A Nano-dual-phase Glass-crystal with Theoretical Strength and its Fabrication Method

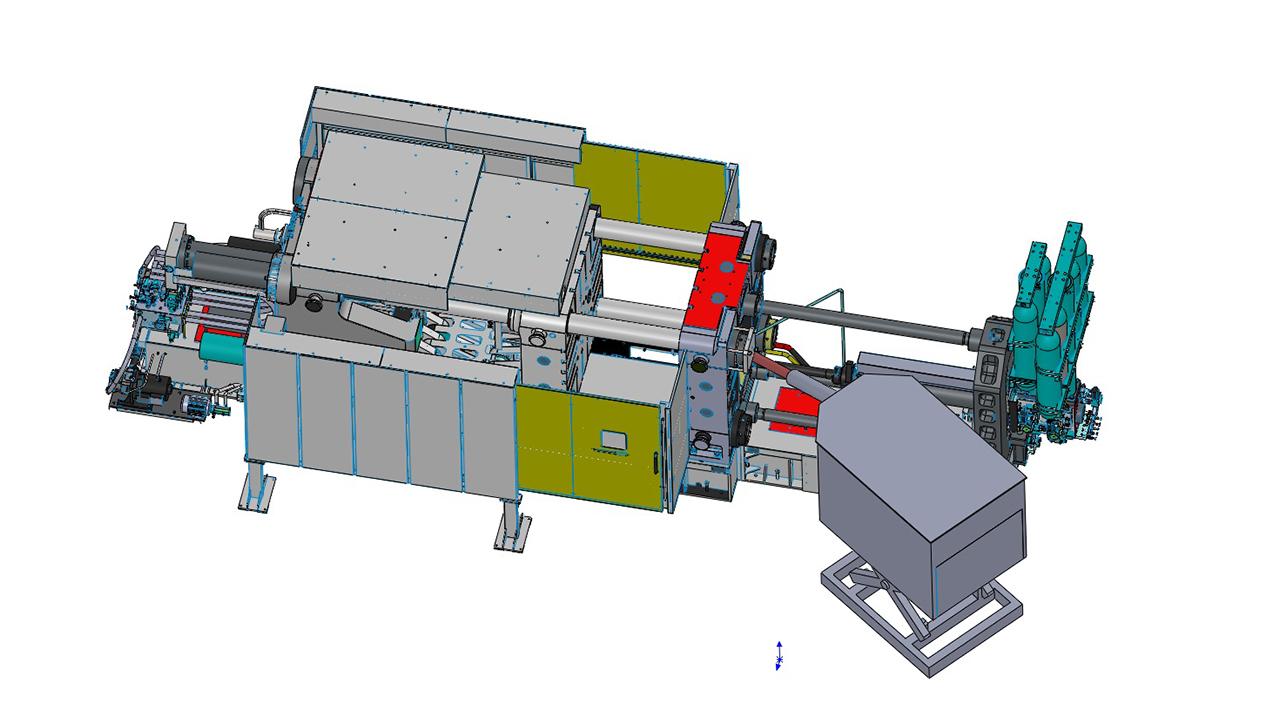

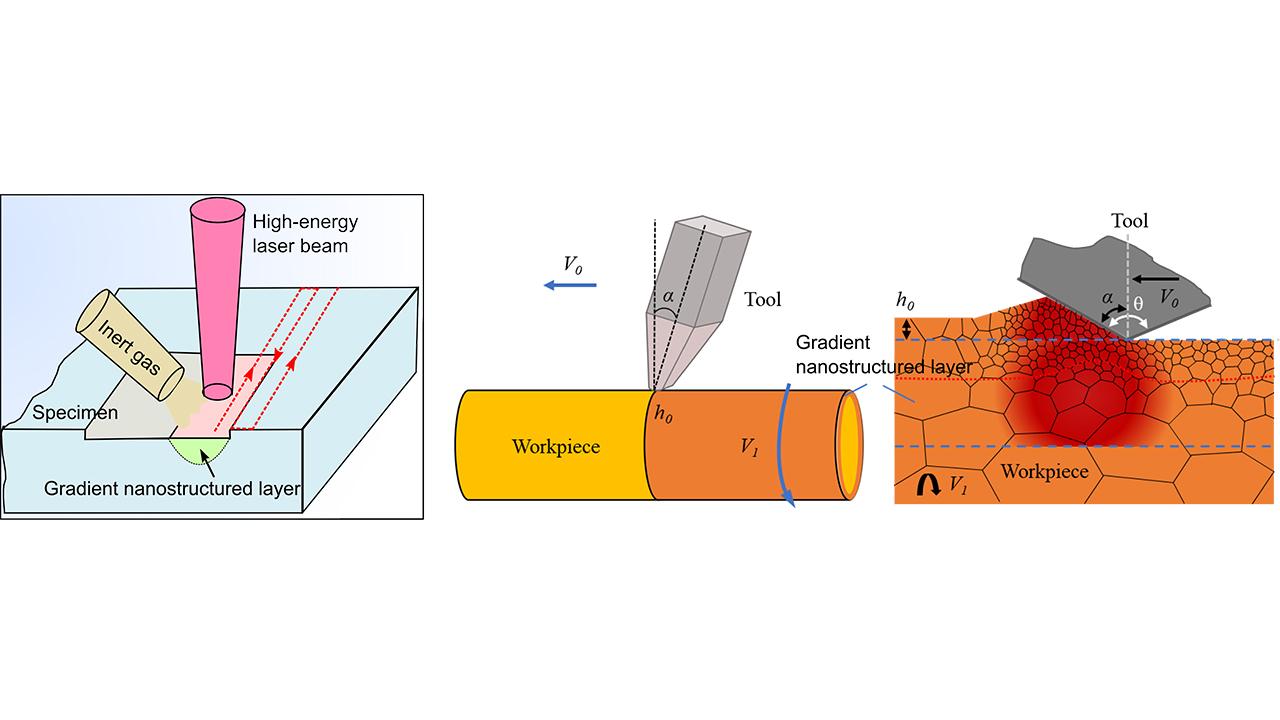

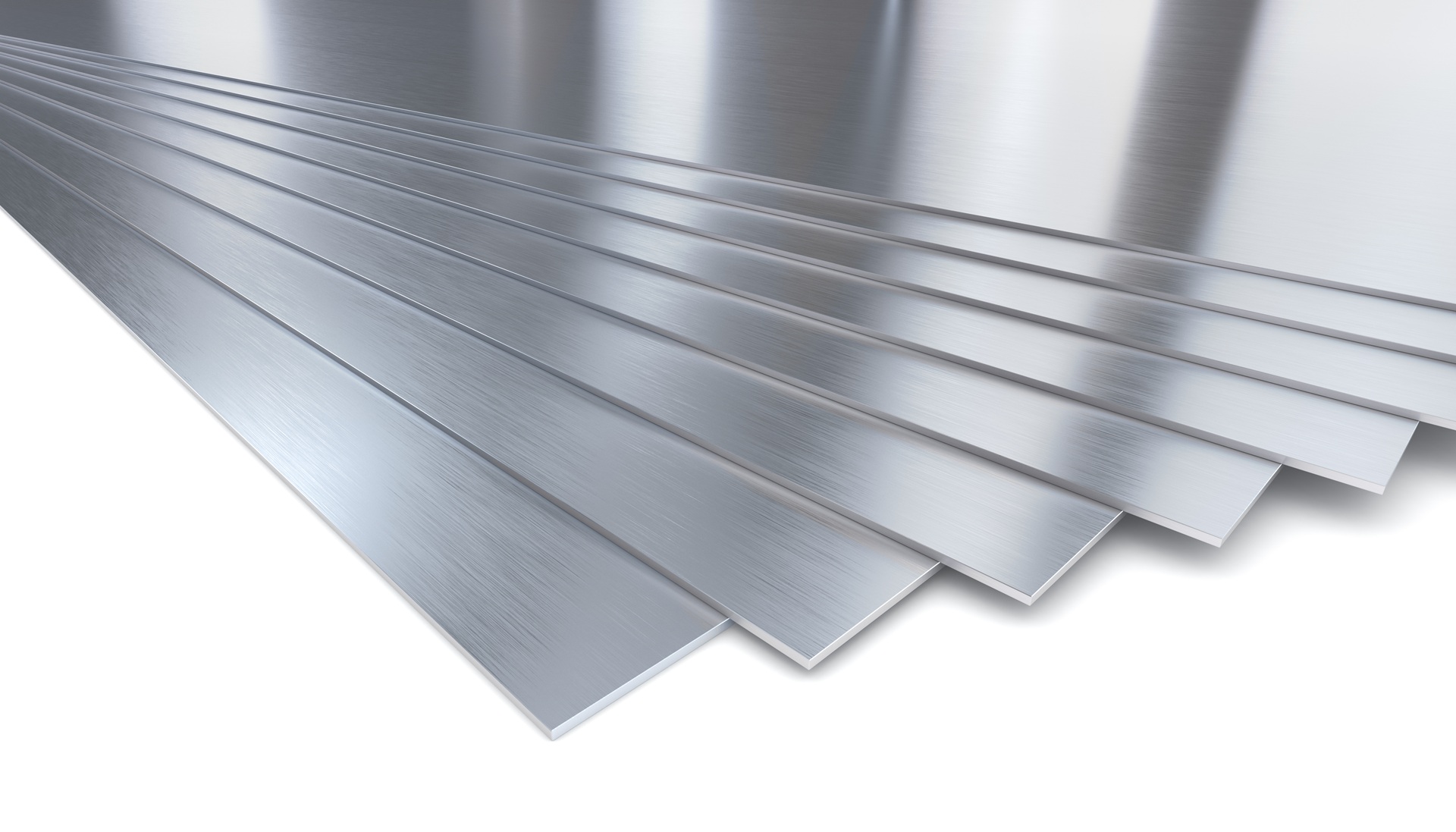

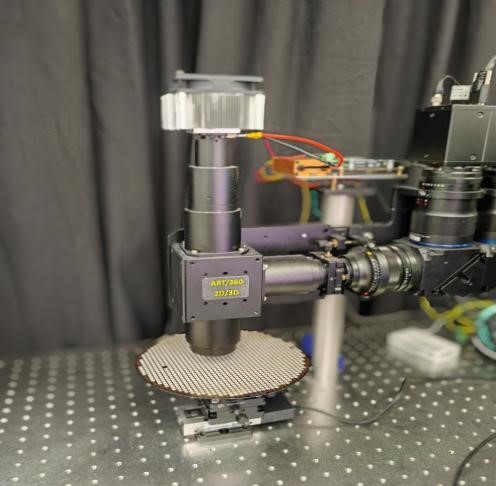

