Pioneer AI Inspection of Textile Materials

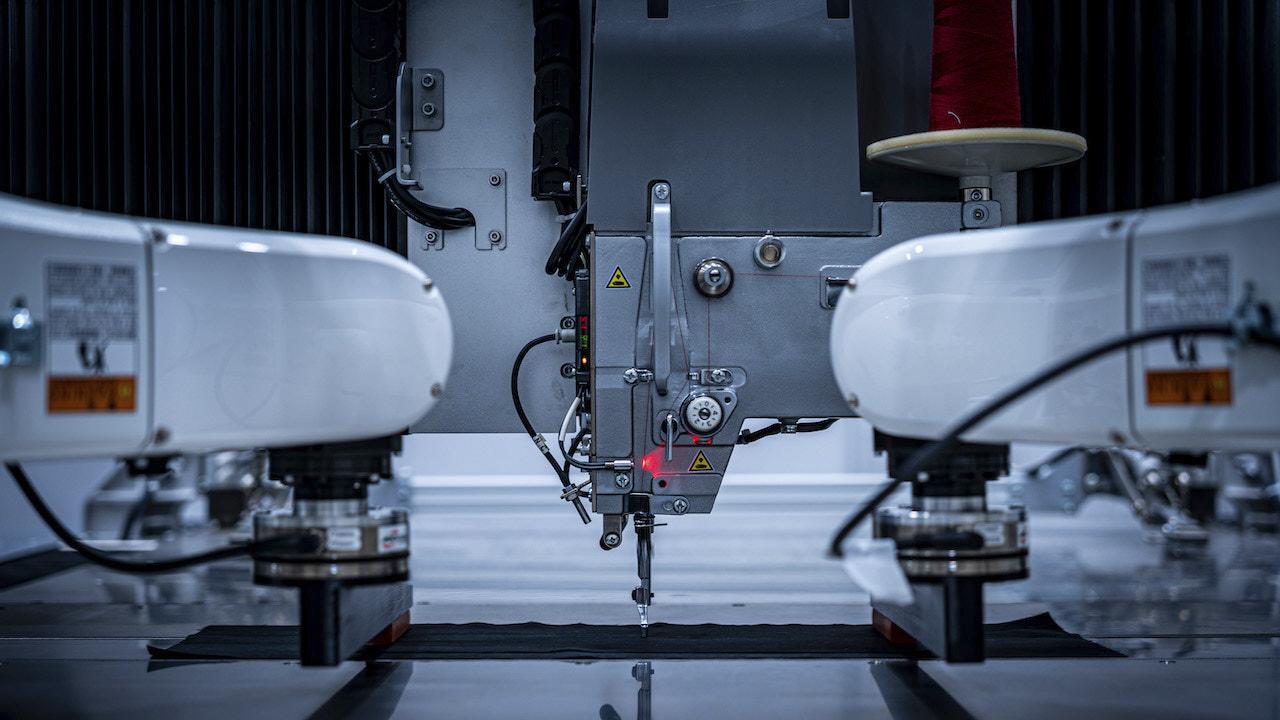

