A Fixture-free 3D Sewing System

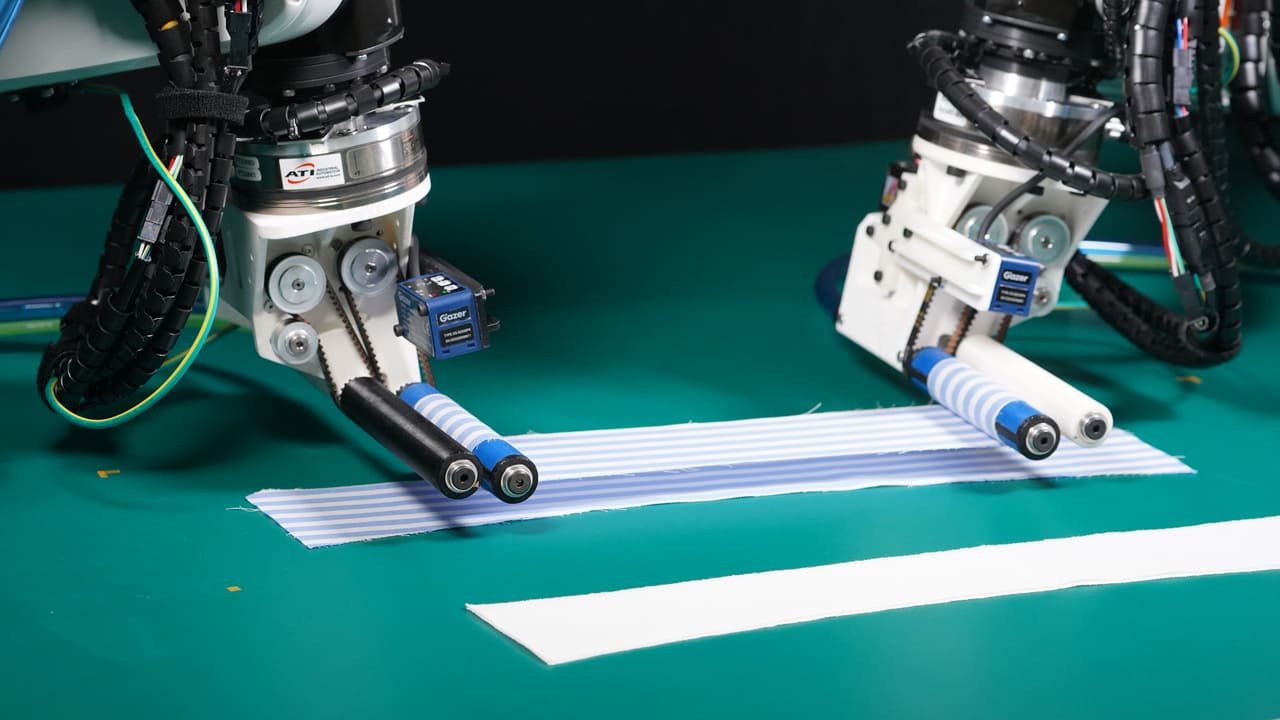

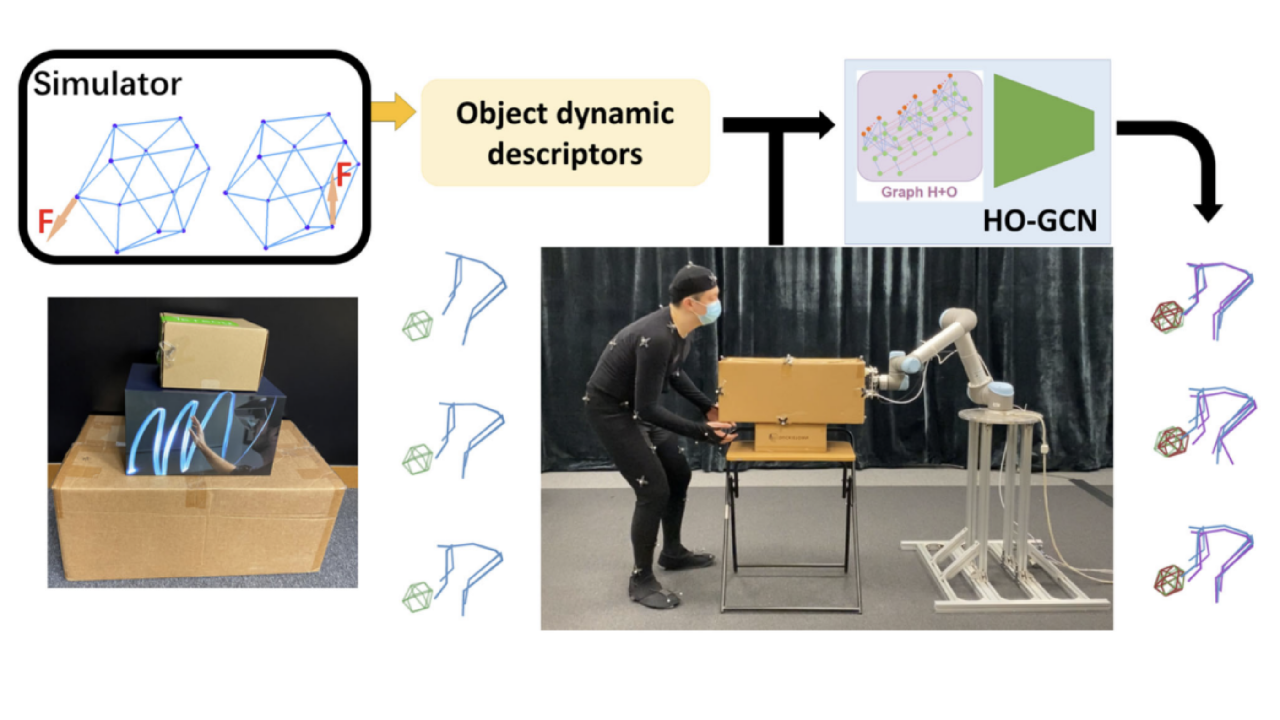

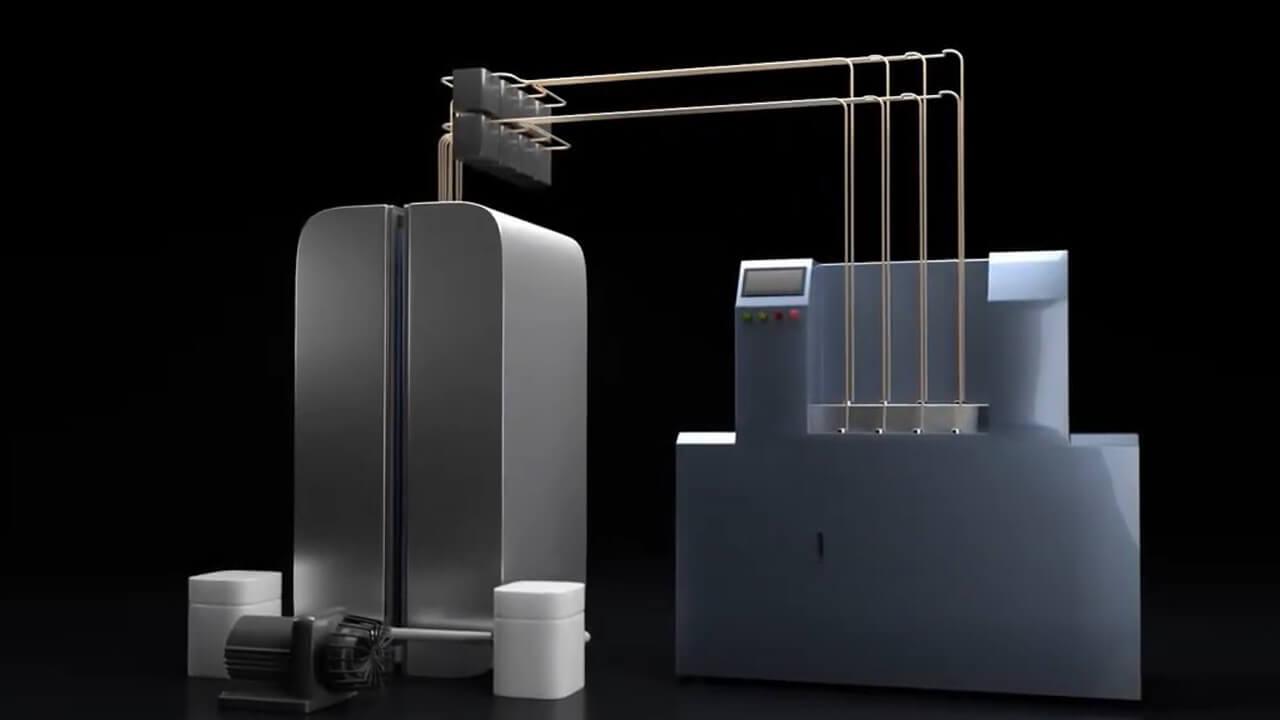

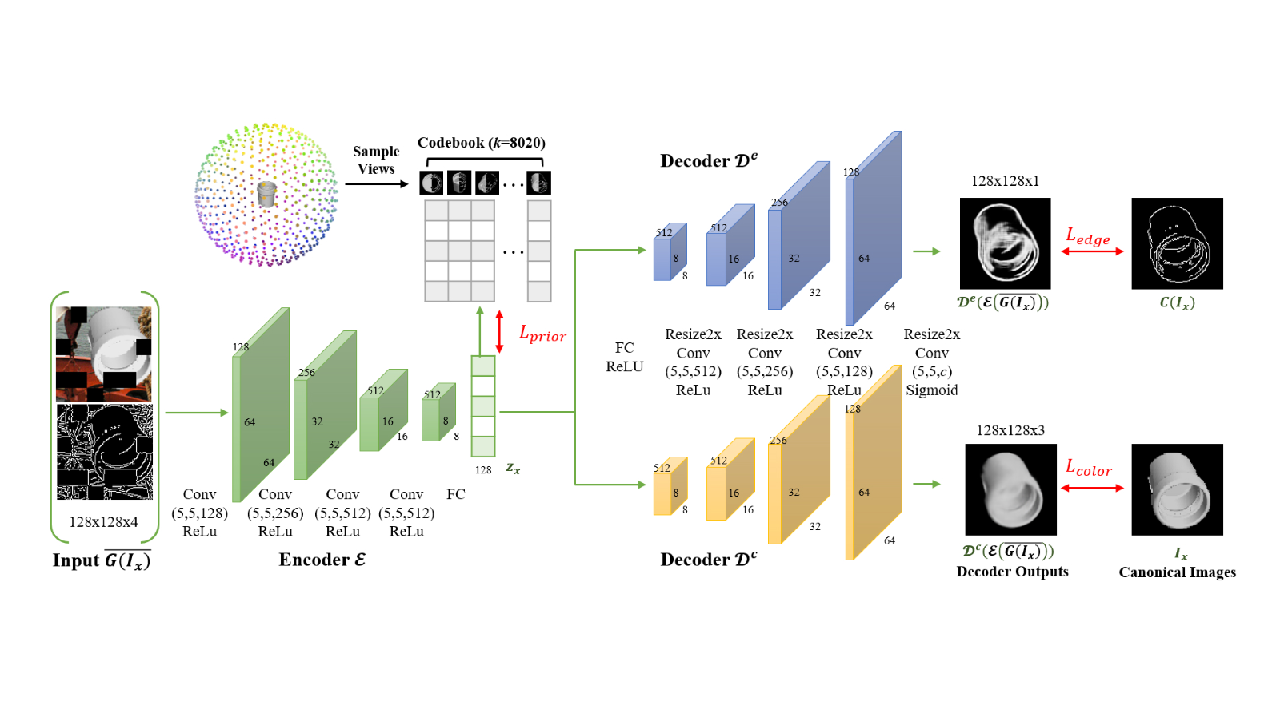

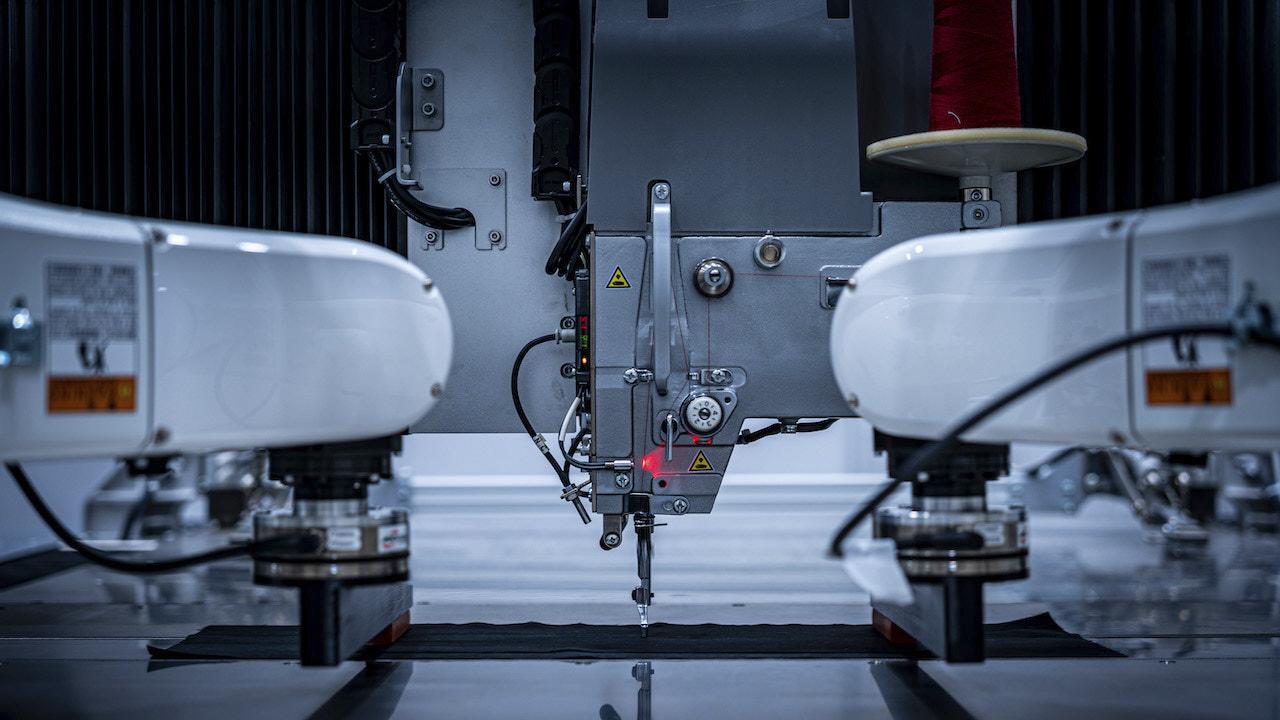

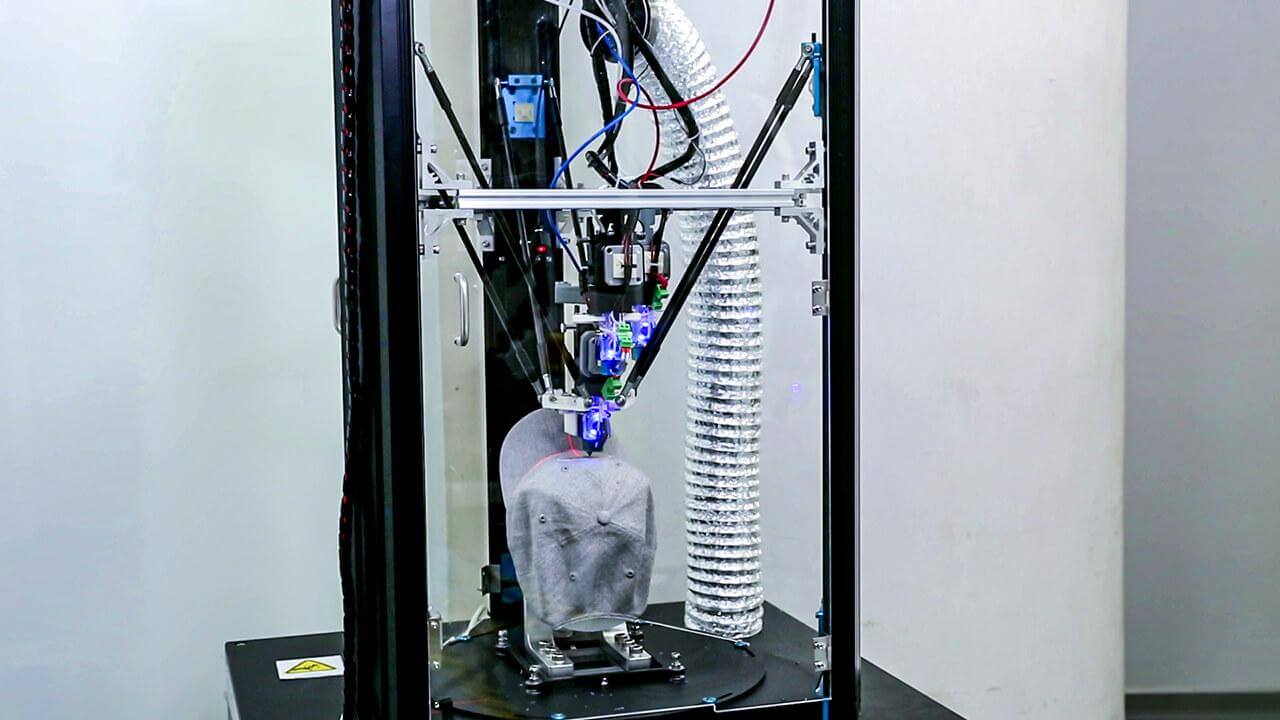

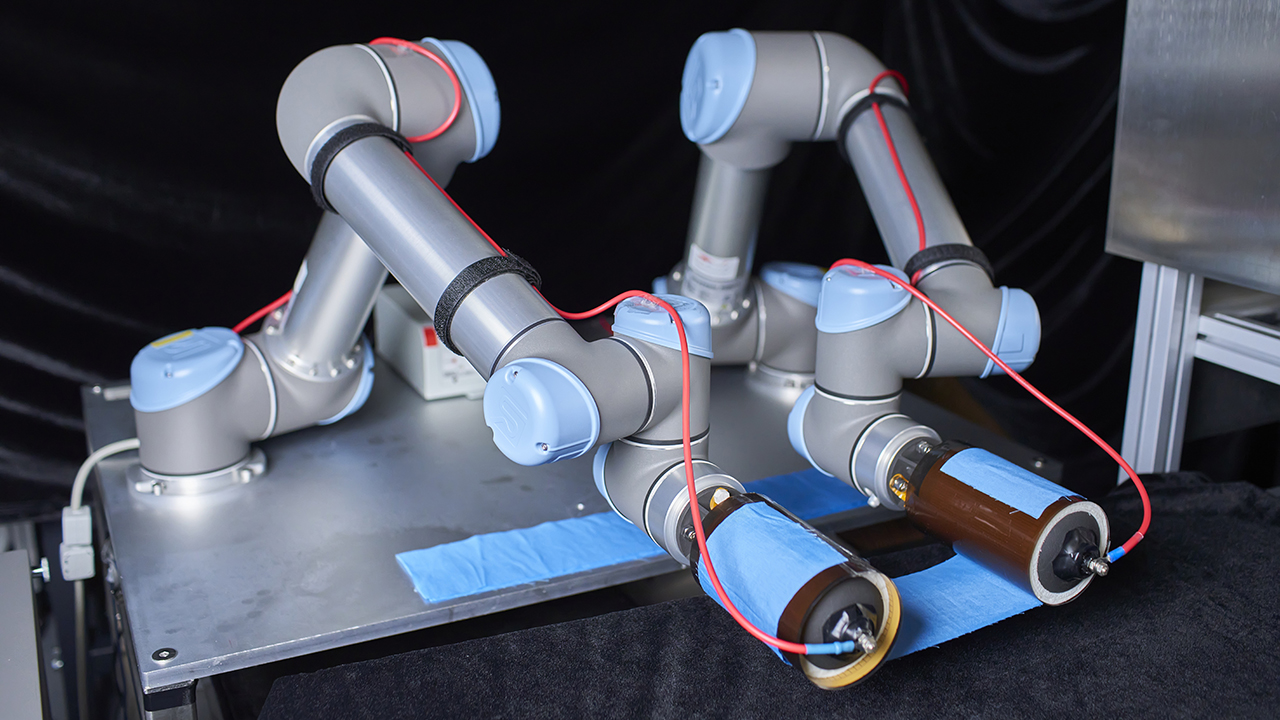

This fixture-free 3D sewing system integrates AI and robotics technology to automate the sewing of two fabric panels with different curvatures into a three-dimensional shape. It achieves this without the need for specialized fixtures, ensuring cost-efficiency and versatility while addressing labor shortages. The technology is applicable to garments, automotive interiors, and more.

Traditional 3D sewing processes require frequent maneuvering of fabric parts in multiple directions, relying heavily on skilled operators. Existing automated 3D sewing systems often depend on specialized fixtures for different fabric sizes and types. Our innovation produces high-quality curved seams without fixtures, offering greater flexibility and addressing the skilled labour shortage in garment manufacturing.