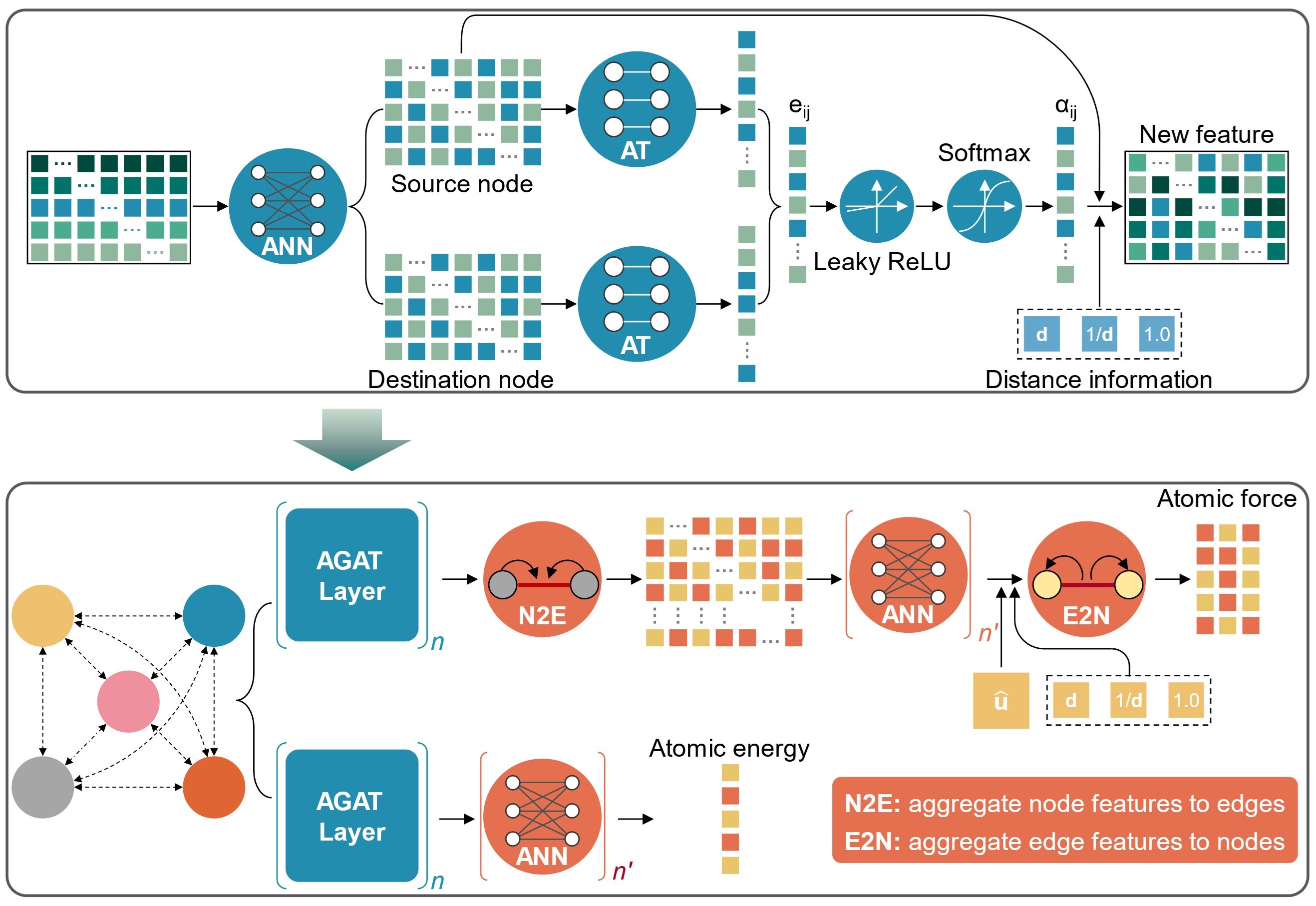

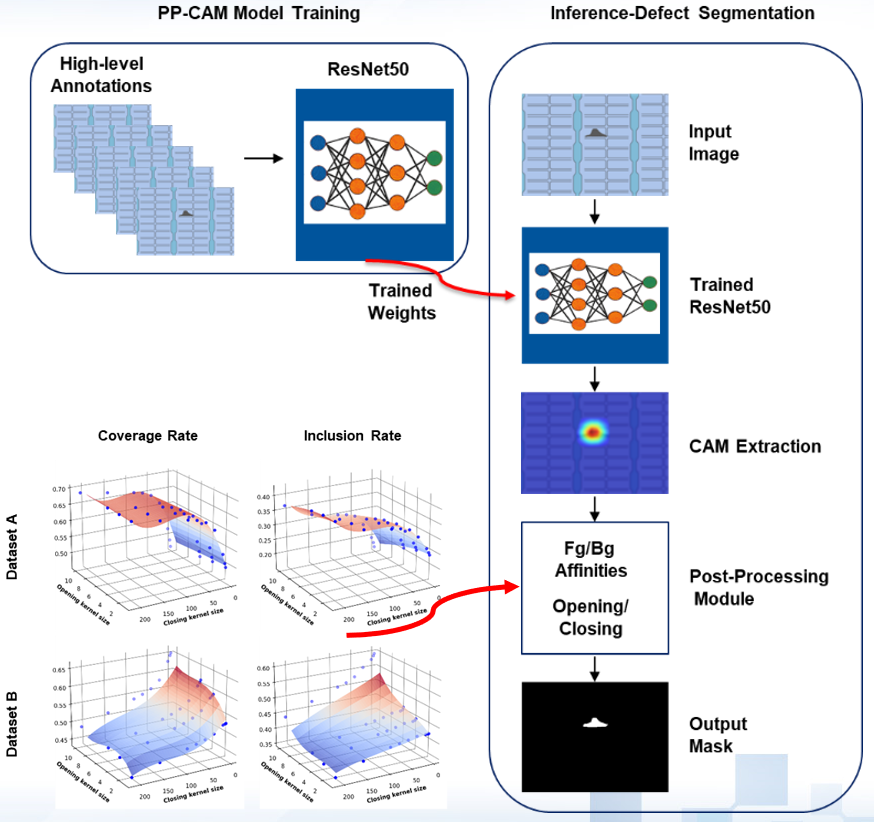

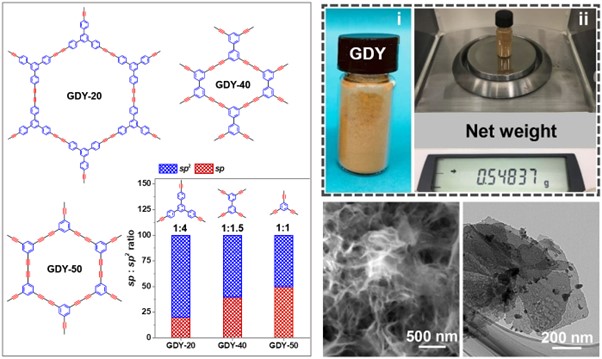

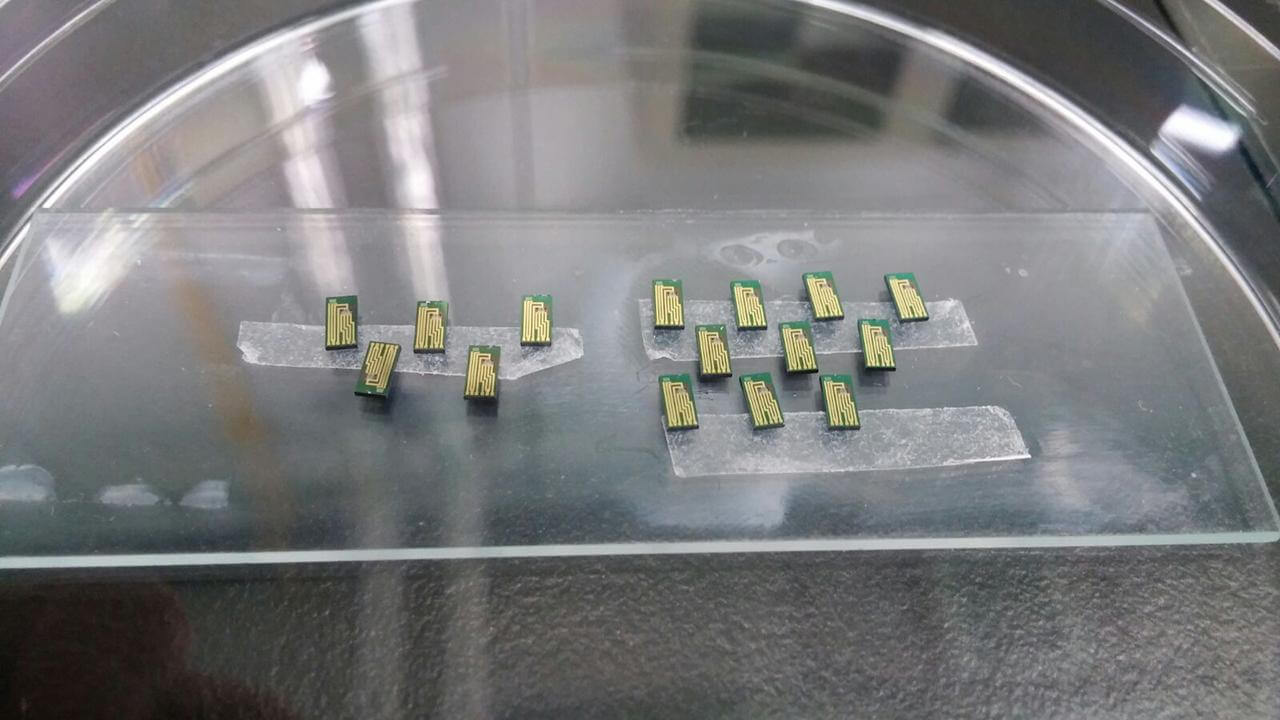

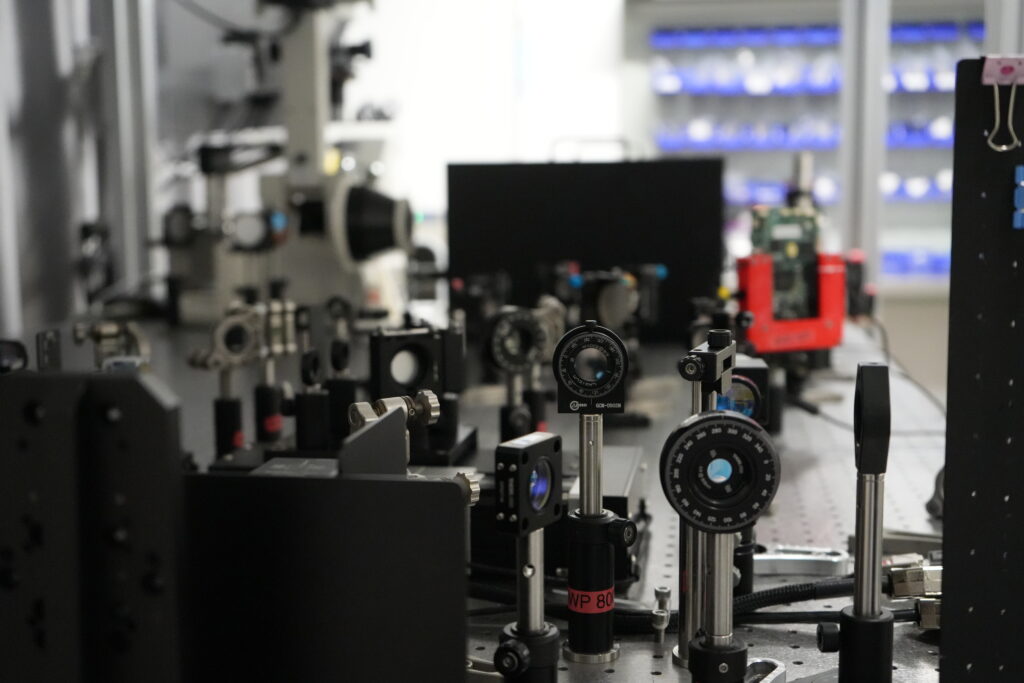

The innovation relates to a metal material and a method for use in fabricating thereof by depositing a metal layer in a magnetron in just one sputtering process. The 0.5 to 50-µm-thick homogeneous film with a large area of 20 cm x 30 cm widens its industrial application.