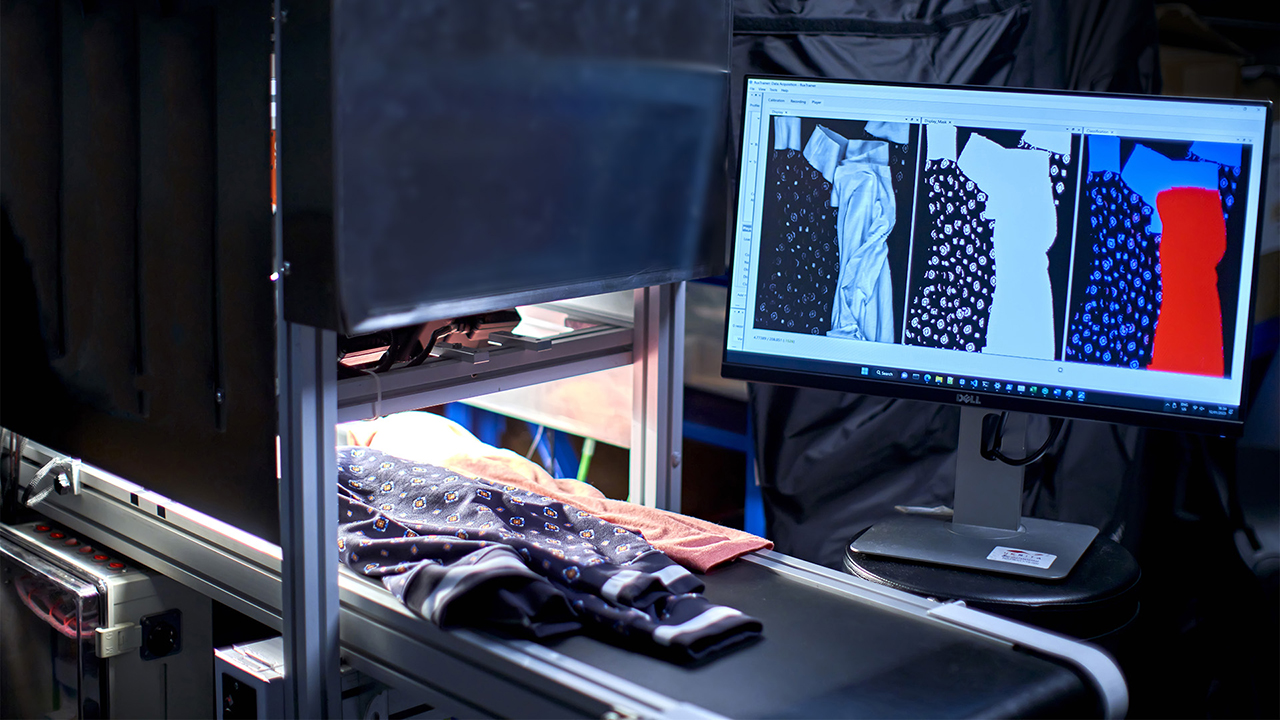

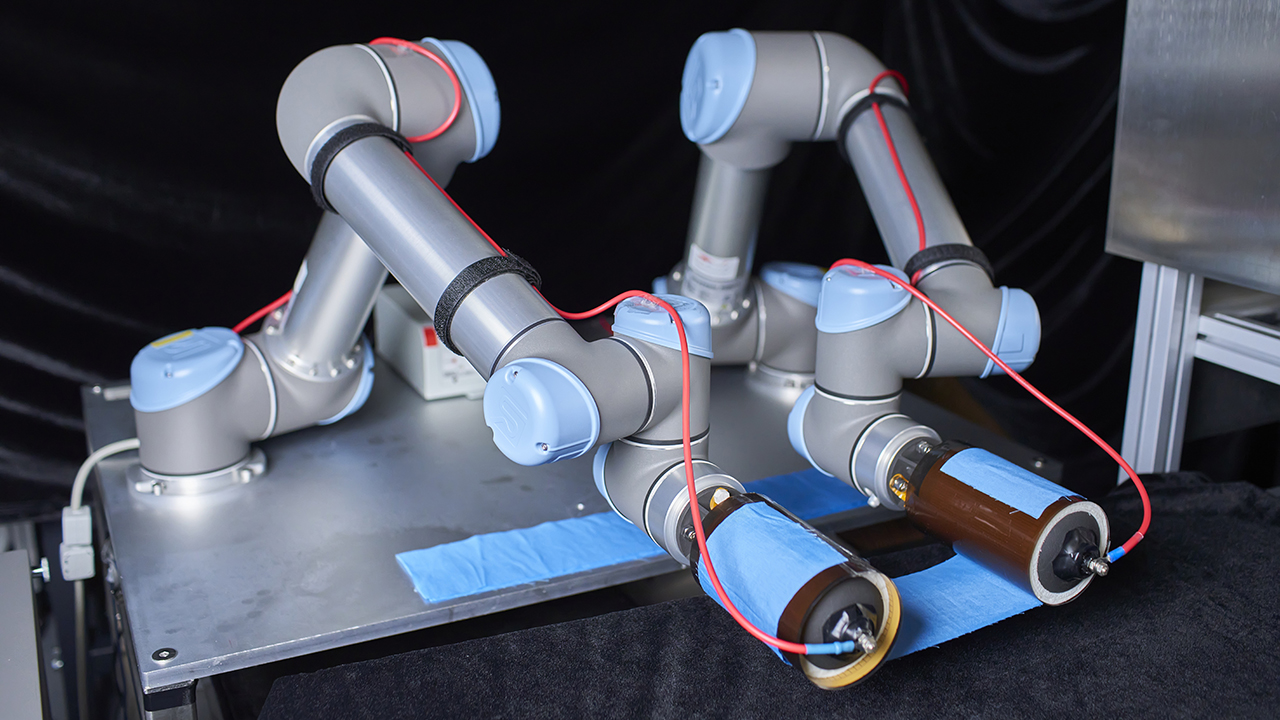

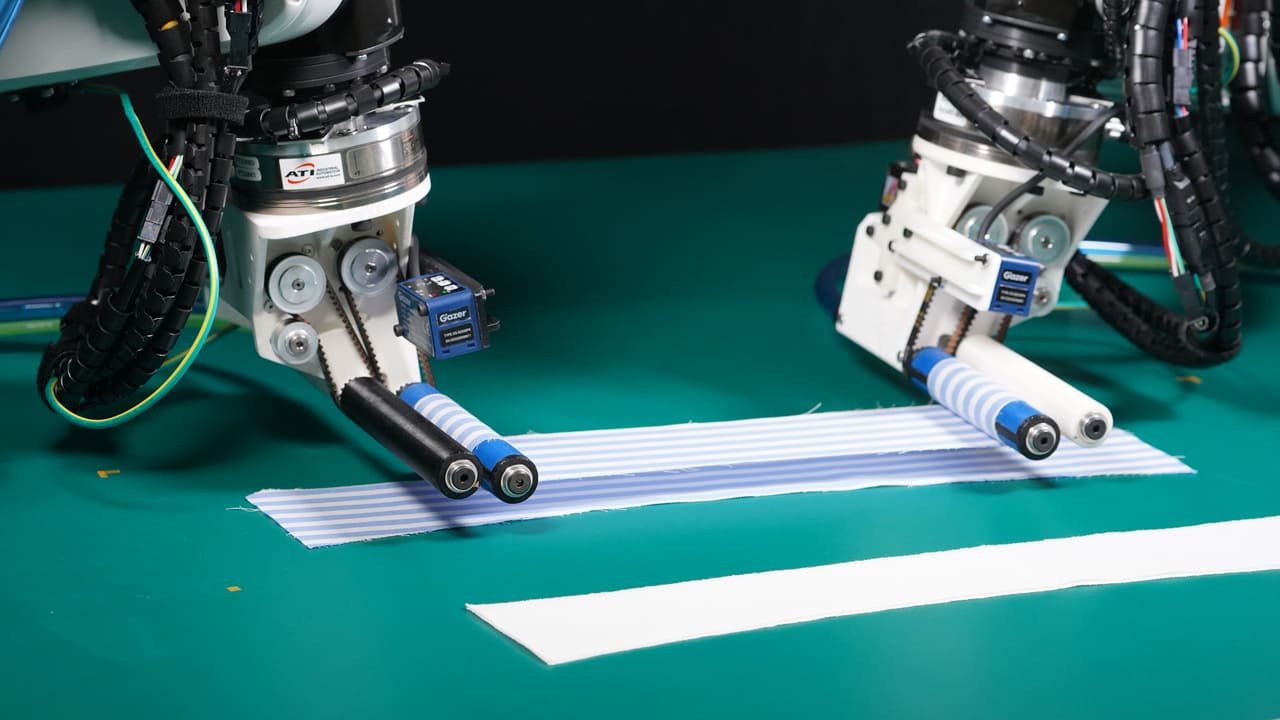

