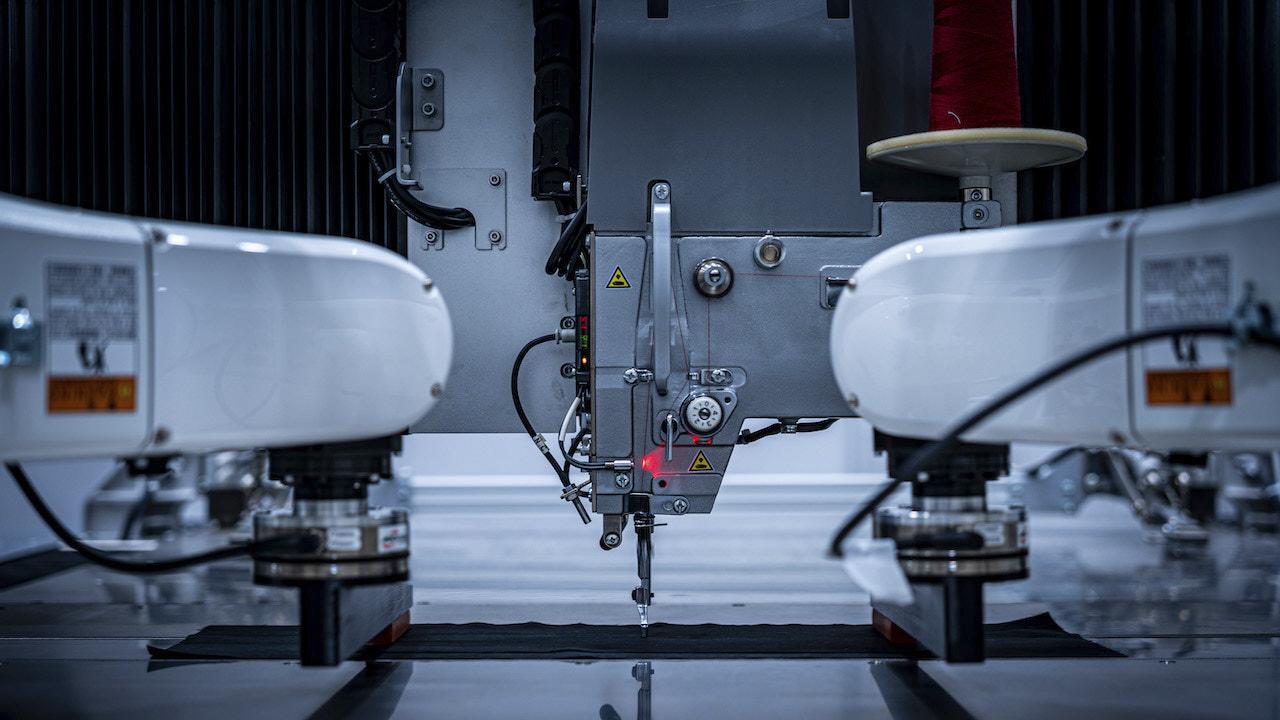

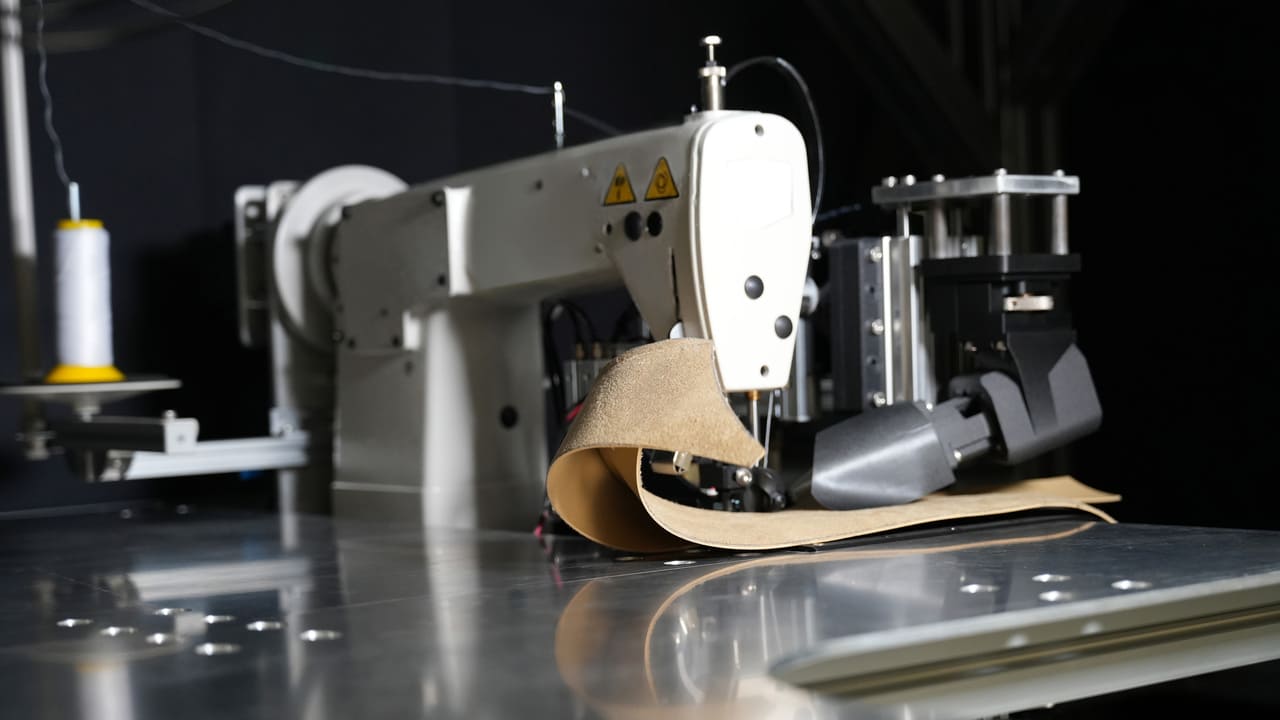

A Fixture-free 2D Robotic Sewing System

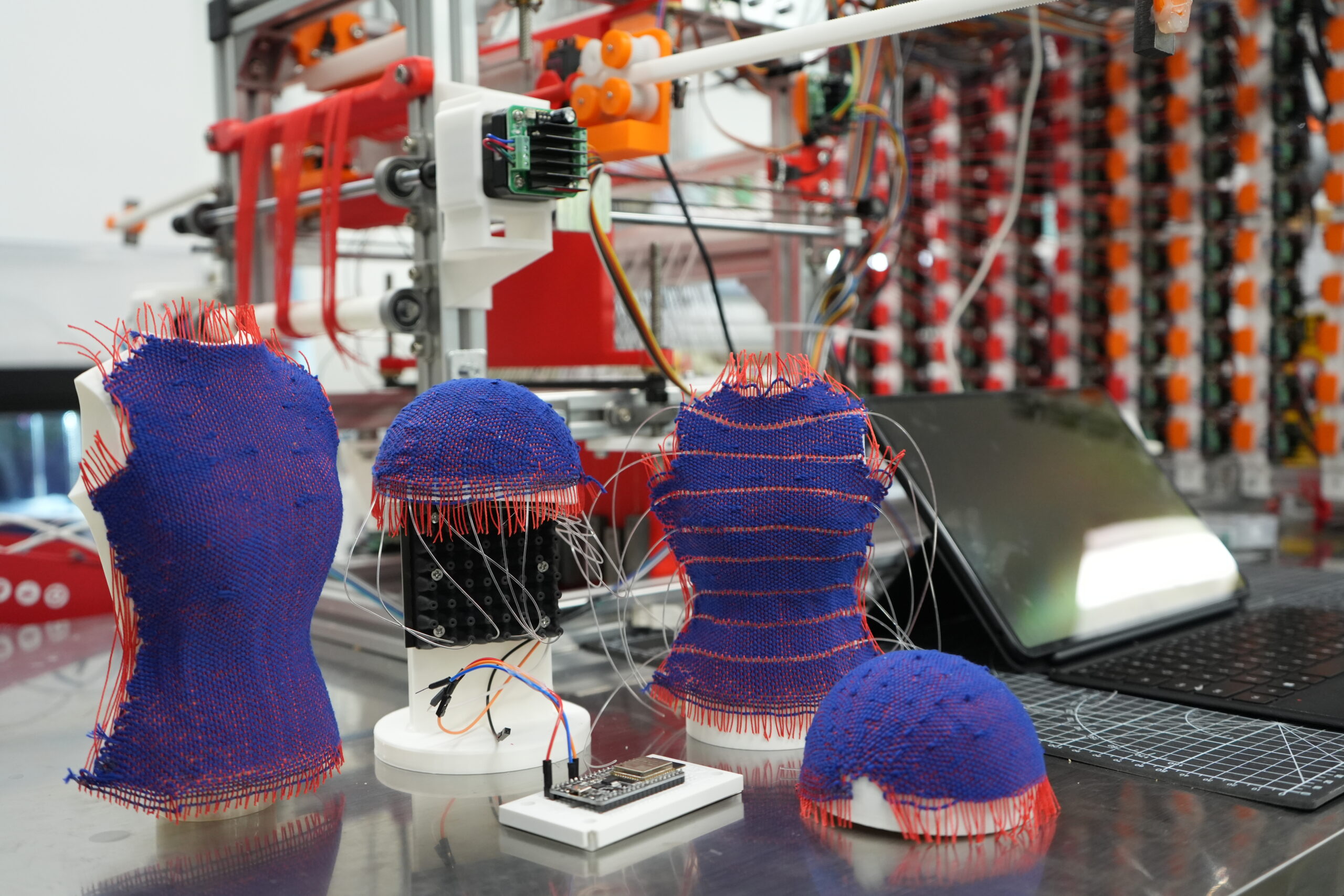

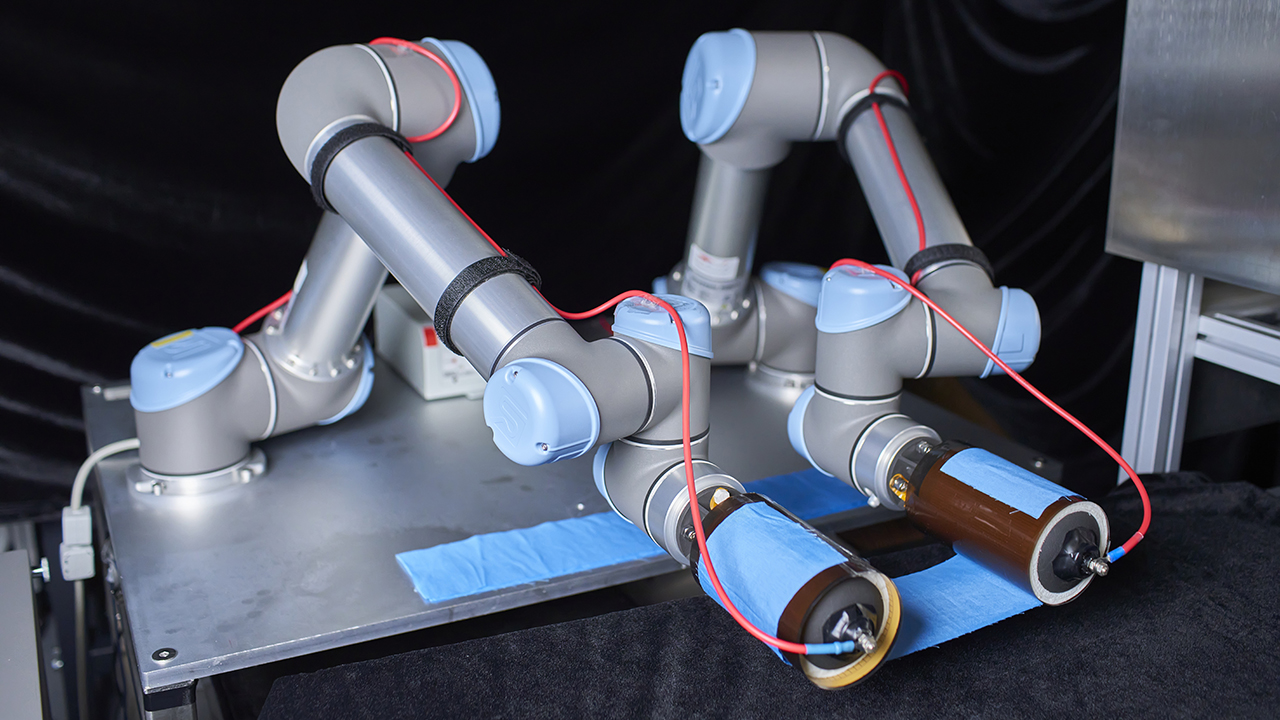

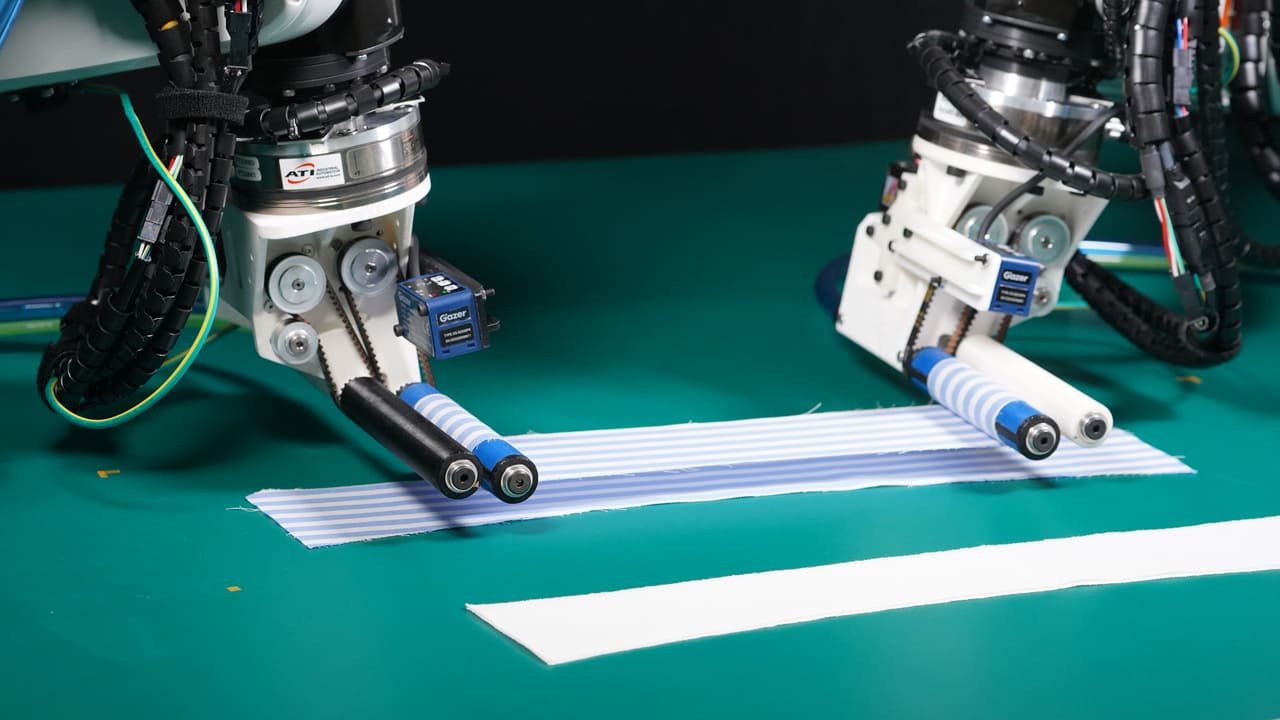

A fixture-free, adaptive, smart robotic system capable of sensing, positioning, aligning and manipulating relevant garment parts precisely during sewing operations.

Fabrics are soft and flexible which are extremely difficult for machines to handle. Existing automated sewing systems on the market often require fixtures specially designed for each size and type of fabric parts to confine their shapes. However, the procedures involved prolonging change-over time and are not cost-effective. The present system eliminates the need for fixtures and allows precise sewing.