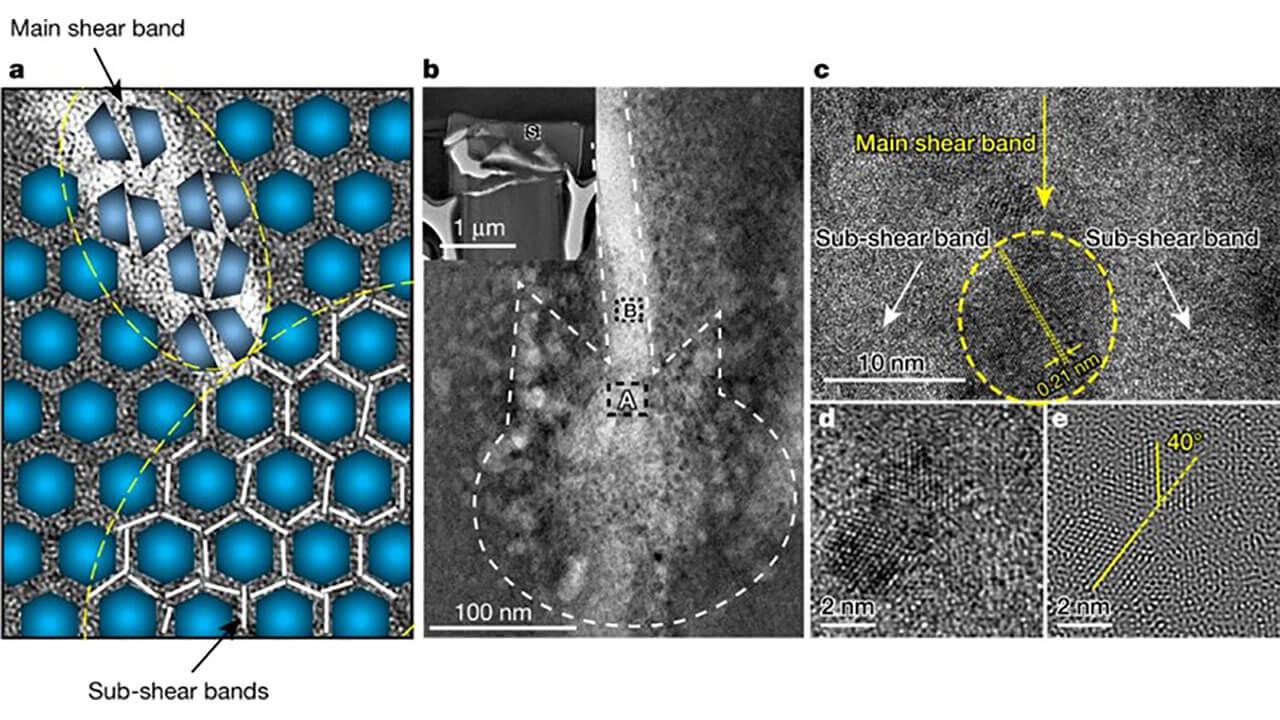

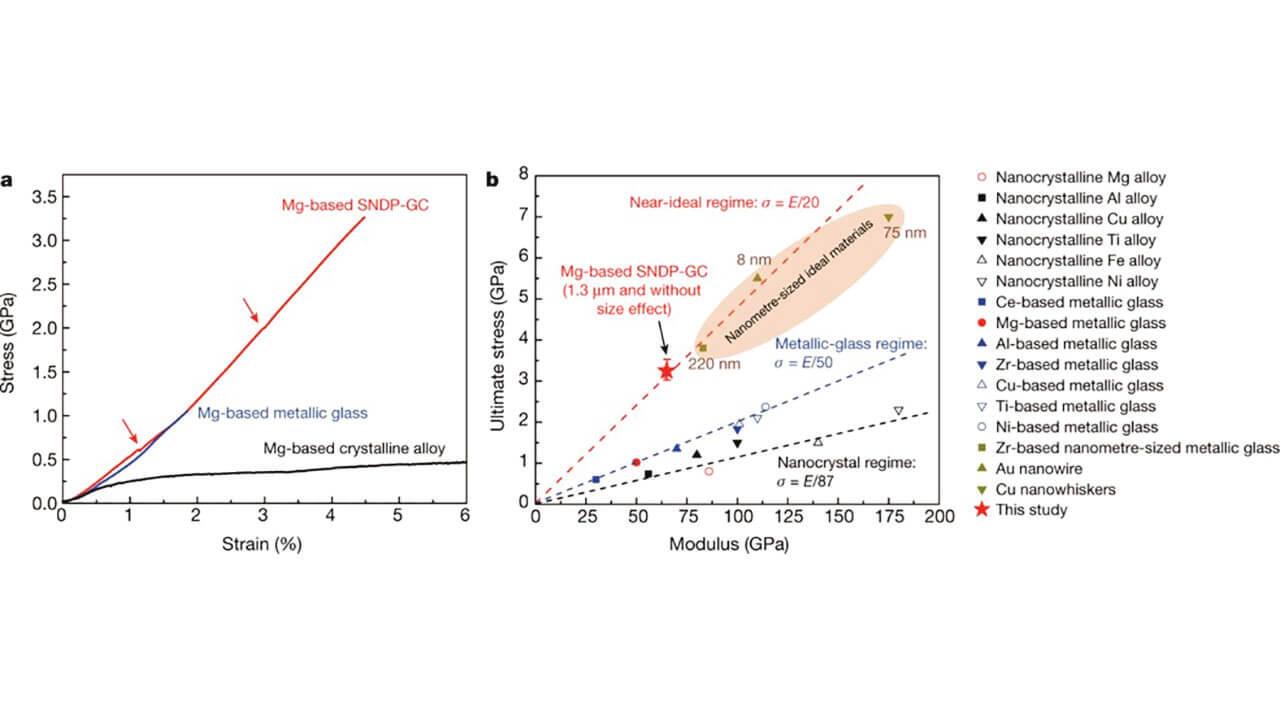

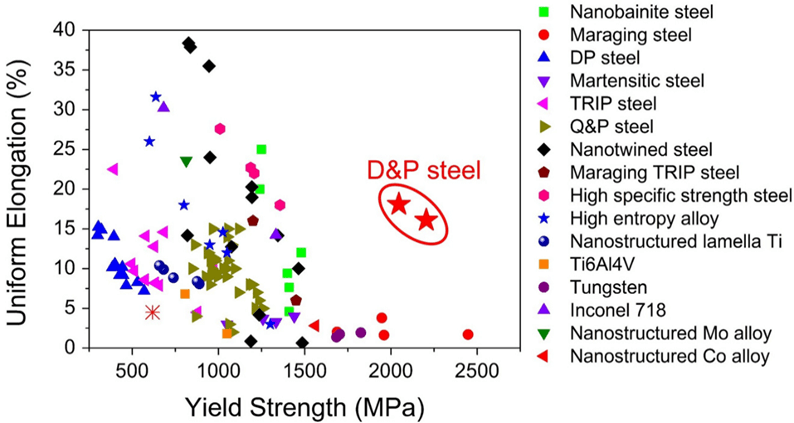

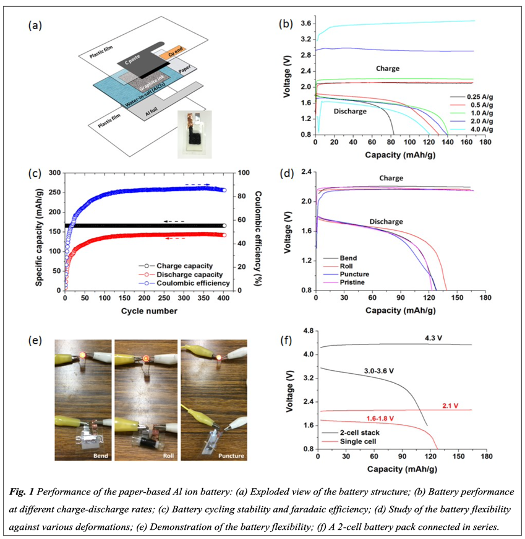

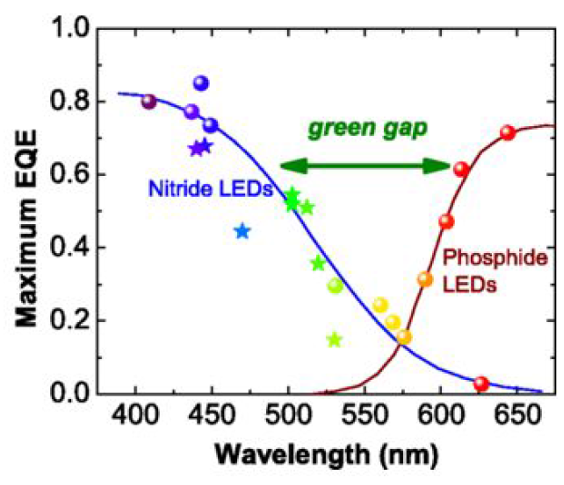

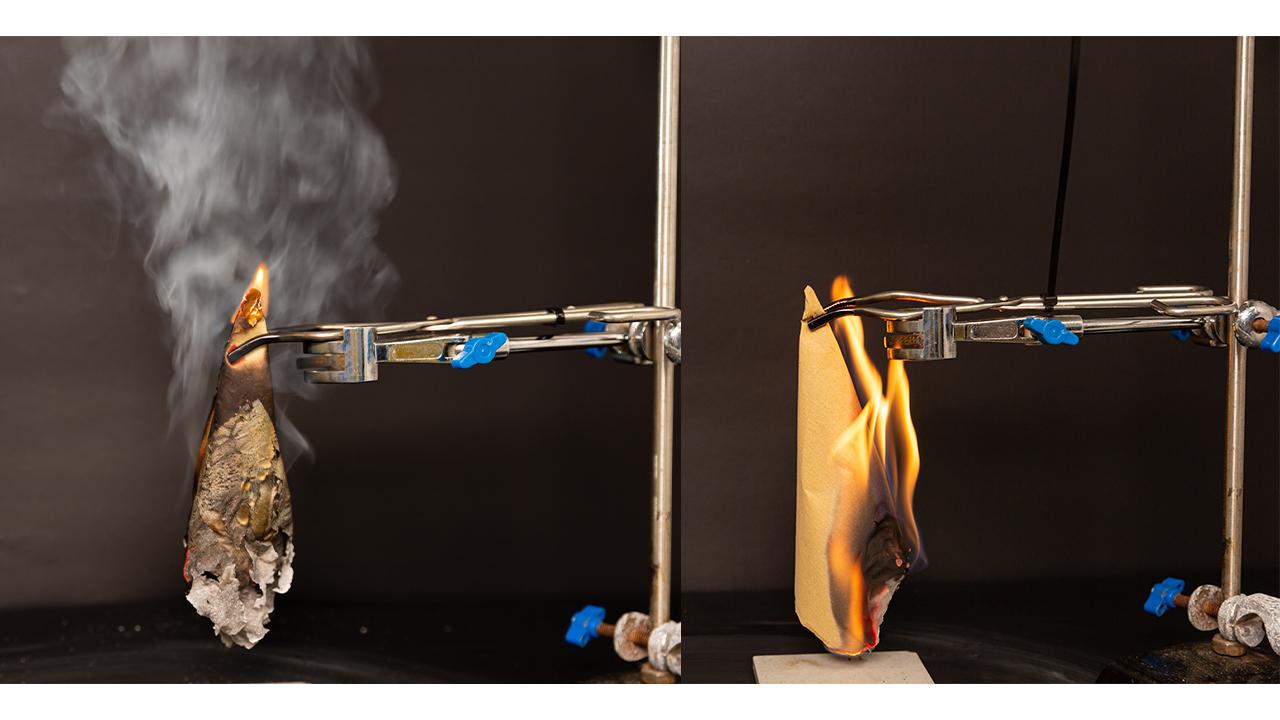

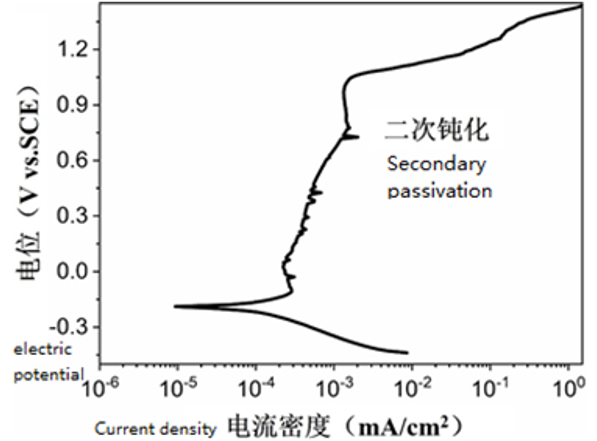

The single phase nanocrystalline alloys and single-phase metallic glasses have very high strength. However, they are usually softened at <2 % strain with an ultimate stress around E/85~E/50 because of the reverse Hall- Petch effect and the softening effect of shear band, respectively. Therefore, they are very difficult to reach the theoretical strength of E/20.