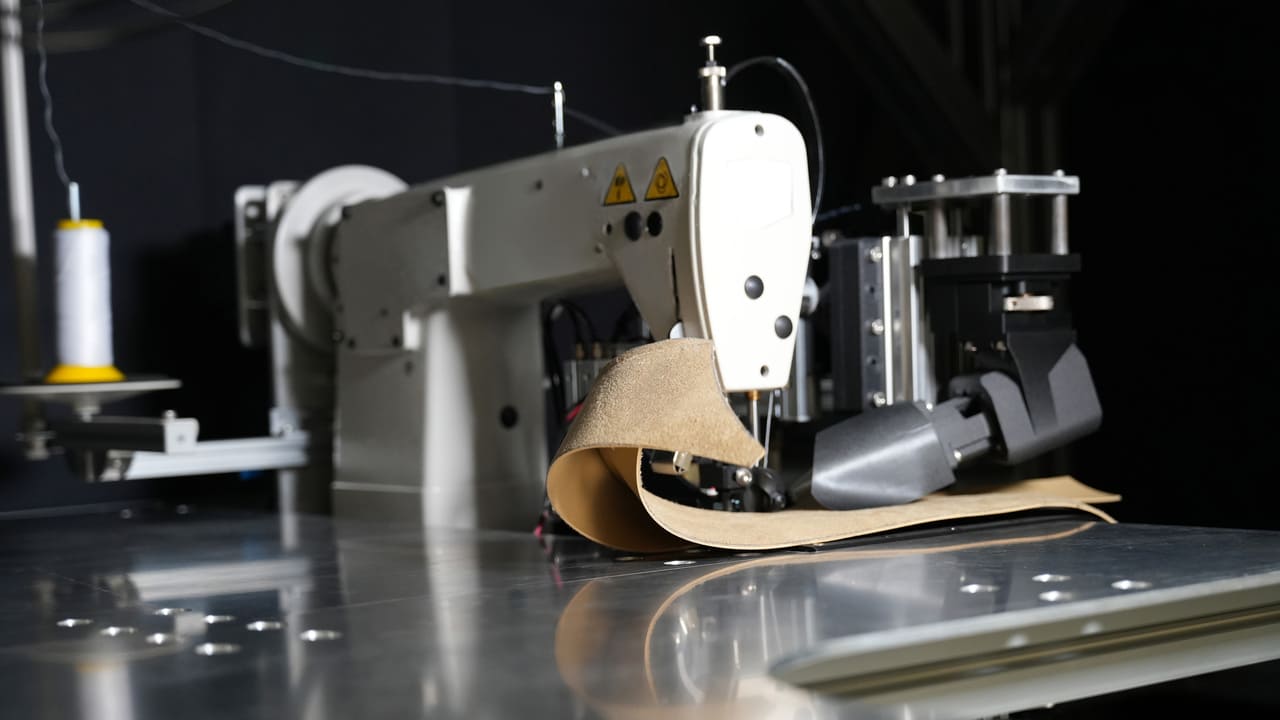

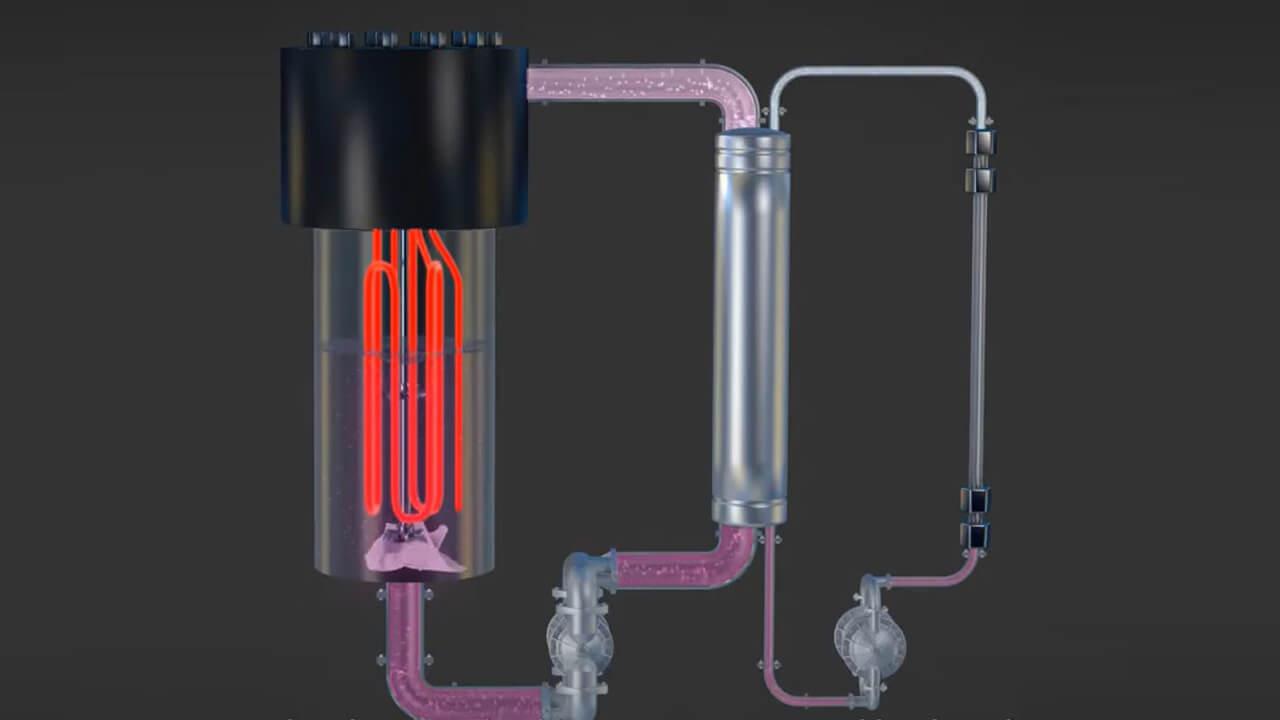

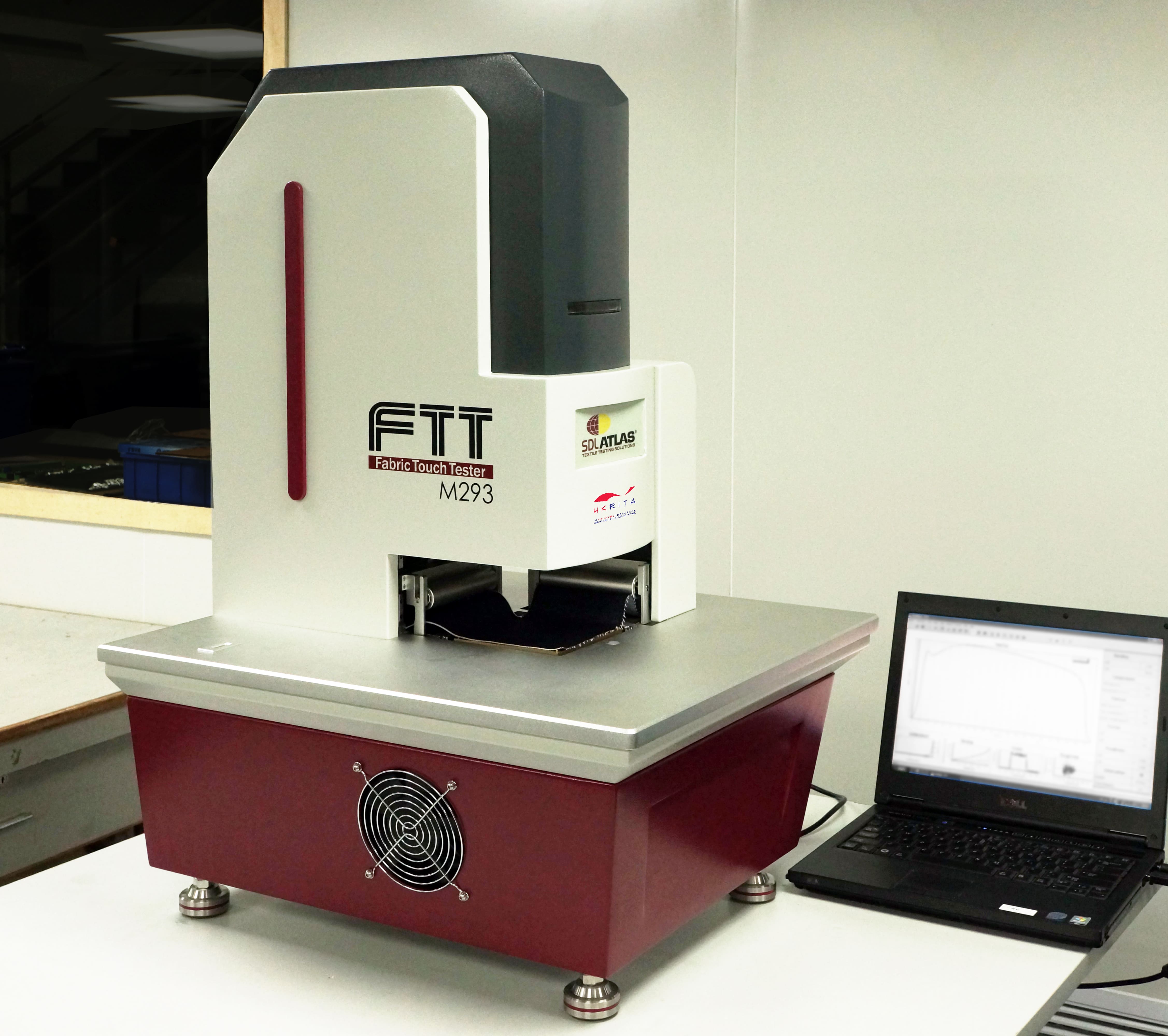

- Proprietary feeding system for real-time fabric manipulation

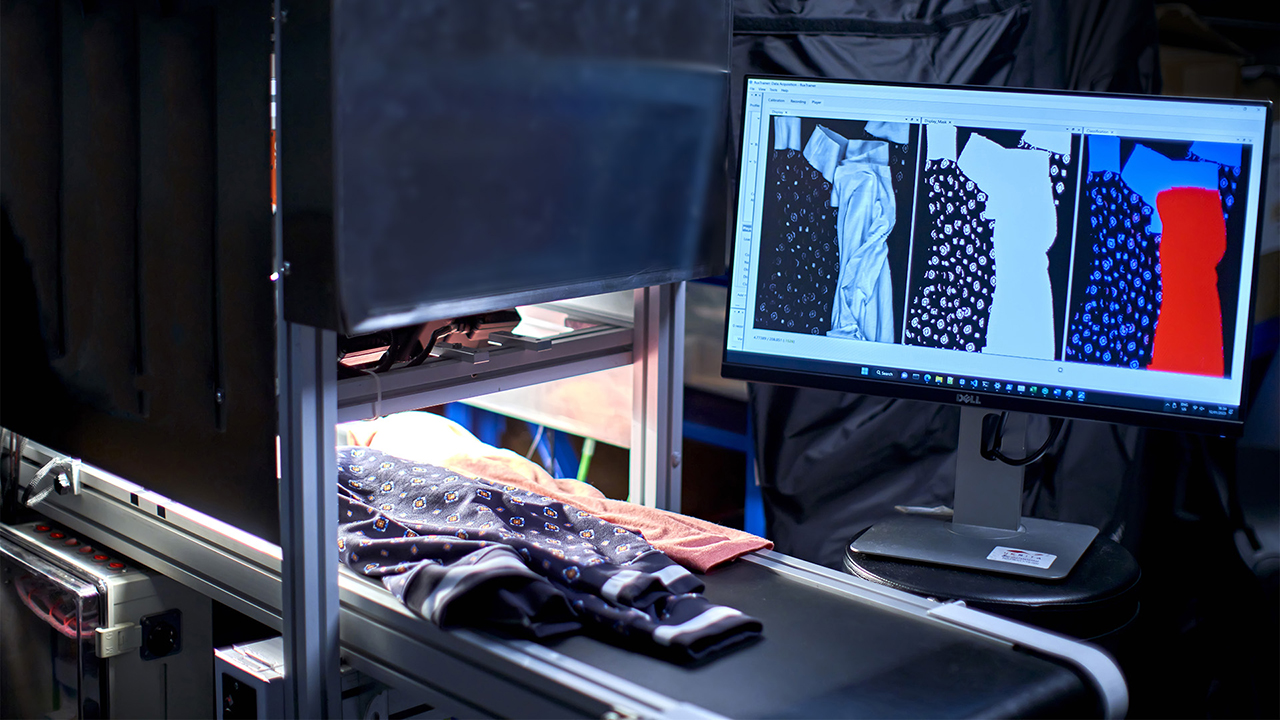

