A method to learn intended motions of human operators for human-robot collaboration

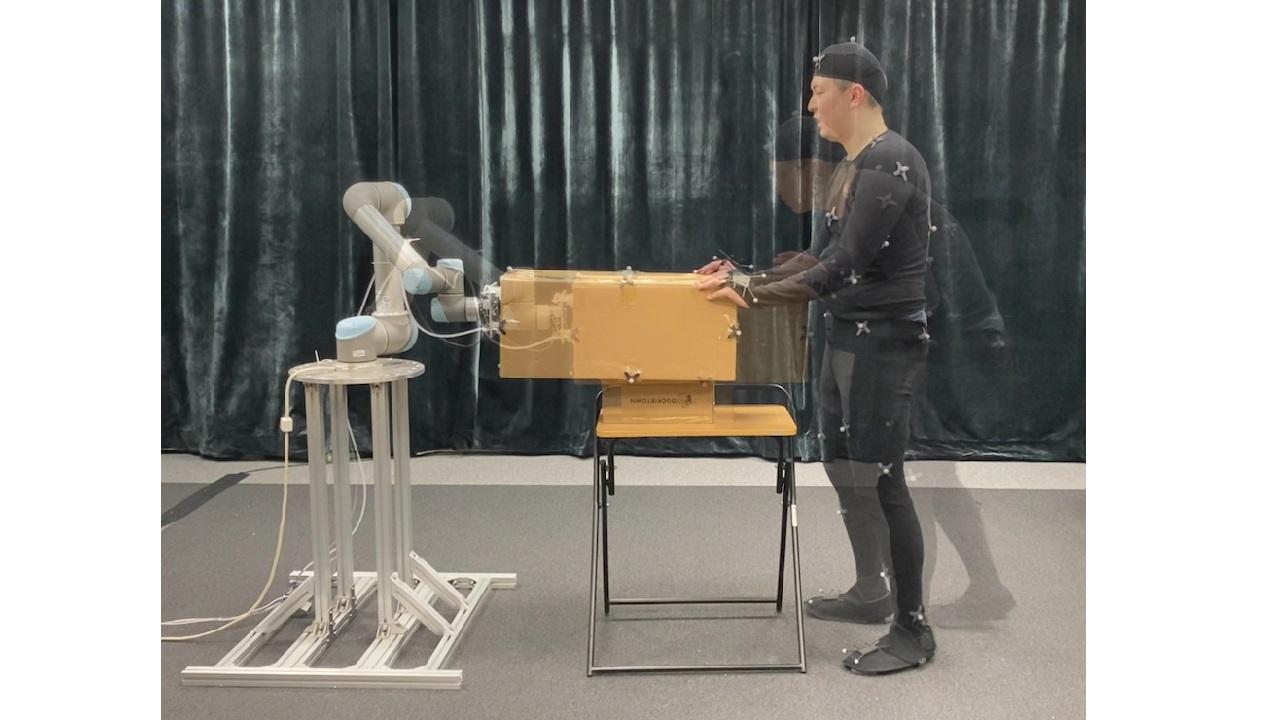

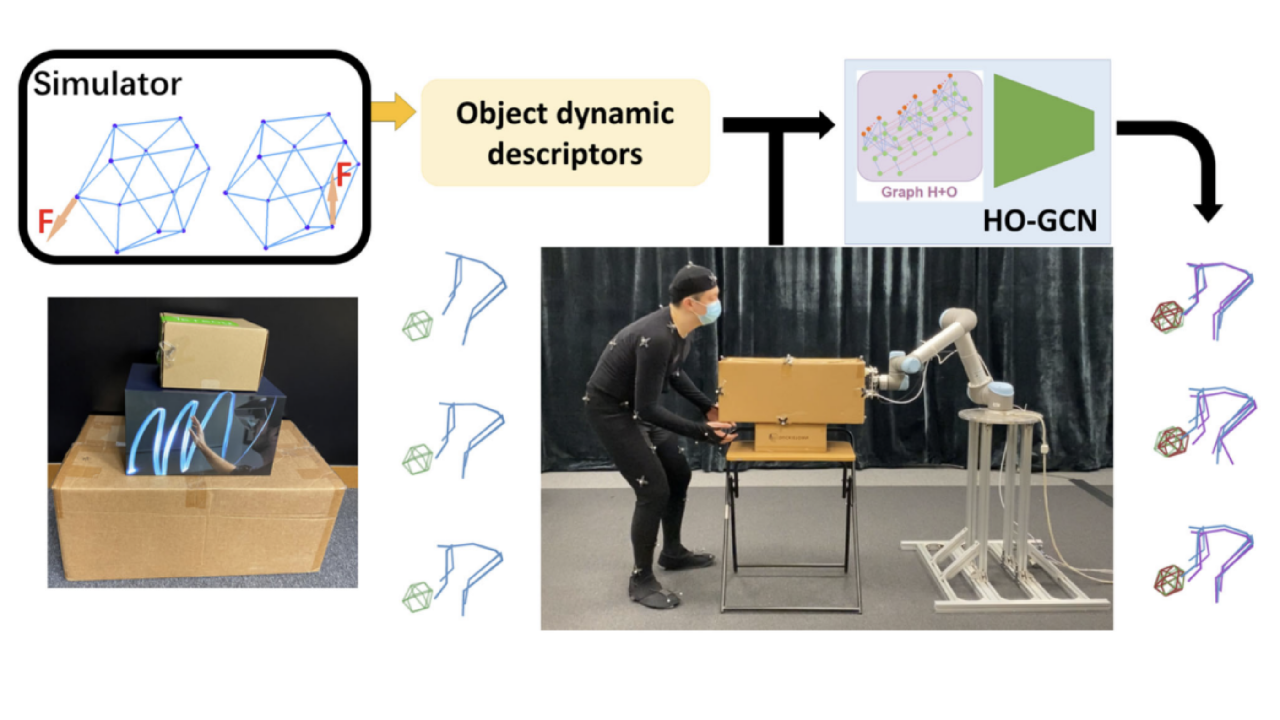