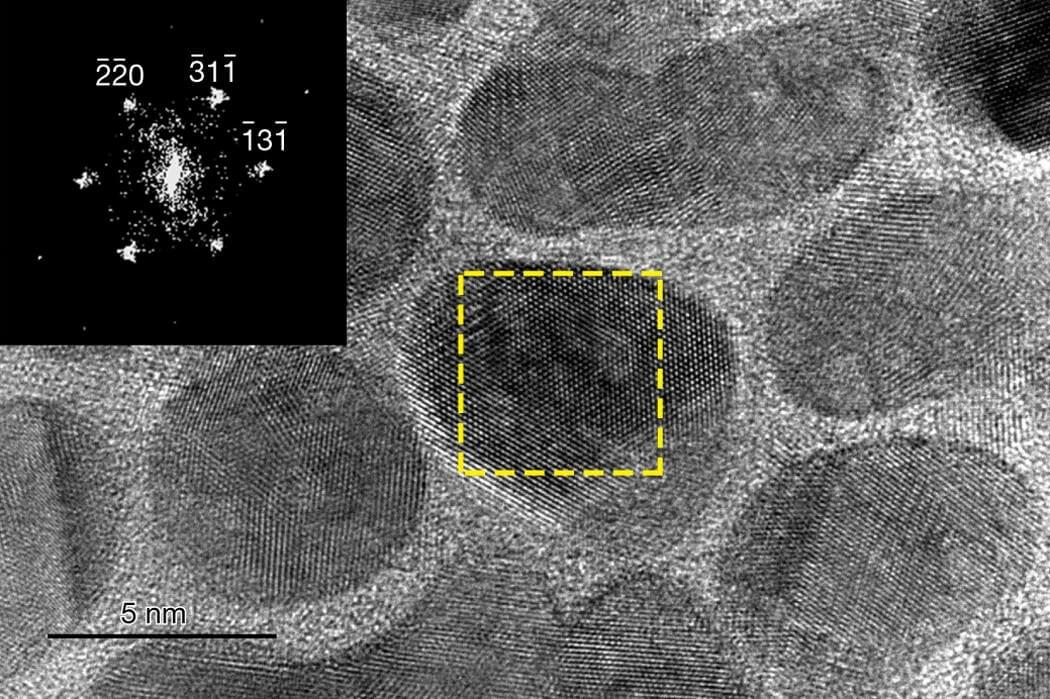

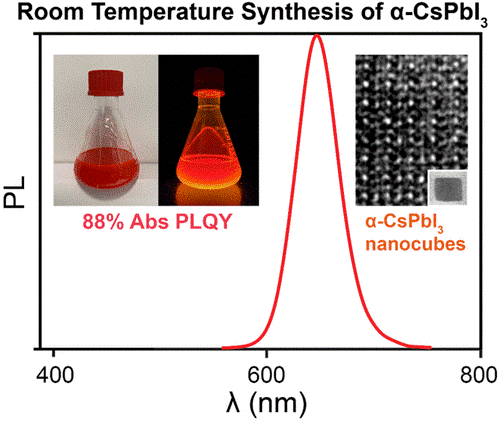

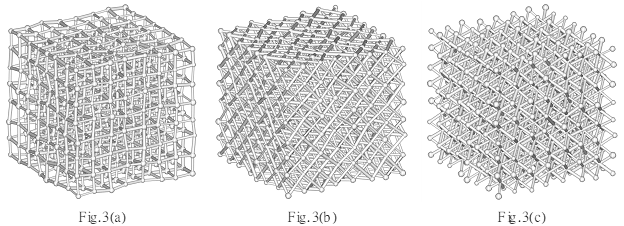

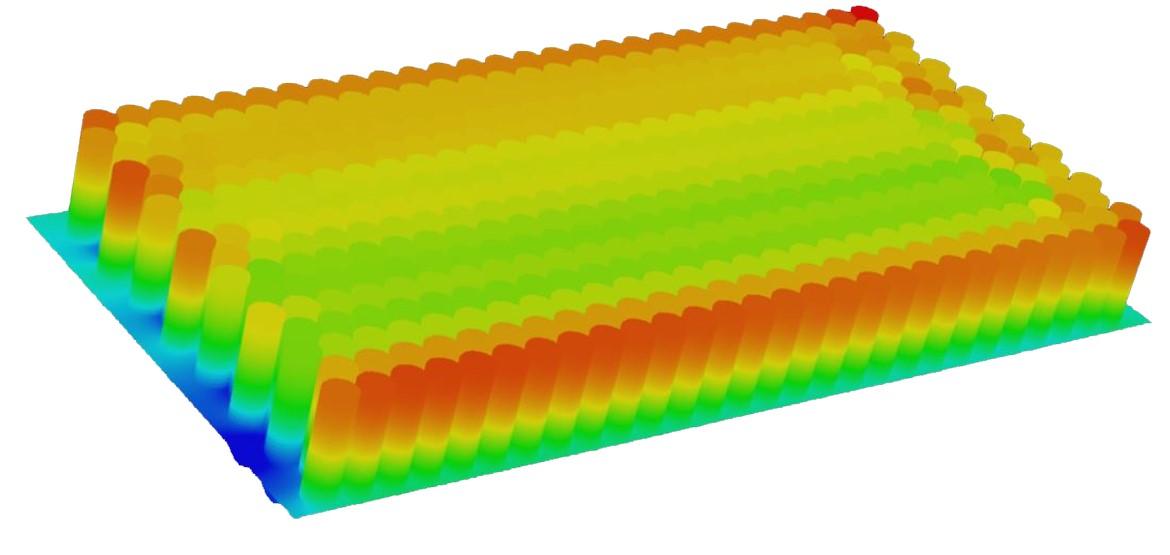

- The innovation presents an in-situ formed amorphous nanocrystalline cores-shells nanostructure for Mg-based nano-dual-phase glass-crystal, which exhibits theoretical strength of 3.3 GPa without sample size effect at room temperature. This strength is 3 times higher than that of the ever-reported strongest Mg alloy.

- The material in this innovation has a larger size of 100 mm x 100 mm x 10 µm than traditional near-ideal-strength material with nanosized scale, which is benefit for large area application.