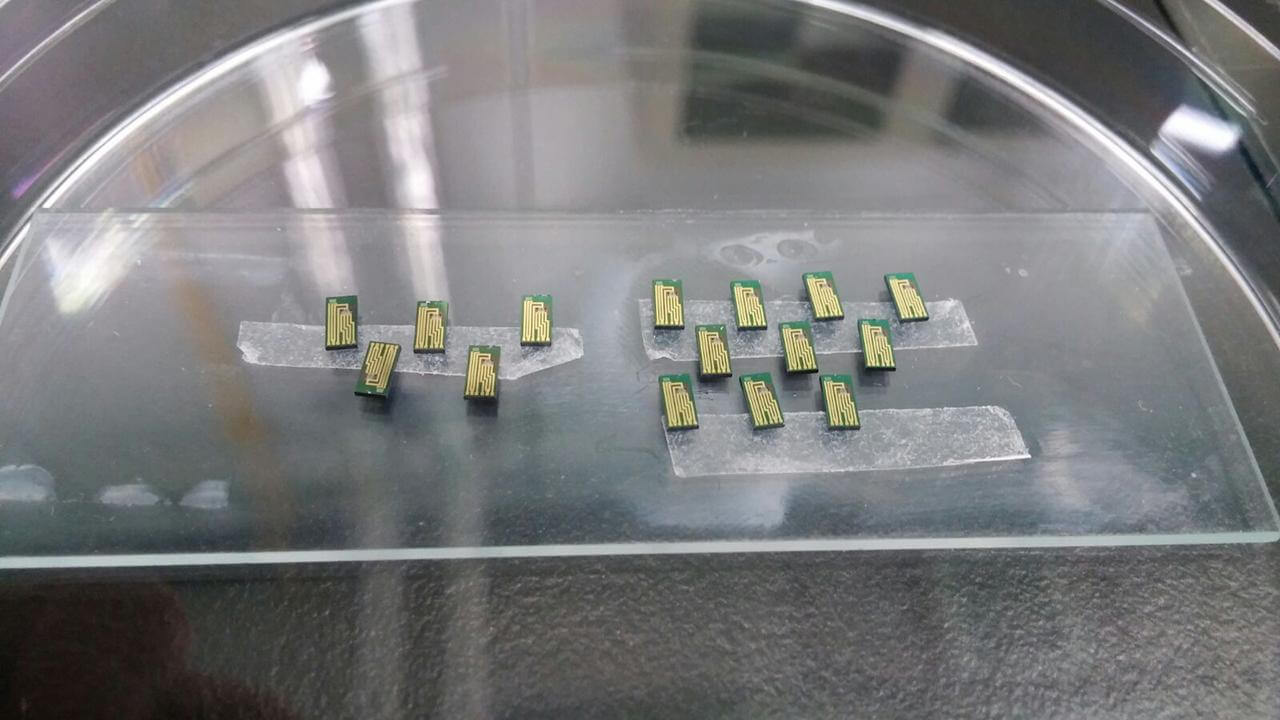

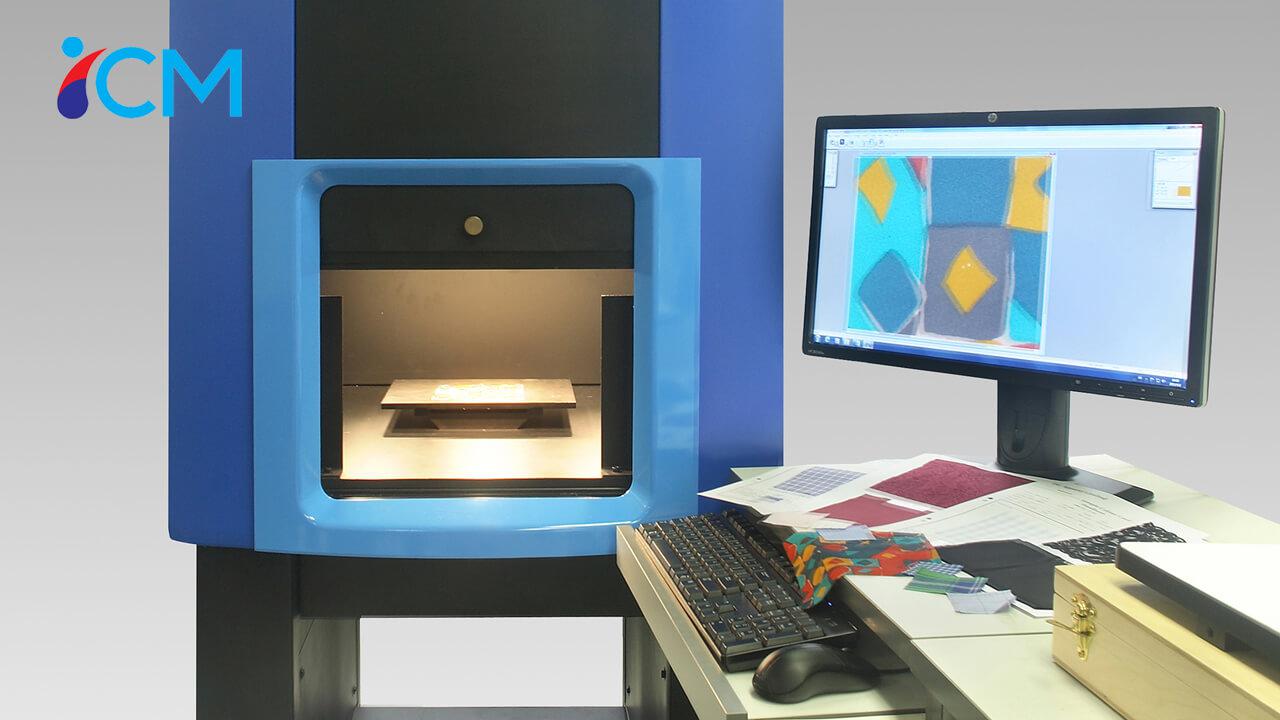

- Advanced edge sensing technology for accurate alignment of non-congruent contours.

- Precision tension control to ensure smooth, puckering-free sewing results.