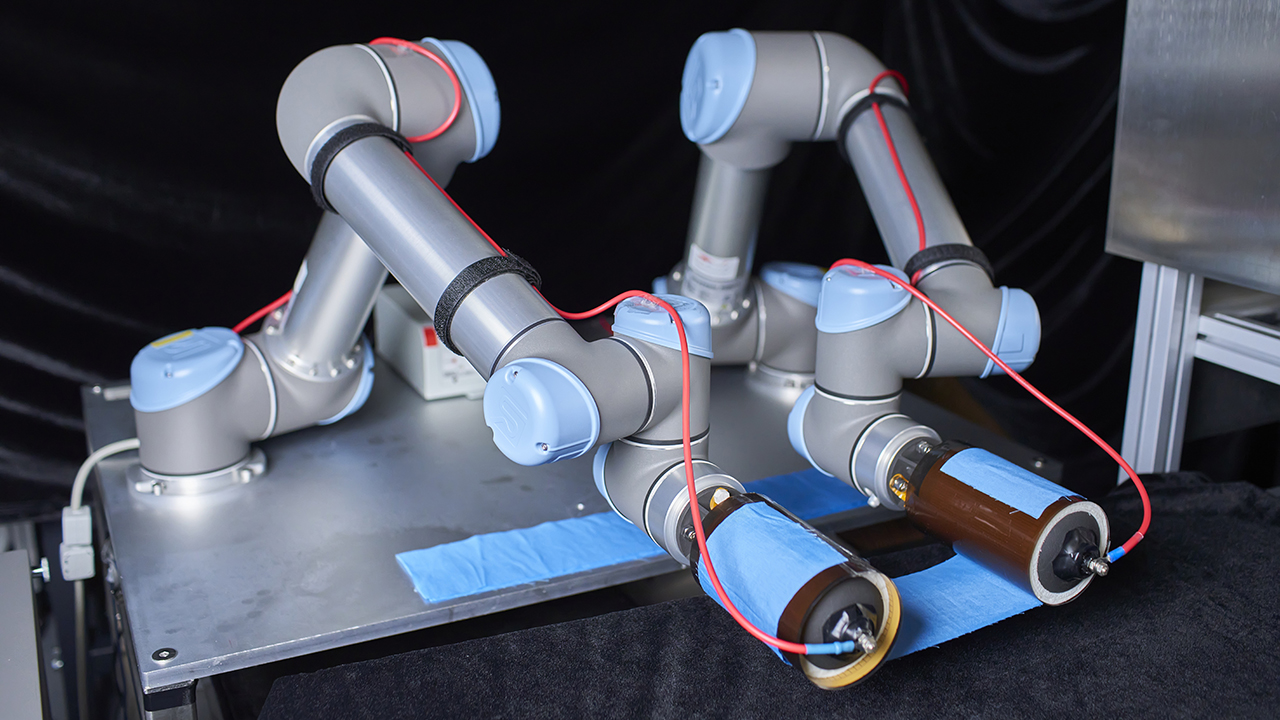

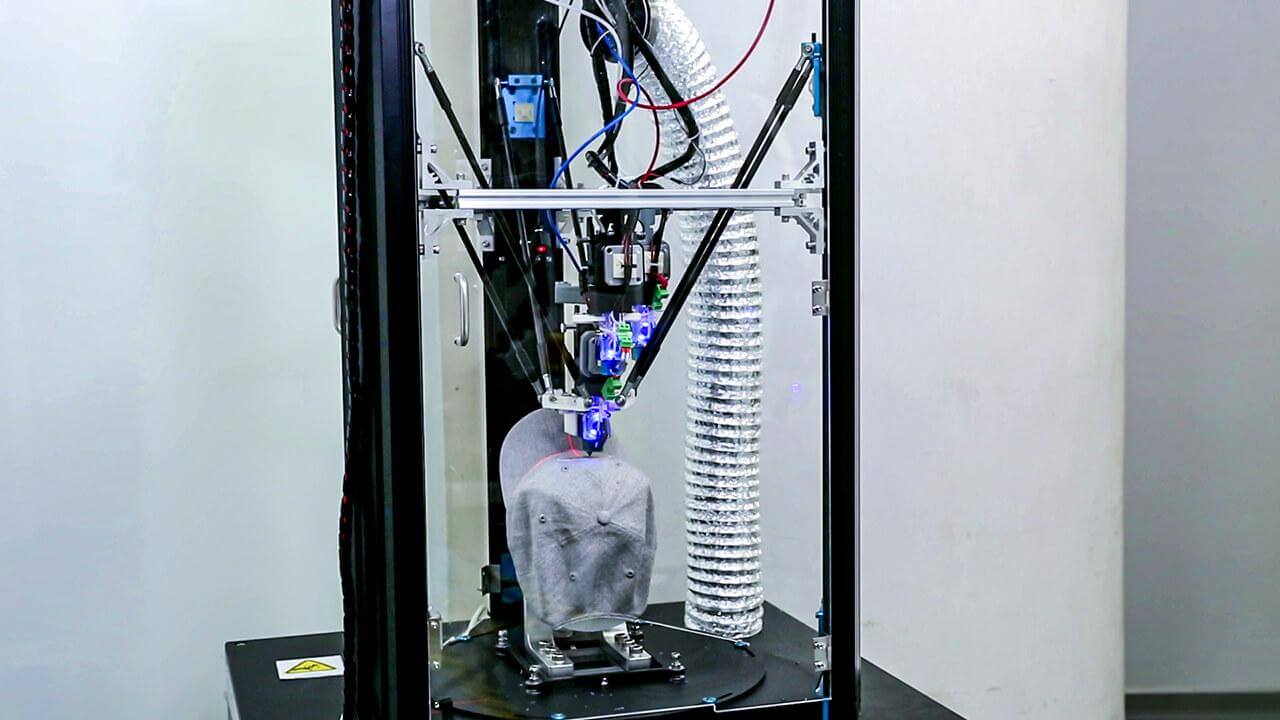

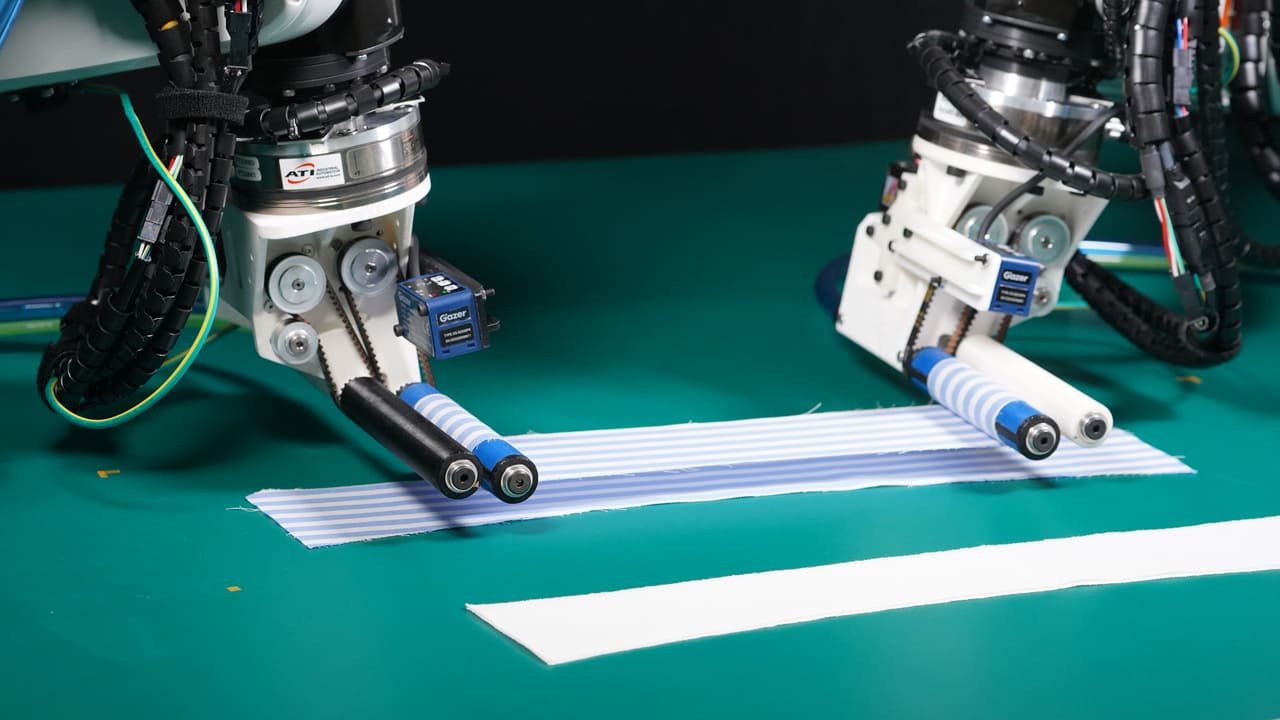

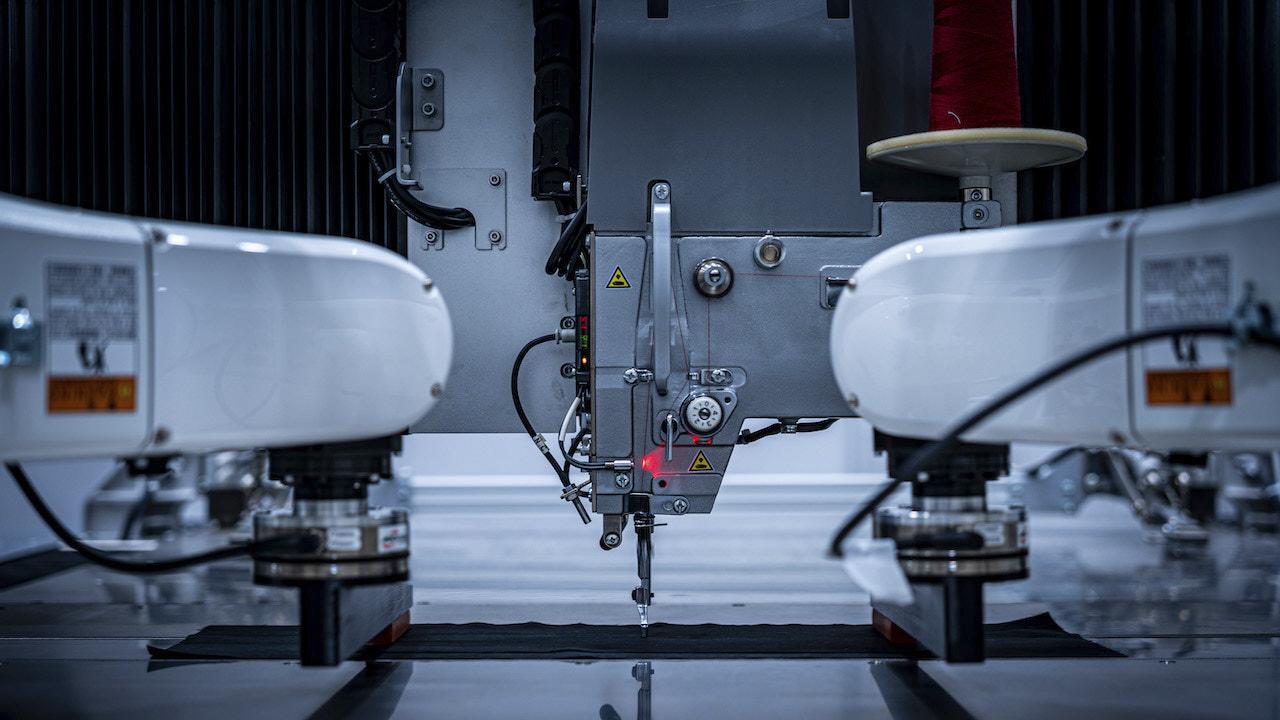