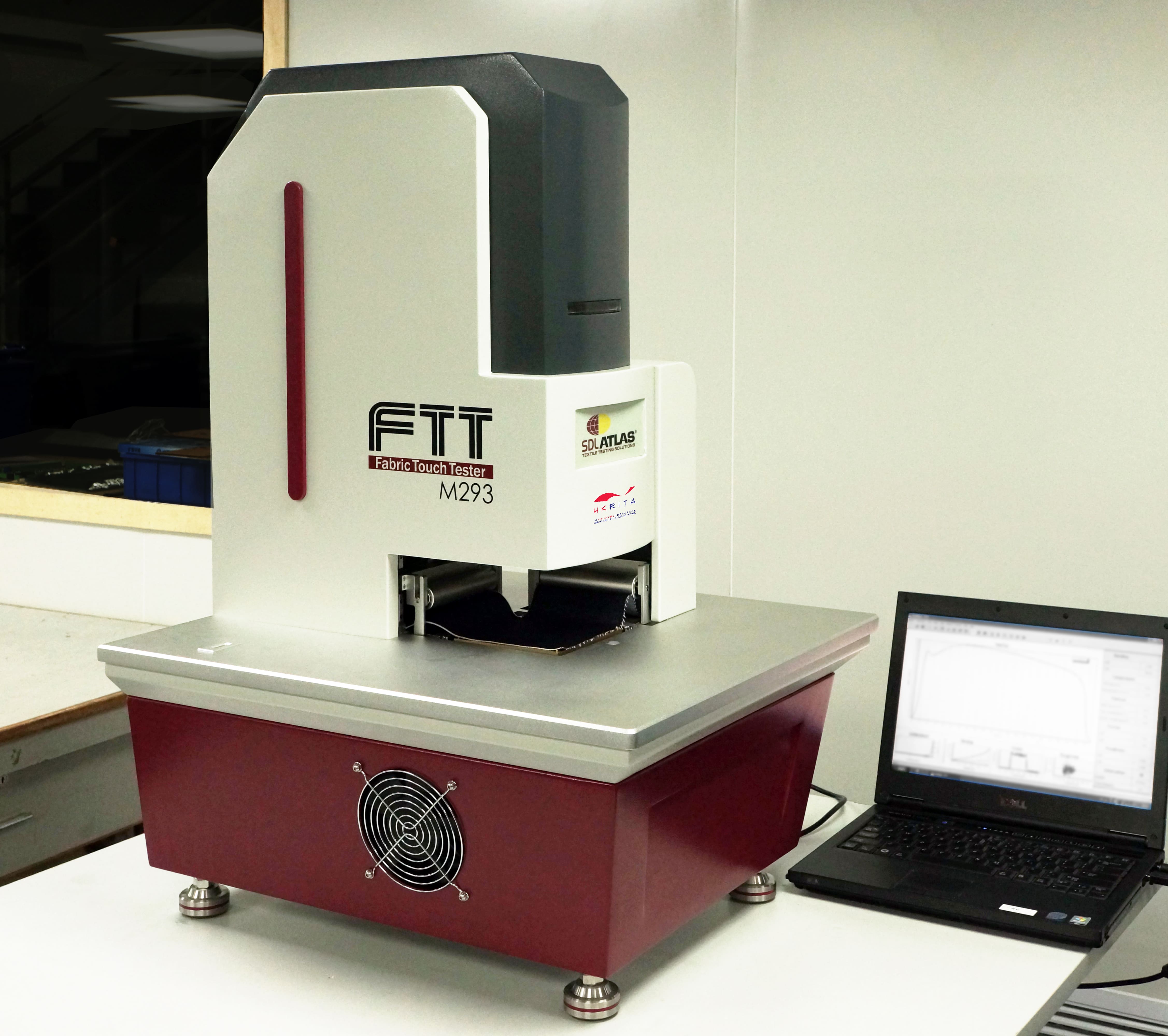

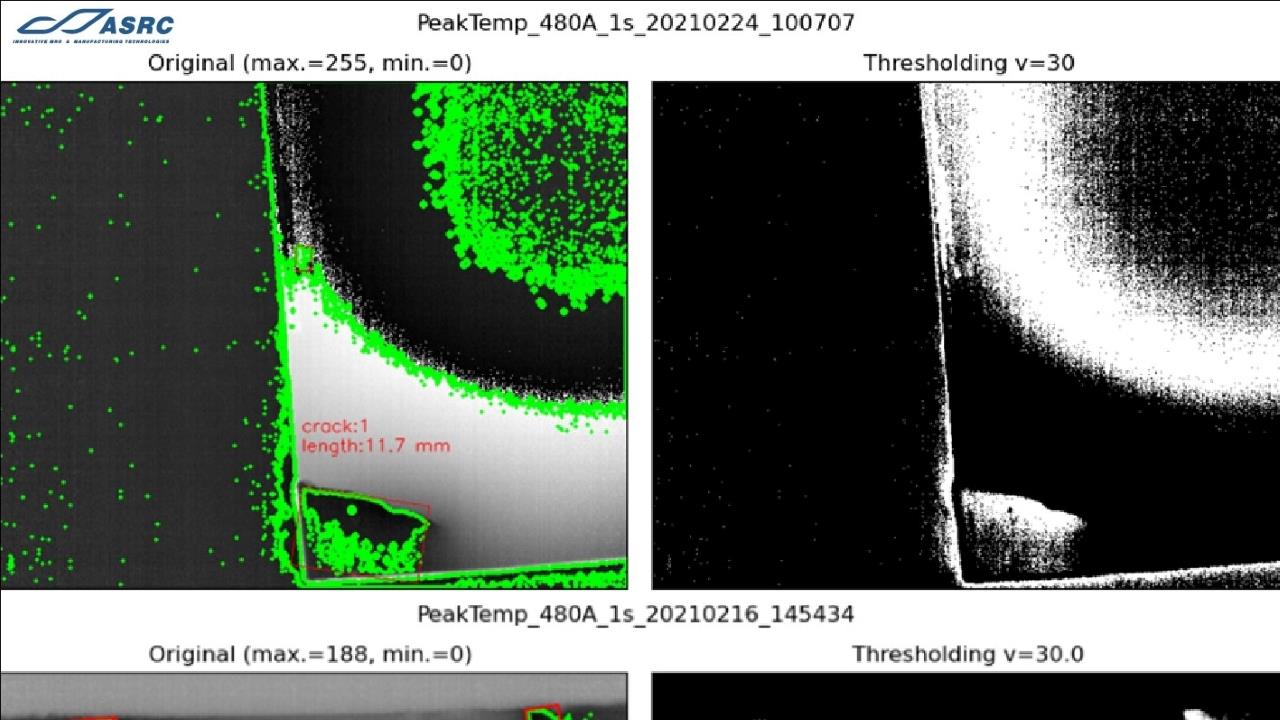