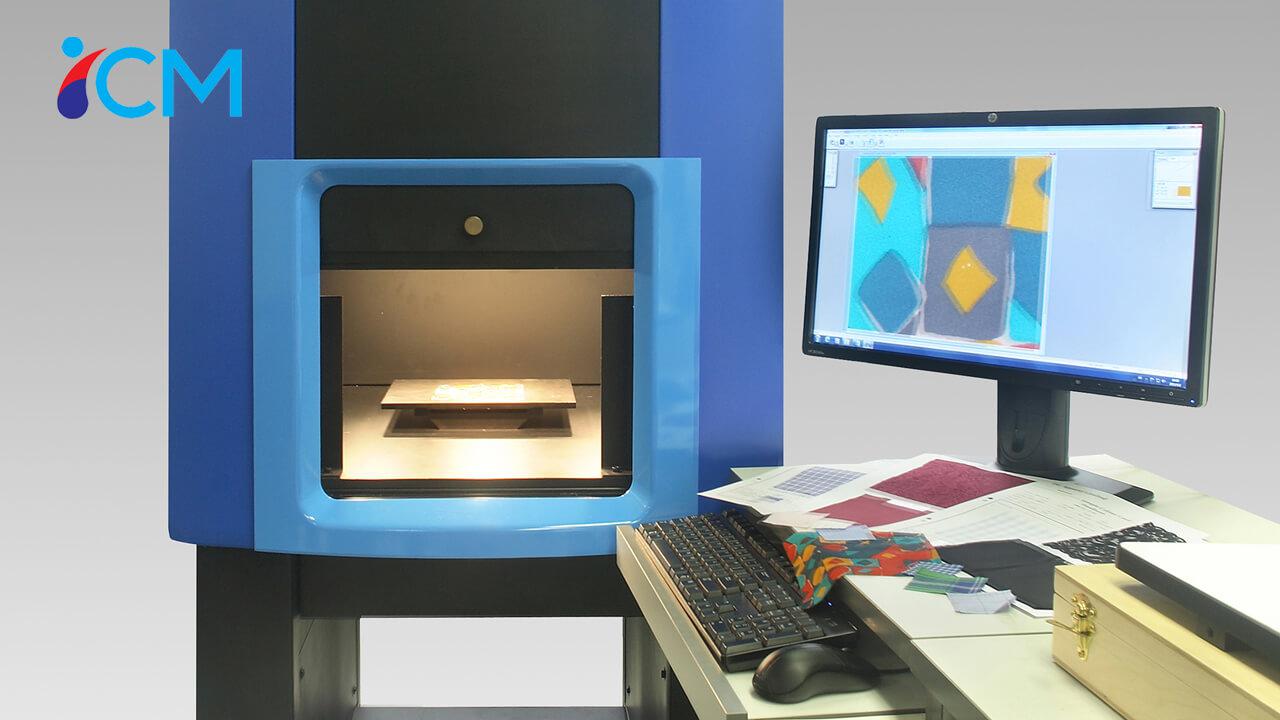

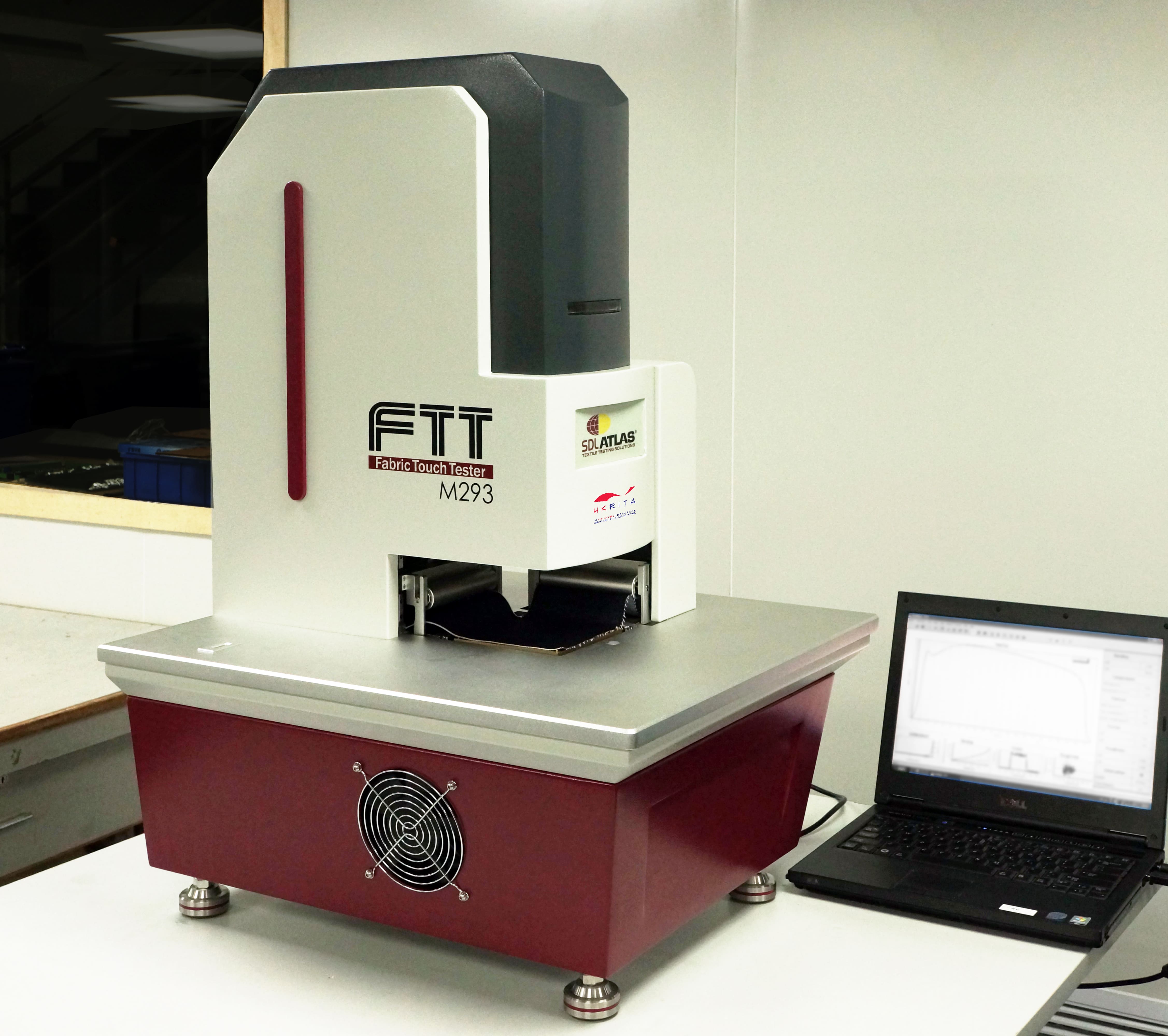

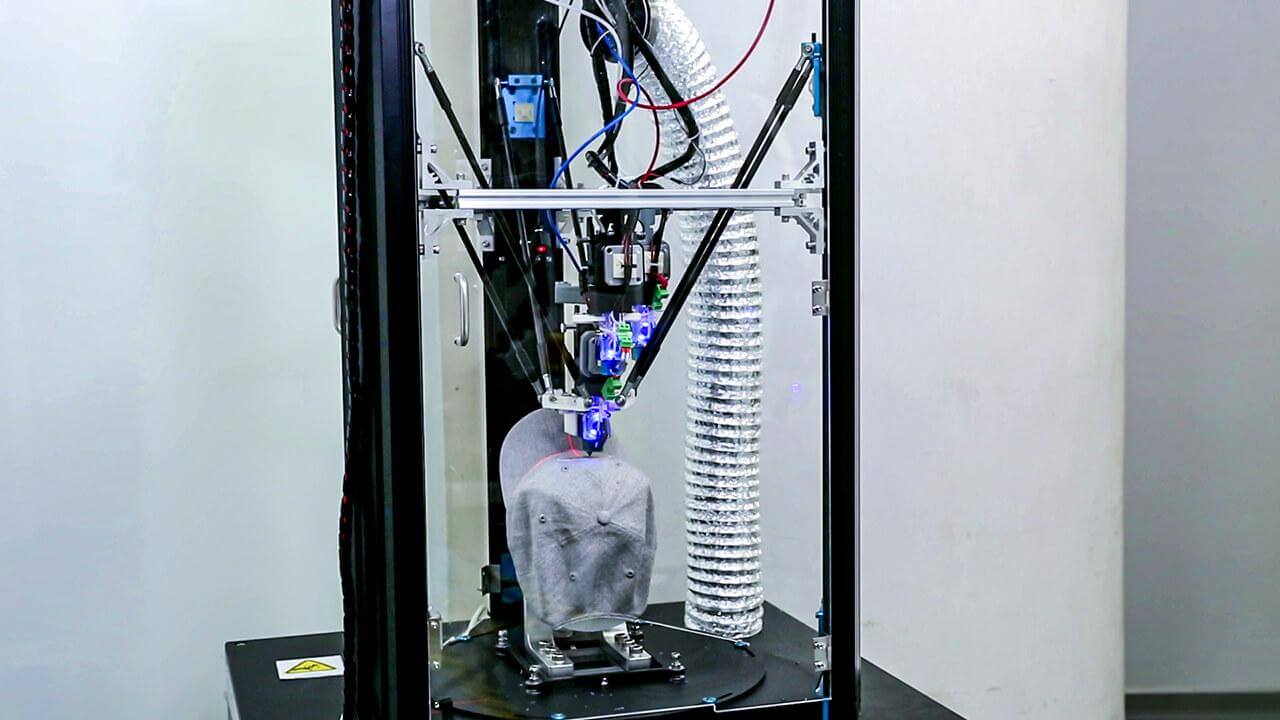

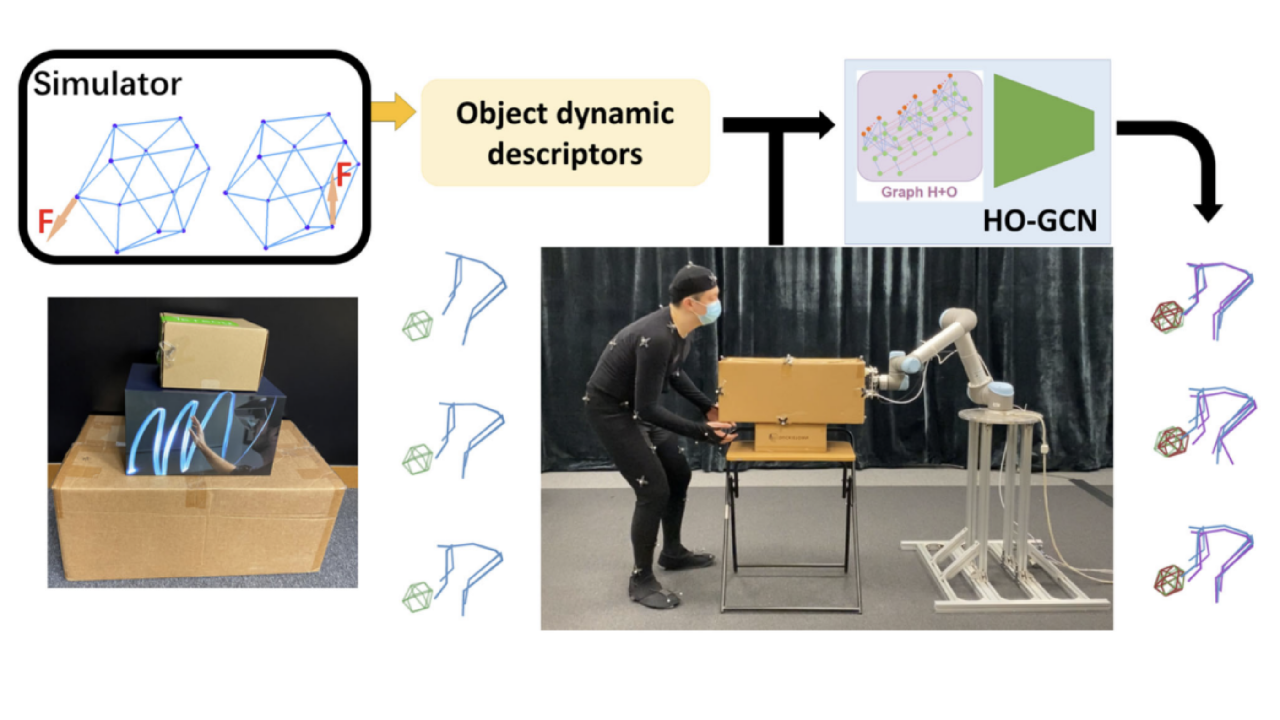

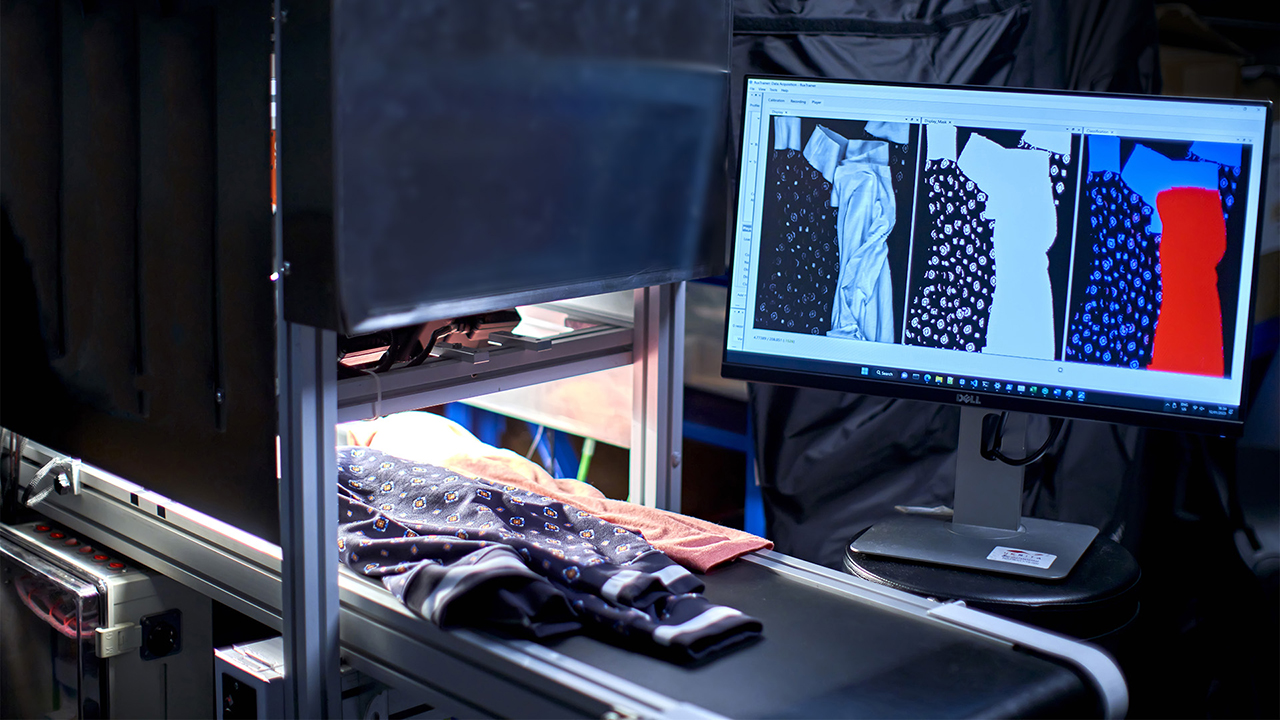

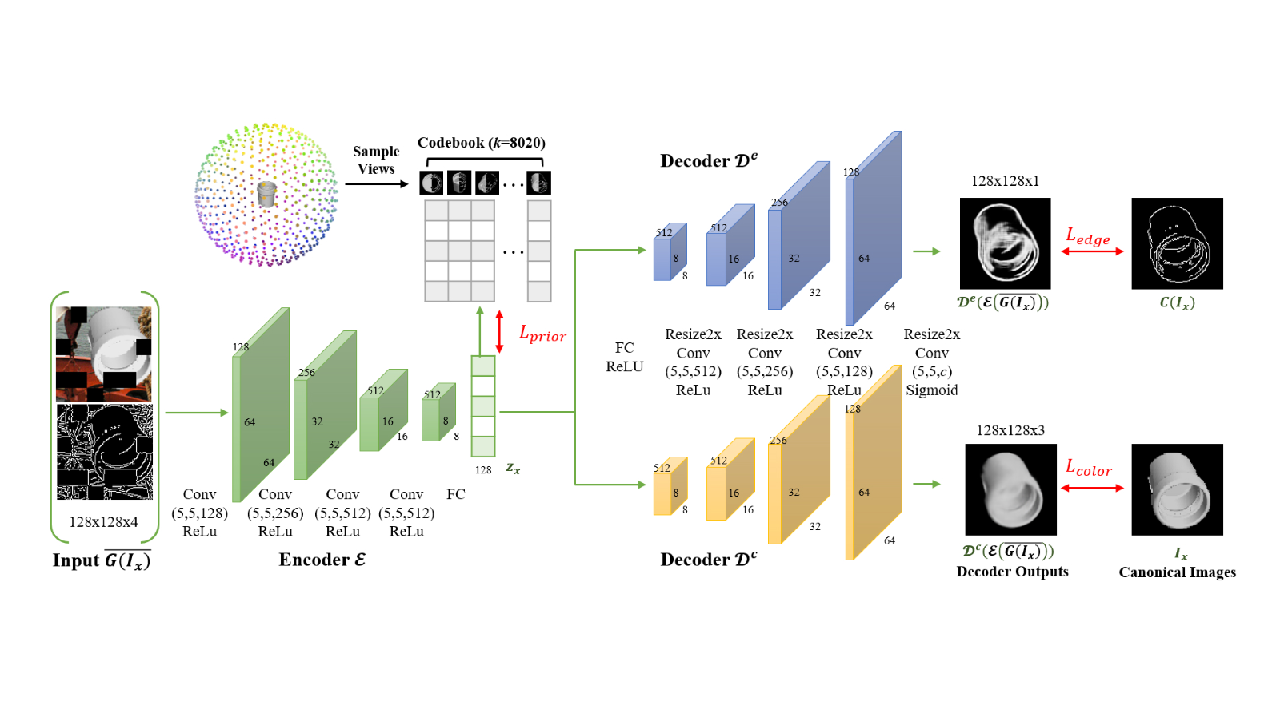

- A machine vision system to identify the sewing line, position and any undesirable deformations of a garment part.