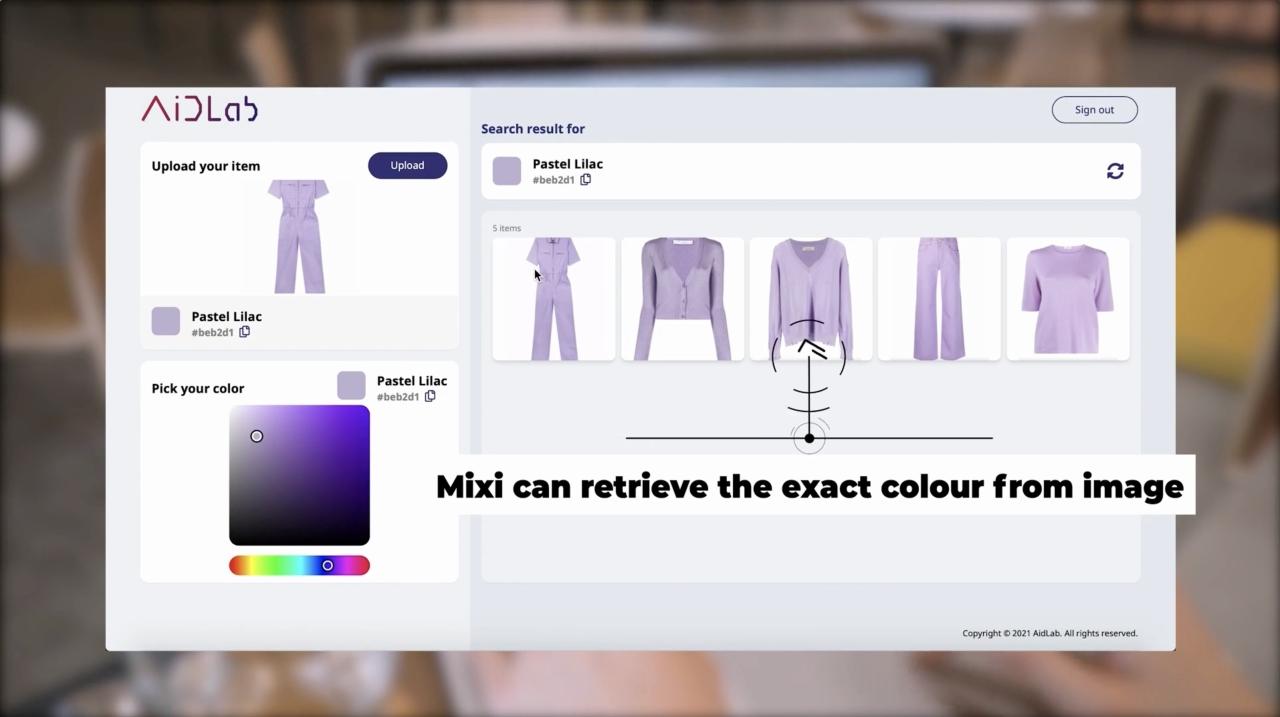

- Easy to use: Streamlines sewing tasks through a user-friendly teaching operation using CAD models, specialised fixtures and programing not required.