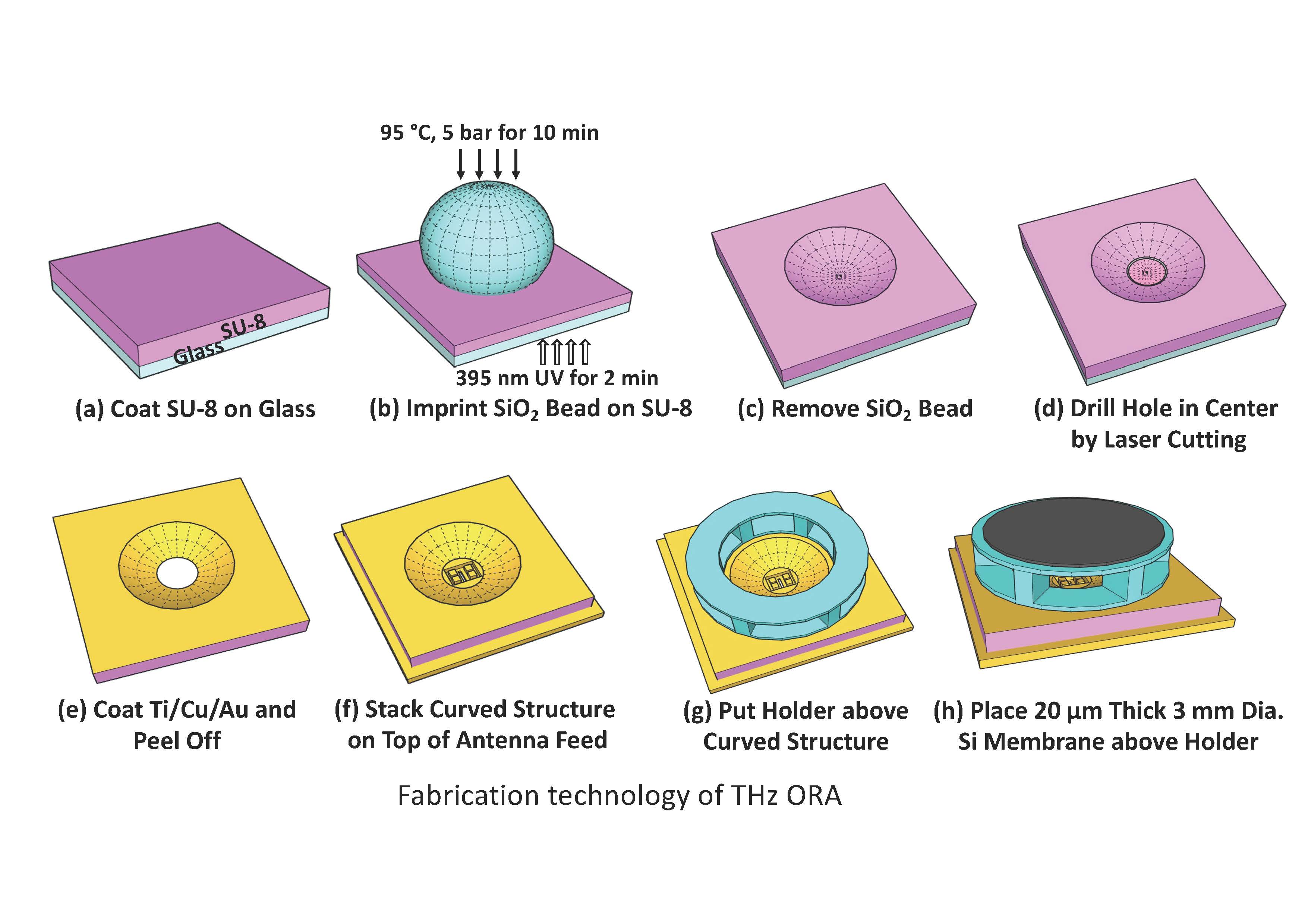

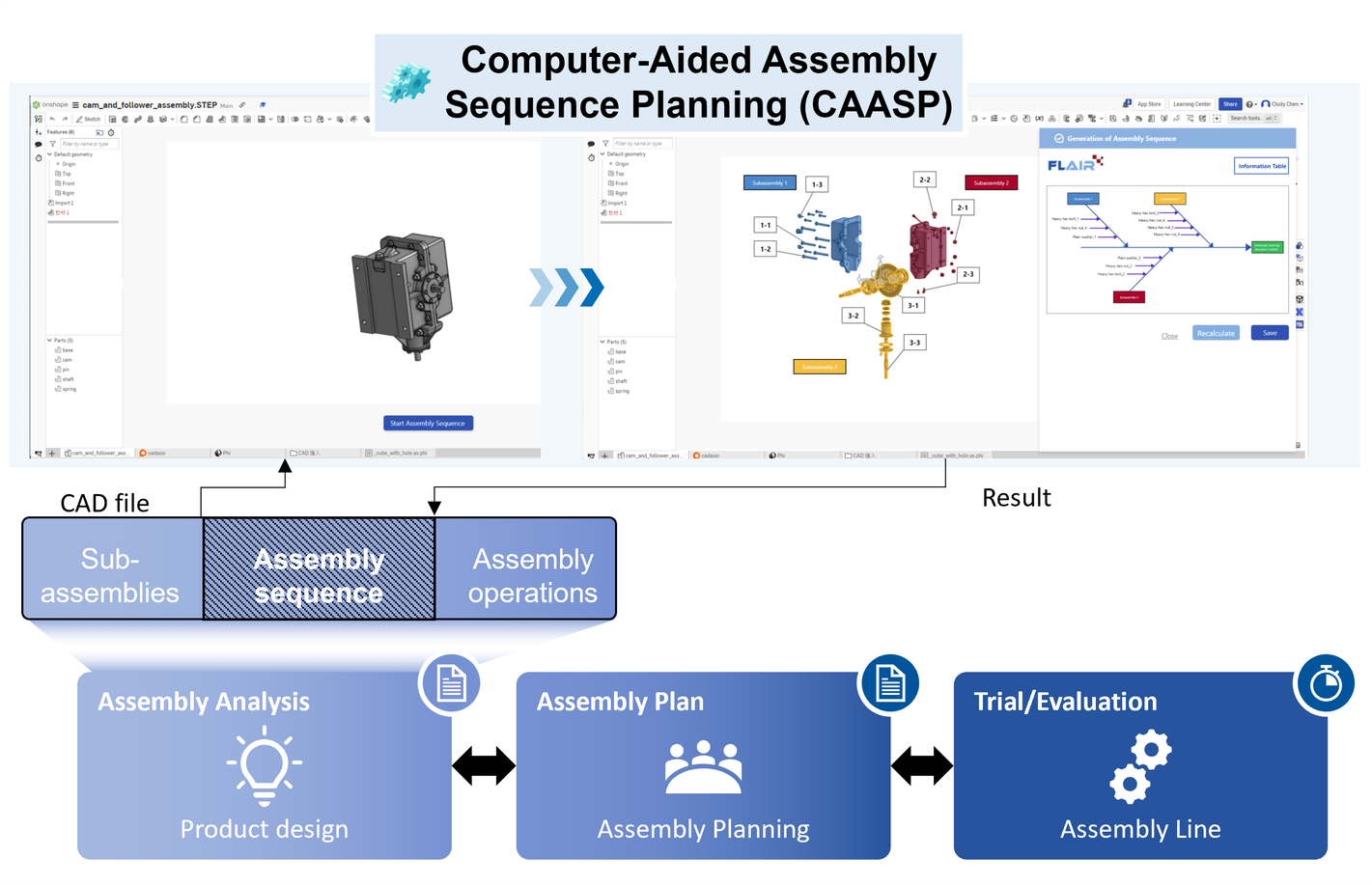

- The fabrication method of this innovation is easy to control the composition and thickness of the NDP-GC structure by adjusting the sputtering parameter, which widens this theoretical strength material’s application in metallic film area.