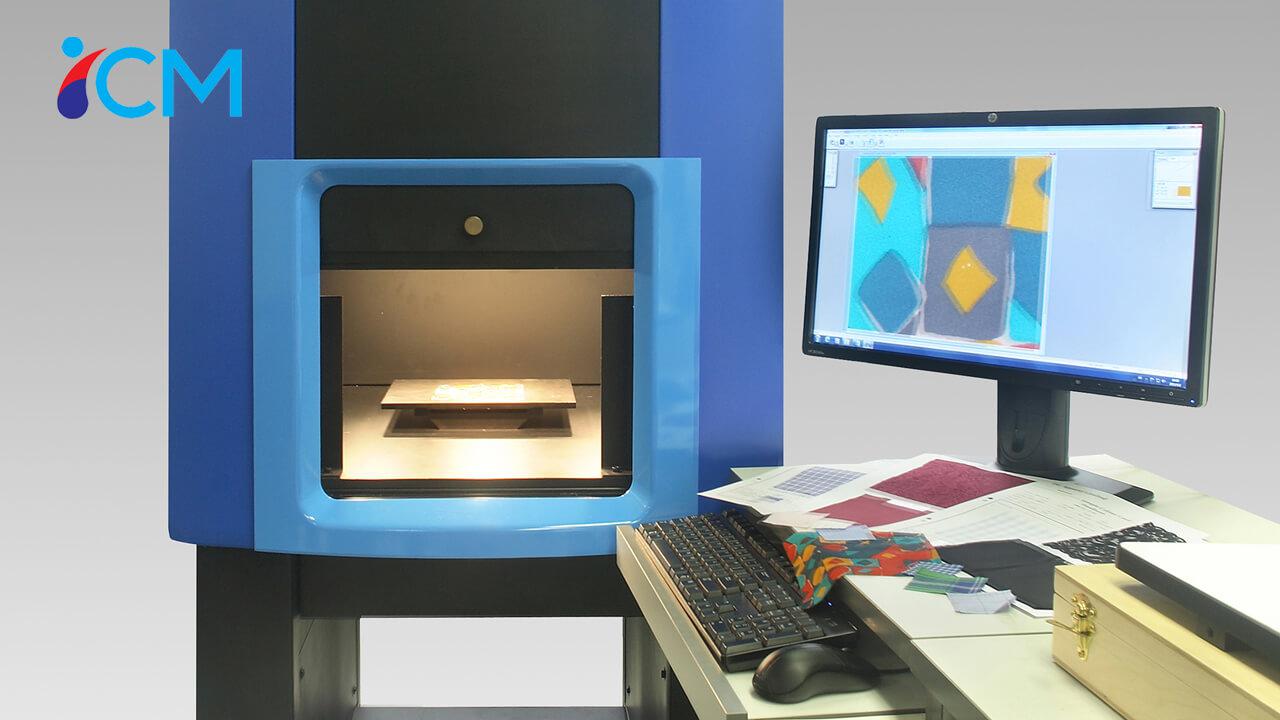

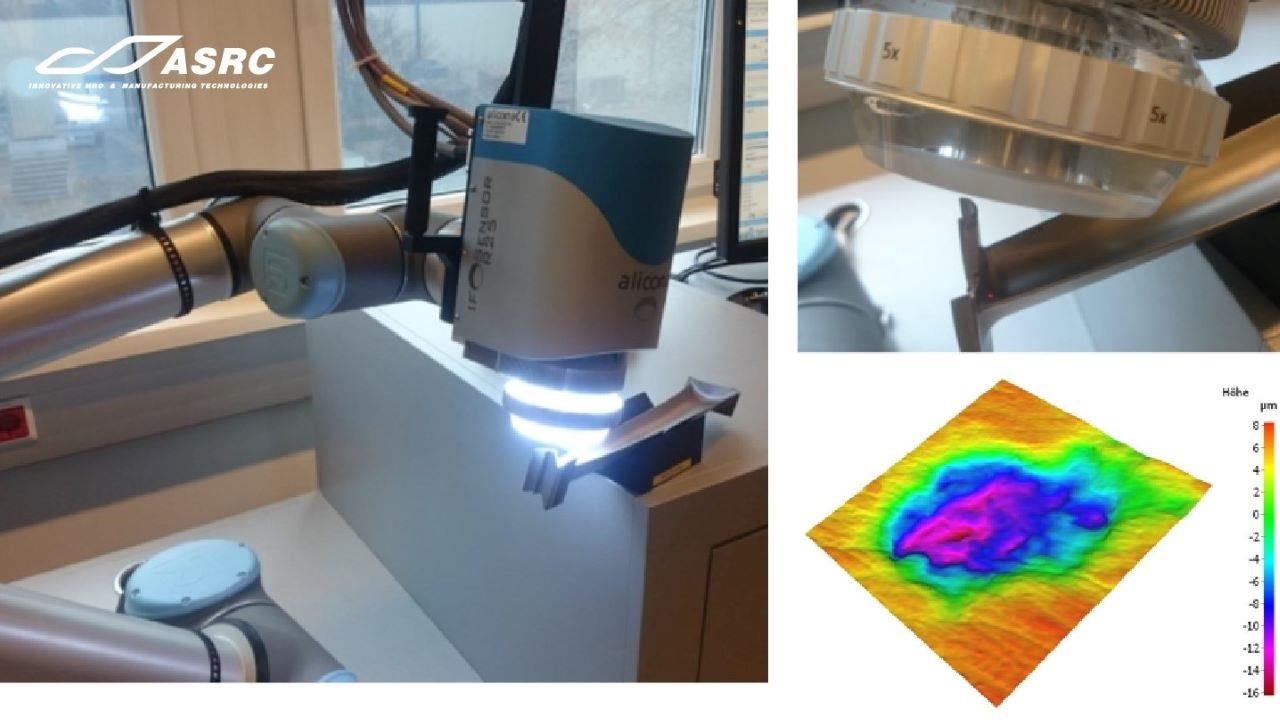

