smart driving.