- Large area application for nanosized material

- Easy control the composition and thickness of the NDP-GC structure

- Widens strength material's application in metallic film area

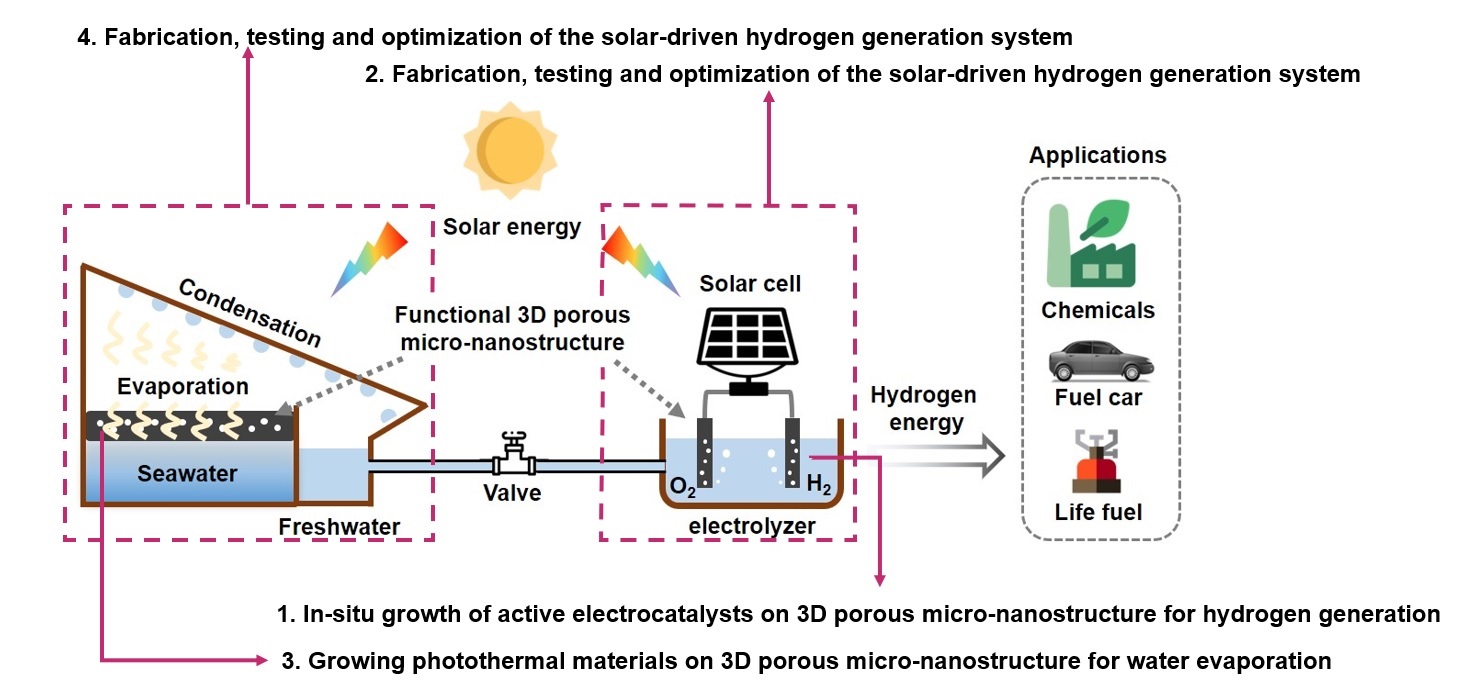

- Excellent biodegradable materials for bioimplants ; Excellent mechanical properties for other light weights materials

- This work was published by Nature (2017) as a cover story.

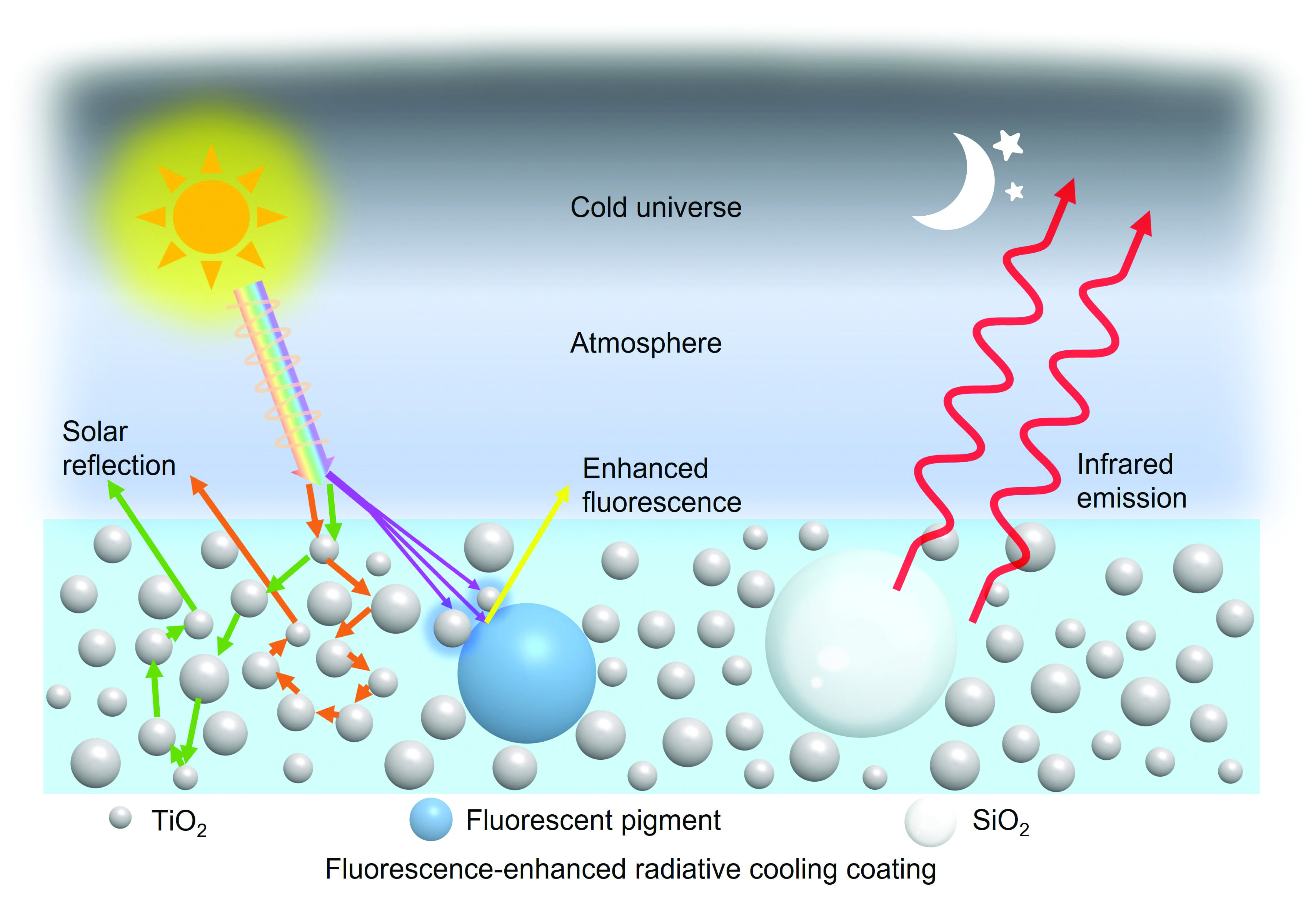

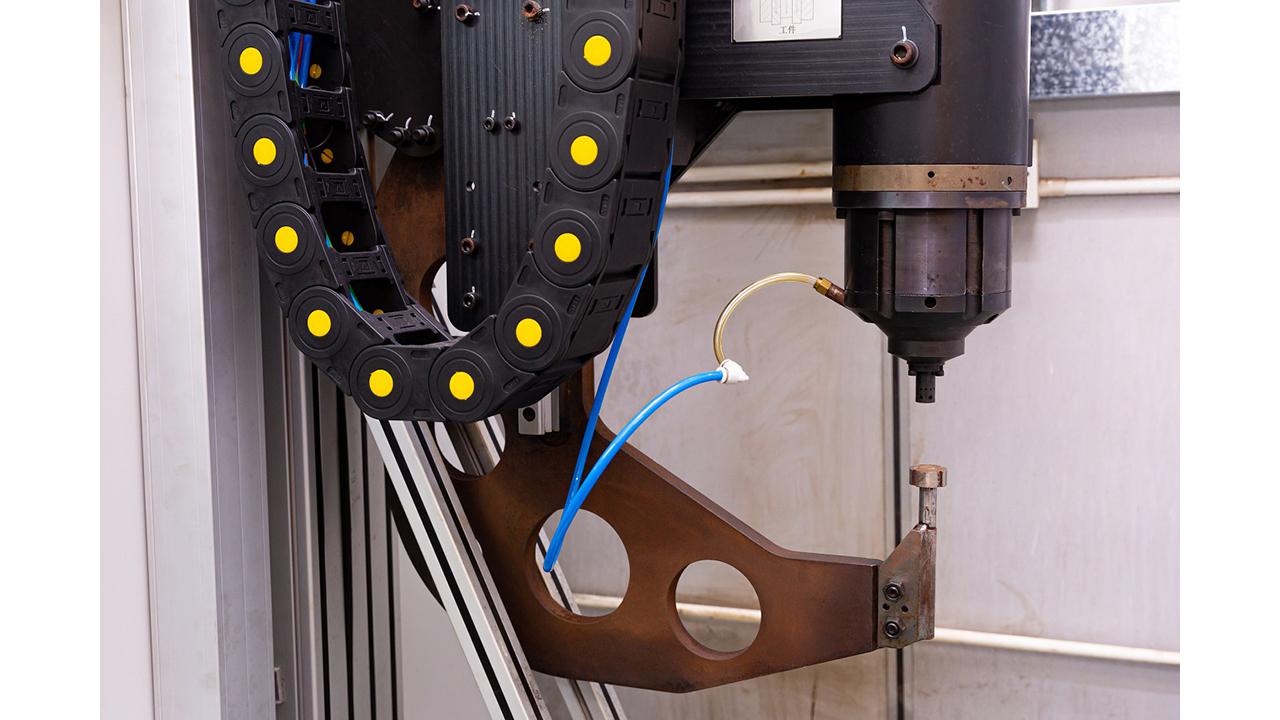

- High wear resistance surface coating for laptop, smart phone, flexible electronics