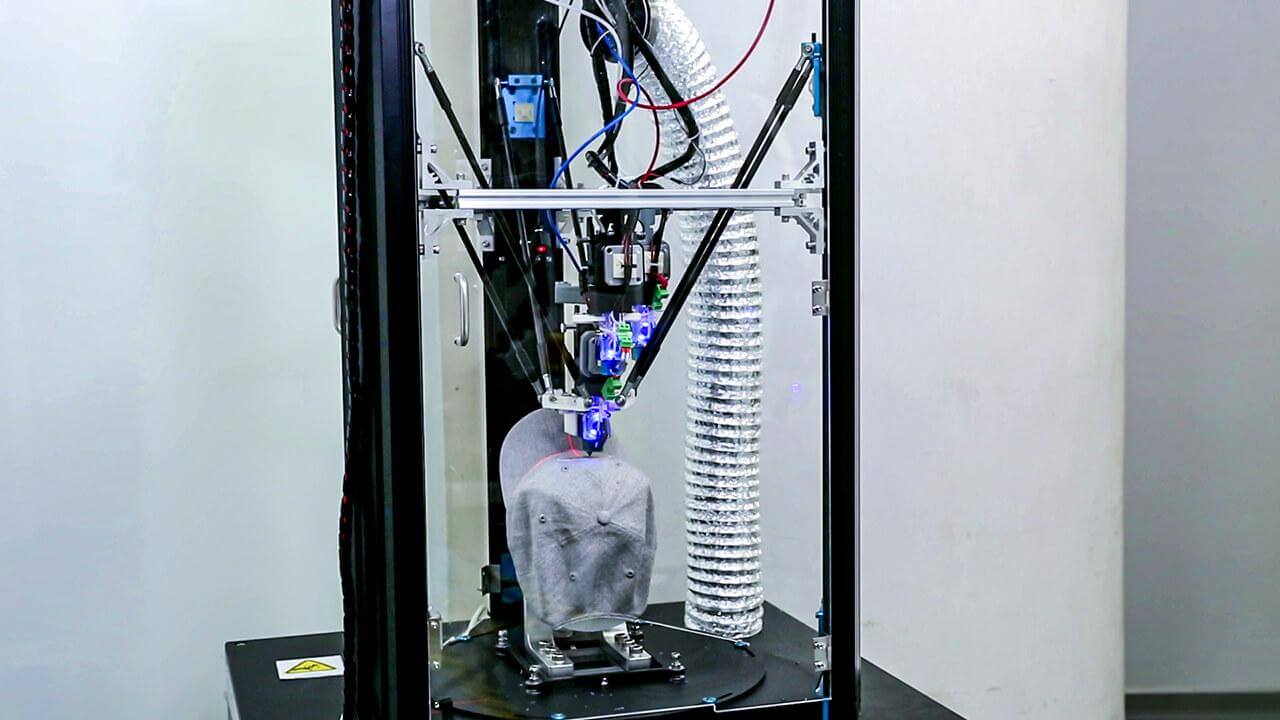

Developed by Prof. Calvin Wong and his team, the inspection system can automatically and accurately detect fabric defects in high-speed and real-time inspection environments.

