Blueberry Harvesting Robot

HKCLR is developing an automated robotic system for blueberry harvesting. This system automates the picking process, accommodates various blueberry varieties, and ensures flexibility and scalability.

Currently, the harvesting of premium blueberries relies heavily on manual labor, with workers spending long hours in the fields hand-picking each berry. Globally, there are few automated devices or robots designed for blueberry harvesting, as the complexity of picking premium blueberries far exceeds that of other crops.

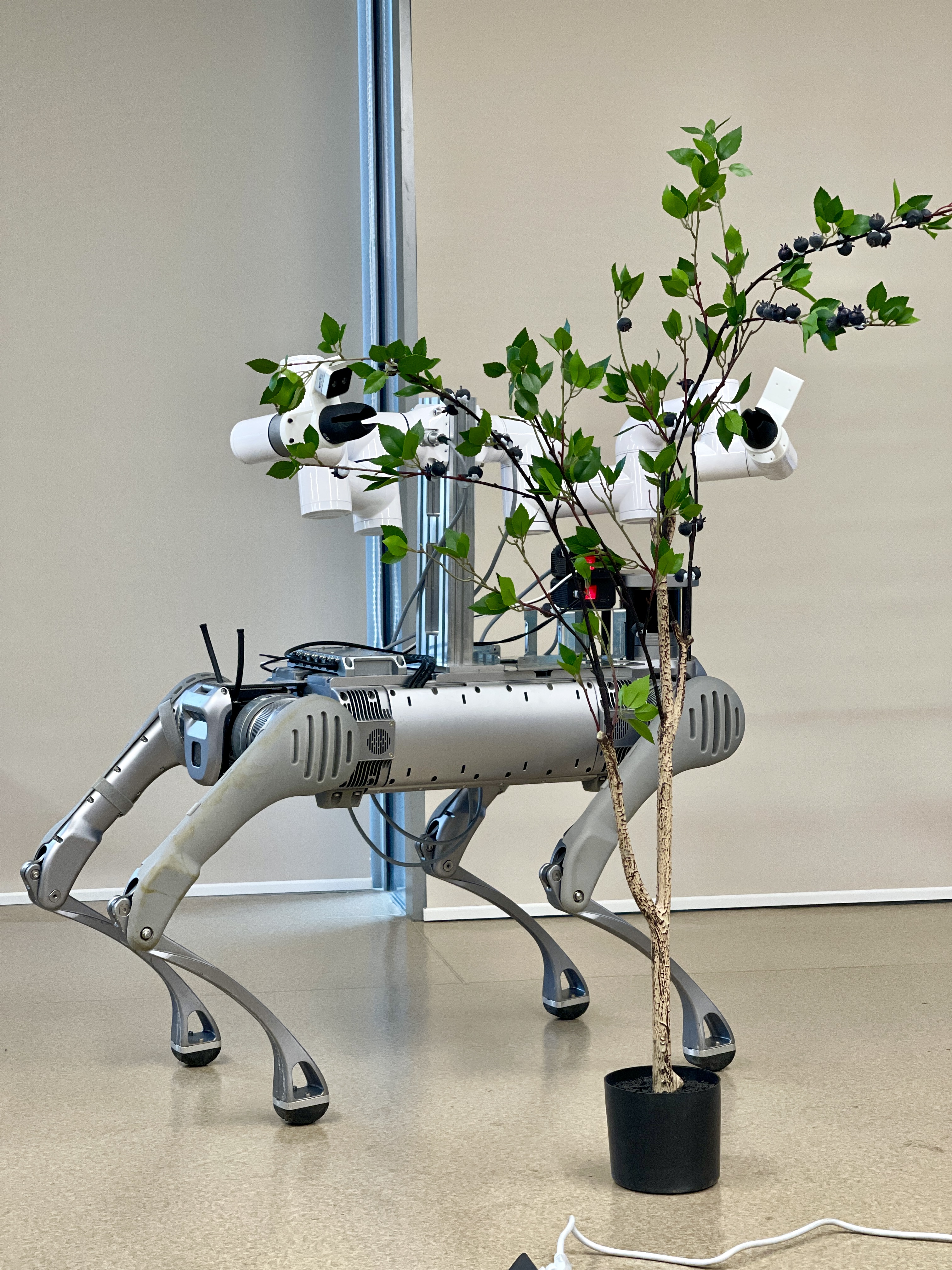

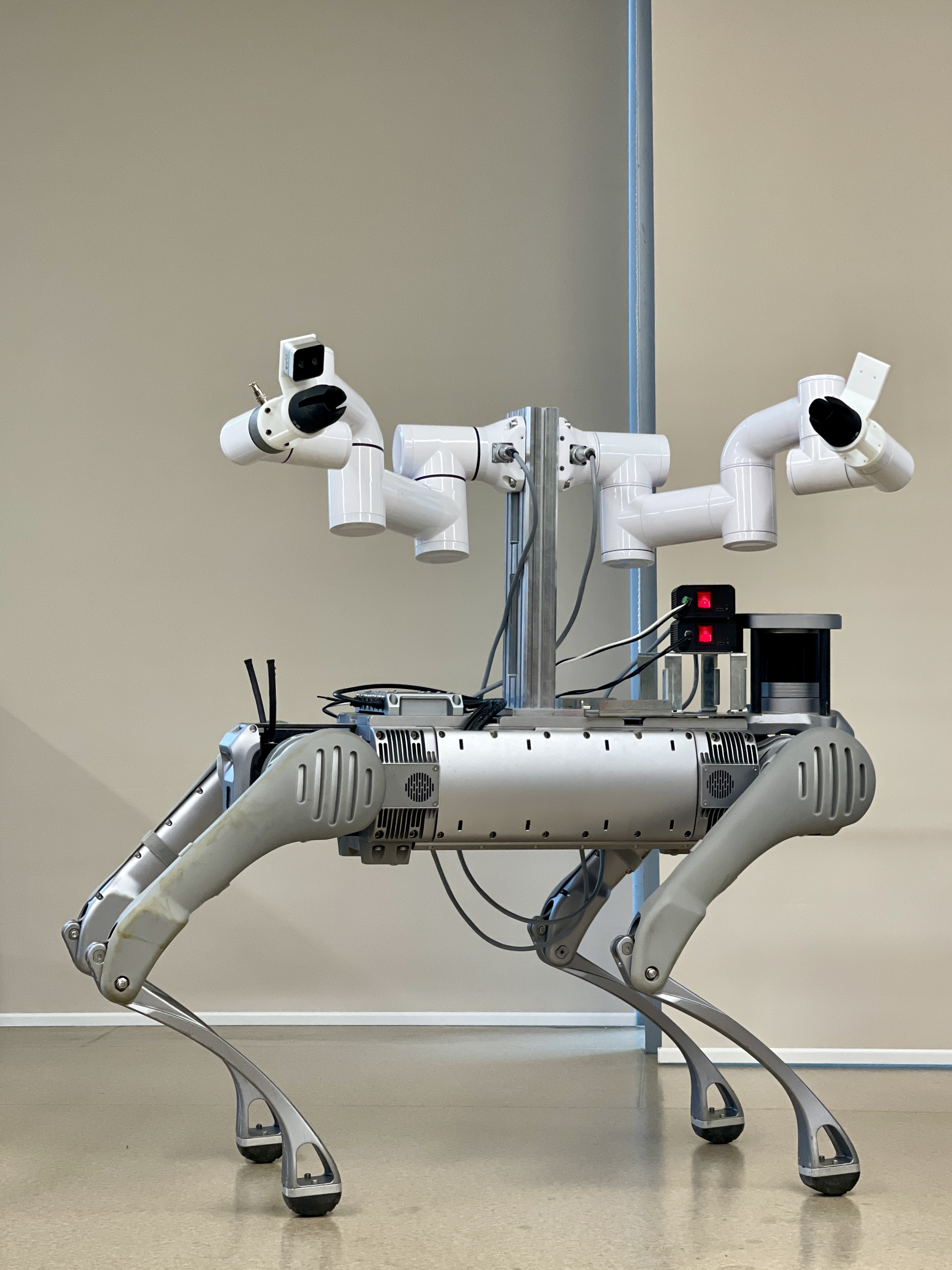

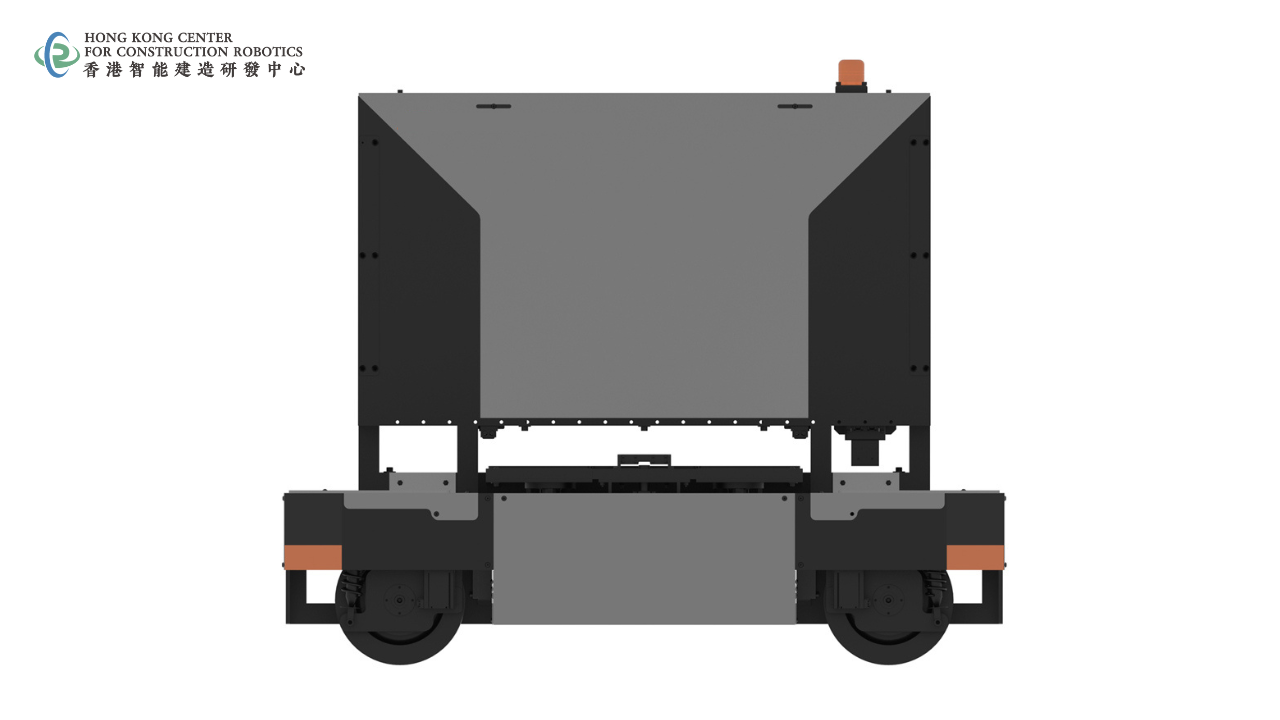

- The blueberry robot innovatively integrates an all-terrain quadrupedal mobile chassis with a dual-arm operating platform. This unique design combines the robust mobility of a robotic dog with the advanced manipulation capabilities of a dual-arm robot.

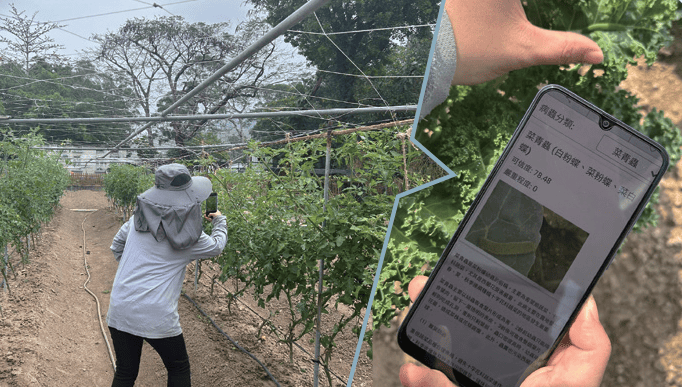

- The robot learns how to identify ripe blueberries and how to harvest them through simulations and real-world scenarios. The learned models are deployed on an advanced edge computing platform, enabling stable and reliable blueberry recognition and harvesting across various weather conditions and time periods.