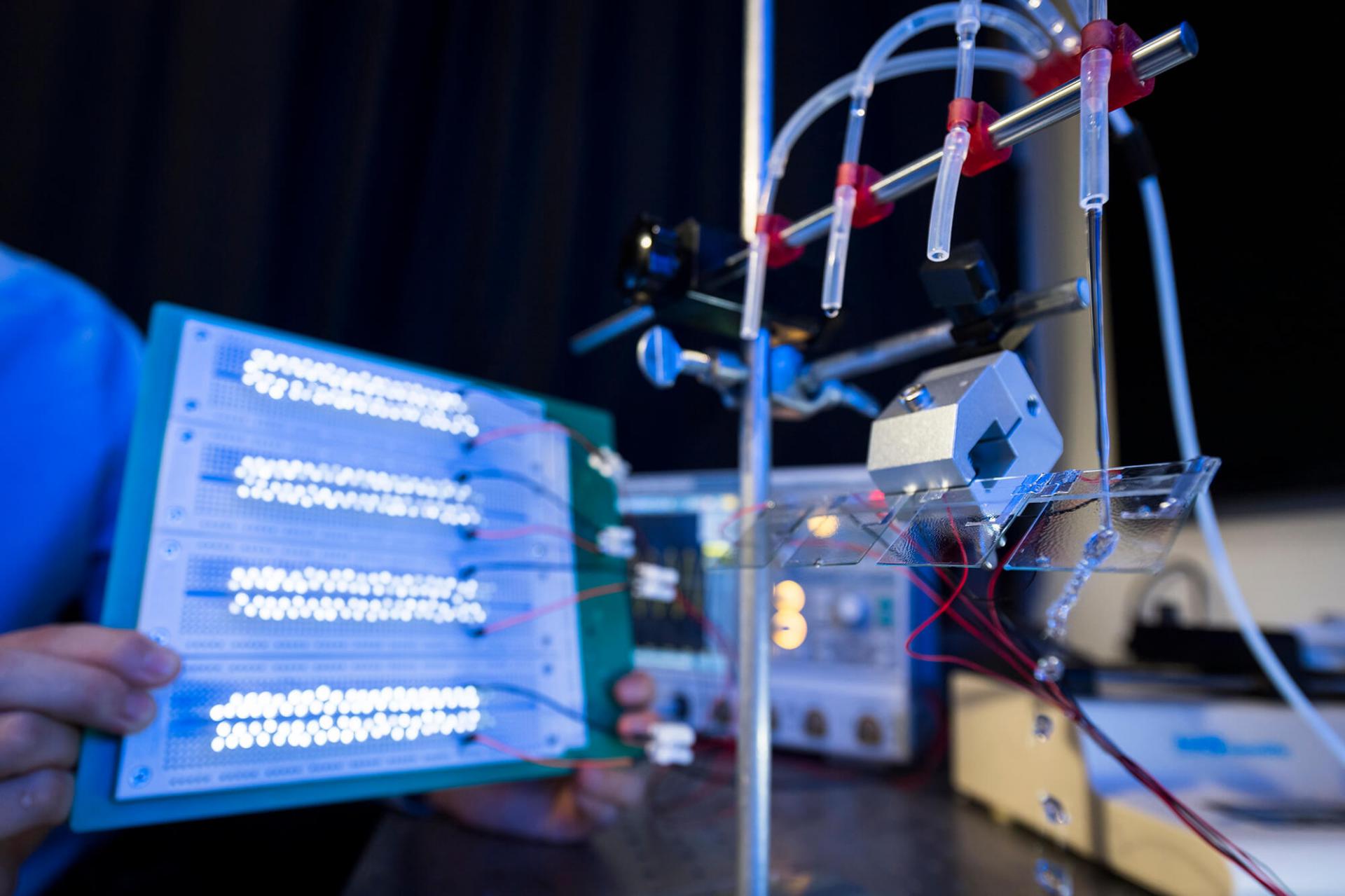

- High strength MEMS devices

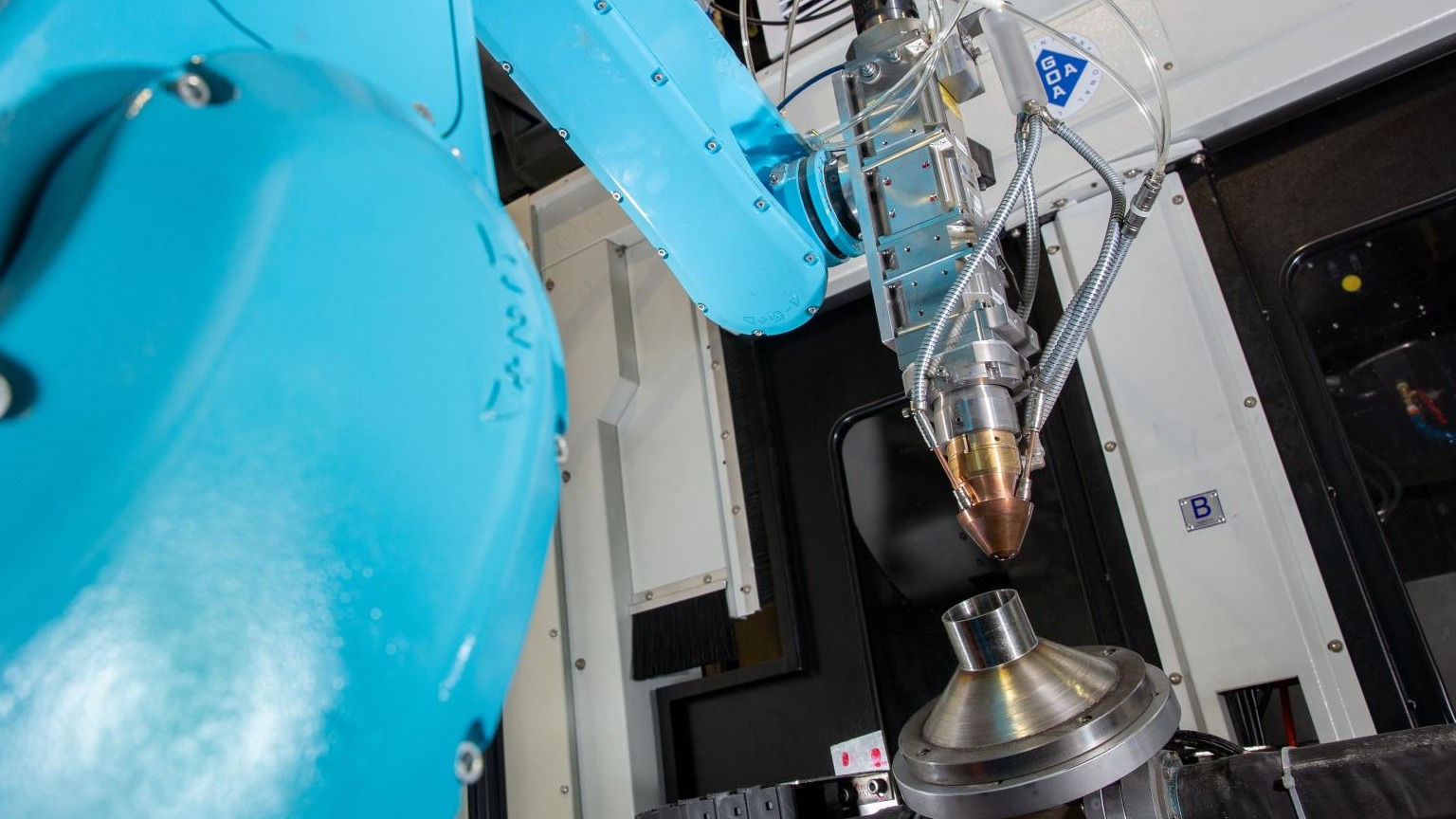

- 3D printing structures

- Mg based implants for orthopedic operation

Patent

- US Patent Application Granted: US 10,895,006

- US Patent Application Granted: US10,428,418

- US Patent Application Granted: US 11,168,401

As one of the fastest growing universities in the world over the past decade, City University of Hong Kong (CityU) is recognised as a hub for innovation in research and professional education. CityU identifies solutions to critical global challenges by extending the frontiers of knowledge both within and beyond existing research paradigms.

The University’s highly qualified academics are drawn from all over the world, not only bringing a wealth of research and professional experience to the teaching programmes, but also contributing to the knowledge and technology advancement.