- The system will precisely control the force and trajectory of the robots and synchronize with the needle motion of the sewing machine. It will also rectify deformation or wrinkling of the garment part once detected.

- Thanks to the universal end-effectors system, the garment parts will be stacked securely and positioned properly during the sewing process.

- The robot can learn each sewing task through an easy and simple teaching operation.

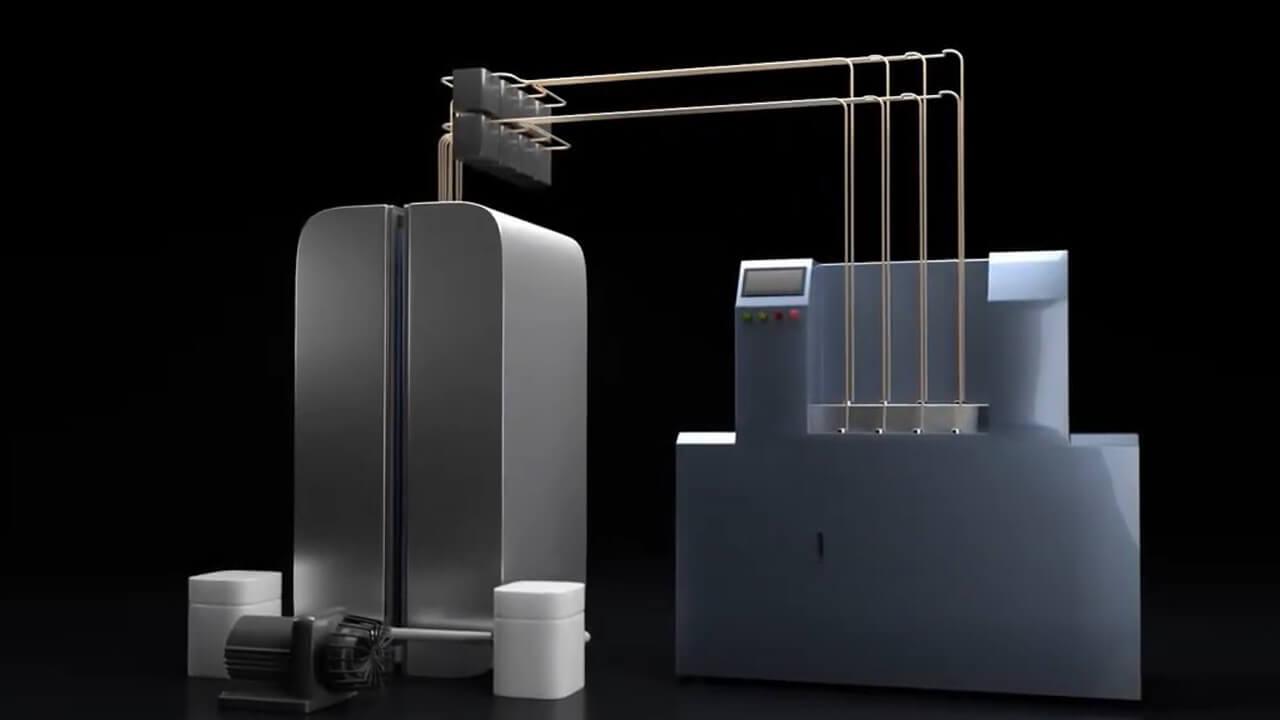

- The system can be integrated with market-available sewing machines.

- The system does not require hardware reconfiguration to work on a different type or size of garment parts.

- Various garment manufacturing processes.

Patent

- PCT patenet filed: PCT/CN2022/118736

Centre for Transformative Garment Production (TransGP) was established with the collaborative effort of The University of Hong Kong and Tohoku University. The Centre aims to provide solutions for the needs of the future society, where labour shortage would arise from population aging, and where increasing percentage of the mankind will be living in megacities. The Centre also targets at driving paradigm shift for reindustrializing selected sectors, i.e. garment industry, which is still relying on labour-intensive operations but with clear and identified processes for transformation. A number of goals are expected to be achieved through the Centre’s research programmes, such as to leverage the proprietary AI and robotics technology to shorten development cycles, to improve engineering efficiency and to prevent faults and increase safety by automating risky activities.