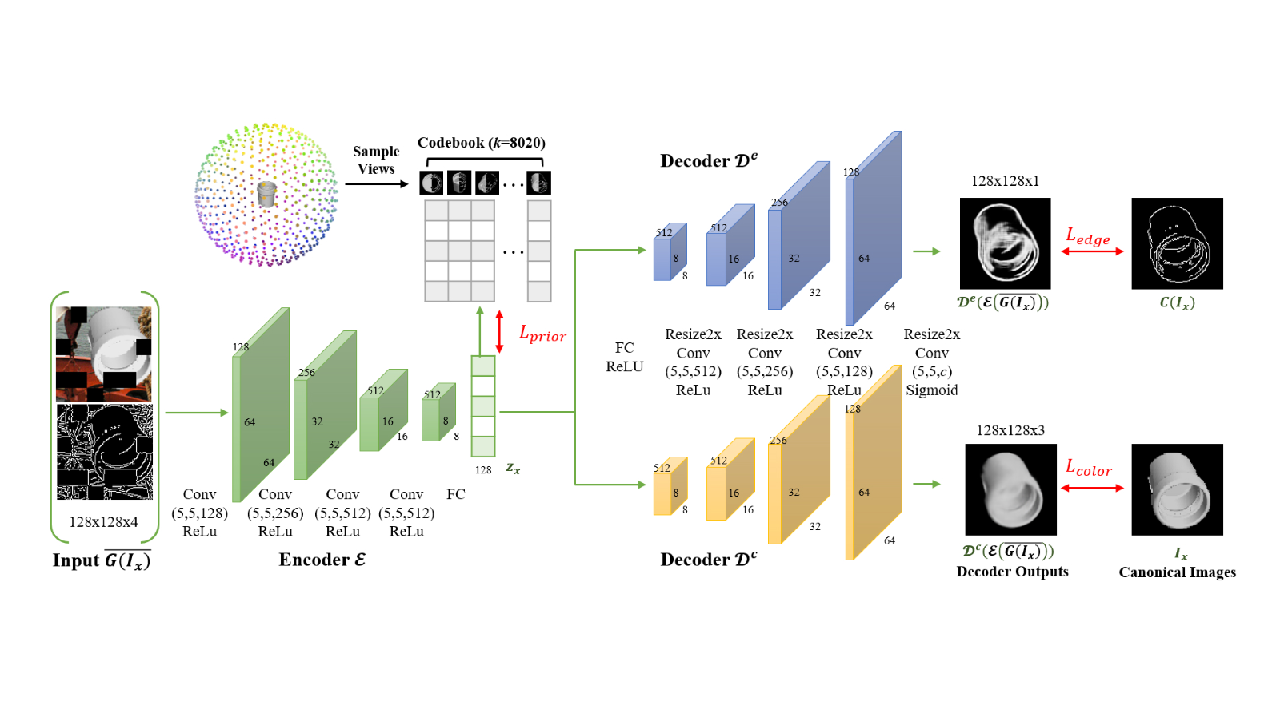

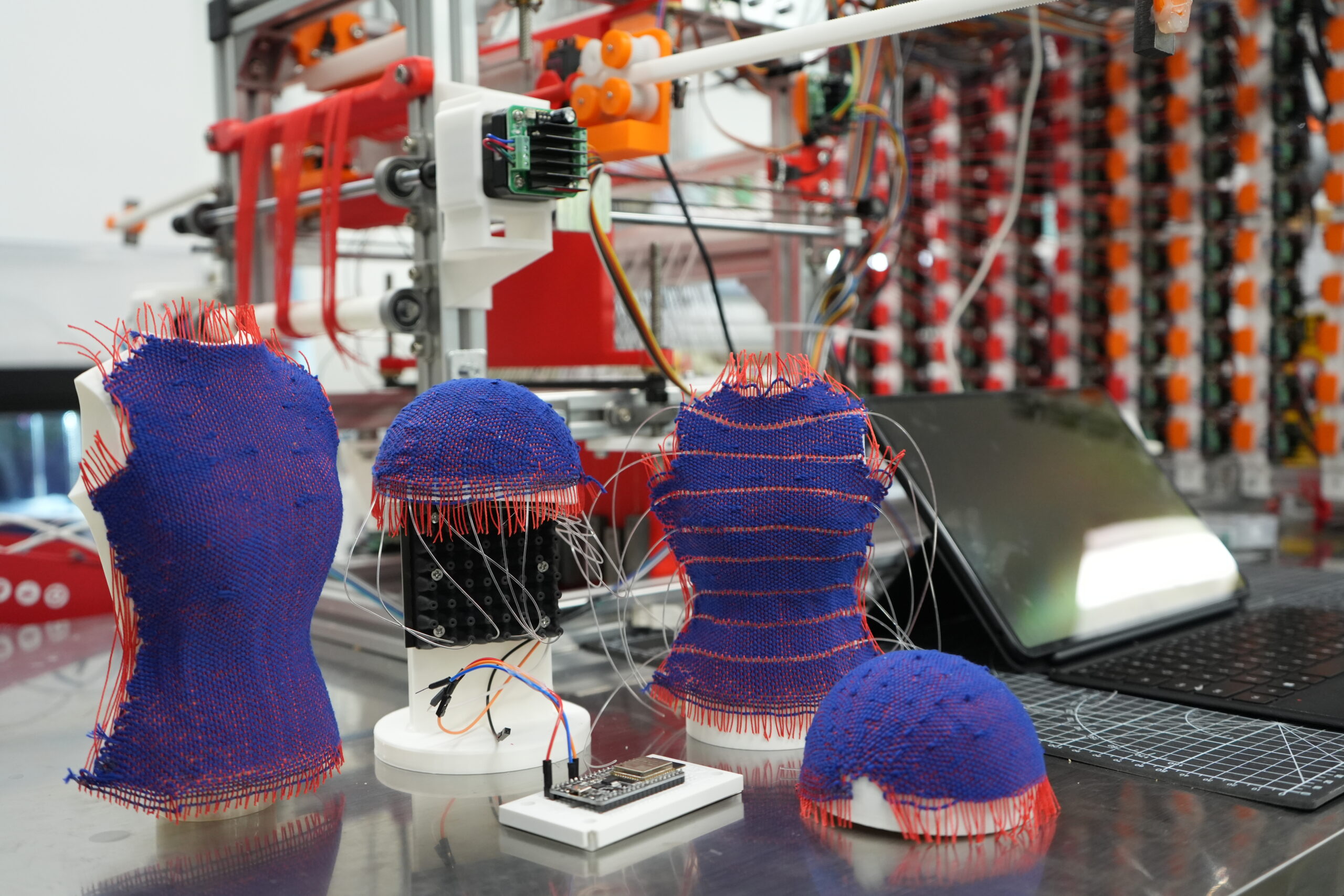

A deep learning approach is developed to predict intended motions of the human operators to allow robots to collaborate with the human operators in the manufacturing scenarios. This method enables prediction of interactive motions when human operators are carrying large-sized objects, estimation of human intended control over the objects during collaborative tasks or remote control in a data-efficient manner.