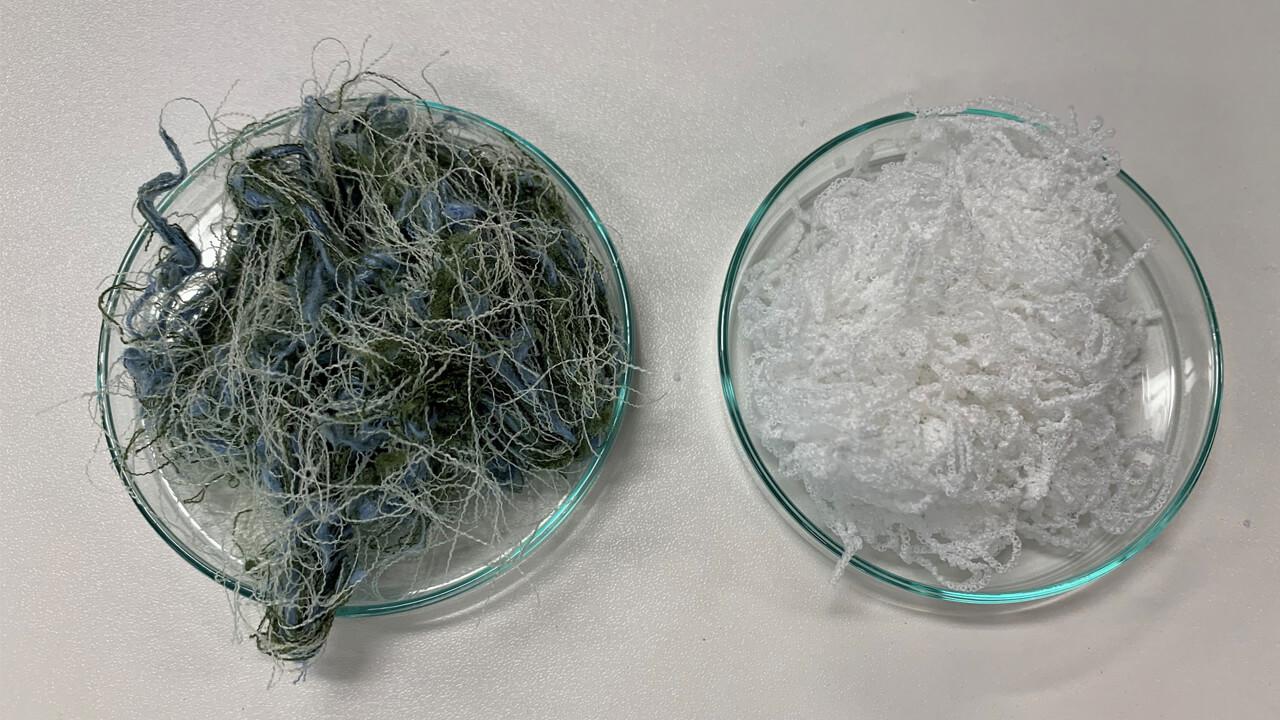

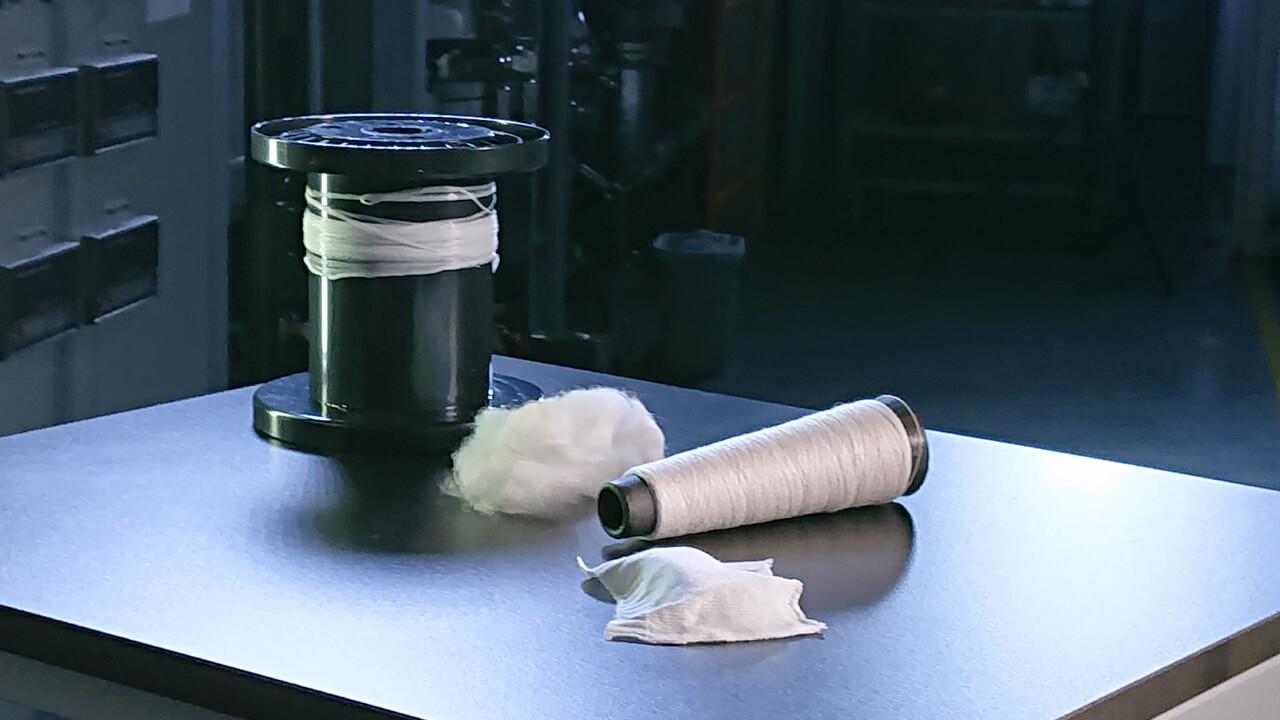

- Unmatched Versatility: Handles a wide range of materials and sewing tasks for a variety of applications, from mass production to custom orders and small-batches.

- Affordable Innovation: Offers more cost-effective alternatives, utilising standard sewing machines and eliminating the need for costly, large-scale robotic arms.

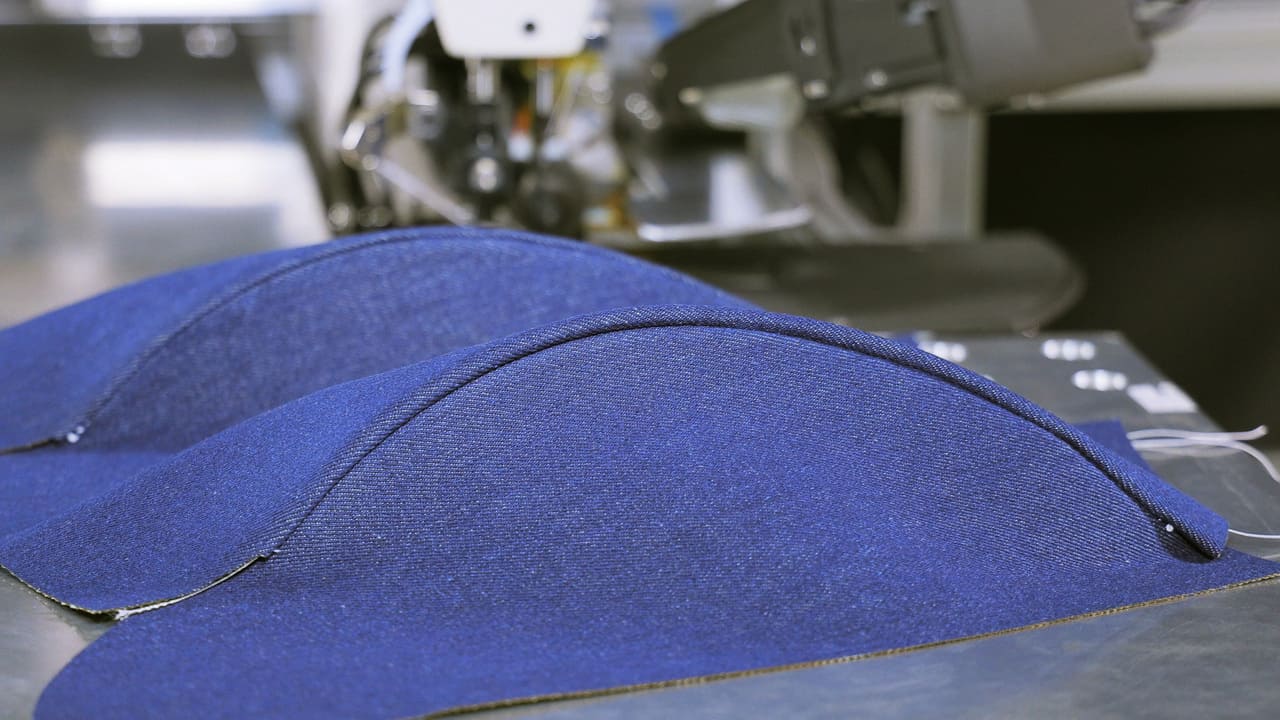

- The production of an array of clothing relies on 3D sewing technology, from suits and jackets to dresses, underwear and sportswear.