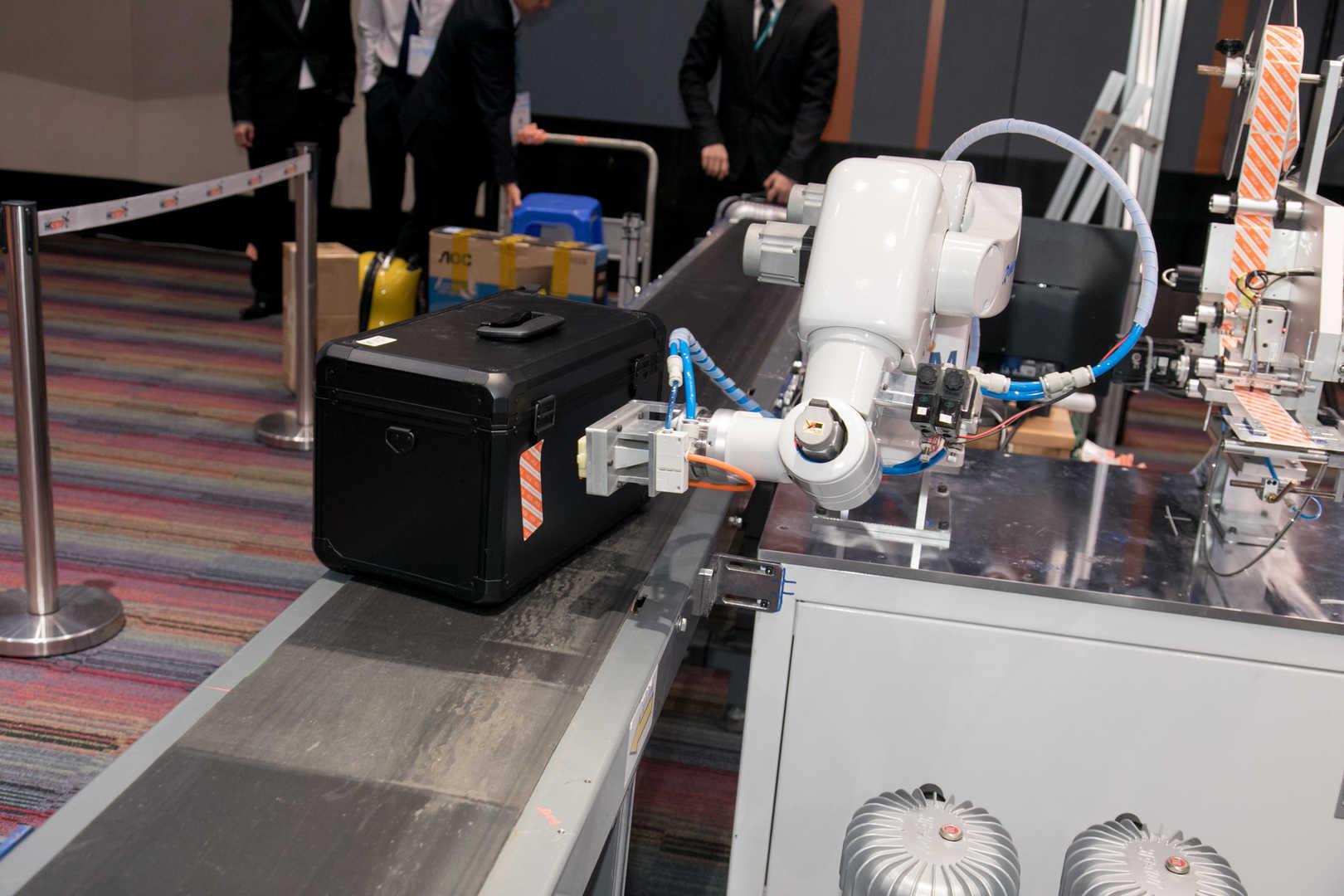

- The blueberry robot employs flexible hands to ensure stable and reliable harvesting while minimizing damage to the blueberry skin and bloom, achieving a quality comparable to manual picking.

- The first-ever automation of premium blueberry harvesting has been achieved.

- Driving innovation in blueberry agricultural technology.

- It can be utilized for the harvesting process, and with simple adjustments, it is capable of performing other tasks in blueberry cultivation, such as pesticide application, de-stemming, and plant protection.

- In addition to various operations in blueberry cultivation, the blueberry robot has the potential to expand to other agricultural products, such as strawberries, raspberries, tomatoes, and more.

- The blueberry robot can collect environmental data from greenhouses and various metrics related to crop growth cycles. It enables the monitoring, analysis, and regulation of environments.