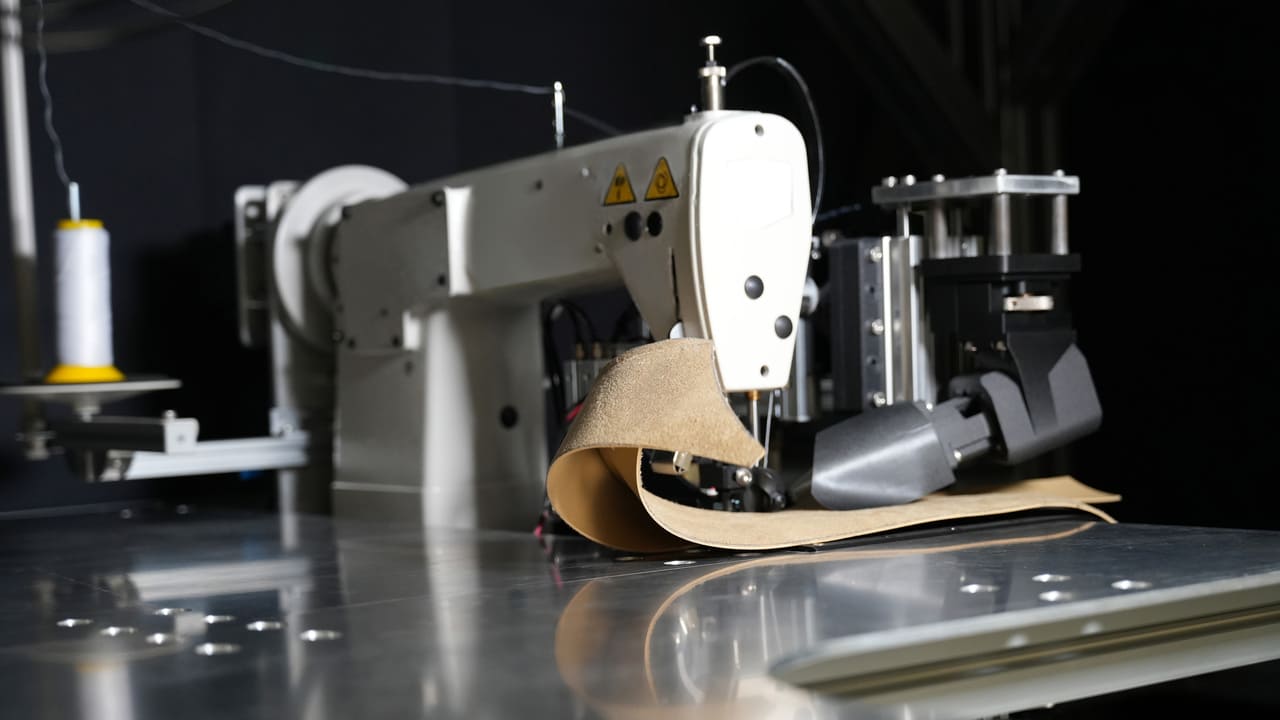

Robots may be frozen to ensure safety when subjected to physical interventions. This is particularly likely when they are deployed in a dynamically changing environment with the presence of mobile co-workers. It is also hard for the robots without any pre-programming to adapt to new environments. While robotic experts are tacking these crucial issues, the existing solution is not scalable to mass customization, a trend being observed in many industrial sectors and garment manufacturing

- Featured an off-line and on-line learning system using deep neural networks that trains the robots to perceive human co-workers’ intention.