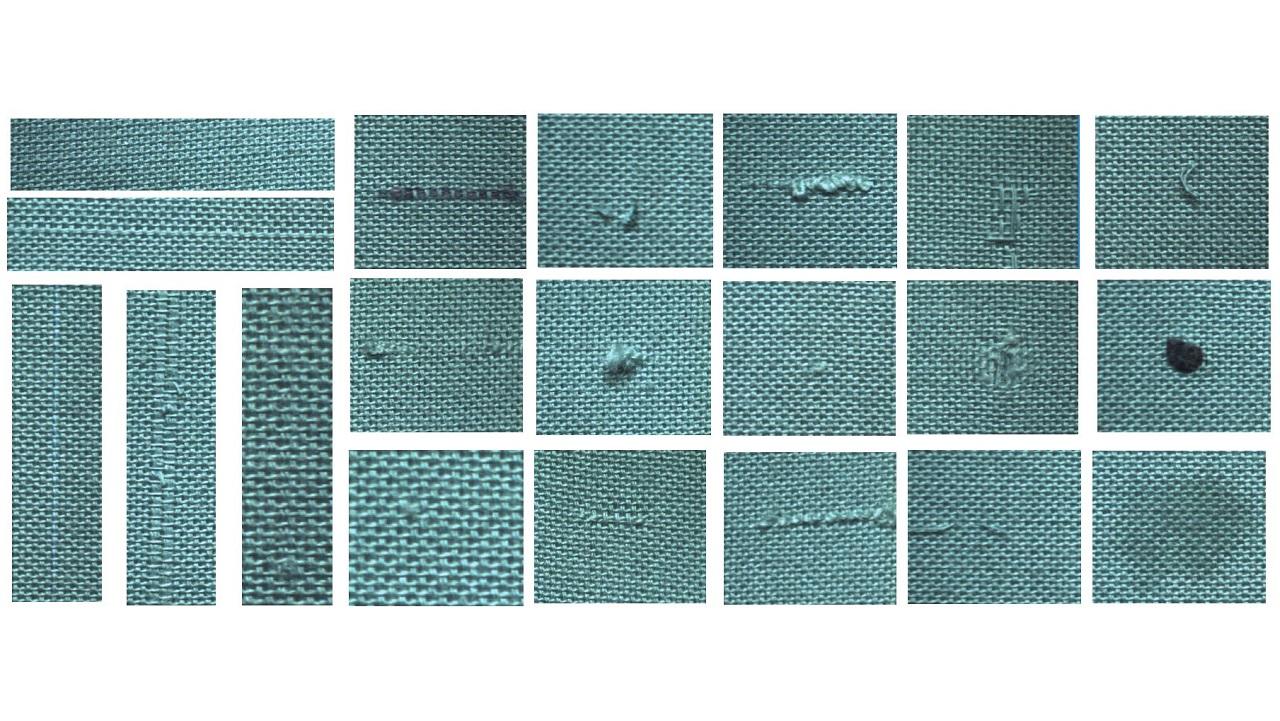

In view of the numerous fabric structures that give great variations in fabric texture and defect types, automatic fabric defect detection has been a challenging and unaccomplished mission in the past two decades.

- With the integration of machine vision algorithms and deep learning techniques, the system tackles the challenge of automatic inspection in the past two decades and achieves greater than 90% accuracy and provides high speed inspection at up to 60 metres per minute.

- In addition to automatic and efficient real-time inspection, the system can also help in auto-labelling the defects to meet the actual need of industry.

- The inspection system can inspect both finished woven and knitted fabric on real time basis, including plain, twill, dobby, single jersey, double jersey structures, and more, in different types of solid colour and pattern, such as striped and checked, covering over 40 common fabric defects and colour shading.

- The system revolutionises conventional manual inspection in the textile and apparel industries. It is is a technological breakthrough coinciding with Industry 4.0 era.

- Traditionally, defects inspection has relied on the naked eye, but this tends to be inconsistent and inefficient due to physical fatigue or loss of concentration. The system tackles it by achieving greater than 90% accuracy and providing high speed inspection at up to 60 metres per minute.

- The inspection system helps to alleviates the shortage of highly skilled quality inspectors.

- The inspection system helps to minimises downstream wastage and support sustainability by increasing the accuracy of inspection.

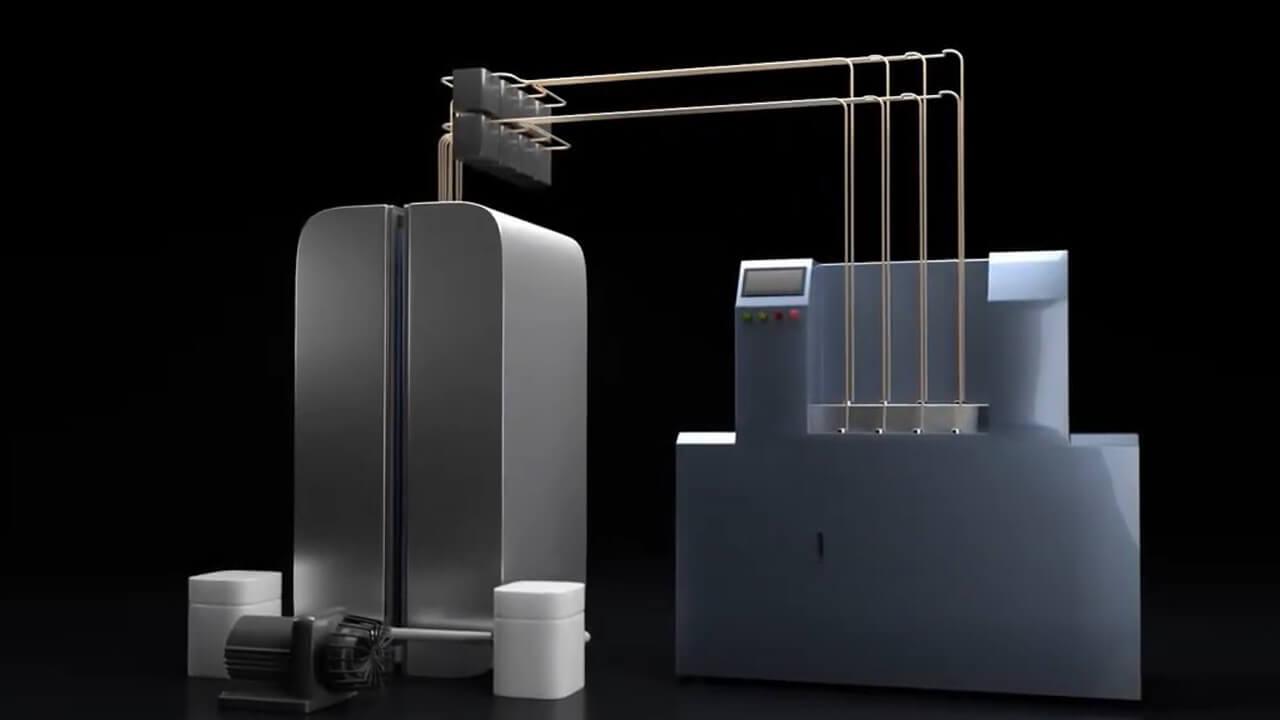

- A standalone machine with AI Fabric Inspection that can inspect both finished woven and knitted fabric on real time basis, including plain, twill, dobby, single jersey, double jersey structures, and more, in different types of solid colour and pattern, such as striped and checked, covering over 40 common fabric defects.