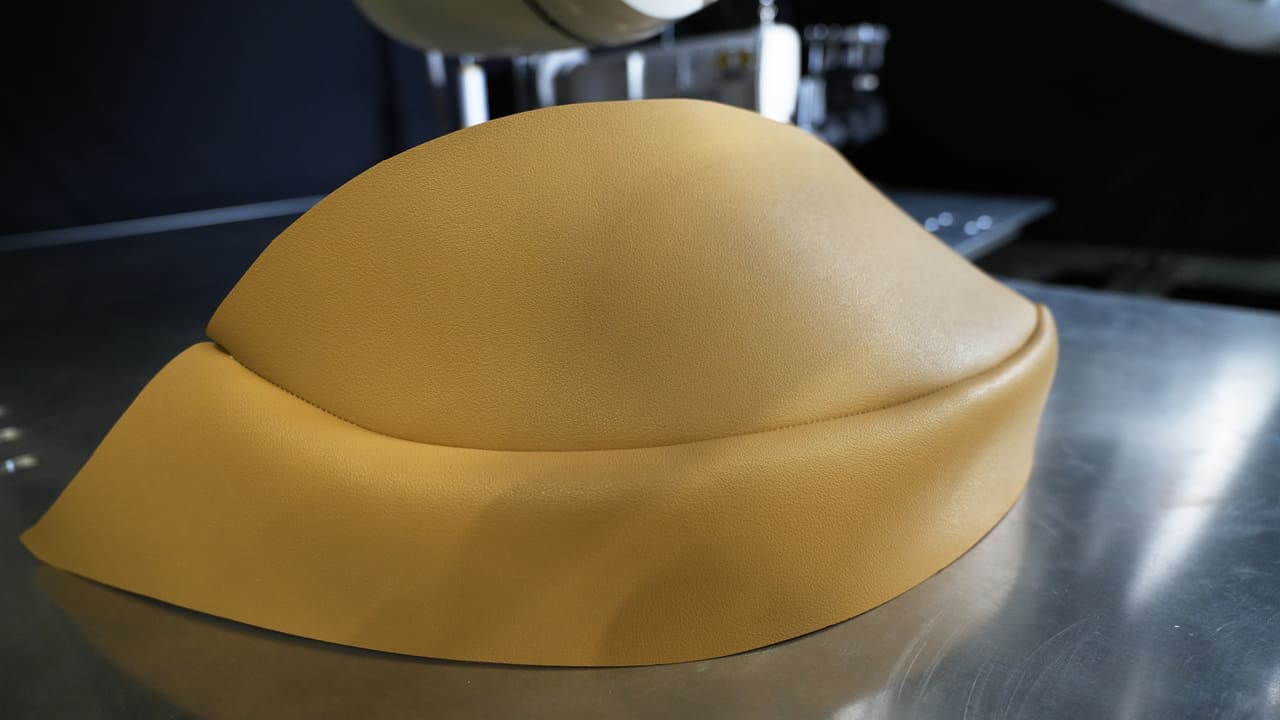

- The production of a wide range of leather products incorporates 3D sewing technology, from automotive leather seats to handbags, shoes, and hats.

Patent

- PCT patenet filed: PCT/CN2024/102499

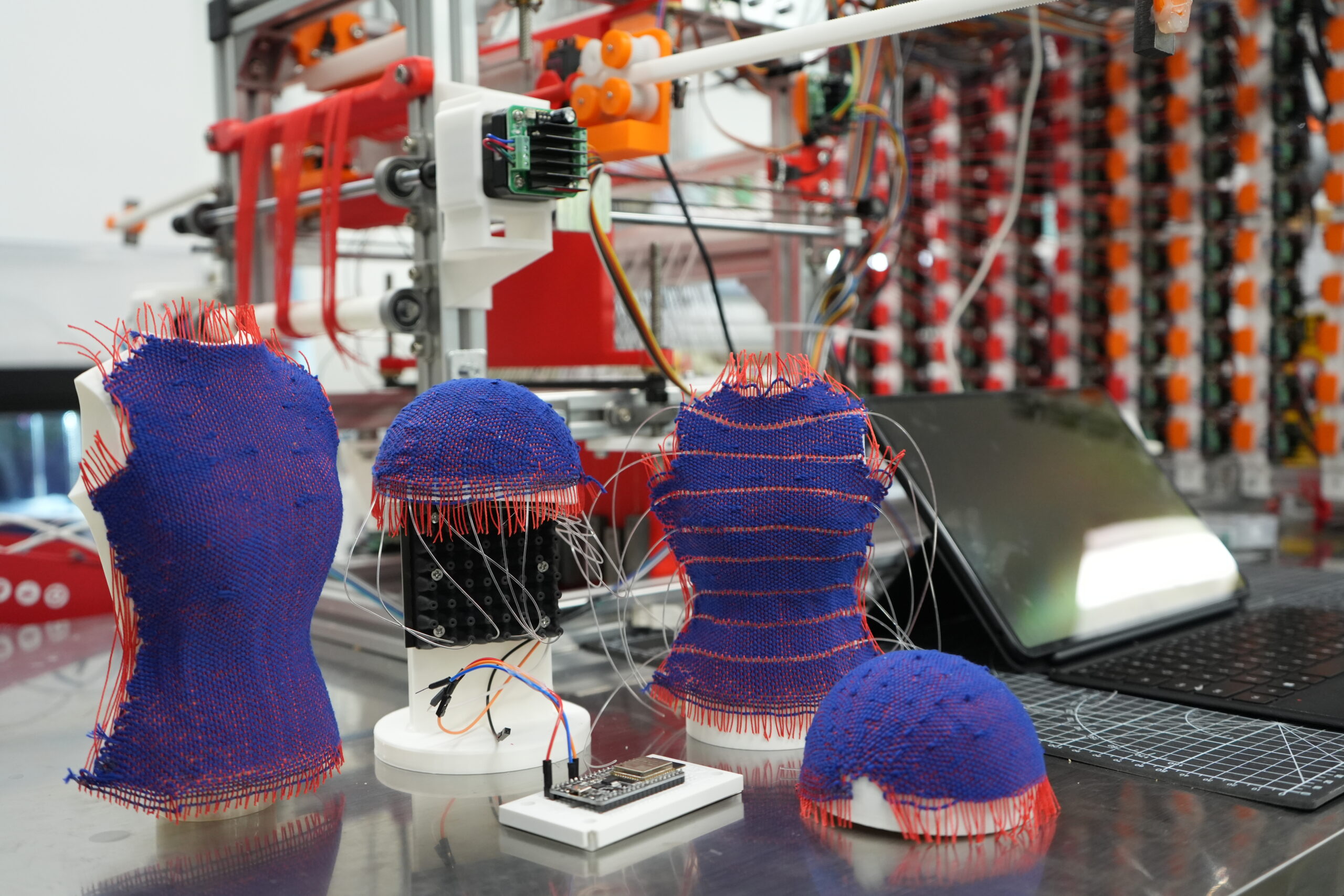

Centre for Transformative Garment Production (TransGP) was established with the collaborative effort of The University of Hong Kong and Tohoku University. The Centre aims to provide solutions for the needs of the future society, where labour shortage would arise from population aging, and where increasing percentage of the mankind will be living in megacities. The Centre also targets at driving paradigm shift for reindustrializing selected sectors, i.e. garment industry, which is still relying on labour-intensive operations but with clear and identified processes for transformation. A number of goals are expected to be achieved through the Centre’s research programmes, such as to leverage the proprietary AI and robotics technology to shorten development cycles, to improve engineering efficiency and to prevent faults and increase safety by automating risky activities.