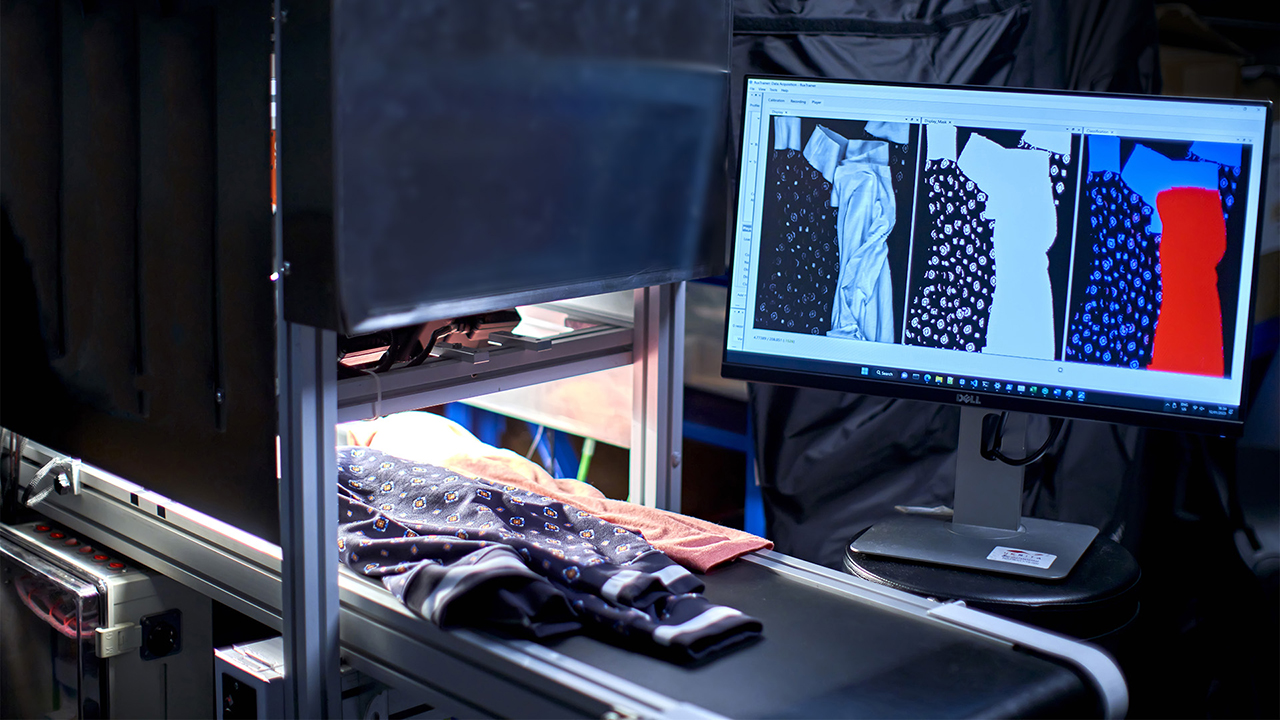

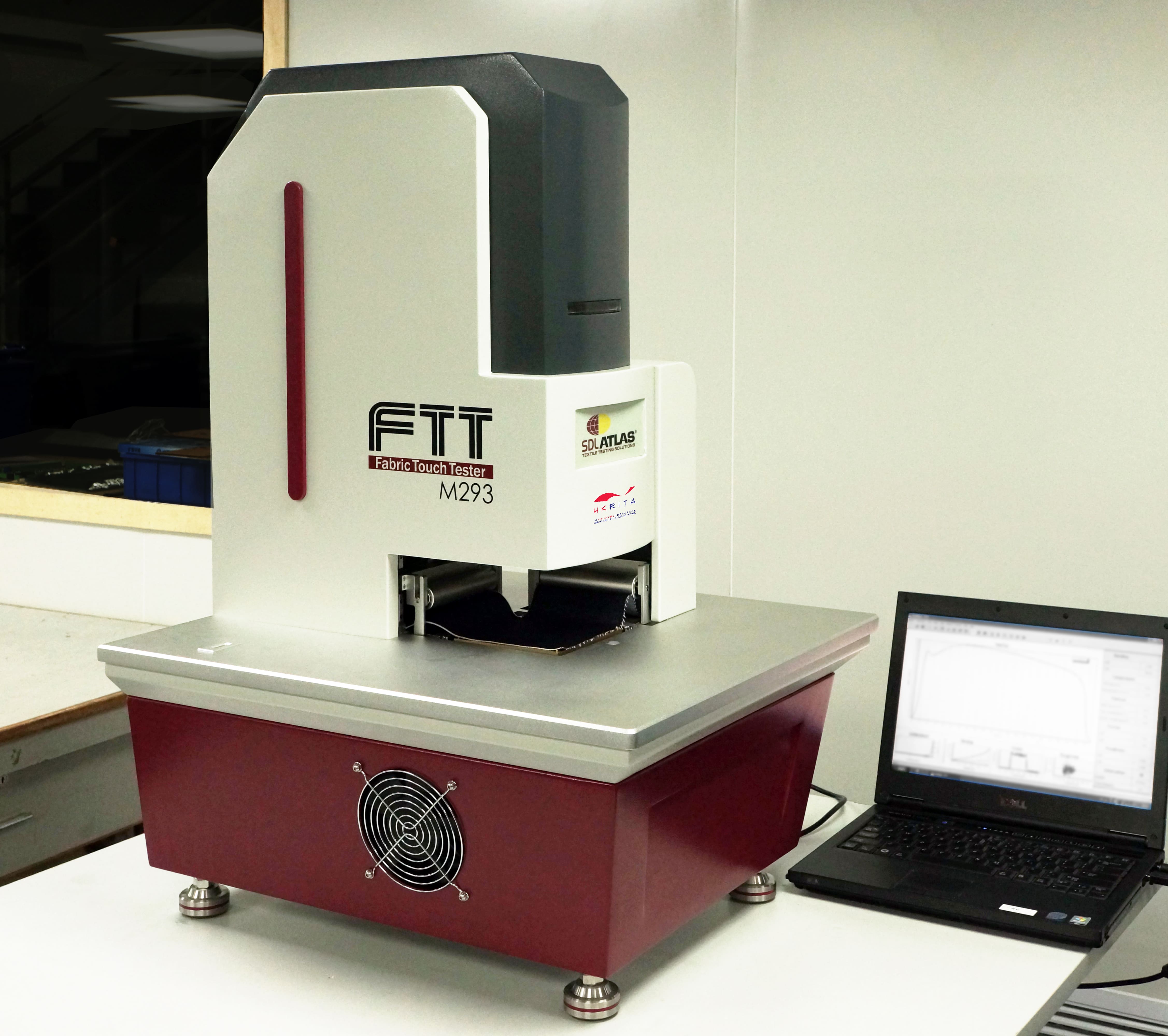

- The developed perception algorithms for accurately and efficiently capturing 3D environment information with the essential ability to correctly perceive and accurately measure the surrounding environment such as human workers, tools and objects and workstation, etc.