- Inspection report generation with detailed defects location

Patent

- Intelligent cloth inspection system and method, computer-readable storage medium, and product (Patent App. No.: CN 202211002876)

- Defect Inspection System for Textile (Chinese Translation) (Patent App. No.: CN 202221286998.2)

- Defect Inspection System for Textile (Short-term Patent App. No.: CN 32022055685.8)

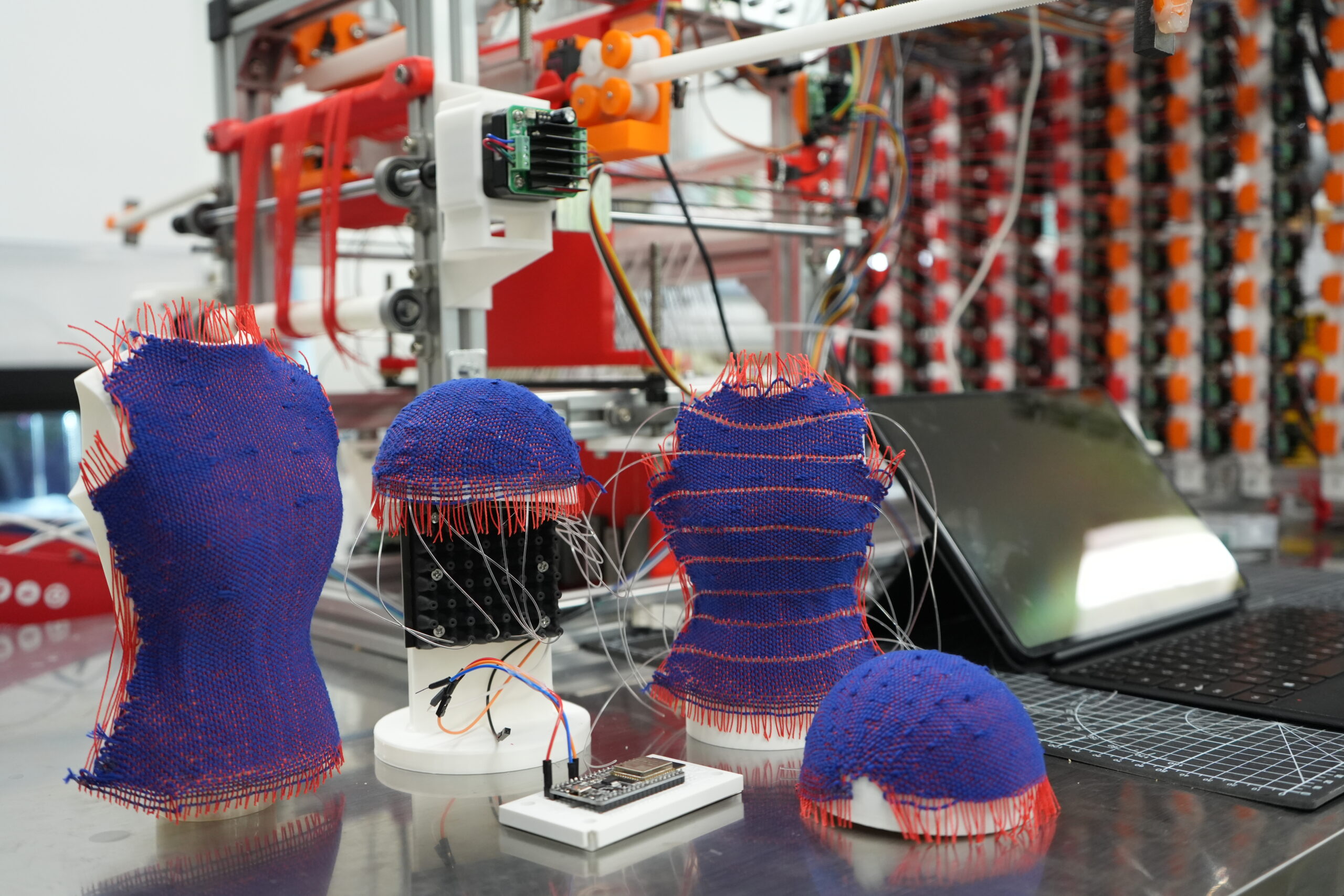

AiDLab is the first research platform that focuses on the integration of Artificial Intelligence (AI) with design. It was jointly established by The Hong Kong Polytechnic University (PolyU) and the Royal College of Art (RCA) in the UK, and is funded by the HKSAR Government under the InnoHK Research Clusters. Located at the Hong Kong Science Park, AiDLab has established a new creative cluster of AI in design and is in a leading position internationally to conduct interdisciplinary research in three thematic programmes: Ergonomic and Inclusive Design, Innovation in Product and Service Design, and Intelligent Fashion Design and Quality Control, that drives innovation and sustainability, and makes a positive impact on both industry and society.