Hong Kong Centre for Logistics Robotics was established in 2020 by The Chinese University of Hong Kong, with research contributions from the University of California, Berkeley. The Centre focuses on the research and development (R&D) of robotics and artificial intelligence (AI) technologies for “future workplace” as well as innovative solutions to the “pressing problems” in the logistics industry. In particular, HKCLR aims to advance robot intelligence in terms of

• Robust Sensing and Perception

• AI-Powered Robot Manipulation

• Human-Robot Collaboration

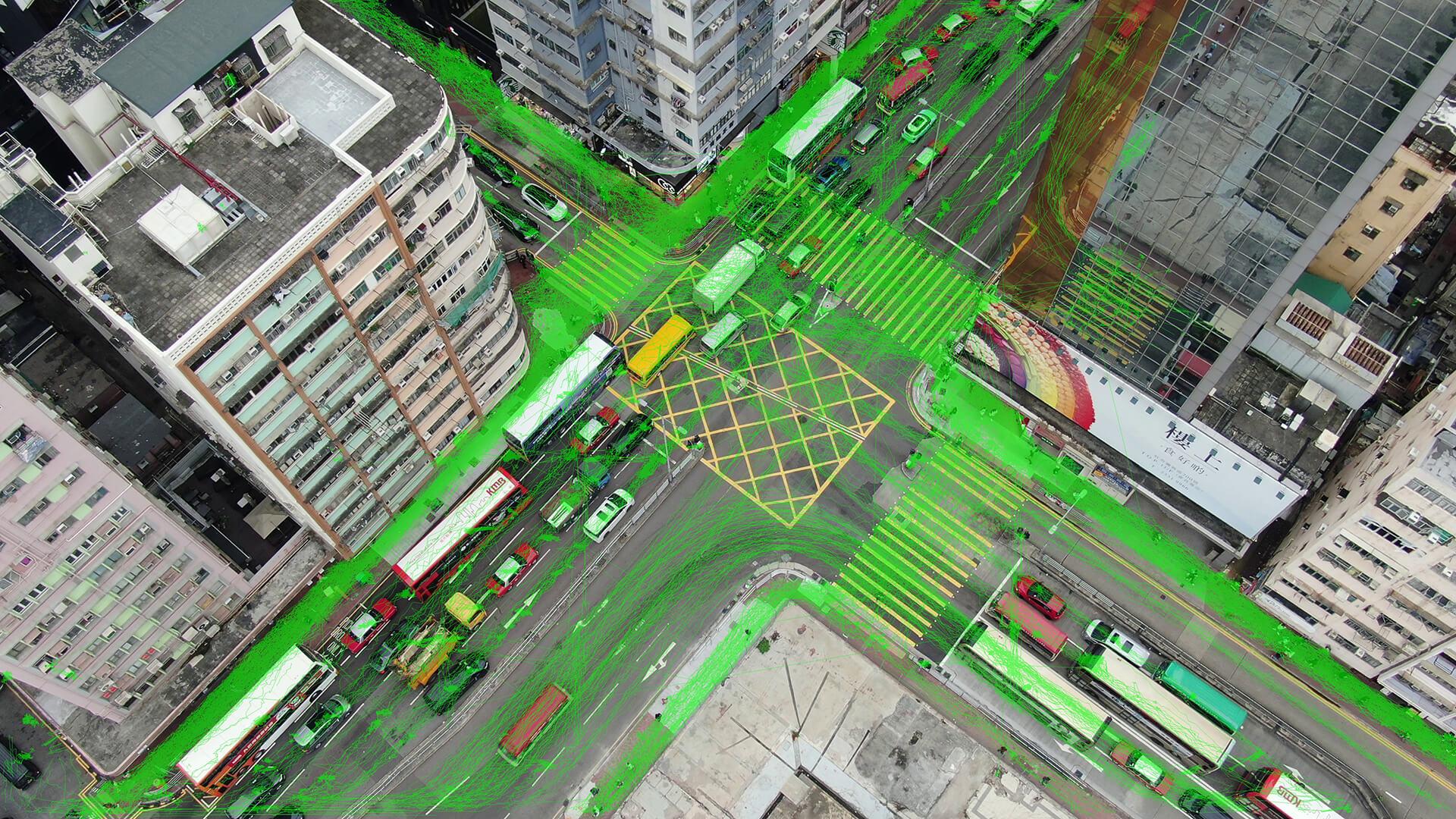

• Unmanned Logistics Vehicles

The research team is composed of distinguished professors from the two universities and accomplished Ph.D. degree holders across world-leading universities. The Centre is dedicated to pursuing innovative breakthroughs in ready-for-use robotics and AI technologies via close collaboration with academic and industrial stakeholders throughout Hong Kong, the Greater Bay Area (GBA), and Chinese Mainland. It is expected that the Centre will foster the leading role of the local logistics industry in GBA and Chinese Mainland, meanwhile enhancing its competitive edge in the global arena.