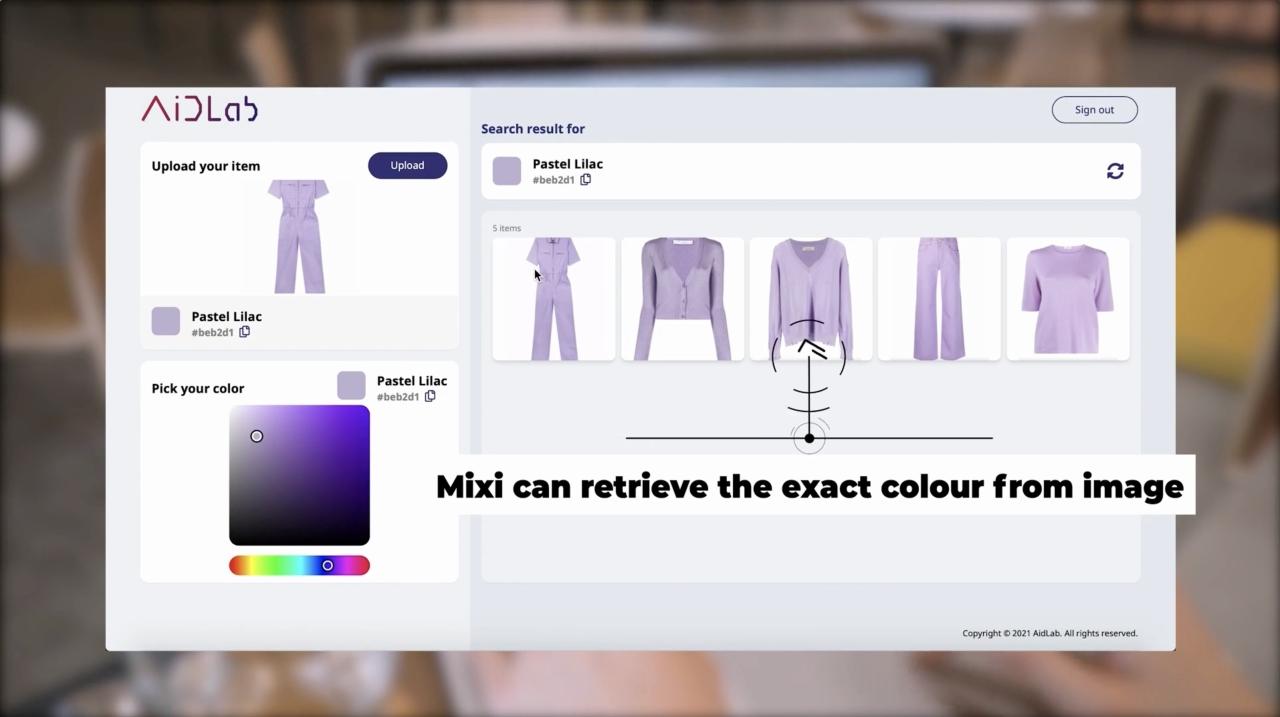

- A specifically designed human-centered interface that enables intuitive communication between robots and humans.

- The system enables robots to reliably predict human co-workers’ intentions and goals of the collaborative tasks by learning from human-human collaborative data and to adapt themselves to specific tasks in real industrial scenarios.

- Robots response properly in real time to adapt to the individual co-worker based on the assigned manufacturing task.

- Ensure operational safety, and achieve efficient and convenient online programming of the robots for different tasks.

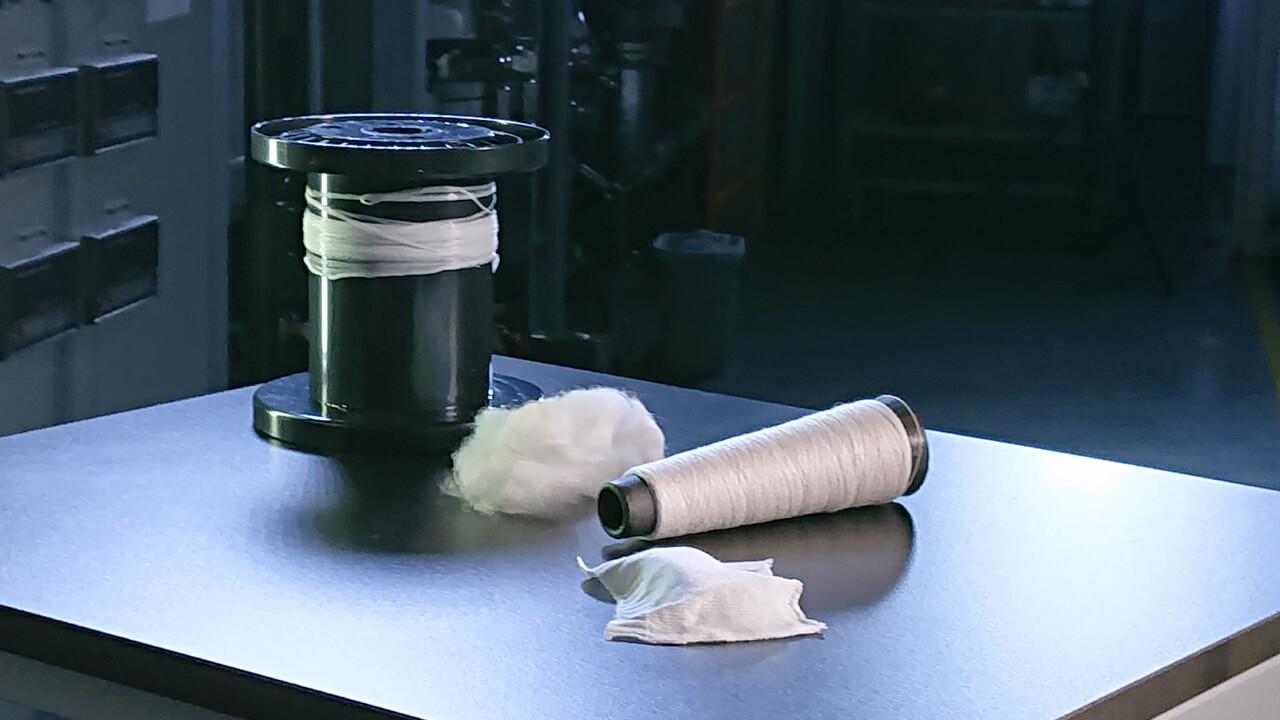

Centre for Transformative Garment Production (TransGP) was established with the collaborative effort of The University of Hong Kong and Tohoku University. The Centre aims to provide solutions for the needs of the future society, where labour shortage would arise from population aging, and where increasing percentage of the mankind will be living in megacities. The Centre also targets at driving paradigm shift for reindustrializing selected sectors, i.e. garment industry, which is still relying on labour-intensive operations but with clear and identified processes for transformation. A number of goals are expected to be achieved through the Centre’s research programmes, such as to leverage the proprietary AI and robotics technology to shorten development cycles, to improve engineering efficiency and to prevent faults and increase safety by automating risky activities.